INHECO Thermoshake AC Operating manual

Thermoshake AC | Thermoshake AC 180

Part No.: 7000160 | 7000161

Teleshake AC | Teleshake 95 AC

Part No.: 7000150 | 7000151

User and installation manual

Shaker with clamping

Doc ID: 901325-000 December 2021

INHECO 2

Doc ID: 901325-000

December 2021

INHECO Industrial Heating and Cooling GmbH reserves the right to modify their

products for quality improvement. Please note that such modifications may not be

documented in this manual.

This manual and the information herein have been assembled with due diligence.

INHECO GmbH does not assume liability for any misprints or cases of damage resulting

from misprints in this manual. If there are any uncertainties, please feel free to contact

[email protected]. → How to contact INHECO, page 6.

The brand and product names within this manual are registered trademarks and belong

to the respective titleholders.

INHECO 03

Doc ID: 901325-000

December 2021

Table of Contents

Important Notes ......................................................................................... 04

General Information ..................................................................................... 04

Explanation of Symbols ............................................................................... 04

Abbreviations and Glossary ........................................................................ 05

Warranty ...................................................................................................... 05

How to contact INHECO .............................................................................. 06

Product Description .................................................................................. 06

Intended Use ............................................................................................... 06

Scope of Supply .......................................................................................... 07

Functional Elements: ................................................................................... 09

Status LED and Firmware update ............................................................... 11

Labels .......................................................................................................... 12

Technical Data (preliminary)........................................................................ 13

Safety Instructions .................................................................................... 14

Product-specic Risks ................................................................................. 14

Technical Alterations ................................................................................... 15

Malfunctions................................................................................................. 15

Hardware Installation ................................................................................ 16

Scope of Supply........................................................................................... 16

Initial Operation............................................................................................ 16

Programming the Movement Pattern........................................................... 17

Fixation of Disposables (Tubes, Reservoirs, Plates)............................................... 17

Removal of Fixation Pins ............................................................................. 18

Installation of Adapter Plates (Inserts, Nests).............................................. 19

Mechanical Integration................................................................................. 20

Software Installation.................................................................................. 21

Daily Usage ................................................................................................ 21

Safety Instructions for Operation ................................................................. 21

How to get the Shaking devices in closed position...................................... 22

How to get the Shaking devices in opened position .................................... 23

Maintenance ............................................................................................... 24

Software Updates ........................................................................................ 24

Trouble-Shooting & Support ........................................................................ 24

Maintenance - Relling of Cooling Liquid Reservoir .................................... 26

Cleaning....................................................................................................... 31

Decontamination.......................................................................................... 31

Calibration / Verication............................................................................... 31

Return for Repair only with RMA Number ................................................... 32

Transportation and Storage ......................................................................... 32

Shut Down and Disposal ............................................................................. 32

Accessories................................................................................................ 33

Multi TEC Control (MTC) / Single TEC Control (STC)................................. 33

Yellow Slot Module ...................................................................................... 33

Thermal Adapter for Temperature Transfer................................................. 33

Miscellaneous .............................................................................................. 33

Appendix .................................................................................................... 34

INHECO 04

Doc ID: 901325-000

December 2021

1 IMPORTANT NOTES

1.1. General Information

Read the user instructions completely. The manual explains how to operate and handle

all shaking devices with automated clamping mechanism (Shaking devices).

Currently INHECO offers 3 types of Shaking devices: Thermoshake AC: 71000160,

Thermoshake AC 180: 7100161; Teleshake AC: 71000151 and Teleshake 95 AC:

71000150. Please follow these manual instructions, as otherwise injury or product

damage cannot be excluded.

Missing or insufficient knowledge of the manual leads to loss of liability against

INHECO GmbH.

This manual is part of the Thermoshake AC, Teleshake AC and Teleshake 95 Shaking

device and must be retained until the device is disposed of and must be passed on with

the devices when the device is taken over by a new user.

The devices with automated clampingmeet the acknowledged rules of technology and

comply with today´s standards.

Manual instructions must be followed in order to ensure safe handling of the device.

Security-related warnings in this manual are classified into three hazard levels:

-The signal word WARNING indicates hazards which – without precautionary

measures – can result in serious injury or even death.

-The signal word CAUTION indicates hazards which – without precautionary

measures – can result in minor to moderate injuries

-The signal word NOTE stands for the general precautionary measures that have to

be taken to avoid damaging the device when using it.

-The signal word NOTICE stands for the general measures that help using the device.

Contact INHECO in case there are any uncertainties of how to operate or how to handle

the devices with auto clamping.

Your opinion about this manual provides us with valuable insights on how we can

improve this document. Please do not hesitate to direct your comments to

[email protected], → How to contact INHECO, page 6.

1.2. Explanation of Symbols

Symbol Explanation

Potential danger of serious injury or death →

signal word WARNINg or CAUTION indicate the severity.

Caution: Potential danger of hot surface.

· Bullet points indicate steps of instructions.

-Hyphens refer to enumerations.

→ Arrows indicate: “refer to” and are mostly an active link

INHECO 05

Doc ID: 901325-000

December 2021

1.3. Abbreviations and Glossary

The following acronyms and items are used in this document

AC Auto Clamping

°C Degree Celsius

°F Degree Fahrenheit

mm Millimeter

in Inch

Hz Hertz [1/s]

KKelvin

kg Kilogram

lbs Pounds

dB(A) Decibel

RH relative humidity

TEC Thermo- Electric- Cooler (Thermoelectric Module)

Vdc Voltage direct current

Adc Ampere direct current

WWatt

rpm revolutions per minute

IVD In Vitro Diagnostic

FDA Food and Drug Administration

MTC Multi TEC Control controls up to 6 INHECO devices individually

STC Single TEC Control controls 1 INHECO device

Oset The dierence between the set temperature and actual value once the

temperature is stable

PT100 PT100 is a Resistive-Temperature-Detector (RTD). This sensor increases its

resistance with increasing temperature.

Calibration Calibration is the validation of specic measurement techniques and

equipment. At the simplest level, calibration is a comparison between

measurements - one of known magnitude or correctness - made or set with

one device and another measurement made in as similar a way as possible

with a second device.

1.4. Warranty

The warranty period starts on the date of shipment. Any damage caused by operating

the Shaking devices outside the specifications and guidelines leads to the loss of

warranty. Broken seals on INHECO devices lead to the loss of warranty as well.

INHECO will only accept parts / devices for return that do not pose a threat to the health

of our staff. In particular, the devices may not have been used in Biosafety Level 3 and 4

environments or have been exposed to radioactive or radiation materials. → Cleaning

and Decontamination, page 30.

Devices exposed to Biosafety Level 3 and 4 Environments are not accepted by

INHECO for return.

INHECO 06

Doc ID: 901325-000

December 2021

1.5. How to contact INHECO

2 PRODUCT DESCRIPTION

2.1. Intended Use

While the Thermoshake AC is one of the most compact heated and cooled shaking

positions for a wide range of standard ANSI/SLAS (formerly SBS) plates and tubes. The

Teleshake AC is offering the shaking without temperature control and the Teleshake

95 AC heating and shaking control up to 125°C without cooling. All AC devcies have a

compact size.

The Shaking devices can be placed on the deck of liquid handling systems with the

lowest possible usage of space. The Shaking devices offer excellent control of

temperature and fluid mixing according to their temperature needs. Shaking curve is

orbital. Due to the new clamp mechanism the device allows higher shaking rpm than

with the standard Thermoshake.

The cooling function of the Thermoshake AC offers the unique possibility to stop

reactions quickly by reducing the temperature of the liquid samples.

The Shaking devices can be operated with two types of precise temperature/rpm

controllers with integrated power supply (MTC or STC). The units are heating/cooling

devices with CE and UL certification. They are mainly used on robotic platforms and

systems in LabAutomation.

The Shaking devices are designed specifically for use in Life Science. The Shaking

device is prepared for easy integration into IVD applications, but the final IVD validation

has to be performed by the first marketer (IVD application).

When using the Shaking devices in a Biosafety Laboratory Environment, the user is

responsible for labeling the devices according to the WHO Laboratory Biosafety Manual

(ISBN 92 4154650 6) and for operating the devices according to this Biosafety Manual.

The Shaking devices must be used exclusively by laboratory professionals trained in

laboratory techniques with LabAutomation systems and having studied the instructions

for use of this instrument as well as the instructions of the workstation the device is used

in.

Contact Tek-Matic at www.tekmatic.com or 815.282.1775

INHECO 07

Doc ID: 901325-000

December 2021

2.2. Scope of Supply

Before initial operation, make sure that the shipment of your unit and its scope of supply

is complete, and no parts are damaged.

In case of parcel or product damages, make photos of the damaged boxes and products

must be reported to INHECO within 7 days of delivery. The following components should

be included in each shipment:

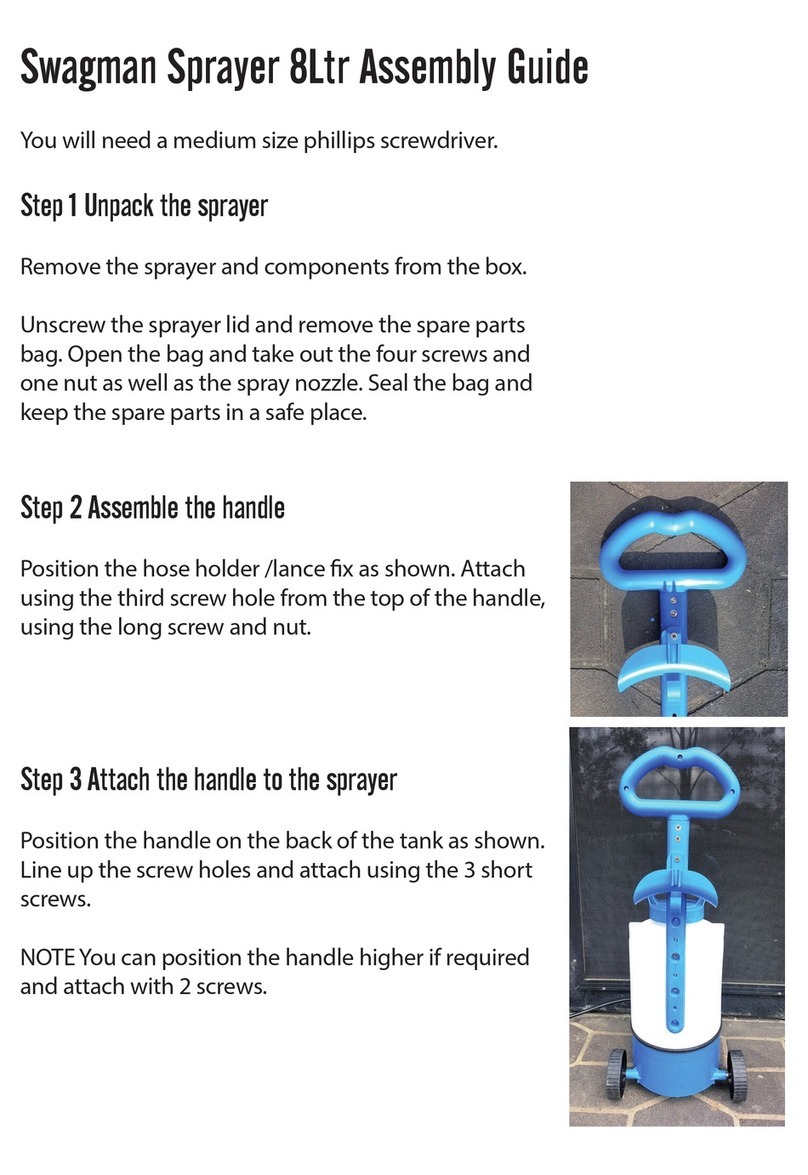

2.2.1. For Thermoshake AC and Thermoshake AC 180

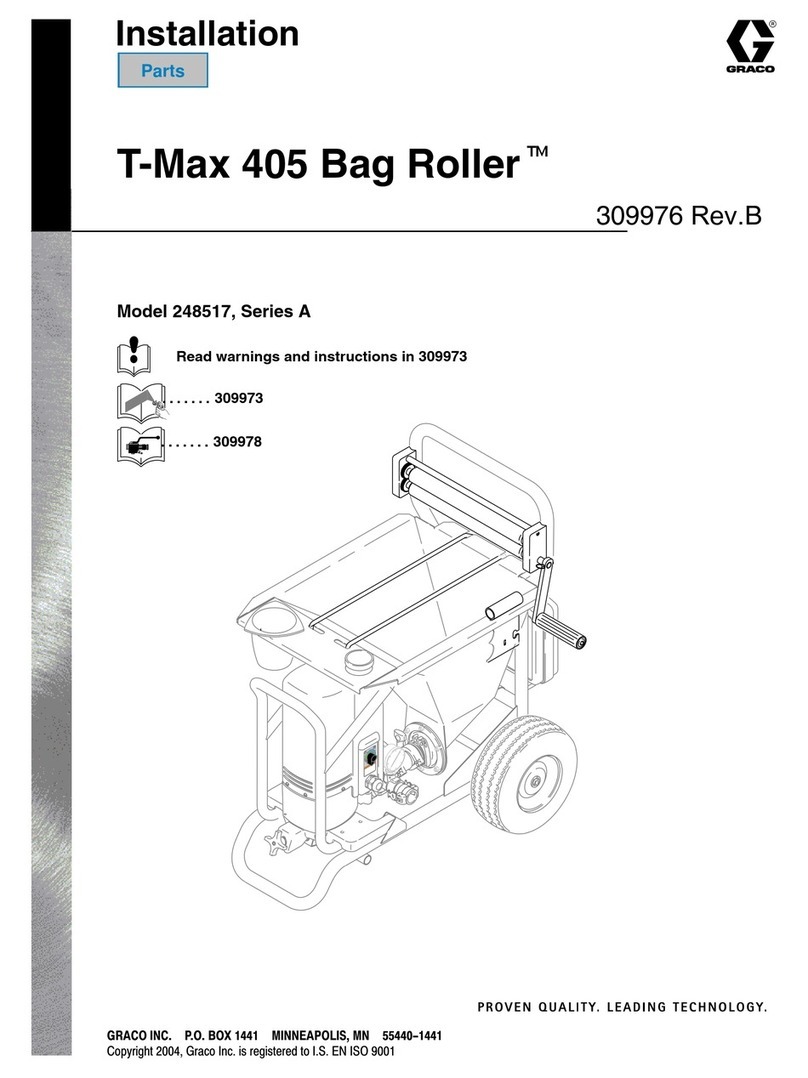

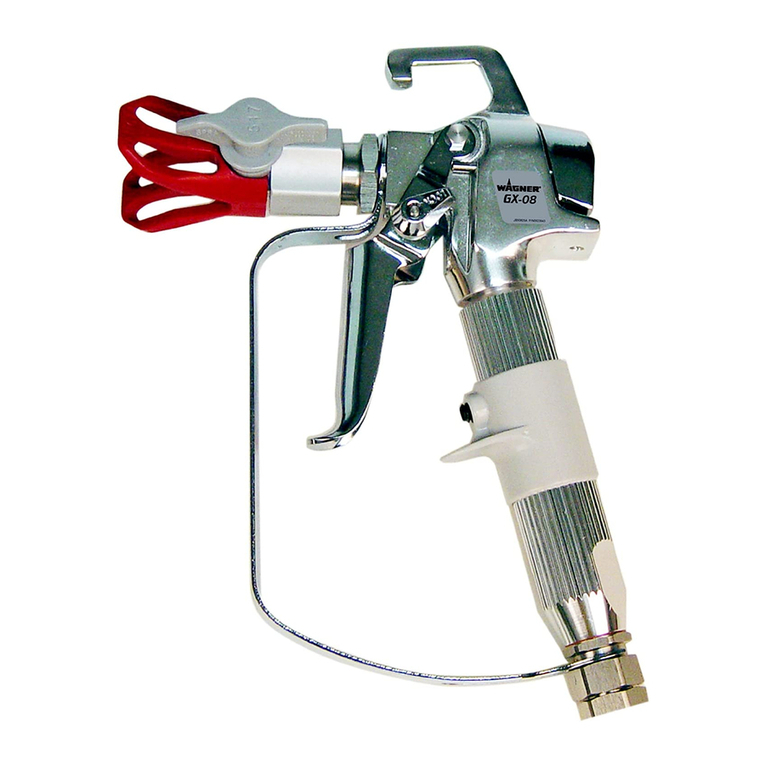

Fig.1: Scope of Supply

( 1 ) Thermoshake AC incl. Sub-D-Connector Cable *

( 2 ) Syringe to refill the cooling liquid

( 3 ) Syringe needle to refill the cooling fluid

( 4 ) Cooling fluid

( 5 ) Socket wrench for filling nozzle of the cooling liquid reservoir

( 6 ) 3 allen screws to fix thermal adapters

* image may vary depending on what Thermoshake AC is ordered.

The Sub-D-Connector Cable is already connected with the Thermoshake AC and it also

needs to be connected to the Yellow Slot Module installed inside the TEC Control Unit

(MTC or STC). → Initial Operation, page 16.

6

1

2

5

3

4

Cable with Sub-D-Connector

INHECO 08

Doc ID: 901325-000

December 2021

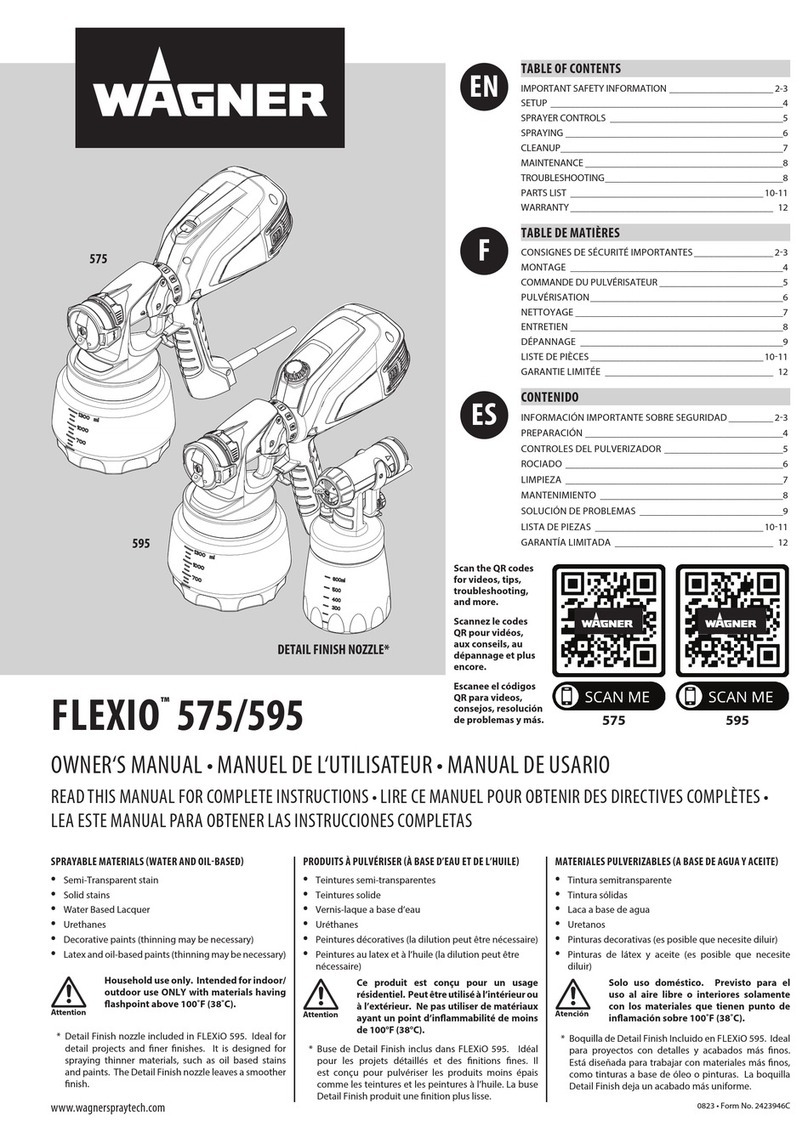

2.2.2. For Teleshake AC and Teleshake 95 AC

Fig.2: Scope of Supply

( 1 ) Teleshake (95) AC incl. Sub-D-Connector Cable

The Sub-D-Connector Cable is already connected with the Teleshake (95) AC and it

also needs to be connected to the Yellow Slot Module installed inside the TEC Control

Unit (MTC or STC). → Initial Operation, page 16.

1

INHECO 09

Doc ID: 901325-000

December 2021

2.3. Functional Elements:

In the following images the Thermoshake AC (180) is shown, but the clamping

mechanism of the Teleshake (95) AC is identical to this. If there are differences in other

functional elements they are clearly pointed out.

2.3.1. Clamping Mechanism

The automated clamping mechanism is suited for ANSI/SLAS standard plates and it will

make sure that the plates will keep in position during shaking. After shaking is stopped

the clamp mechanism will automatically open and the shaker table will go back into in 0.

position.

WARNING

In case the plate is not complying with standard ANSI/SLAS plates and / or the

shaking speed is not set according to the specications, the clamping mechanism

might not suciently x the plate on the shaker table during shaking.

Fig.3: Clamp Mechanism "Open"

Fig.4: Clamp Mechanism "Closed"

CAUTION

Pinching of nger: While the clamp mechanism is closing you might pinch your

nger or your glove. Closing or opening takes about 5 sec.

INHECO 10

Doc ID: 901325-000

December 2021

2.3.2. Fixation Pins

Fig.5: Fixation Pins of Clamp Mechanism

CAUTION

Pinching of nger: While the clamp mechanism is closing you might pinch your

nger or your glove. Closing or opening takes about 5 sec.

2.3.3. Cold plate (temperature area)

(only for Thermoshake AC and Teleshake 95 AC)

Fig.6: Heated area of Thermoshake AC (Teleshake 95 AC is similar)

WARNING

Devices can burn your skin. Even after switching off the TEC Control Unit, the

connected devices can still be hot and could seriously burn your skin as the material´s

temperature can reach up to +125°C [+257°F]! It takes a while to cool down after the

device has been switched off.

INHECO 11

Doc ID: 901325-000

December 2021

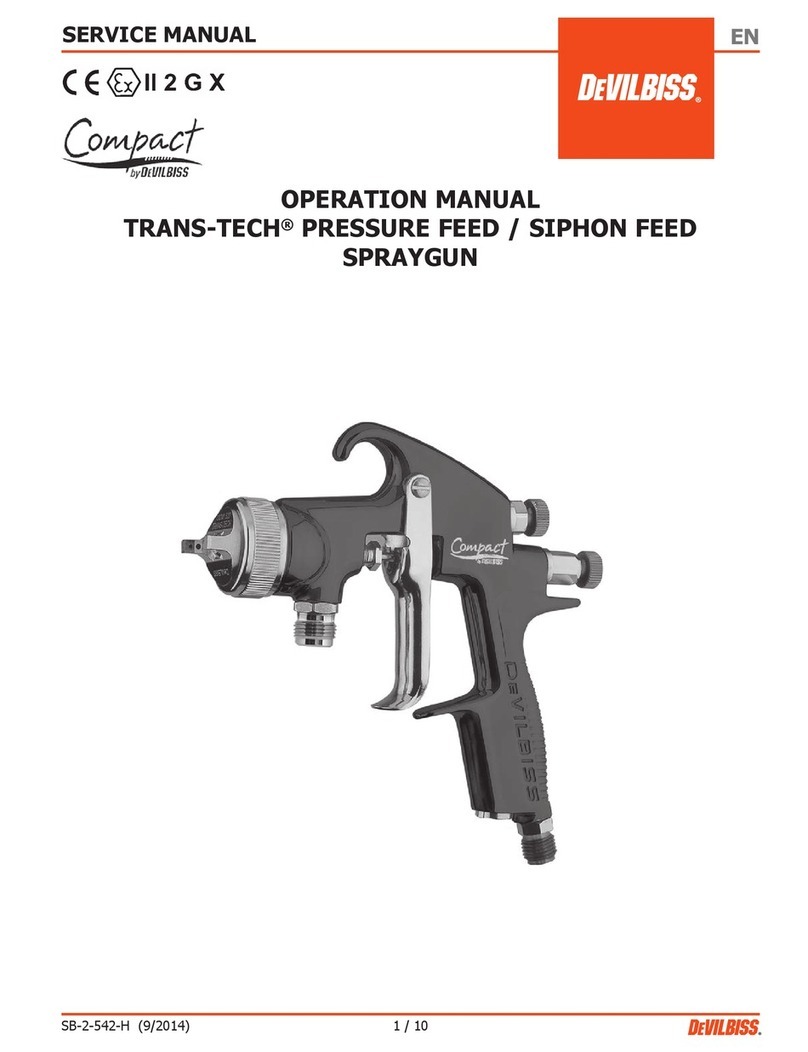

2.3.4. Ventilation of Thermoshake AC and Thermoshake AC 180

The ventilation is the big difference between Thermoshake AC and Thermoshake AC

180. With the standard device the fans airflow direction if from the outside to the inside

sucking ambient room temperature into the device. The Thermoshake AC 180 has a

turned fan which means the hot air is blown out.

Fig.7: Ventilation

The Teleshake AC and Teleshake 95 AC do not have any ventilation.

2.4. Status LED and Firmware update

(only for Teleshake AC and Teleshake 95 AC)

The Teleshake provide a functionality to check the status at the device itself.

Furthermore, there is a microUSB connector and a button for firmware update. How to

perform a firmware update will be explained in an additional manual.

Fig.8: Functional Elements Teleshake AC and Teleshake 95 AC

( 1 ) Status LED

Color of LED State Description

red steady for 30 sec. shortly o,

and again 30 sec steady

device is booting

green blinking device is ready for

communication

( 2 ) microUSB connector

( 3 ) Button for use during firmware update

INHECO 12

Doc ID: 901325-000

December 2021

2.5. Labels

The identification label with part number and serial number also contains important

technical indications. The electrical specification on the label must meet your local

situation. The label is placed on the side of the device. The identification label must not

be removed. If it has become illegible or falls off, it has to be replaced by a new

identification label. New labels can be ordered at INHECO. In case the label is missing

and you do not know the part number and serial number, they can also be read out with

the software (MTC/STC Demo Tool) which can be downloaded from INHECO´s login

section on www.inheco.com. → Trouble Shooting & Support, page 18f.

Thermoshake AC Teleshake 95 AC

1000

INHECO GmbH

82152 Martinsried / Germany

01PN:

SN:

Input: 24V Imax: 5,3A

7100160-A

Thermoshake AC

2017-11

Rev.:

Fig.9: Product labels on the device (example , not all types are shown)

Thermoshake AC

00002

INHECO GmbH

82152 Martinsried / Germany

00PN:

SN:

Input: 24V Imax: 1,5A

7100151-A

Teleshake AC

2020-01

Rev.:

Fig.10: Product labels on the device

INHECO GmbH

82152 Martinsried / Germany

1000

00PN:

SN:

7100160-A

Thermoshake AC

2017-11

Rev.:

Storage and transportation conditions:

-10°C to +60°C [+14.0°F to +140°F],

10% to 80% RH, non condensing

Fig.11: Example shipment labels on the package

Fig.12: Other labels on the product (for Thermoshake AC (180) and Teleshake 95 AC)

00006

INHECO GmbH

82152 Martinsried / Germany

00PN:

SN:

Input: 24V Imax: 5,3A

7100150-A

Teleshake 95 AC

2020-01

Rev.:

GMA

2018-10-05 Piktogramm_02.docx 1/1

Do not lift at the top plate!

切

切

勿

勿

提

提

拉

拉

顶

顶

板

板!

Caution Hot

INHECO 13

Doc ID: 901325-000

December 2021

2.6. Technical Data (preliminary)

Technical Data incl. Dimensions

Thermoshake AC type Teleshake

AC

Teleshake 95 AC Thermoshake

AC and 180

Outer dimensions

height

p/n 7100150 p/n 7100151 p/n 7100160

p/n 7100161

height (bottom to contact

surface)

47.3 mm

[1.862 in]

47.3mm

[1.862 in]

109.9mm

[4.327 in]

height with standard xation

pins

53.7 mm

[2.144 in}

53.7 mm

[2.144 in]

115.9 mm

[4.563 in]

Length x width 144 x 101 mm

[5.669 x 3976 in]

144 x 101 mm

[5.669 x 3976 in]

147 mm x 104 mm

[5.787 in x 4.095 in]

Temperature range ---*1up to +125°C

[up tp +257°F]

+4°C to +70°C

[+39.2°F to

+158°F]

Maximum temperature

dierence in cooling mode

∆T (=Tambient- Ttarget)

--- --- 25K

Noise Max. 42dB(A)

Protection Category IP 20

Weight including cables 2.2 kg

[4.85 lbs]

2.2 kg

[4.65 lbs]

3.5 kg

[7.7 lbs]

*1) ambient +5K

Technical information regarding shaking for all devcies

Teleshake (95) AC

7100150+7100151

Thermoshake AC

Maximum load 1.0 kg

Shaker frequency

weight reduce the max. speed

200 to 3000 rpm 300 to 3000 rpm*2)

Shaking amplitude 2 mm [0.07874 in]

Shaking pattern Orbital

*2) Depending on the load, as otherwise liquid might get spilled or adapter might not be hold tight to the clamp

mechanism. We recommend to test the speed you want to use with a microtiter plate and water to test the

behavior first.

The use of RPM smaller 300 with the Thermoshake AC is possilble. However, the shaking performance

cannot be guaranteed. In case the shaking is not steady you will receive a warning "error 35 slot x (x = slot ID).

This error can be igrnored if no other error or warning are set in the same time. It is not INHECO´s

responsibility if there is any method failure due to this low RPM.

Enviromental Conditions

Tolarable relative humidity Operation 10-80% RH (non condensing*3)) at

+20°C up to +30°C [+68°F to + 86°F]

Transportation and

storage

10-80% RH (non condensing*3)) at

+20°C up to +30°C [+68°F to + 86°F]

Temperature Operation +15°C to +32°C [+59°F to 90°F]

Transportation and

storage

-10°C to + 60°C [+14°F to 140°F], non

condensing*3)

*3) Condensate can prevent the Shaking devices from operating properly and can damage the Thermoshake

AC. Condensate should be eliminated on a daily basis or more often, for example by heating cycles in

between cooling cycles.

INHECO 14

Doc ID: 901325-000

December 2021

3 SAFETY INSTRUCTIONS

3.1. Product-specic Risks

WARNING

Follow the safety instructions given below in order to avoid danger for user and device.

General

-The Shaking device (“the device”) needs maintenance on a regular basis regarding

cooling liquid, → Thermoshake AC Maintenance (Relling of Cooling Liquid

Reservoir), page 24ff.

-The device has to be placed in an upright position. On non-observance, it will

eventually overheat, causing the temperature fuse to blow.

-The main power switch of the TEC Control Unit must always be accessible.

-Free air supply must be ensured to prevent damage to the device. Do not cover the

ventilation openings at the front and rear panel at any time. Ensure a minimum of at

least 30 mm (1.2 inch) of free space between the ventilation openings at the front and

at the back and adjacent devices or walls.

-Ensure that there is no other device installed next to the device increasing the inletair

temperature for the device above the specified temperatures. In case of doubt, please

contact INHECO for further analysis.

-Do not insert any parts into the ventilation inlet or outlet.

-Do not exceed minimum or maximum ambient temperature and humidity conditions

during operation or storage of the device → Technical Data, page 13.

-The device must not be used in environments with risk of explosion.

-The device is for indoor use only.

Burning Hazard:

-Devices can burn your skin. Even after switching off the TEC Control Unit, the

connected devices can still be hot and could seriously burn your skin as the material‘s

temperature can reach up to 125°C [+257°F]! It takes a while to cool down after the

device has been used.

Pinching of finger:

-While the clamp mechanism is closing you might pinch your finger or your glove.

Electrical Shock:

-The device must not be used if the device itself or the power cable shows visible

signs of damage.

-You can suffer an electric shock and injuries, if the device is not connected properly

or if you do not disconnect the device from the TEC Control Unit outlet before opening

the housing.

-Never connect or remove the power plug of the TEC Control Unit with wet hands.

-Original power cable for the TEC Control Unit provided by INHECO has to be used to

guarantee safe and proper operation.

-The wall power outlet must have a ground earth connection (Safety Class 1).

-Where an ungrounded receptacle is encountered, a qualified electrician must replace

it with a properly (PE) grounded receptacle in accordance with the local electrical

code.

INHECO 15

Doc ID: 901325-000

December 2021

- Make sure that the electrical specification on the identification label at the side panel

meets your local situation. → Labels, page 12.

Biosafety Laboratory Environment

- When using the devices in a Biosafety Laboratory Environment, the user is

responsible for labeling the devices according to the WHO Laboratory Biosafety

Manual (ISBN 92 4154650 6) and for operating the devices in accordance to this

WHO Laboratory Biosafety Manual.

3.2. Technical Alterations

- Do not alter the product. Any modification or change which is not approved by

INHECO leads to the loss of warranty. Broken seals on INHECO devices lead to the

loss of warranty as well.

- Use only original parts provided by INHECO. Parts provided by other suppliers can

impair the functionality of the unit.

- Damages due to the use of non-original parts are excluded from INHECO's liability.

3.3. Malfunctions

- In case of a malfunction, switch off and disconnect the device immediately. Make sure

to inform the authorized person in charge.

- Make sure that the malfunctioning unit is not accidentally re-inalled and used before

the malfunction is eectively eliminated. → Trouble Shooting and Support, page 24.

INHECO 16

Doc ID: 901325-000

December 2021

4 HARDWARE INSTALLATION

4.1. Scope of Supply

Before initial operation, make sure that the shipment of your unit is complete and neither

packaging nor parts are damaged → Scope of Supply, chapter 2.2.

4.2. Initial Operation

4.2.1. How to connect devices to the MTC / STC

In order to connect an INHECO heating/cooling/shaking device, the TEC Control Unit

has to be equipped with the corresponding Slot Module. There are blue, black, and red

Slot Modules available. The following table shows the appropriate Slot Module for each

heating/cooling/shaking device.

Product Color Article No. Heating/cooling/shaking Device

Black Slot Module black 2400125 CPAC HT 2-TEC, HeatPAC, Heated Lid,

Teleshake 95, Thermoshake AC,

Blue Slot Module blue 2400128 CPAC (only 7000190 & 7000179)

Yellow Slot Module yellow 2400211 Thermoshake AC, Thermoshake AC 180

Teleshake 95 AC, Teleshake AC

Fig.13: Example of connected heating/cooling/shaking device (image shows CPAC)

NOTE

Never plug in our plug out a device while the Controller is running. Always turn o the

Controller before disconnecting or connecting the device.

For clear identication, all Slot

Modules and connectors are

marked in blue, black or yellow.

When connecting a new device,

the color code has to be strictly

respected.

In case of wrong connection,

interaction will not be possible,

and an error message will be

issued.

The color coding of the Slot

Modules is visible from the

outside through small round

windows.

At the connectors, the sleeve

must be marked in the same

color as the Slot Module.

INHECO 17

Doc ID: 901325-000

December 2021

•Disconnect the power cord of the TEC Control Unit.

•Connect the Shaking device to the appropriate Slot Module and lock the connector.

The Shaking device must be connected to a Yellow Slot Module.

•Connect the power cord of the TEC Control Unit.

•Switch the TEC Control Unit on.

The touch-screen display of the TEC Control Unit shows the name (or abbreviation)

of the currently connected device. When multiple devices are installed, you can

switch between the devices by touching the arrow left or arrow right button of the

touch screen.

4.3. Programming the Movement Pattern

In difference to the standard Thermoshake and Teleshake 95 without clamp mechanism

the only movement pattern of the Shaking device in this manual is orbital and

anticlockwise.

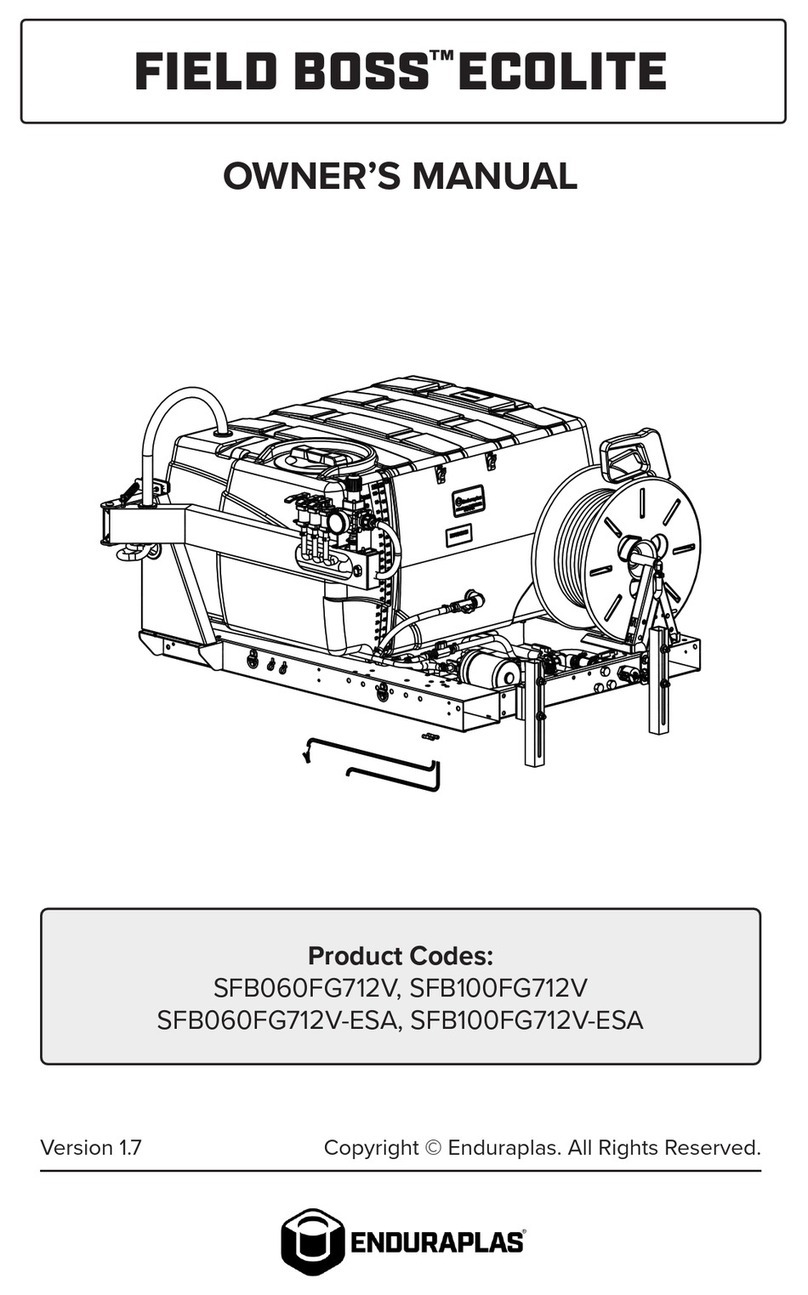

Fig.14: Shaking pattern

4.4. Fixation of Disposables (Tubes, Reservoirs, Plates)

A proper positioning of the disposable is essential to avoid uncontrolled motions of the

plate, and to achieve the desired shaker frequency.

NOTICE

Please test your requested shaking frequency with a disposable first, then with the

disposable filled with water to make sure that the frequency is not set too high for your

set up.

NOTICE

The Labware needs to be SBS size, if labware is too small or too big the clamping

mechanism will not close correctly and might get damaged.

Tubes, reservoirs, and plates without flat bottom require a thermal adapter (insert, nest),

-> Installation of Adapters, page 19. A flat bottom plate can be placed directly onto the

contact surface and is positioned by the holder at two corners of the thermoshake.

A custom-fit thermal adapter plate (insert, nest) for the temperature transfer into the tube

or plate also ensures a proper positioning of the plate. The holder at the four corners can

be taken off in case the standard holder is not suitable for your set up. → chapter 4.5.

Visit www.inheco.com to find the custom-fit adapter for your disposable and contact

NOTICE

Optimized temperature settings require a temperature off-set value adjusted to the

thermal characteristics of the disposable. → Manual MTC/STC for further details.

INHECO 18

Doc ID: 901325-000

December 2021

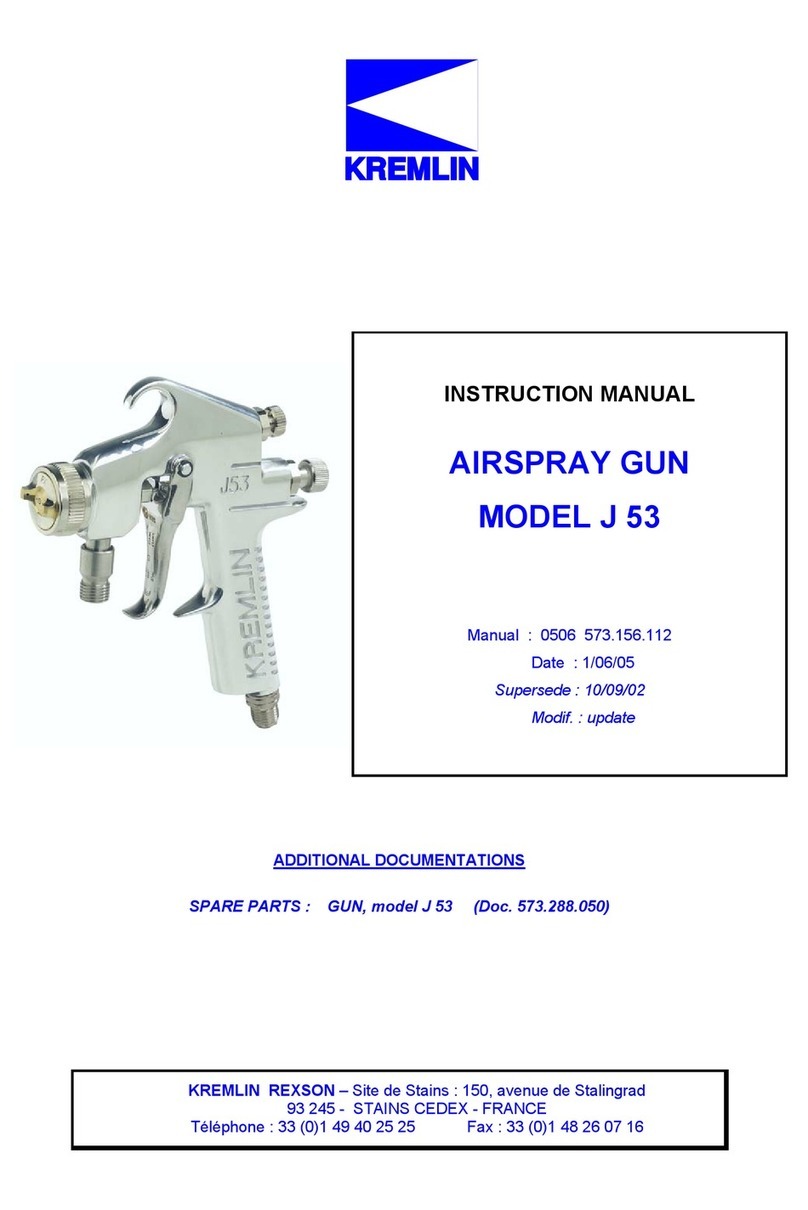

4.5. Removal of Fixation Pins

Use an open-end wrench to unscrew the pins and replace them with the custom-fit pins

provided by INHECO.

Fig.15: Removal of Fixation Pins

•use the open-end wrench to screw the new pins back in position.

NOTICE

In case the standard fixation pins don’t work with your plate please contact INHECO

([email protected]) for customized fixation pins.

INHECO 19

Doc ID: 901325-000

December 2021

4.6. Installation of Adapter Plates (Inserts, Nests)

A thermal adapter is not needed for microplates with flat bottoms. Such plates can be

placed directly onto the temperature contact surface of the Shaking device.

Custom-fit adapters are required for all tubes, reservoirs and plates without flat bottoms,

to ensure temperature transfer into the disposable/assay. The adapter may facilitate

accurate positioning for easy robotic handling plate.

Visit www.inheco.com to find the adapter which fits your tube, reservoir or plate. In case

custom design.

There are two orientations possible for the installation of the adapter plates.

Fig.16: Threaded holes to x or unx the adapter plates

Fig.17: Device with installed PCR adapter plate (3 screw holes used )

INHECO 20

Doc ID: 901325-000

December 2021

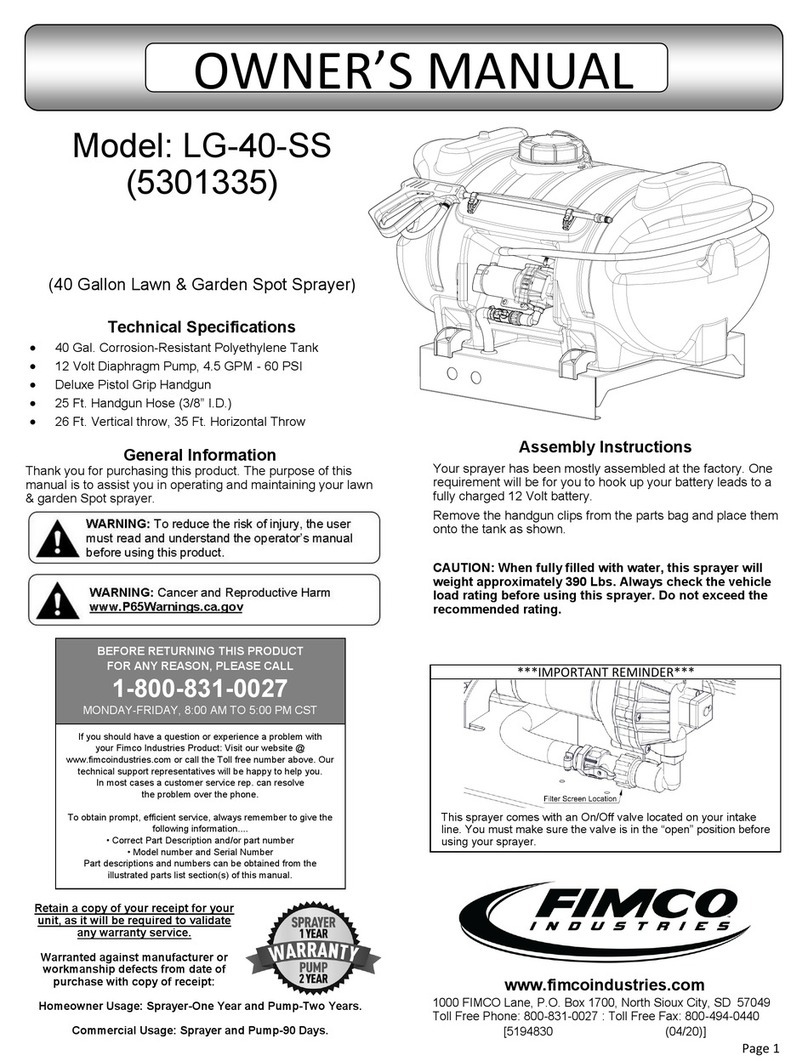

4.7. Mechanical Integration

The Shaking devices are usually integrated into liquid handling workstations. The way of

fixation depends on the hardware provided by the automation platform manufacturer.

When the Thermoshake Shaking devices are placed on a bench top, they must be fixed

to the ground with two M4 screws via the thread holes of the units. The ground must be

firm and even.

Drilling schematic for secure mounting of the Thermoshake AC (180):

Fig.18: Drilling Scheme

NOTE

The Shaker always needs to be xed to the ground for proper shaking performance. But

shaking inuence is less then with the standard Thermoshake.

Drilling schematic for secure mounting of the Teleshake (95) AC unit (It is nearly identical

but the total length of the device is difference).

Fig.19:

88

±0,1

= =

101

= =

144

4,30 (2x)

4h8

straight pin (2x)

131

±0,1

5mm max overhead

Teleshake AC

working table

Drilling Scheme

Information for teaching your robotic system:

After shaking is stopped the clamp mechanism will automatically open and the shaker is

back in Zero-position.

This manual suits for next models

7

Table of contents