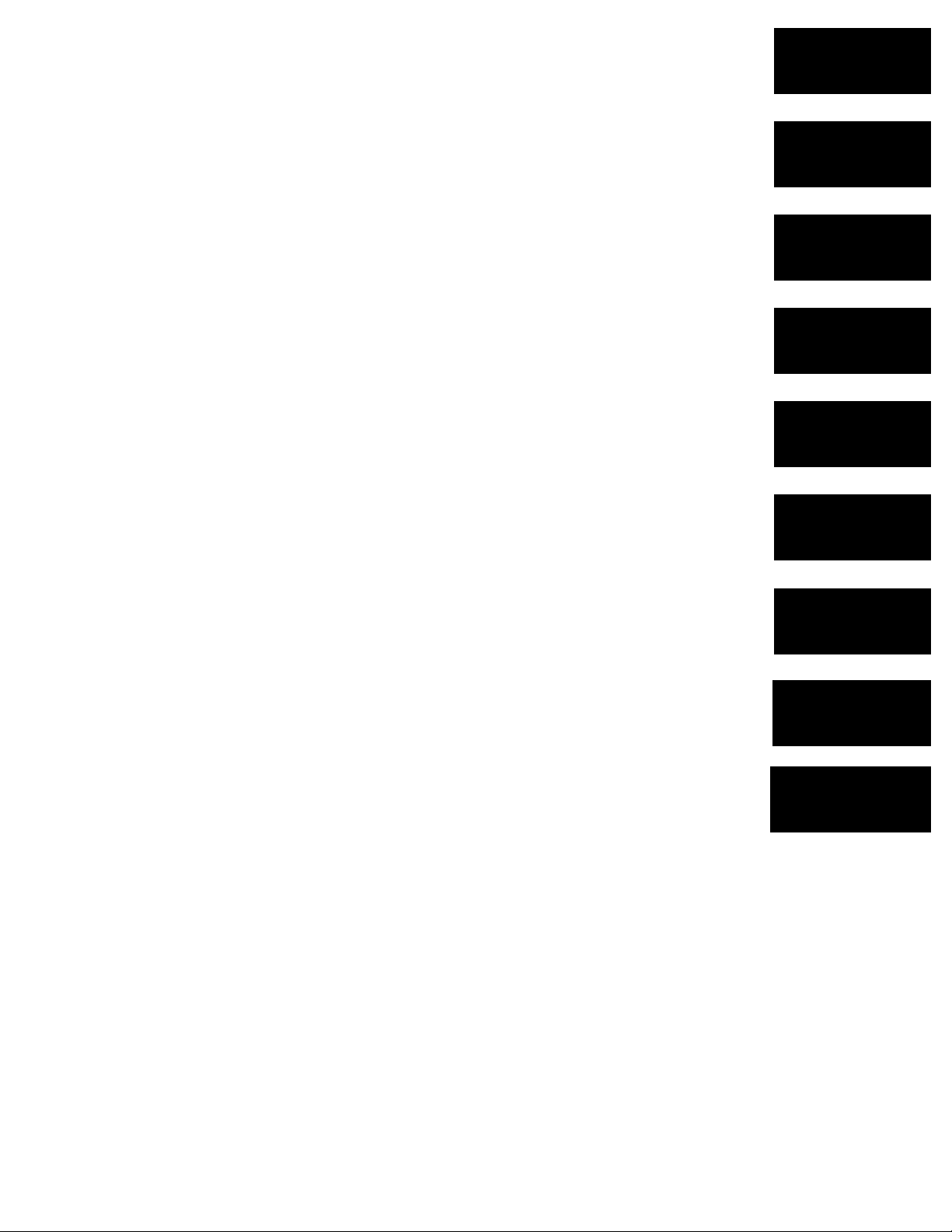

ALPHABETICAL INDEX

AIR CLEANER ........................................................ 70-01

AIR CLEANER SERVICE ....................................... 10-01

ALTERNATOR ........................................................ 60-01

ALTERNATOR BELT............................................... 10-01

ARM CYLINDER..................................................... 20-01

ARM ........................................................................ 50-01

AXLE AND DIFFERENTIAL (FRONT).................... 40-01

AXLE AND DIFFERENTIAL (REAR) ...................... 40-01

AXLE TOE-IN.......................................................... 10-01

BACKHOE BOOM LOCK........................................ 10-01

BACKHOE CONTROL VALVE................................ 20-01

BATTERY................................................................ 60-01

BOB-TACH.............................................................. 50-01

BOB-TACH HAND LEVER...................................... 10-01

BOOM ..................................................................... 50-01

BOOM CYLINDER .................................................. 20-01

BRAKE CALIPER ................................................... 40-01

BUCKET ................................................................. 50-01

BUCKET CYLINDER .............................................. 20-01

CAB DOOR ............................................................. 50-01

CAB LIGHTS........................................................... 60-01

COMPONENTS ...................................................... 80-01

CONVERSIONS ................................................SPEC-01

DRIVESHAFT ......................................................... 40-01

DROP BOX ............................................................. 40-01

ELECTRICAL SYSTEM INFORMATION ................ 60-01

ENCLOSED CAB.................................................... 50-01

ENGINE .................................................................. 70-01

ENGINE COMPONENENTS AND TESTING ......... 70-01

ENGINE COOLING SYSTEM................................. 10-01

ENGINE COVER ......................................... 10-01, 50-01

ENGINE LUBRICATION SYSTEM.......................... 10-01

ENGINE SIDE COVERS......................................... 50-01

ENGINE SPECIFICATIONS...............................SPEC-01

ENGINE SPEED CONTROL .................................. 70-01

FENDER ................................................................. 50-01

FLOOR PANELS..................................................... 50-01

FLYWHEEL ............................................................. 70-01

FLYWHEEL HOUSING ........................................... 70-01

FRONT AXLE .............................................. 10-01, 40-01

FRONT AXLE PIVOT FRAME ................................ 50-01

FRONT LIGHTS...................................................... 60-01

FRONT WIPER....................................................... 60-01

FUEL LEVEL SENDER........................................... 60-01

FUEL SYSTEM ....................................................... 10-01

FUEL TANK............................................................. 50-01

GEAR PUMP .......................................................... 20-01

GRILL...................................................................... 50-01

GRILL FRAME ........................................................ 50-01

HEATER FAN ..........................................................80-01

HEATER UNIT .........................................................80-01

HYDRAULIC FILTER HOUSING .............................20-01

HYDRAULIC FLUID RESERVOIR ..........................20-01

HYDRAULIC SYSTEM INFORMATION ..................20-01

HYDRAULIC/HYDROSTATIC FLUID

SPECIFICATIONS ............................................ SPEC-01

HYDRAULIC/HYDROSTATIC SYSTEM..................10-01

HYDROSTATIC DRIVE MOTOR .............................30-01

HYDROSTATIC PUMP ............................................30-01

HYDROSTATIC SYSTEM INFORMATION..............30-01

HYDROSTATIC TESTING.......................................30-01

INSTRUMENT PANEL.............................................60-01

LOADER BACKHOE SPECIFICATIONS........... SPEC-01

LOADER BACKHOE TORQUE ......................... SPEC-01

LOADER CONTROL VALVE ...................................20-01

LIFT ARMS..............................................................50-01

LIFT ARM SUPPORT DEVICE................................10-01

LIFT CYLINDER ......................................................20-01

LIFTING AND BLOCKING THE

LOADER BACKHOE ...............................................10-01

LUBRICATING THE LOADER BACKHOE ..............10-01

MAIN RELIEF VALVE ..............................................20-01

MUFFLER................................................................70-01

OIL COOLER...........................................................30-01

OPERATOR CAB ....................................................50-01

OPERATOR SEAT...................................................50-01

PARKING BRAKE....................................................40-01

PORT RELIEF VALVE

(BACKHOE CONTROL VALVE) .............................20-01

PORT RELIEF VALVE

(LOADER CONTROL VALVE)................................20-01

RADIATOR ..............................................................70-01

REAR AXLE .................................................10-01, 40-01

REAR WINDOW ......................................................50-01

REAR WIPER..........................................................60-01

RECONDITIONING THE ENGINE ..........................70-01

RUBBER DRIVE COUPLER ...................................70-01

SERVICE SCHEDULE ............................................10-01

SIDE SHIFT LOCK CYLINDER...............................20-01

STABILIZER FRAME...............................................50-01

STABILIZER CYLINDER .........................................20-01

STEERING ANGLE ADJUSTMENT

(FRONT AXLE)......................................................40-01

STEERING ANGLE ADJUSTMENT (REAR AXLE)40.01

STEERING CYLINDER (FRONT) ...........................20-01

STEERING CYLINDER (REAR)..............................20-01

STEERING PUMP...................................................20-01

STEERING VALVE ..................................................20-01

Find manuals at https://best-manuals.com