INIS InisBofin Operating manual

InisBofin Insert Boiler Multi-fuel Stove

1

InisBofin

Insert boiler

User and Installation

Manual

InisBofin Insert Boiler Multi-fuel Stove

2

Contents

Stove user Manual

Cover page……………………………………………………………………………………………………………………………………1

Contents…………………………………………………………………………………………………………………………………………2

Safety notices…………………………………………………………………………………………………………………………3

Stove Features…………………………………………………………………………………………………………………………4

Paint curing………………………………………………………………………………………………………………………………5

General points…………………………………………………………………………………………………………………………6

Recommended Fuels…………………………………………………………………………………………………………………6

Lighting the stove………………………………………………………………………………………………………………7

Refuelling……………………………………………………………………………………………………………………………………8

Continuous Burning………………………………………………………………………………………………………………8

Ash Clearance……………………………………………………………………………………………………………………………9

Stove cleaning & maintenance……………………………………………………………………………………9

Troubleshooting………………………………………………………………………………………………………………………11

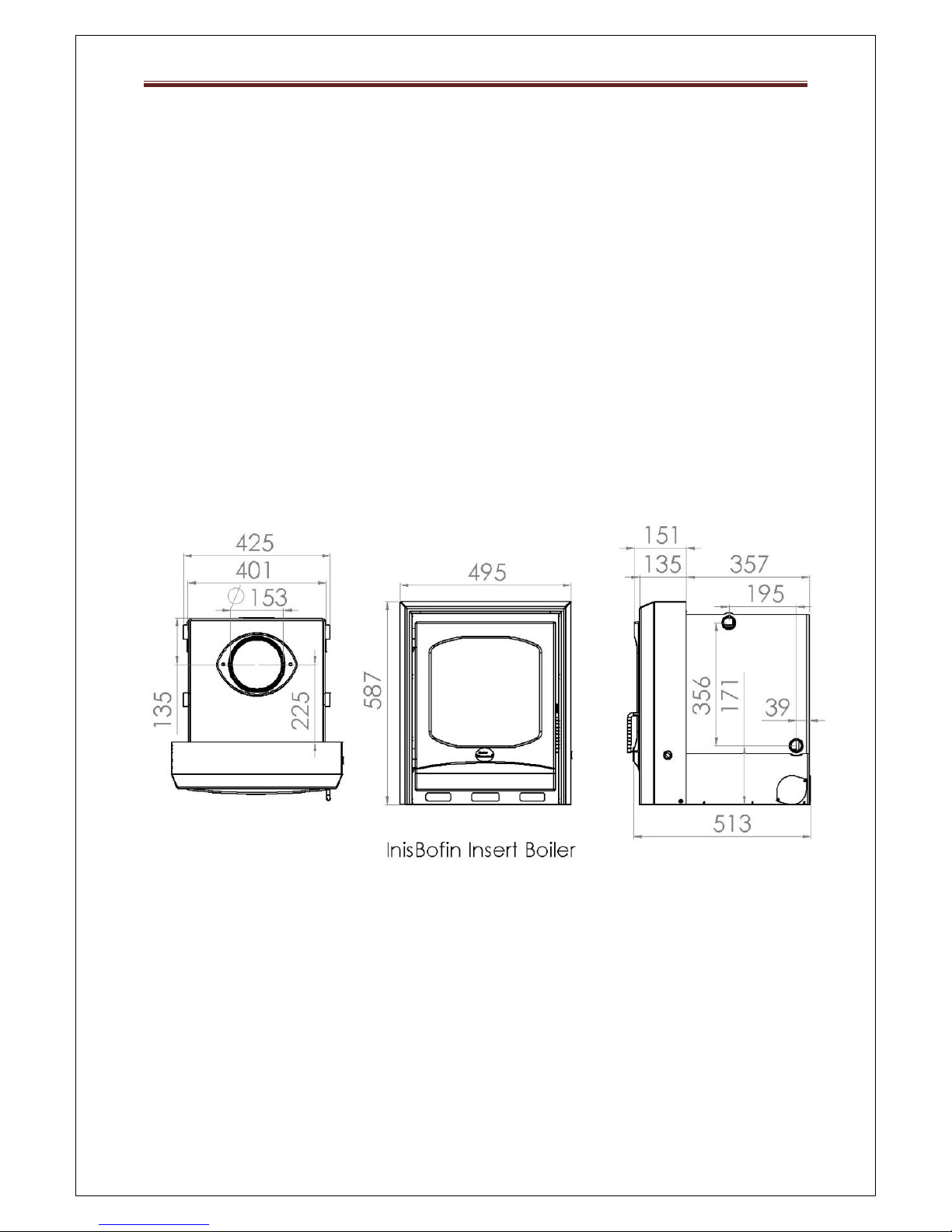

Stove Dimensions……………………………………………………………………………………………………………………13

Stove installation Manual

Health & Safety notices…………………………………………………………………………………………………14

Air requirements……………………………………………………………………………………………………………………15

Stove Preparation…………………………………………………………………………………………………………………16

Chimney……………………………………………………………………………………………………………………………………………16

Hearth & Fire Surrounds…………………………………………………………………………………………………18

Stove Fitting……………………………………………………………………………………………………………………………19

Central Heating System……………………………………………………………………………………………………22

Pre-Firing check……………………………………………………………………………………………………………………27

First Firing and commissioning………………………………………………………………………………27

Exploded view and parts list……………………………………………………………………………………28

InisBofin Insert Boiler Multi-fuel Stove

3

Congratulations on the purchase of

your new InisBofin insert boiler

stove. We here at Inis Stoves

truly love building high quality

stoves for our customers. The

stove we produced for you was not

just an appliance to us; we hope

that you will see it as a focal

point in your home. When fitted

and operated correctly, you should

enjoy many years, trouble free

warmth from your InisBofin insert

boiler stove. Please read the user

manual fully before operating the

stove.

Safety Notice

Fireguard:

Ensure that a certified fireguard

to BS8423:2010 is always used

where the elderly, infirmed or

children have access to the stove

to prevent burning. Proper

supervision of the elderly,

infirmed or children around the

stove is required at all times and

please be aware that the stove

remains hot for many hours after

the fire has gone out.

CO and Fire alarm:

Inis Stoves highly recommend the

fitting of fully certified CO

alarm to BS EN 50292:2002 and

Building Regulations require that

whenever a new or replacement

fixed solid fuel or wood/biomass

appliance is installed in a

dwelling that a carbon monoxide

alarm MUST be fitted in the same

room as the appliance. Inis Stoves

also recommend that a fire alarm

is fitted and that regular checks

to be sure the alarms are

operational for the proper

protection for you, your family

and your home.

PROVISION OF A CARBON MONOXIDE

ALARM MUST NOT BE CONSIDERED A

SUBSTITUTE FOR EITHER INSTALLING

THE APPLIANCE CORRECTLY OR

ENSURING REGULAR SERVICING AND

MAINTENANCE OF THE APPLIANCE AND

CHIMNEY SYSTEM.

Ensure that the installer of this

stove is fully qualified to

complete all relevant work.

The Installation must be completed

in accordance with all National,

European Standards and all local

Codes.

Fume emissions into the room

must not be tolerated:

If this happens close the door of

the stove, open up some windows,

close the damper and let the fire

out. Call a qualified chimney

expert to ascertain the problem

before lighting the stove again.

Chimney fire:

In the event you believe there may

be a chimney fire, close the stove

door, close the damper and allow

the fire to die out. If you still

believe a fire exists, call the

InisBofin Insert Boiler Multi-fuel Stove

4

Fire Brigade immediately. After a

chimney fire, the chimney must be

examined by a chimney expert

before using the stove again.

Stove Features

Figure 1 below shows how to use

the stove door handle. Gently pull

the handle out from the stove and

it swings upward.

Fig.1

As can be seen in Fig 2 below, the

riddling mechanism is located on

the left hand side of the stove

towards the bottom of the facade.

To operate the riddling mechanism,

insert the tool into the

rectangular slot as shown. Then

the hand tool faces downward at 45

degrees the riddling grate is in

the closed position. This position

is used when burning wood.

Fig.2

When the hand tool is raised fully

up at 45 degrees, the grate is in

the open position and this

position must be used when burning

manufactured solid fuels and peat.

To riddle the grate, use the

riddling hand tool and gently

oscillate the riddler back and

forth. Avoid using excessive force

to avoid damaging the riddling

mechanism.

Normally it is advisable to have

the doors closed at all times

except when re-fuelling, de-ashing

and when igniting the stove. If

excess fumes flow into the room

results at any time when the door

is opened, it should be closed

immediately and expert help

sought.

InisBofin Insert Boiler Multi-fuel Stove

5

Figure 3 below shows the stove

damper controls.

Fig.3

The stove has been designed for

ease of use by the operation of

just one air control slider. The

damper slider governs all the air

flows throughout the stove for

optimum efficiency and

performance. This adjustment

slider is found on the right side

of the stove towards the top of

the facade. To operate the damper

slider, use the hand tool to move

the slider downward fully to close

the damper and upward to open the

damper. No adjustment of the

damper assembly is necessary. To

help keep the stove glass clean,

use kindling which lights quickly

and fire the stove at a high rate

for 45-60 minutes after lighting

to fully heat the glass. Operating

the stove for extended periods of

time at low outputs will lead to

blackening of the glass.

Paint Curing

Please adhere to the curing

procedure described below as over-

firing the stove before the paint

has cured will lead to fading of

the paint and this is not covered

by your warranty.

When the stove is used for the

first number of times the process

of curing the paint will occur. To

do this a small fire using only

kindling wood should be started for

approximately 30 minutes, allow the

stove to cool slightly then repeat

the small fire using only kindling

wood for another 20 minutes. The

final action to cure the paint is

to put on a normal sized fire

before the stove has cooled down,

at full output for at least one

hour. The stove paint will emit

fumes which are non-toxic but a

window should be opened to avoid

fumes building up during the curing

process.

Before you operate the stove,

consult with the installer that all

the relevant work has been carried

out correctly and that they have

ignited a small fire in the stove

and it is operating correctly.

Check that all relevant local,

national and European Standards

have been adhered to when

installing the stove.

InisBofin Insert Boiler Multi-fuel Stove

6

General Points

1. Never use liquid fuels in the

stove

2. When in operation, the stove

will be hot and care should

be taken to avoid injury.

3. When using solid fuels like

smokeless coal, the ash pan

should be emptied before it

is filled completely to avoid

damage to the grate.

4. Never attempt to modify the

stove in any way and always

use genuine Inis Stove spare

parts.

5. Never place combustible or

non-combustible materials

near, in or around the stove

that will interfere with the

proper heat convection and

air supply to the stove. The

stove surround should be

fireproof. Never leave the

stove fuels too close to the

stove.

6. For safe and efficient

operation of the stove,

regular cleaning of the

stove and chimney is

essential. Dirty surfaces

within the stove will lead

to poor heat transfer to the

boiler and the room and will

waste your money.

7. Care should always be taken

when emptying the ash pan of

the stove. Hot ashes should

never be put in a plastic

dust bin, bag or container.

Ideally, empty the ash pan

when the ashes are cold.

8. Inis Stoves is dedicated to

the principal of using

renewable fuels in all our

stoves. Using wood as fuel

goes a long way in reducing

your home’s carbon footprint

and also reduces our

dependence on imported

energy. We recommend using

nationally sourced wood fuel

with a maximum moisture

content of 20% in our stoves.

9. To refuel the fire, open the

door and place the fuel in

the firebox. Fill the

firebox without fuel

overflowing the front

firebar.

10. Never burn household

waste in the stove.

Fuels

Inis Stoves recommend that wood

fuel be used to fuel the stove for

three good reasons,

A. It is considered a low carbon

fuel which is a big environmental

benefit,

B. High quality low moisture wood

fuel can now be nationally and

locally sourced which lowers

foreign fuel imports and helps the

economy by keeping your money in

the local area.

C. Wood fuels are easy to handle,

generally clean, easy to light,

InisBofin Insert Boiler Multi-fuel Stove

7

burn brightly and have a very low

ash content usually less than 1%.

If possible, always use light dry

kindling when lighting the stove.

Wood with a maximum moisture

content of 20% should be used. If

the moisture content is any

higher, the fire will produce much

less heat than is possible and the

stove glass, stove and chimney

flue will build-up tar deposits.

Hard woods like beech ash and oak

are excellent long burning wood

fuels and tend to be better than

soft woods like pine etc. The

smaller the thickness of the wood

the faster the fuel will burn. For

long burn time at night time etc.

use larger size pieces of wood.

The wood should have a maximum

diameter of approximately 3-4

inches and approximate length of

8”-12”.

Manufactured wood fuels that

contain no additives are also an

excellent fuel and burn very hot

and clean with little ash.

SOLID FUELS:

There are numerous fuels on the

market that contain partial or

full percentages of Petroleum

coke. These fuels are high in

sulphur with leads to acid attack

of the stove, flues and chimney.

Petroleum also has low ash content

which will damage the stove grate

and other parts of the stove in a

very short period of time.

Examples of these fuels are

“Calco”and “Superblend”.

Using any fuel containing

Petroleum coke will invalidate

your warranty. To find a complete

list of approved solid fuels for

use in closed appliances, please

consult the Hetas website at

www.hetas.co.uk/wp-

content/mediauploads/HETAS_Guide_F

uels.pdf

Don’t burn coal pellets, singles

or coal dust. Burning slack is not

recommended.

Try and ensure the solid fuel is

not wet when fuelling the stove.

Peat and briquettes can be used

provided they are dry.

Lighting the fire

The key to quick and easy lighting

of the stove is the ample use of

kindling wood. If too little

kindling is used, the fire will be

slow to start and will produce

excessive smoke and deposits on

the glass.

The grate should be put in the

open position (handle up) and the

damper fully opened. Firelighters

or well crumpled paper should be

surrounded with small pieces of

kindling toward the FRONT of the

grate. As the stove is quite deep,

it is advisable to light the fire

towards the front of the stove to

InisBofin Insert Boiler Multi-fuel Stove

8

get heat to the room as early as

possible.

Light the fire and with the door

lock engaged but the door slightly

ajar let the fire light up. After

the kindling is well alight add

larger pieces of fuel to the fire

and after a few more minutes this

fuel should be well alight. The

stove can be fully loaded now and

a bright high temperature fire

should result. Once the fire is

well alight the door can be fully

closed. When using wood fuel, at

this point the grate can be

closed. The stove damper will

normally not require adjustment

down until after at least forty

five minutes, as the stove will

take this time to fully heat up.

Under normal conditions the damper

will be moved between fully opened

and half way closed.

Refuelling

Do not let the fire burn down too

low before refuelling as the new

fuel will smoke excessively and

will require a long time to become

fully alight. Open the damper

fully every time you refuel the

stove for at least five to ten

minutes to aid rapid lighting of

the new fuel (not necessary when

using dry wood fuel). This will

help prevent excessive smoking and

will help to keep the stove and

the glass clean. Once the new fuel

is well alight, the damper can be

adjusted down to an appropriate

setting.

Continuous burning

The InisBofin insert boiler stove

is capable of continuous burning

making overnight burning possible

at a reduced output. To achieve

overnight burning, open the damper

fully and fill the firebox) with a

full charge of fuel and let it

ignite fully (Empty the ash pan if

using solid fuel). When the fire is

burning brightly, the stove damper

can then be closed down. With the

damper mostly closed and the

correct draft in the chimney, an 8-

12 hour burn time is possible. For

more heat output over a shorter

time span the damper can be opened

up as necessary. To avoid excessive

blackening of the glass the damper

should be left slightly open.

To revive the fire after overnight

burning, riddle the grate, refuel

the firebox with a small amount of

light kindling fuel and open the

damper fully. A strong fire for at

least twenty minutes is required

to burn off excess build-up of

soot deposits after a prolonged

period at low output.

Please bear in mind that operating

the stove at very low outputs is

not the most efficient way to burn

the fuel and the stove and chimney

will require more cleaning with

the possibility of creosote build-

InisBofin Insert Boiler Multi-fuel Stove

9

up in the chimney when the stove

is operated this way.

Ash clearance

The stove has one ash pan designed

for ease of handling. The ash pan

should be emptied before it gets

overfilled to protect the grate

from over-heating especially when

burning solid fuels as the ash is

an excellent insulator and excess

build-up of ash will cause grate

damage.

Great care should be observed when

emptying the ashes as it can be

very hot and it could start a fire

if it comes into contact with

combustible material like plastic

bins etc.

Stove and chimney

cleaning and

maintenance

Stove cleaning:

Regular cleaning is essential for

safe and efficient operation of the

stove.

During the heating season it is

recommended to clean the stove

weekly or fortnightly. Inspect on a

regular basis the condition of the

door seal and if found to be worn

replace it immediately.

Only clean the stove when it is

fully cold. A Pair of gloves should

be used when cleaning the stove and

care should be taken to avoid

injury as a number of the stove

components are quite heavy.

As per figure 5 below, to remove

the baffle assembly for cleaning,

pull the top casting up slightly

and forward to release the front

mounting clip and then lower the

plate and remove from the stove.

Above the cast iron baffle will be

a vermiculite insulation plate.

This can be lowered away if it

doesn’t come down with the cast

iron baffle. Access to the flue

outlet is now possible for cleaning

and the chimney can be cleaned up

through the stove at this point.

Fig 5

To clean the bottom part of the

stove the rear airway must be

cleared out, see Fig.6 below

1. Remove the firebox cast iron

side plates.

InisBofin Insert Boiler Multi-fuel Stove

10

2. Remove 3-4 riddler bars

starting at the second from

the back and working forward.

To remove the riddler bars

for airway cleaning first

lift the front of each

firebox side plate and swing

toward the stove centre. They

can them be lifted out of the

stove. A knife or screwdriver

can be used to lever forward

the rear cast plate at the

top of the casting and then

it can be lifted out of the

stove to expose the rear

airway channel for vacuuming

out. To remove a riddler bar

first put the bars in the

half way opened position

(Hand tool in horizontal

position), then remove the

ash pan. Use a knife or

screwdriver to lift the left

side of the riddler bar

slightly forward as you lift

it and then the bar can be

lifted away.

3. (Fig.6) Vacuum out all visible

ash thoroughly. Re-assembly is the

reverse of dis-assembly.

Fig 6

4. Check that the riddler mechanism

operates free and clear.

Inis Stoves highly recommends

annual servicing of the stove as

the service engineer will ensure

correct and thorough cleaning of

the entire stove.

Inspect all internal parts of the

stove and replace if needed.

Only Inis Stoves or an approved

Engineer on our behalf should

modify the stove in any way.

Paint work:

To clean the paint of the stove we

recommend the use of a dry cloth

containing a small amount of light

oil, for example “WD40”. Avoid

using abrasive material on the

paint of the stove.

Door seals:

The door seals should be inspected

regularly to check for damage and

InisBofin Insert Boiler Multi-fuel Stove

11

changed if needed. Also check the

seal on the door glass for

tightness and seal integrity.

Shutdown:

If the stove is to be unused for a

prolonged period of time, for

instance over the summer months,

the stove and chimney should be

fully cleaned and a light oil like

“WD40”applied to all moving parts

and all surfaces within the stove

to displace moisture. The damper

may be left slightly open to

facilitate a little air movement

through the stove and avoid

moisture build up. Avoid excess

opening of the damper as this will

result in excess heat loss through

the stove up the chimney. After a

prolonged period being unused,

inspect the chimney before use to

ensure no blockage has occurred.

Also ensure that the air vent to

the room of the stove is clear.

Trouble shooting

NOTE: Excessive fume

emission to the room must

not be tolerated.

Fire burns very rapidly and

refuelling periods are not being met:

1 Chimney draught is very high,

chimney damper may be required.

2 Fuel load too small for damper

setting.

3 Door seals are worn.

4 Adjust the damper to a lower

setting for proper fire control.

Fire will not burn properly:

1 Chimney draught is too low

2 Damper is closed

3 Chimney height too low,

flue/chimney seals leaking

4 Chimney blocked, damaged

5 Ash covering all air ways into

firebox

6 Fuel is wet

7 No permanent air vent present in

room.

Stove emits fumes:

1 Chimney blocked

2 Door seals require replacing

3 Excess down drafts in chimney

4 Chimney draughts below 25Pa when

warm.

5 Extractor fan affecting stove.

Some/all radiators not heating:

1 Check that the fire is burning at

full output

2 Check that the pipe stat for the

heating is not set too high or too

low. (Typical range of

temperatures 55*C-60*C)

3 Check if the system needs

balancing and that the radiators

are turned on. Check that a system

link isn’t preventing flow to the

InisBofin Insert Boiler Multi-fuel Stove

12

required radiators and that the

radiators don’t require bleeding.

4 Ask the installer to check that

the stove is sitting level and

that air is not built up in the

boiler.

5 Check that the pump is working.

6 Check that the flow rate of the

pump is not set too high or very

low due to blockage etc.

Riddler grate locks up when

burning solid fuels:

When burning solid fuels like

smokeless coal, the grate must

always be kept in the open

position. The grate can be riddled

by oscillating the grate back and

forth without excessive force

being used. The grate is not

designed to fully close when

burning solid fuels. If the grate

jams it may be due to a foreign

particle like a stone or nail

jamming the riddler action. To

clear a jam, let the stove

completely cool down, remove the

cast iron firebox side plates and

remove the riddler bars starting

at the front. Clear any ash and

particles and reassemble the

riddler assembly. The problem will

usually be solved by this process.

Glass blackens excessively:

If the stove is fitted correctly

and the correct lighting and

operation of the stove is adhered

to, blackening of the glass should

always burn off after a period of

full output. A poor draught and or

the use of wet or improper fuel

will often lead to excessive glass

blackening. Often clean glass

operation will be attained with a

little experience of operation.

Using a ceramic cooker cleaner for

instance “Mr Muscle oven cleaner”

is excellent at cleaning the glass.

Please refer to manufacturer’s

instructions on these products for

proper and safe use.

Chimney fire:

If the stove and chimney are kept

clean, no fire should occur. If

however it does happen, close the

stove damper fully, close the stove

door tightly. Only once the fire in

the stove and chimney has gone out

should the stove be opened and the

stove and chimney cleaned

thoroughly. If the fire is

substantial and doesn’t extinguish,

the fire brigade should be called.

After a bad chimney fire, expert

help should be sought to have the

chimney examined for any damage

before the stove is used again.

Freezing:

If there is any reason whatsoever

as to believe that any part of the

piping system may be frozen, do not

use the stove.

CO Alarm Sounds:

InisBofin Insert Boiler Multi-fuel Stove

13

If at any time the Co (Carbon

monoxide) alarm sounds, open all

windows and doors, close down the

stoves and leave the room. After it

has been deemed safe to re-enter

the room only after the fire has

gone out, it MUST be established as

to the reason why the alarm sounded

before any attempt is made to re-

light the stove.

InisBofin Insert Boiler Multi-fuel Stove

14

Stove installation Manual

Specification

Output Kw

Water Kw

Room Kw

13.5-16.9

12.0-14.0

1.5-5.0

Flue Diameter

153mm 6”

Flue Gas Temperature

ºC

282-395

Fuels

Wood, eco fuels,

peat dried,

smokeless coal

Min distance to

combustibles

Above mm

Front mm

Floor mm

Sides mm

525

550

350

350

CO% @ 13%O2

0.29

Stove Mass Kg.

141

Minimum Flue Draft

25 Pa, 0.25mbar

Maximum boiler

pressure

2 Bar

Boiler fittings

1” BSP

Refuelling interval

1Hr wood,

2Hr M.S.F

The heat outputs as shown were

obtained using well-seasoned

hardwood using a refuelling time

of 1 hours. Similar results are

achieved using Smokeless coal

(MSF) over a 2 hour refuelling

period.

Health and Safety

precautions

Please ensure that the

installation of the stove complies

with all the requirements of the

relevant Health and safety at work

acts applicable.

Some materials used in fire cement

are caustic and contact with the

skin should be avoided. In case of

contact with the skin wash with

plenty of cold water.

If any structural work is required

for installation please take note

of the possible presence of

asbestos. If the presence of

asbestos is found to be the case

please contact a registered

asbestos removal firm.

In addition to installation

instructions supplied, the

requirements of BS.8303 and

BS.6461 Parts 1&2; 1984 must be

fulfilled. Also all local

authority bylaws and domestic

building regulations including

those referring to national and

European Standards regarding the

installation of solid fuelled

burning appliances, flues and

chimneys must be followed.

InisBofin Insert Boiler Multi-fuel Stove

15

Air requirements

Proper air supply must be insured

to the room into which the stove

is to be installed. A permanent

vent opening with a minimum free

area of 55 cm²must be present and

care should be taken to ensure

that this vent cannot be blocked.

Under no circumstances should

there be an extracting fan in the

same room as the stove, to avoid

the possibility of combustion

gases being drawn into the room.

If a chimney draft stabilizer is

fitted to the chimney, a larger

vent is required of at least 8.5

cm²per Kw of output over 5kw.

The vent must be of a permanently

opened design. The vent must be

dimensionally stable and must not

be prone to collapse. There must

not be a facility to close the

vent. If the vent crosses into a

cavity to the outside on an

external wall it must span the

full span across the cavity and

must be weather resistant to

prevent the ingress of moisture.

The vent must not be located at a

position in the room that will

result in an air current

traversing through normally

occupied areas of the room.

Care must also be taken to ensure

that the vent cannot be blocked by

object left against the wall

outside or debris like leaf litter

etc.

A larger vent is required if there

is an appliance like an extractor

fan or tumble drier in an

adjoining room. To ascertain if

more venting is required, these

appliances should be operated

together and all external windows

and doors closed to detect

spillage into the room from the

stove.

If the vent crosses into another

internal room, that room should

not be a bedroom, bathroom or room

with a shower and it must not

cross into another internal

separate building for example a

bedsit.

Especially air tight buildings:

If the stove is to be installed

into an especially air tight house

at least 5.5 cm² per Kw of stove

output must be installed to ensure

proper operation of the stove.

External Air provision:

This stove has the provisions made

for connection to an external air

system for buildings where

mechanical heat ventilation is

installed. There are 3 positions

for connection to an external air

pipe, at the centre rear facing

backward and each side of the

stove at the rear facing away from

the stove.

InisBofin Insert Boiler Multi-fuel Stove

16

It MUST be checked if using the

external air provision that the

base plate if fitted so that the

front air grill on the front

bottom face of the stove are

covered by the base plate. If

these grills are open then the

base unit must be turned around

for external air mode. If

questions still remain please

contact Inis Stoves for further

details. The required blanking

plate can then be removed and the

coupling bolted on instead.

Stove preparation

The crate should be carefully

unscrewed to avoid possible damage

to the stove. Remove the plastic

packaging. Use a screw driver to

remove the screw holding the stove

in place. The wooden crating the

stove was shipped in can be cut up

for fuel in the stove. Take great

care to avoid damaging the facade

of the stove when removing the

stove from its shipping crate and

moving it into position.

To help with fitting of the

stove, the stove door and facade

and baffle assembly should be

removed. The door is removed by

opening the door and lifting up

approx. 20mm until the hinges are

clear and lift away. Take great

care not to drop the door as it is

quite heavy and the door glass can

easily be broken.

Façade removal:

The facade is removed (See Fig 8)

by unscrewing of the two screws on

both sides of the façade at floor

level, gently but firmly lift the

facade approx. 5mm by holding

towards the left and right sides

of the façade along the top to

avoid deforming the facade in the

middle. When the façade has been

lifted up, gently swing forward

from the top and dis-engage the

mounting tangs and lift away. Be

aware of the damper slider on the

left hand side and the riddling

mechanism on the right hand side

when pulling the façade out.

Remove the baffle assembly as

shown in the user manual and

remove the firebar and ash pan.

With the baffle assembly removed

the flue collar can be removed

prior to fitting of the stove.

Chimney

This stove is not suitable for a

shared flue arrangement. This

stove is only suitable for

installation into a fireplace with

an existing chimney. Chimneys must

satisfy standard EN 15287:2007. A

draught test should always be

performed prior to the fitting of

the stove to ensure that a proper

draft in the chimney is present

(Min 25Pa constant when warm.). A

chimney height of at least 4m from

the top of the stove and

InisBofin Insert Boiler Multi-fuel Stove

17

must be at least 150mm diameter or

150mmx150mm square. The chimney

must be in good condition, be

cleaned and free from cracks and

blockages. The chimney must not

have too great a cross sectional

area (200mm diameter maximum) and

if it has, it is recommended to

line the chimney with a suitable

liner for solid fuels to BS EN

15287-1:2007 with suitable

refractory infill around the

liner. Please refer to EN13384-1

for calculations on the particular

chimney for suitability.

The outlet of the chimney should

be above the roof of the dwelling

in accordance with the provisions

of The Building Regulations Part

J.

All chimneys and flues used must

be sealed for the best possible

performance. The draught in the

chimney must be at least 25 Pa

when warm and must not suffer from

down draughts and if there is an

excessive draught in the chimney a

draught stabiliser should be

fitted. If any doubt exists please

contact a chimney expert. If it is

an existing chimney that has been

is use with an open fire, the

chimney must be thoroughly cleaned

and inspected. Two to three weeks

after the stove has been in use,

have the chimney cleaned again as

soot previously secure may come

loose as the flue gas from the

stove is quite different than that

from an open fire.

Particular care must be taken if

the dwelling has an old chimney as

these most often have a very large

cross section. The use of a

register plate may be needed along

with any other required remedial

InisBofin Insert Boiler Multi-fuel Stove

18

work on the chimney structure

before the liner and infill are

used. Any flue sections used in

the installation must not have 90º

bends with 45º bends maximum.

Hearth and Fire Surround

If the installer has any doubts as

to the positioning of the stove

and necessary fire proofing,

expert advice should be sought

before any work begins. The stove

must be placed onto a fire proof

hearth of at least 12mm in depth

that is flat and level. The stove

positioning and hearth size are

governed by building regulations

for class 1 appliances. As can be

seen below in Fig 9 the minimum

sizes of the opening are shown

with minimum hearth thickness. The

hearth must extend at least 300mm

in front of the stove and 150mm to

the sides.

Fig 10 shows the minimum distances

to combustibles.

Fig 9

InisBofin Insert Boiler Multi-fuel Stove

19

Fig 10

The minimum depth of the recess

for the stove from the front face

should be 390mm. In most cases

this will require that the removal

of the fireback and the removal of

loose material. The distance from

the face of the fireplace to the

centre of the flue should be

checked to verify it is between

230mm and 330mm. Please ensure

that the stove in the recess sits

flat with the hearth.

Stove Fitting

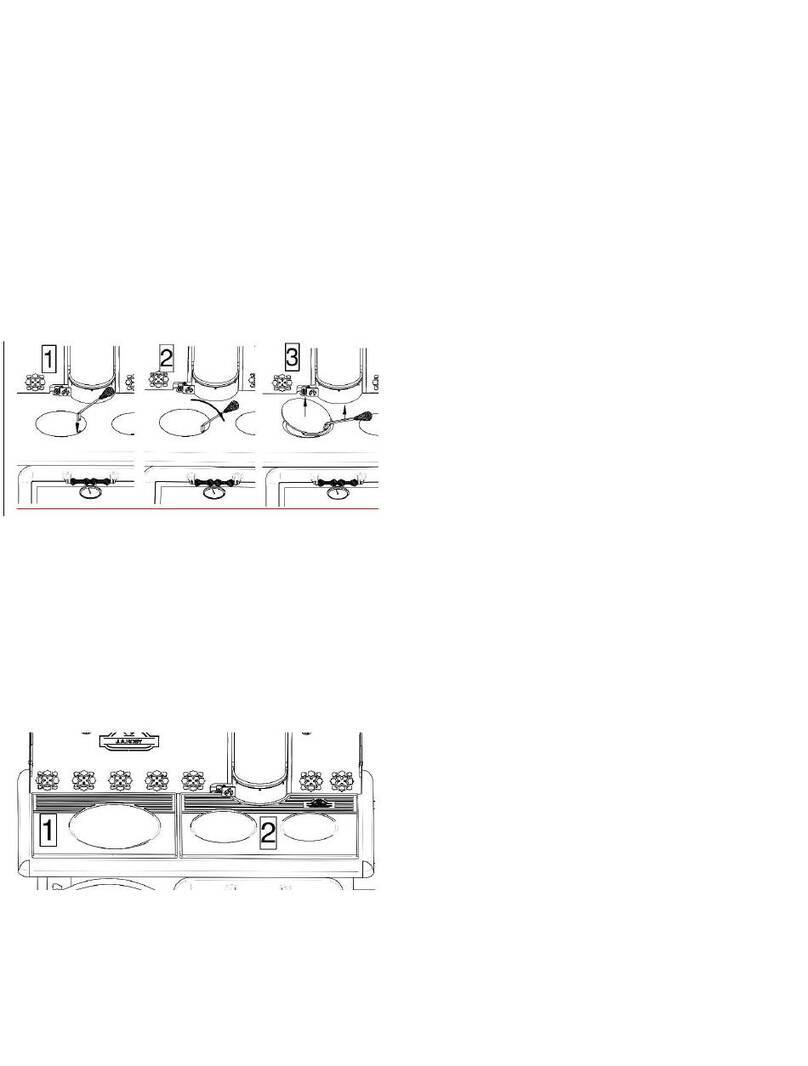

There are two main methods of

connecting the stove to the

chimney. Method 1 is to use a

closure pipe adaptor section and

an extension piece. Method 2 is to

line the chimney with a suitable

6” liner for solid fuel and

connecting to the stove with a

solid section connector.

Method 1.

The fire surround will usually

need to be removed to fit the

stove and facilitate plumbing of

the stove. To aid rapid heating of

the water it may be beneficial to

place some fibre glass around the

boiler of the stove when

installing the stove. The closure

pipe adaptor section of flue

should have an offset built in to

allow for the difference in depth

from the front face of the

fireplace to the flue outlet on

the stove. Once the closure pipe

adaptor has been put in the

InisBofin Insert Boiler Multi-fuel Stove

20

correct position, fire cement

should be used to make a tapered

seal between the clay liner and

the adaptor to ensure any

condensate or rain will flow into

the flue and not down around the

stove body. The extension piece of

flue is now pushed fully up onto

the closure adaptor to allow for

the stove to be positioned into

the proper position. Please note

that the extension pipe must fit

OVER the bottom end of the closure

adaptor pipe. The stove facade

should be offered up to the stove

at this point to ensure proper

depth placement of the stove. Now

pull the extension pipe down

through the stove and using some

fire cement fit the flue collar to

the end of the extension pipe and

when fully sealed, push the flue

collar up into position and bolt

into place.

Check that the joints are all

fully sealed with fire cement and

haven’t being damaged during

fitting. The stove can now be

plumbed as per the section below

on central heating system.

Finally fit the facade onto the

stove ensuring that the damper

mechanism is free and clear in

operation. Once the liner is fully

fitted to the stove, vermiculite

infill can be used to fill in

around the liner down to the

stove. All pipe work should be

fully lagged to prevent excessive

heat loss from the system

.

Method 2

The fire surround will usually

need to be removed to fit the

stove and facilitate plumbing of

the stove. To aid rapid heating of

the water it may be beneficial to

place some fibre glass around the

boiler of the stove when

installing the stove. The stove is

placed in position and the facade

is placed on the stove to check

that the depth of the stove into

the recess is right. A straight

section of solid fuel flue pipe

approx. 6”-8” long with a flexible

liner adaptor on the top of it

should be mounted to the bottom of

the flexible liner and fully

tighten the holding screws on the

adaptor. Push the flexible liner

and straight pipe section down the

chimney and pull down onto the

flue collar. The flexible liner

MUST fit into the adaptor on the

straight flue piece not over it.

Using some fire cement mount the

flue collar onto the bottom of the

straight pipe section and bolt the

flue collar into place with the

two bolts provided. Check that the

joints are all fully sealed with

fire cement and haven’t been

damaged during fitting in place.

Finish the installation of the

Table of contents

Other INIS Stove manuals

Popular Stove manuals by other brands

UNGARO

UNGARO BiFuel en ELS34 user manual

Quadra-Fire

Quadra-Fire EXPLR-III-PBK installation manual

Coleman

Coleman FYRESTORM 9770 Instructions for use

Buderus

Buderus Logastyle Convexus Important notes on installation/assembly

Coleman

Coleman 2000000117 Instructions for use

Relags

Relags Origin Outdoors SCOPE manual

CASTLE

CASTLE Serenity 41278 Operator's manual

Woodstock Soapstone

Woodstock Soapstone Keystone owner's manual

Woolly Mammoth

Woolly Mammoth WM 5 user manual

Morso

Morso 3600 Series Installation and operating instructions

Quadra-Fire

Quadra-Fire GRAND BAY 40 GB40FS Installation, operation, venting and maintenance instructions

THERMOROSSI

THERMOROSSI BOSKY 25 Installation, user & service manual