5

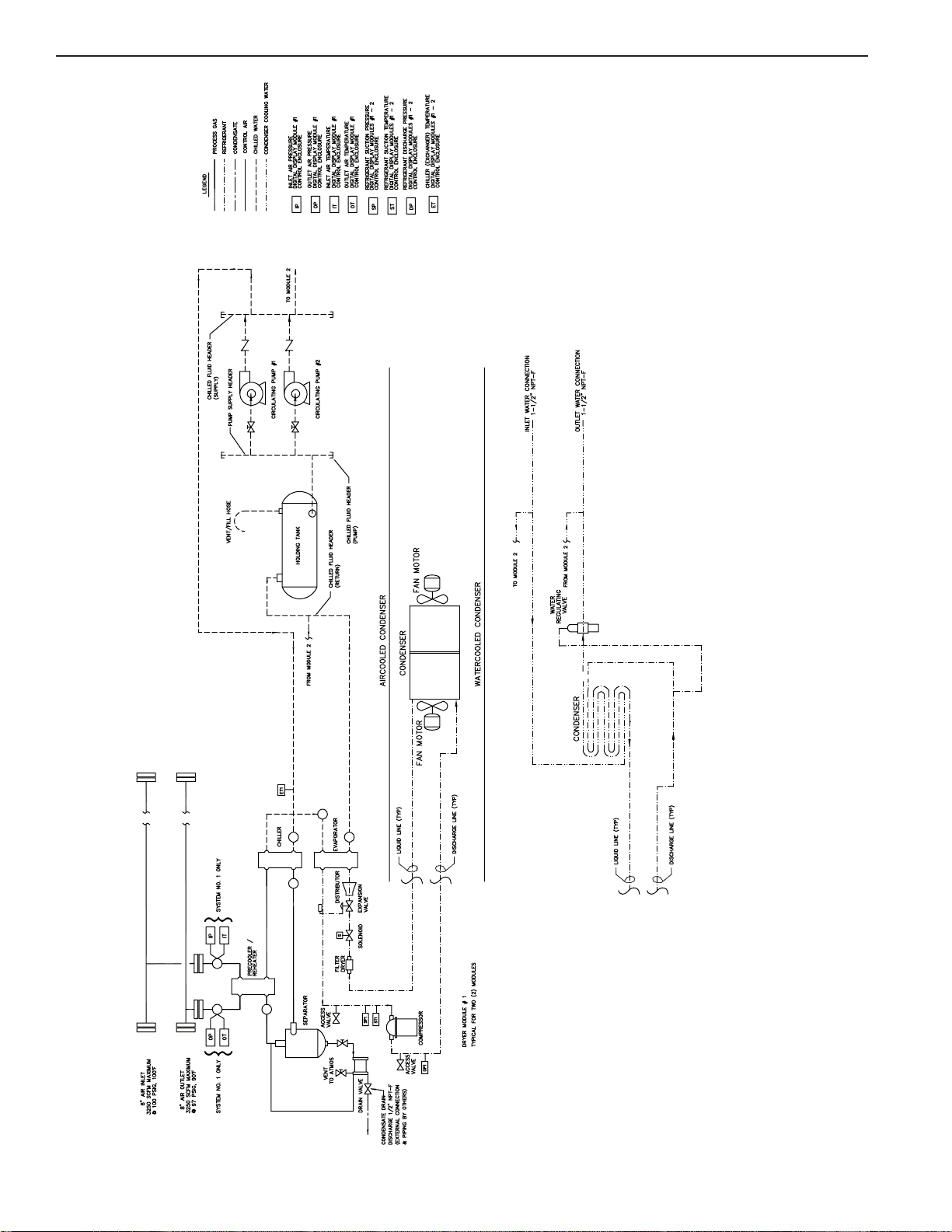

7.1 INTRODUCTION

Ingersoll Rand multiple module dryers remove moisture from

compressed air by cooling the air to a low temperature ( adjustable

between 32 and 50°F). This causes water vapor to condense into water

droplets which can then be easily removed from the air. The multiple

module design consists of two (2) or more Air / Refrigeration Modules.

All modules are connected by common Inlet and Outlet Headers. The

major systems of the dryer are: Air System, Moisture Removal System,

Refrigeration System and the Controls System The following sections

describe each of the systems in greater detail.

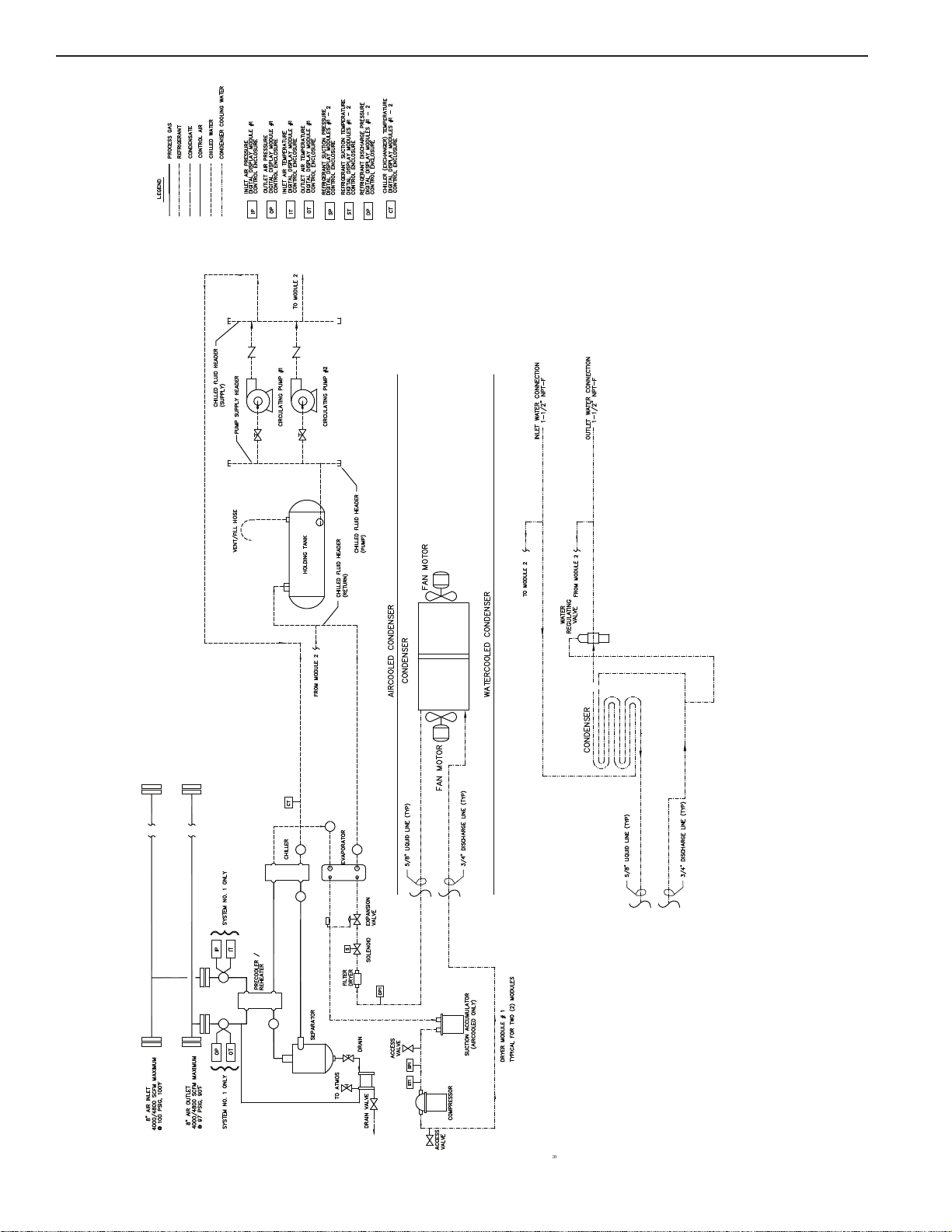

7.2 AIR SYSTEM

The Air System for each module consists of the dryer components which

are in contact with the compressed air. Referring to the Flow Diagram

and following the bold “AIR FLOW,” hot saturated air from the air

compressor enters the inlet header and then the precooler/reheater

where the air temperature is reduced prior to entering the chiller by the

cool air exiting the air/moisture separator. The air then goes into the

chiller section where it is further cooled to the desired dew point by a

thermal mass fluid. The temperature of the thermal mass fluid is

maintained by the refrigeration circuit and controls. The air continues to

the separator where moisture is removed, thereby, allowing the cool, dry

air to return to the precooler/reheater to be heated by the incoming moist

hot air. The air exiting the “reheater” portion of the dryer should be

approximately 15°- 20°F lower than the inlet air temperature based on

standard conditions at full rated flow. Air from each module is collected

in the outlet header and exits the dryer.

7.3 MOISTURE REMOVAL SYSTEM

Ingersoll Rand condensate drains discharge condensed moisture and

lubricants (condensate) from compressed air equipment. The

condensate drain operates as a zero-air-loss drain, returning air that is

displaced in the drain bowl back into the compressed air system.

Consistent discharging of condensate from compressed air equipment

is essential for proper equipment operation and performance.

The drain valve is designed for trouble-free and maintenance free

draining of unwanted accumulations of condensation and other foreign

matter from any collection point in a compressed air system without the

need for electricity.

7.4 REFRIGERATION SYSTEM

The Refrigeration System consists of all the components in each module

that handles the R-404A refrigerant. This is a hermetically sealed

closed-loop system. Referring to Figure 1 and following the phantom

“REFRIGERANT” line, refrigerant for each module is shown leaving its

respective evaporator section where, in the process of removing heat, it

is changed from a low pressure liquid into a low pressure gas. This gas

enters the suction side of the compressor where it is compressed into a

high pressure gas. The high pressure gas is cooled in the air cooled or

water cooled condenser section until it becomes a high pressure liquid.

It then goes to a liquid receiver and through a permanent filter dryer that

ensures the refrigeration system is free of contaminants.

7.0 PRINCIPLES OF OPERATION

A thermostatic expansion valve meters the refrigerant for introduction

into the evaporator. The refrigerant pressure is reduced upon entering

the evaporator where as it evaporates, heat is removed from the thermal

mass fluid.

Heavy-duty hermetic compressors are standard on multiple module

dryers. These compressors are equipped with an oil sight glass and

internal overload controls.

7.5 THERMAL MASS CIRCULATING SYSTEM

The heat is removed from the fluid in the evaporator by the refrigeration

system. The thermal mass holding tank is sized to minimize refrigeration

cycles during reduced air load periods. The thermal mass fluid is pulled

from the bottom of the holding tank and pumped through the chiller,

removing heat from the air and then returned to the evaporator. While

the individual refrigeration systems cycle on and off based on loading

conditions, the circulating pump runs continuously to maintain flow

through the chiller at all times.

7.6 CONTROLS

Ingersoll Rand Refrigerated Compressed Air Dryers are equipped with

the Microprocessor Control on each module. This advanced

microprocessor-based controller has been engineered by Ingersoll

Rand exclusively for use with Ingersoll Rand Compressed Air Dryers.

The Microprocessor Control cycles the refrigeration system based on

the dryer's Chiller Temperature. A temperature sensor samples the

thermal mass temperature as it enters the chiller exchanger. The

Chiller Temperature Set point is a user adjustable set point that is used

to set the Refrigeration Compressor Off temperature. Once the Chiller

Temperature has fallen below the Chiller Temperature Set point, the

refrigeration compressor will de-energize. The Operating Temperature

Differential is factory set at 3°F above the Chiller Temperature Set point.

Therefore, if a user adjusts the Chiller Temperature at 36°F, the

Refrigeration Compressor On temperature will be 39°F.

The Microprocessor Control features three levels of access. The default

level CUSTOMER MODE permits adjustment of dryer parameters to

address seasonal variations for drain timing and pressure dew point

temperature. A protected TECHNICIAN MODE permits access to and

manipulation of additional parameters. A password protected

FACTORY MODE is also included for use with Ingersoll Rand Service

Personnel for troubleshooting the dryer.

Nirvana Cycling Refrigerated Dryer Models 3250-8000

ingersollrandproducts.com