Inficon IC1000 Quick guide

Translation of the Original Operating Instructions

IC1000

Interface adapter

jiqn22en1-01-(2205)

Catalog No.

525-200

From software version

V1.11

INFICON GmbH

Bonner Strasse 498

50968 Cologne, Germany

INFICON Table of contents

IC1000-Operating-Instructions-jiqn22en1-01-(2205) iii

Table of contents

1 About this manual .......................................................................................................................................... 4

1.1 Other associated documents ................................................................................................................... 4

1.2 Warnings .................................................................................................................................................. 4

1.3 Target groups........................................................................................................................................... 4

1.4 Dangers.................................................................................................................................................... 5

2 Safety............................................................................................................................................................... 6

2.1 Intended use ............................................................................................................................................ 6

2.2 Duties of the operator............................................................................................................................... 6

2.3 Owner requirements................................................................................................................................. 6

3 Scope of delivery, transport, storage........................................................................................................... 8

4 Description...................................................................................................................................................... 9

4.1 Function ................................................................................................................................................... 9

4.2 Structure of the IC1000 .......................................................................................................................... 10

4.3 Technical data........................................................................................................................................ 13

4.4 Cleaning the device................................................................................................................................ 13

5 Installation and removal .............................................................................................................................. 14

5.1 Mount IC1000 and DIN-TS35 top-hat rail............................................................................................... 14

5.2 Establish connections ............................................................................................................................ 14

5.3 Remove the IC1000 from the DIN-TS35 top hat rail .............................................................................. 16

6 Decommissioning ........................................................................................................................................ 17

6.1 Disposing of the device .......................................................................................................................... 17

6.2 Returning the device for maintenance, repair or disposal...................................................................... 17

7 Appendix ....................................................................................................................................................... 19

7.1 Accessories ............................................................................................................................................ 19

7.2 CE Declaration of Conformity................................................................................................................. 20

7.3 RoHS...................................................................................................................................................... 22

1 | About this manual INFICON

4 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

1 About this manual

This document applies to the software version stated on the title page.

Product names may occur in the document, which are added for identification

purposes only and belong to the respective owner of the rights.

1.1 Other associated documents

Operating manual of the connected leak detector

Operating manual of the connected BM1000 jiqb10

Ecotec-E3000 Protocol-Descriptions kins22

1.2 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation resulting in potential death or serious injuries

CAUTION

Hazardous situation resulting in minor injuries

NOTICE

Hazardous situation resulting in damage to property or the environment

1.3 Target groups

This instruction manual is intended for operators and technically qualified personnel

with experience in leak detection technology and the integration of leak detectors in

leak detection systems. In addition, the installation and use of the device require

knowledge of electronic interfaces.

INFICON About this manual | 1

IC1000-Operating-Instructions-jiqn22en1-01-(2205) 5 / 24

1.4 Dangers

The measuring instrument was built according to the state-of-the-art and the

recognized safety regulations. Nevertheless, improper use may result in risk to life and

limb on the part of the user or third parties, or damage to the unit or other property

may occur.

• Reverse polarity of the power supply (plus / minus at nominal voltage)

• Connection of a voltage supply that is too high > Nominal voltage

• Connection of an AC power supply

• Connection of a voltage supply that is too low < Nominal voltage

• Connecting a non-compatible device to the RS232 interface

• Connecting a non-compatible device to the LD interface

• Assignment of the actually unused RS485 terminals

• Use in radioactive areas

• Operation under unsuitable ambient conditions

• Use outside the technical specifications.

• Use of wrong cables and wires

2 | Safety INFICON

6 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

2 Safety

2.1 Intended use

The IC1000 is an interface adapter between a leak detector and a BM1000.

►Operate the device only according to this instruction manual.

2.2 Duties of the operator

• Read, observe, and follow the information in this manual and in the work

instructions provided by the owner. This concerns in particular the safety and

warning instructions.

• Always observe the complete operating instructions for all work.

• If you have any questions about operation or maintenance that are not answered

in this manual, contact customer service.

2.3 Owner requirements

The following notes are for companies or any person who is responsible for the safety

and effective use of the product by the user, employees or third parties.

Safety-conscious operation

• Operate the device only if it is in perfect technical condition and has no damage.

• Only operate the device properly in accordance with this instruction manual, in a

safety and risk conscious manner.

• Adhere to the following regulations and observe their compliance:

– Intended use

– Universally valid safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional device-related provisions and regulations

• Only use original parts or parts approved by the manufacturer.

• Keep this instruction manual available on site.

INFICON Safety | 2

IC1000-Operating-Instructions-jiqn22en1-01-(2205) 7 / 24

Personnel qualifications

• Only instructed personnel should be permitted to work with and on the device. The

instructed personnel must have received training on the device.

• Make sure that authorized personnel have read and understood the instruction

manual and all other applicable documents, see “Other associated documents

[}4]“.

3 | Scope of delivery, transport, storage INFICON

8 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

3 Scope of delivery, transport, storage

Scope of delivery Item Quantity

IC1000 1

Data cable 1

Set of cables 1

Operating manual 1

►Check the scope of delivery after receipt of the product to make sure it is complete

and to check for external damage.

Transport

NOTICE

Damage due to unsuitable packaging material

Transport in unsuitable packaging material can damage the device.

► Keep the original packaging.

► Only transport the device in its original packaging.

Storage ► Always store the device in compliance with the technical data, see "Technical

Data".

See also

2Technical data [}13]

INFICON Description | 4

IC1000-Operating-Instructions-jiqn22en1-01-(2205) 9 / 24

4 Description

NOTICE

Interference due to emission of high frequencies

Devices in the immediate vicinity may be disturbed.

► Do not use the device in living areas.

► Only use the device in rooms that are closed on all sides and dry.

NOTICE

The IC1000 does not perform a safety function

In the event of strong electromagnetic interference, communication may

be distorted.

Regularly check the function of the device.

4.1 Function

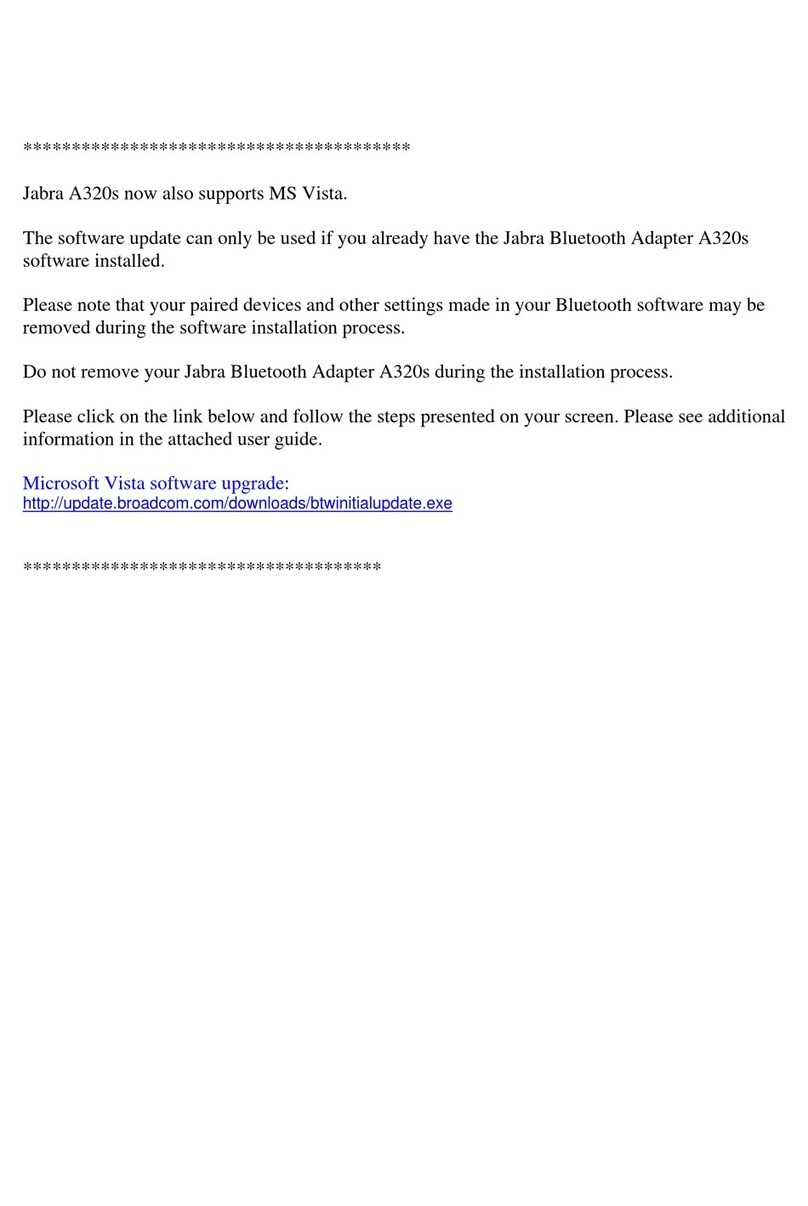

The system at a glance

I/O Port RS-232

IC1000 BM1000

Programable Logic Controller

INFICON Leak Detectoor

12

3

4

Fig.1: The system at a glance

1 Power supply 24 V DC 2 Serial cable

3 Data cable 4 Fieldbus cable

The IC1000 is an interface between a leak detector and a BM1000.

It allows the BM1000 to be used on a leak detector without LD interface (M12

connector).

4 | Description INFICON

10 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

A prerequisite is that the leak detector has an RS232 interface that can handle the LD

protocol with 19200 or 38400 baud.

For this purpose, the IC1000 has an RS-232 port for connection to the leak detector

and an LD interface for connection to the BM1000. this only applies to the ECOTEC

E3000 from software version V3.33.

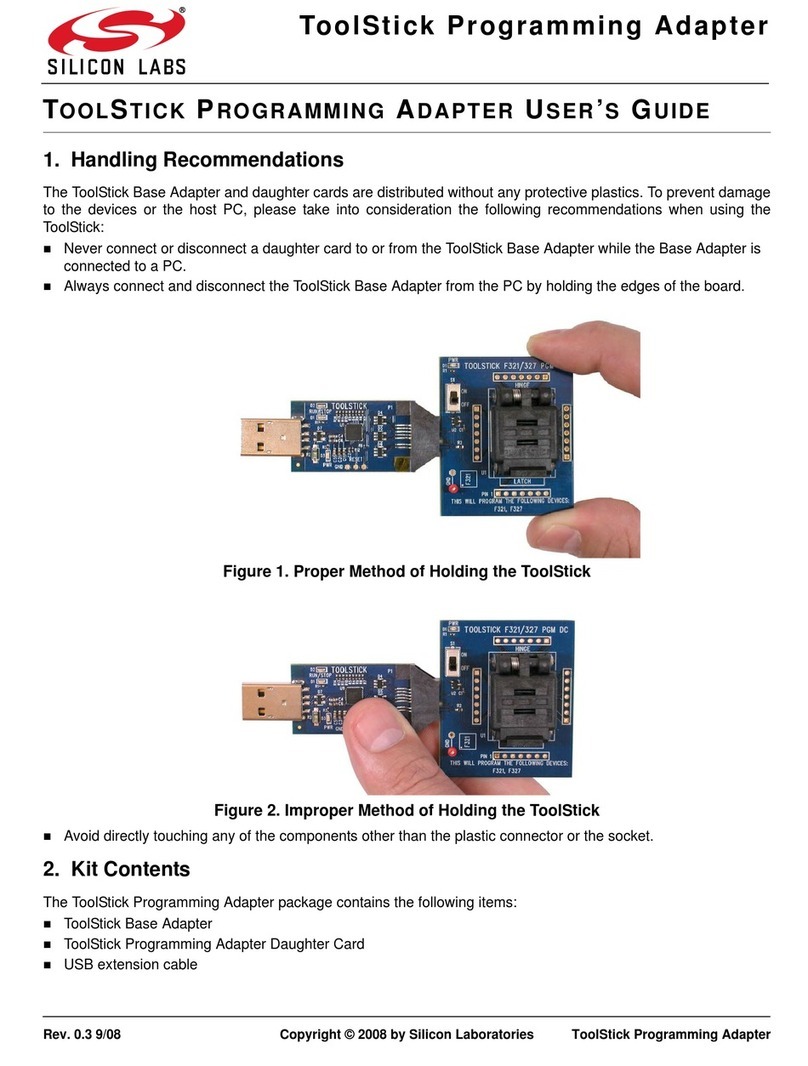

4.2 Structure of the IC1000

1

234

5

6

1 DIP switch cover and fuse 4 Status LED

2 BM1000 connection 5 24 V IN, 24 volt Input

3 RS232, connection leak detector 6 RS485 (not used)

INFICON Description | 4

IC1000-Operating-Instructions-jiqn22en1-01-(2205) 11 / 24

DIP switch and fuse Under the cover there is a fuse (0.75 A, Schurter 7010.9800.xx) for the power supply

of the BM1000 via LD interface of the IC1000.

Also two DIP switch blocks (S1 and S2). The baud rate for the LD protocol on the

RS232 interface can be selected via DIP switch S2 / 1 on the IC1000.

The IC1000 supports 19200 or 38400 baud (8 data bits, no parity, 1 stop bit, no

hardware flow control).

S2 / 1 = On means 38400 baud.

S2 / 1 = Off means 19200 baud.

All other switches must be OFF for proper operation.

LD port Connection for BM1000

RS232 Connection for leak detector

Galvanic isolation (max. 60 V DC, 25 V AC against GND)

Pin assignment:

Pin Name

2 TxD

3 RxD

5 GND

Connect the leak detector to the supplied cable via this connection.

Status LED Color Status Meaning

Red illuminates Device not functional or defective

Red flashes Not ready for operation, communication to

leak detector is not available

Cyan illuminates Ready for operation; communication to leak

leak detector available

Green Flashes quickly Boot loader active, ready for software

update

Green Flashes slowly Data reception on RS232

Yellow Flashes slowly Data reception on RS485

– off No operating voltage

4 | Description INFICON

12 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

24V IN 24 V input

Pin assignment:

Pin Name

+ + 24V

- GND

The voltage supply is normally provided by the leak detector.

Use the appropriate cable from the supplied cable set for this purpose.

INFICON Description | 4

IC1000-Operating-Instructions-jiqn22en1-01-(2205) 13 / 24

4.3 Technical data

Mechanical data

Dimensions (L × W × H) 107.6mm x 89.7mm x 76.6mm

Weight 0.5 kg

Electrical data

Protection class EN 60529 IP20

UL 50E type 1

Nominal voltage 24 V DC voltage

Nominal current < 0.5 A

Overvoltage category II

The power supply must meet the requirements for energy-limited circuits according to

DIN EN 61010-1.

Ambient conditions

Max. height above sea level 2000m

Max. relative humidity above 40 °C 50 %

Max. relative humidity from 31°C to 40°C 80% to 50% (decreasing linearly)

Max. humidity up to 31 °C

no condensation

80%

Max. storage temperature -20°C … 60°C

Permissible ambient temperature (during

operation)

5°C … 50°C

Degree of contamination II

4.4 Cleaning the device

The housing of the device is composed of synthetic material.

1Switch off the device and disconnect from the mains.

2When cleaning the housing, use an agent accepted for synthetic surfaces (for

example a light household cleaner). Do not use any solvents that attack

synthetic materials.

5 | Installation and removal INFICON

14 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

5 Installation and removal

5.1 Mount IC1000 and DIN-TS35 top-hat rail

Fig.2: Mount IC1000

1. Hook device on top hat rail at bottom.

2. Press device onto top hat rail at top.

5.2 Establish connections

Connect IC1000 with leak detector

Connect the RS232 and 24V IN ports to the leak detector using the cables supplied in

cable set 200010785.

If for some reason you want to operate the IC1000 with a separate 24 V supply

voltage, observe the following note:

NOTICE

The device must be supplied with a circuit that meets the requirements of "Energy-

limited circuits" of DIN EN 61010-1 (VDE 0411-1).

INFICON Installation and removal | 5

IC1000-Operating-Instructions-jiqn22en1-01-(2205) 15 / 24

Connect IC1000 with BM1000

Use the data cable to connect the LD connector on the IC1000 to the LD connector on

the BM1000.

Length (in meters) Catalog number

0.5 560-334

2 560-332

5 560-335

10 560-340

Table1: Data cable

NOTICE

The data cables cannot be connected in series.

The voltage supply is normally provided by the leak detector. The length must not

exceed 30 meters.

Do not use other cable lengths.

Then make the necessary settings on the leak detector. Refer to instructions of the

leak detector.

5 | Installation and removal INFICON

16 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

5.3 Remove the IC1000 from the DIN-TS35 top hat

rail

Fig.3: Remove IC1000

1. Use the flat-tip screwdriver to pull out the locking device.

2. Pull the device off of the top hat rail.

INFICON Decommissioning | 6

IC1000-Operating-Instructions-jiqn22en1-01-(2205) 17 / 24

6 Decommissioning

6.1 Disposing of the device

The device can either be disposed of by the operator or be sent to the manufacturer.

The device consists of materials that can be recycled. This option should be exercised

to prevent waste and also to protect the environment.

During disposal, observe the environmental and safety regulations of your country.

Device cannot be disposed of as normal domestic waste.

6.2 Returning the device for maintenance, repair or

disposal

WARNING

Danger due to harmful substances

Contaminated devices could endanger health. The contamination declaration serves

to protect all persons who come into contact with the device. Devices sent in without a

completed Declaration of Contamination will be returned to the sender by the

manufacturer.

► Fill in the declaration of contamination completely.

1Contact the manufacturer and send in a completed declaration of contamination

before return shipment.

ðYou will then receive a return number and the shipping address.

2Use the original packaging when returning.

3Before shipping the instrument, attach a copy of the completed contamination

declaration to the outside of the package.

6 | Decommissioning INFICON

18 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

INFICON Appendix | 7

IC1000-Operating-Instructions-jiqn22en1-01-(2205) 19 / 24

7 Appendix

7.1 Accessories

Length (in meters) Catalog number

0.5 560-334

2 560-332

5 560-335

10 560-340

Table2: Data cable

NOTICE

The data cables cannot be connected in series.

The voltage supply is normally provided by the leak detector. The length must not

exceed 30 meters.

7 | Appendix INFICON

20 / 24 IC1000-Operating-Instructions-jiqn22en1-01-(2205)

7.2 CE Declaration of Conformity

This manual suits for next models

1

Table of contents