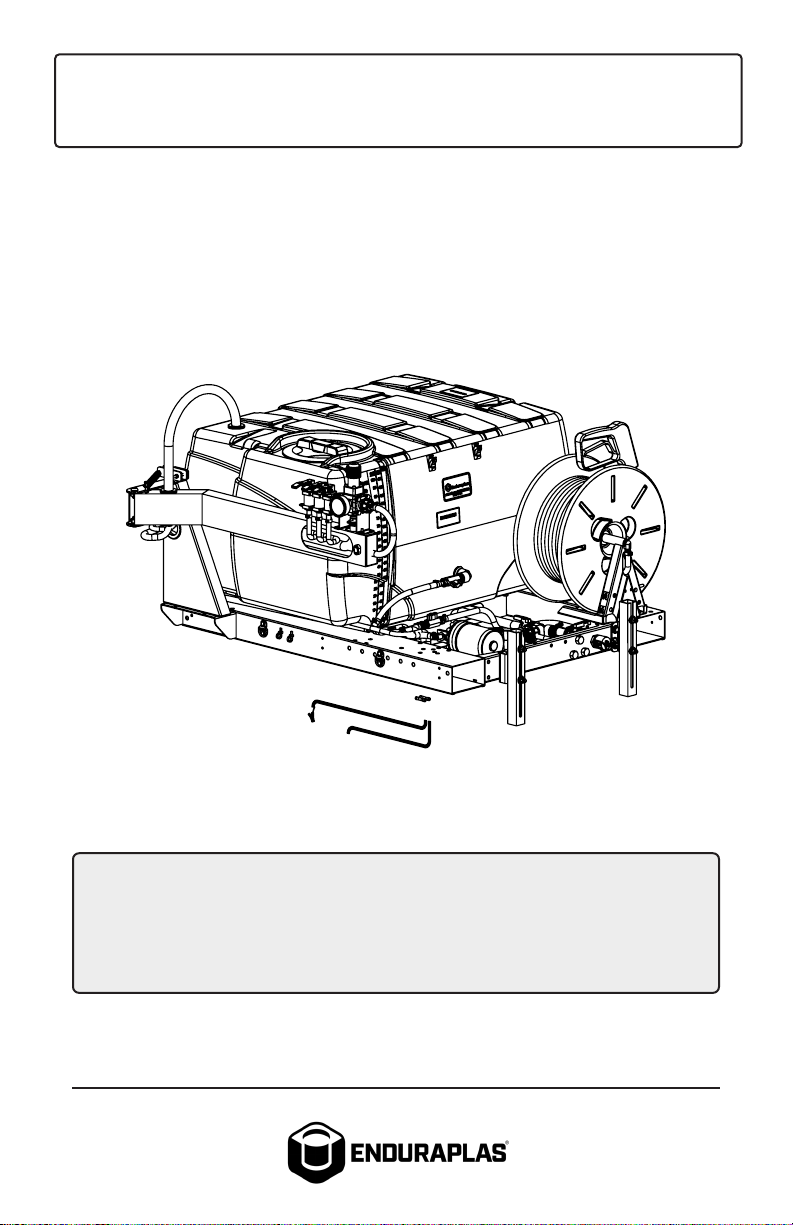

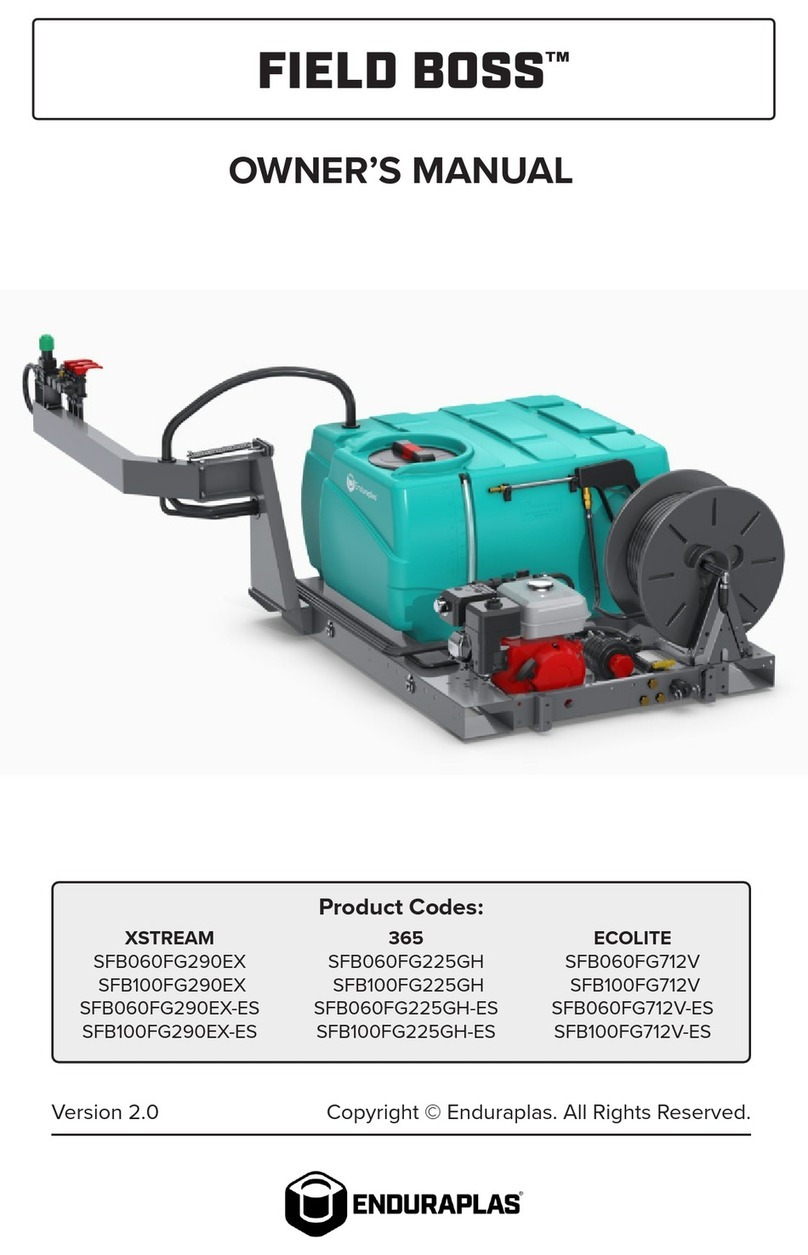

Enduraplas FIELD BOSS ECOLITE SFB060FG712V User manual

This manual suits for next models

3

Table of contents

Other Enduraplas Paint Sprayer manuals

Enduraplas

Enduraplas XSTREAM User manual

Enduraplas

Enduraplas STEEL BOOM User manual

Enduraplas

Enduraplas ICEMASTER LIQUID MASTER T Series User manual

Enduraplas

Enduraplas CLEAN BOSS PRO User manual

Enduraplas

Enduraplas FIELD BOSS 365 SFB060FG225GH User manual

Enduraplas

Enduraplas SPOT CHIEF SSC025212V User manual

Enduraplas

Enduraplas IceMaster Systems Liquid Master W Series User manual

Enduraplas

Enduraplas Gold Series User manual

Popular Paint Sprayer manuals by other brands

WAGNER

WAGNER WallPerfect W665 Translation of the original operating instructions

Mesto

Mesto 3555B Original operating instructions

Smithco

Smithco Spray Star 2000 manual

Tecomec

Tecomec GEOline 8406024 instruction manual

swissmex

swissmex SP Series Operator's manual

MS Schippers

MS Schippers Atomist 1952A owner's manual