Ink Bird ITC-310T-B User manual

Programmable Outlet Thermostat

Copyright

Copyright©

2016 Inkbird Tech. Co., Ltd. All rights reserved. No part of this document may be reproduced

without prior written permission.

Disclaimer

Inkbird has made every effort to ensure that the information contained in this document is

complete; however, the contents of this document are subject to revision

Inkbird to ensure you have the latest v

Programmable Outlet Thermostat

ITC-310T-B

User Manual

Version 1.0

Inkbird Tech. Co., Ltd.

2016 Inkbird Tech. Co., Ltd. All rights reserved. No part of this document may be reproduced

Inkbird has made every effort to ensure that the information contained in this document is

complete; however, the contents of this document are subject to revision

without notice.

Inkbird to ensure you have the latest v

ersion of this document.

Programmable Outlet Thermostat

2016 Inkbird Tech. Co., Ltd. All rights reserved. No part of this document may be reproduced

Inkbird has made every effort to ensure that the information contained in this document is

accurate and

without notice.

Please contact

Inkbird Tech. Co., Ltd. www.ink

1. Safety Precautions

................................

2. Overview

................................

Main Features

................................

3. Specification

................................

4. Keys Instruction

................................

5. Key Operation Instruction

5.1 ................................

................................

5.2 How to Set Parameters

5.3 Setup Flow Chart

................................

6. Menu Instruction

................................

6.1 Temperature Control Setting

6.1.1 When setting temperature in Centigrade.

6.1.2 W

hen setting temperature in Fahrenheit.

6.1.3 When TR=1 or TR=2.

6.1.4 When setting STA=12, menu codes as below chart.

6.2.1

Temperature setting Range (TS, HD, CD)

6.2.2 Alarm High/Low Limit Setting (AH, AL)

6.2.3 Compressor Delay (PT)

6.2.4 Tempe

rature Calibration (CA)

6.2.5 Display in Fahrenheit or Centigrade unit (CF)

6.2.6 Timer-

Temperature Set Values

6.2.7 Cycle and Auto Mode (MD, AT)

7. Error Description

................................

Sensor fault alarm

................................

8. Technical Assistance and Warranty

8.1 Technical Assistance

................................

8.2 Warranty

................................

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

2

Contents

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

5. Key Operation Instruction

................................................................

......................

................................

................................

................................

................................................................

................................

................................

................................

................................

................................

................................

................................

6.1 Temperature Control Setting

................................................................

...............................

6.1.1 When setting temperature in Centigrade.

................................

................................

hen setting temperature in Fahrenheit.

................................

................................

6.1.3 When TR=1 or TR=2.

................................................................

.............................

6.1.4 When setting STA=12, menu codes as below chart.................................

Temperature setting Range (TS, HD, CD)

................................

................................

6.2.2 Alarm High/Low Limit Setting (AH, AL)

................................

................................

6.2.3 Compressor Delay (PT)

................................................................

...........................

rature Calibration (CA)

................................

................................

6.2.5 Display in Fahrenheit or Centigrade unit (CF)

................................

............................

Temperature Set Values

................................

................................

6.2.7 Cycle and Auto Mode (MD, AT)

................................

................................

................................

................................

................................

................................

................................

................................

8. Technical Assistance and Warranty

................................

................................

................................

................................

................................

................................

................................................................

.........................

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

................................

3

................................

............. 4

................................

......................... 4

................................

........ 5

................................

... 6

......................

7

................................

......... 7

................................

....... 7

................................

............... 8

................................

.. 9

...............................

9

................................

.... 9

................................

.. 10

.............................

10

................................

................... 11

................................

. 13

................................

..... 16

...........................

16

................................

.................. 17

............................

17

................................

................ 17

................................

................ 18

................................

18

................................

................. 18

................................

....... 19

................................

........ 19

.........................

19

Inkbird Tech. Co., Ltd. www.ink

1.

Safety Precautions

Ensure the product using

Do not touch the terminals at least while power is being supplied. Doing so may

occasionally result in injury due to electric shock.

Do not allow pieces of metal, wire clippings, or fine metallic shaving or filings from

installati

on to enter the product. Doing so may occasionally result in electric shock,

fire, or malfunction.

Do not use the product where subject to flammable or explosive gas. Otherwise,

injury from explosion may occasionally occur.

Never disassemble, modify or rep

Electric Shock, fire, or malfunction may occasionally occur.

If the output relays are used over their life expectancy, contact fusing or burning may

occasionally occur. Always consider the application con

relays within their rated load and electrical life expectancy.

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

3

Safety Precautions

Ensure the product using

within the specification.

Do not touch the terminals at least while power is being supplied. Doing so may

occasionally result in injury due to electric shock.

Do not allow pieces of metal, wire clippings, or fine metallic shaving or filings from

on to enter the product. Doing so may occasionally result in electric shock,

Do not use the product where subject to flammable or explosive gas. Otherwise,

injury from explosion may occasionally occur.

Never disassemble, modify or repair the product or touch any of the internal parts.

Electric Shock, fire, or malfunction may occasionally occur.

If the output relays are used over their life expectancy, contact fusing or burning may

occasionally occur. Always consider the application conditions and use the output

relays within their rated load and electrical life expectancy.

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

Do not touch the terminals at least while power is being supplied. Doing so may

Do not allow pieces of metal, wire clippings, or fine metallic shaving or filings from

on to enter the product. Doing so may occasionally result in electric shock,

Do not use the product where subject to flammable or explosive gas. Otherwise,

air the product or touch any of the internal parts.

If the output relays are used over their life expectancy, contact fusing or burning may

ditions and use the output

Inkbird Tech. Co., Ltd. www.ink

2. Overview

ITC-310T-B is a dual-relay

outlet thermostat

be set to automatically

contr

This ITC-310T-B can be

mainly used to control temperature during fermentation process of

beer and wine brewing, also widely used in home brewing, aquarium, pet breeding,

hatching, barbecue, boiler tem

pump constant temperature cycle, strain culture fermentation, seed sprouting, electric

heating, electric oven, over

-

system of all kinds of el

ectrical equipment, etc.

This plug-n-play

product with dual relay,

equipment easily to realize ideal temperature control. It’s equipped with dual LED display,

and offers display options of Centigrade and Fah

temperature control. With large output power 1,200W (110V) /2,200W (220V), it’s suitable

for most applications.

ITC-310T-B

is designed with compressor delay protection for refrigeration, high and low

temperature alarm, an

d sensor fault alarm, which makes the temperature controller more

safe and reliable. Functions such as temperature calibration, separately set differential for

refrigeration and heating, enable more accurate temperature control.

Main Features

Programmabl

e, 12 temperatures in 12 periods of time;

Constantly control 12 stages of temperatures by setting it once;

Wide timer setting range: 1~999(min/hr), 1~90(days);

Can be set single or cycle control mode;

Plug and play design, easy to use;

Dual relays, heating

and cooling outputs;

F / C temperature display;

Easy to set, PV and SV dual display screen;;

User calibration;

Delay protection for refrigeration control;

Can be set high and low temperature alarms;

Alarm when over-

temperature and sensor error.

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

4

outlet thermostat

with programmable

timer function

contr

ol 12 periods timer stages

with different temperature

mainly used to control temperature during fermentation process of

beer and wine brewing, also widely used in home brewing, aquarium, pet breeding,

hatching, barbecue, boiler temperature control, geothermal temperature control, heating

pump constant temperature cycle, strain culture fermentation, seed sprouting, electric

-temperature protection and automatic temperature control

ectrical equipment, etc.

product with dual relay,

can be connected

with refrigeration and heating

equipment easily to realize ideal temperature control. It’s equipped with dual LED display,

and offers display options of Centigrade and Fahrenheit, enabling more humanized

temperature control. With large output power 1,200W (110V) /2,200W (220V), it’s suitable

is designed with compressor delay protection for refrigeration, high and low

d sensor fault alarm, which makes the temperature controller more

safe and reliable. Functions such as temperature calibration, separately set differential for

refrigeration and heating, enable more accurate temperature control.

e, 12 temperatures in 12 periods of time;

Constantly control 12 stages of temperatures by setting it once;

Wide timer setting range: 1~999(min/hr), 1~90(days);

Can be set single or cycle control mode;

Plug and play design, easy to use;

and cooling outputs;

F / C temperature display;

Easy to set, PV and SV dual display screen;;

Delay protection for refrigeration control;

Can be set high and low temperature alarms;

temperature and sensor error.

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

timer function

, which can

with different temperature

s.

mainly used to control temperature during fermentation process of

beer and wine brewing, also widely used in home brewing, aquarium, pet breeding,

perature control, geothermal temperature control, heating

pump constant temperature cycle, strain culture fermentation, seed sprouting, electric

temperature protection and automatic temperature control

with refrigeration and heating

equipment easily to realize ideal temperature control. It’s equipped with dual LED display,

renheit, enabling more humanized

temperature control. With large output power 1,200W (110V) /2,200W (220V), it’s suitable

is designed with compressor delay protection for refrigeration, high and low

d sensor fault alarm, which makes the temperature controller more

safe and reliable. Functions such as temperature calibration, separately set differential for

Inkbird Tech. Co., Ltd. www.ink

3. Specification

Temperature Control Range

Temperature Resolution

Measuring Accuracy

Temperature Control Mode

Timing Range

Timing Accuracy

Periods of Time

Cycle Setting

Input Voltage

Control Output

Alarm

Sensor Type

Sensor Length

Relay Output

Relay Life

Input Power Cable Length

Dimension

Operating Ambient Temperature

Storage Condition

Warranty

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

5

Temperature Control Range

-50.0~120 ℃ /-58.0~248 ℉

0.1

℃

(-50.0~99.9

℃

) / 0.1

℉

(-50.0~99.9

1 ℃(100~120℃)/ 1℉(100~248℉)

±1℃ (-50.0 ~ 70℃) / ±2℉ (-

58 ~ 158

On/Off Control, Heat

ing and Cooling

1~999

(

min/hr

),

1~90

(

day

)

24hour±1.7s

Max: 12 periods

1-

999 times cycle, or 00 infinite cycle

100 ~240VAC, 50Hz/60Hz

Current: Max.10A

Voltage: 100~240V AC

Power: Max.1200W(120V)/2200W(220V)

High and Low Temperature Alarm

NTC Sensor(including)

2m / 6.56ft

Cooling(10A,100-240VAC)

Heating(10A,100-240VAC)

Mechanical;Electrical;

1.5m ( 5ft )

140x68x33 mm(body)

Operating Ambient Temperature

-30~ 75 ℃ / -22~ 167℉

Temperature: -20~ 60℃ / -

4~ 140

Humidity: 20~85% (No freeze or moisture

condensation)

1 Year

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

50.0~99.9

℉

)

58 ~ 158

℉)

ing and Cooling

999 times cycle, or 00 infinite cycle

Power: Max.1200W(120V)/2200W(220V)

4~ 140

℉

Humidity: 20~85% (No freeze or moisture

Inkbird Tech. Co., Ltd. www.ink

4. Keys I

nstruction

① SET Button: P

ress and hold SET

and hold SET button fo

r more than 3 seconds

setting process.

② UP Button:

Under running mode, when TR=1 or 2, press this button can view the

specific stage of the operating;

decrease the setti

ng value.

③ DOWN Button:

Under running mode, when TR=1 or 2, press this button can view the

left working time;

Under setting mode, press this UP button can increase the setting

value.

④ Heating Indicator Light

:

⑤ Cooling Indicator Light

:

status of compressor delay.

⑥

Centigrade/Fahrenheit Reading:

⑦ PV (Process Value):

Under

mode, display menu code.

⑧ SV (Setting Value):

Under

mode, display setting values.

⑨

Heating Device Socket:

⑩

Cooling Device Socket:

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

6

nstruction

ress and hold SET

button for 3 seconds to enter setting

menu

r more than 3 seconds

to

quit and save the settings during the

Under running mode, when TR=1 or 2, press this button can view the

specific stage of the operating;

Under setting mode, press this DOWN button can

ng value.

Under running mode, when TR=1 or 2, press this button can view the

Under setting mode, press this UP button can increase the setting

:

Light on, heating start working.

:

Light on, cooling start working; light flickering

,

status of compressor delay.

Centigrade/Fahrenheit Reading: Select Celsius or Fahrenheit temperature reading.

Under

normal mode

, display current temperature; Under

mode, display menu code.

Under

normal mode,

display set temperature value; Under setting

mode, display setting values.

Heating Device Socket:

For heating output.

Cooling Device Socket:

For cooling output.

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

menu

, then press

quit and save the settings during the

Under running mode, when TR=1 or 2, press this button can view the

Under setting mode, press this DOWN button can

Under running mode, when TR=1 or 2, press this button can view the

Under setting mode, press this UP button can increase the setting

,

being in the

Select Celsius or Fahrenheit temperature reading.

, display current temperature; Under

setting

display set temperature value; Under setting

Inkbird Tech. Co., Ltd. www.ink

5. Key O

peration

5.1

When controller works normally, if TR=0, there will be no reaction by shortly

pressing“ ” or “

” button; If TR=1 or 2, short press “

will display the left current working time; short press “

display the specific stage of current working and then return to normal temperature

displaying mode after 3 seconds.

5.2 How to Set Parameters

When controller works normally, press and hold “SET” key for more than 3 seconds to

enter into the mod

ify parameter mode, “ SET” indicator light will on, PV window displaying

the first code ”TS” in menu, if TR=1 or 2, there will be second mode “HD” displaying and

the related setting value displaying in SV window.

Press “SET” button to save the set value an

button can change the current value. After setting, keep pressing “SET” button for 3

seconds at any status will save the changed value and then return to the normal

temperature displaying.

During setting, if th

ere is no operation for 10 seconds, system will automatically quit the

menu and return to the normal temperature displaying mode with automatically save the

modified settings.

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

7

peration

Instruction

When controller works normally, if TR=0, there will be no reaction by shortly

” button; If TR=1 or 2, short press “ ” button once then release,

will display the left current working time; short press “ ” button once then rele

display the specific stage of current working and then return to normal temperature

displaying mode after 3 seconds.

5.2 How to Set Parameters

When controller works normally, press and hold “SET” key for more than 3 seconds to

ify parameter mode, “ SET” indicator light will on, PV window displaying

the first code ”TS” in menu, if TR=1 or 2, there will be second mode “HD” displaying and

the related setting value displaying in SV window.

Press “SET” button to save the set value and go to next setting, then press “

button can change the current value. After setting, keep pressing “SET” button for 3

seconds at any status will save the changed value and then return to the normal

ere is no operation for 10 seconds, system will automatically quit the

menu and return to the normal temperature displaying mode with automatically save the

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

When controller works normally, if TR=0, there will be no reaction by shortly

” button once then release,

” button once then rele

ase, will

display the specific stage of current working and then return to normal temperature

When controller works normally, press and hold “SET” key for more than 3 seconds to

ify parameter mode, “ SET” indicator light will on, PV window displaying

the first code ”TS” in menu, if TR=1 or 2, there will be second mode “HD” displaying and

d go to next setting, then press “

” or “ ”

button can change the current value. After setting, keep pressing “SET” button for 3

seconds at any status will save the changed value and then return to the normal

ere is no operation for 10 seconds, system will automatically quit the

menu and return to the normal temperature displaying mode with automatically save the

Inkbird Tech. Co., Ltd. www.ink

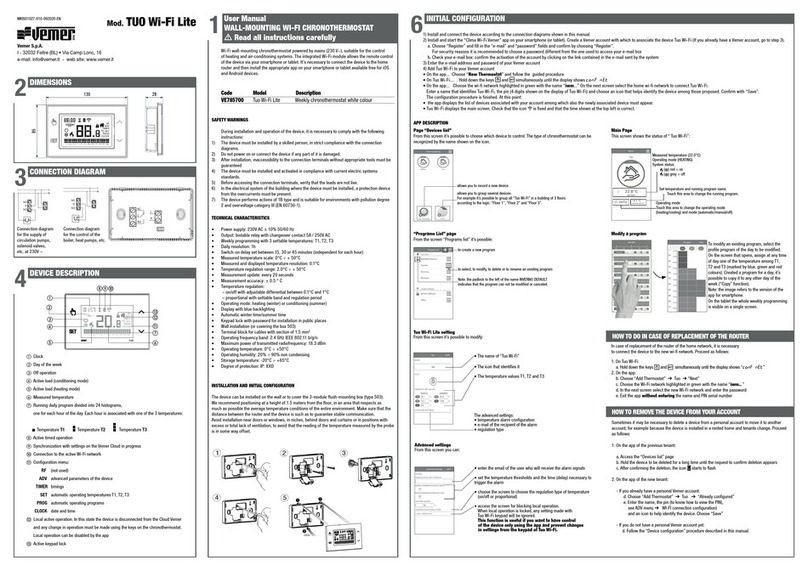

5.3 Setup Flow Chart

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

8

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

Inkbird Tech. Co., Ltd. www.ink

6. Menu I

nstruction

6.1 Tem

perature Control Setting

6.1.1

When setting temperature in Centigrade.

Symbol Code

TS

Temperature Set

HD

Heating Differential

CD

Cooling Differential

AH

Alarm High Limit

AL

Alarm Low Limit

PT

Compressor Delay

CA

CF

Centigrade/

TR

Timer Setting

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

9

nstruction

perature Control Setting

When setting temperature in Centigrade.

Function

Setting

Range

Default Setting

Temperature Set

Value

-50.0~120℃ 25.0℃

Heating Differential

Value

0.3~15.0℃ 2.0℃

Cooling Differential

Value

0.3~15.0℃ 2.0℃

Alarm High Limit

-50.0~120℃ 100℃

Alarm Low Limit

-50.0~120℃ -40.0

℃

Compressor Delay

0~10 minutes

0 m

inute

Calibration -15.0~15.0℃

0.0℃

Centigrade/

Fahrenheit C

Timer Setting

0、1or2 0

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

Default Setting

Remarks

in heating

in cooling

℃

inute

0->off

;

1 or 2->on

Inkbird Tech. Co., Ltd. www.ink

6.1.2 When setting temperature in Fahrenheit.

6.1.3 When TR=1 or TR=2.

Symbol Code

Function

UT

Time Unit Setting

MD

Cycle Setting Mode

AT

Auto Mode

STT

Stage Setting Value

SST

Start Stage Setting

Value

Symbol

Code

Function

TS T

emperature Set Value

HD

Heating Differential

Value

CD

Cooling Differential

Value

AH

Alarm High Limit

AL

Alarm Low Limit

PT

Compressor Delay

CA

Calibration

CF

Centigrade/

Fahrenheit

TR

Timer Setting

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

10

6.1.2 When setting temperature in Fahrenheit.

Function

Setting Range

Default Sett

Time Unit Setting

D, H, M D

Cycle Setting Mode

0-999 1

Auto Mode

0 or 1 0

Stage Setting Value

1~12 1

Start Stage Setting

Value

1~12 1

Function

Setting Range

Default Setting

emperature Set Value

-50.0~248℉ 77.0℉

Heating Differential

Value

1.0~30.0℉ 3.0℉

Cooling Differential

Value

1.0~30.0℉ 3.0℉

Alarm High Limit

-50.0~248℉ 212℉

Alarm Low Limit

-50.0~248℉ -40.0

℉

Compressor Delay

0~10 minutes

0 minute

Calibration

-15.0~15.0℉ 0.0℉

Centigrade/

Fahrenheit

F

Timer Setting

0、1 or 2 0

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

Default Sett

ing

Remarks

D: Day

H:Hour

M: Minute

00, Infinite

Cycle

0: Manual

1:Auto

Find the

below chart.

The stage

start to

work.

Default Setting

Remarks

Min unit: 1℉

Min unit: 1℉

Min unit: 1℉

Min unit: 1℉

℉

Min unit: 1℉

0 minute

0-> off ; 1

or 2-> on

Inkbird Tech. Co., Ltd. www.ink

6.1.4 When setting STA=12

, menu codes as below chart.

Symbol Code

Function

S01

Stage 1 Temperature Set

Value

H01

Control Duration

U01

Finished Ala

S02

Stage 2 Temperature Set

Value

H02

Control Duration

U02

Finished Alarm of Stage

S03

Stage 3 Temperature Set

Value

H03

Control Duration

U03

Finished Alarm of St

S04

Stage 4 Temperature Set

Value

H04

Control Duration

U04

Finished Alarm of Stage

S05

Stage 5 Temperature Set

Value

H05

Control Duration

U05

Finished Alarm of Stage

S06

Stage 6 Temperature Set

Value

H06

Control Duration

U06

Finished Alarm of Stage

S07

Stage 7 Temperature Set

Value

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

11

, menu codes as below chart.

Function

Default Setting

Stage 1 Temperature Set

Value

25.0℃ or 77.0℉

Same setting range as TS.

Control Duration

10

Finished Alarm of Stage

1 n

Stage 2 Temperature Set

Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

2 n

Stage 3 Temperature Set

Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

3 n

Stage 4 Temperature Set

Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

4 n

Stage 5 Temperature Set

Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

5 n

Stage 6 Temperature Set

Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

6 n

Stage 7 Temperature Set

Value

25.0℃ or 77.0℉

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

Remarks

Same setting range as TS.

Note 6.2.6

Note 6.2.6

Note 6.2.6

Note 6.2.6

Note 6.2.6

Note 6.2.6

Inkbird Tech. Co., Ltd. www.ink

H07

Control Duration

U07

Finished Alarm of Stage

S08

Stage 8 Temperature Set

Value

H08

Control Duration

U08

Finished Alarm of Stage

S09

Stage 9 Temperature Set

Value

H09

Control Duration

U09

Finished Alarm of Stage

S10

Stage 10 Temperature

Set Value

H10

Control Duration

U10

Finished Alarm of Stage

S11

Stage 11 Temperature

Set Value

H11

Control Duration

U11

Finished Alarm of Stage

S12

Stage 12 Temperature

Set Value

H12

Control Duration

U12

Finished Alarm of Stage

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

12

Control Duration

10

Finished Alarm of Stage

7 n

Stage 8 Temperature Set

Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

8 n

Stage 9 Temperature Set

Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

9 n

Stage 10 Temperature

Set Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

10 n

Stage 11 Temperature

Set Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

11 n

ge 12 Temperature

Set Value

25.0℃ or 77.0℉

Control Duration

10

Finished Alarm of Stage

12 n

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

Note 6.2.6

Note 6.2.6

Note 6.2.6

Note 6.2.6

Note 6.2.6

Note 6.2.6

Inkbird Tech. Co., Ltd. www.ink

6.2.1 Temperature setting

Range

When controller works normally,

automatically switch

working modes of cooling and heating.

When TR=0

Under normal temperature control mode, w

(Temperature Set Value

)

mode with

cooling indicator lamp

Indicator Light

flickering

protection; w

hen measured temperature

indicator light

off, cooling relay stop wor

When measured temperature

Differential Value)

, entering into

heating relay start working; when measured temperature

Value), heating indicator

light

For example, Set TS=25.0 , CD=2.0 , HD=3.0 : if measured temperature ℃ ℃ ℃

≥27.0 (TS+CD), cooling will turn on; if measured temperature ≤25.0 , cooling will turn ℃ ℃

off.

If measured temperature ≤22.0 (TS℃

≥25.0 , heating will turn off.℃

NOTE:

W

hen TR=0, under plug in or exit setting mode, no need to compare the current measured

temperature with the heating or cooling differential values but only compare directly with

the TS value.

For example, when plug in or exit setting mode, Set TS=25.0

measured temperature>

TS(25.0

cooling will turn off and then return to normal temperature control mode.

If measured temperature

<

≥25.0℃

, heating will turn off and then return to normal temperature control mode.

When TR=1 (Continuous Timer mode)

With this setting, the TS(temperature set value) will be

based on the setting values of S01~S12, H01~H12 and U01~U12.

For example, when periods of time within the range of the control duration of H01, if

measured temperature PV≥(Temperature Set Value )TS1+(Cooling Differenti

then cooling on with cooling indicator light on and cooling relay start working.

About the condition that the interval time between two refrigeration operations shorten

than PT(compressor delay time), please note 6.2.3.

When TR=2 (Target Tim

er mode)

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

13

Range

(TS, HD, CD)

When controller works normally,

PV screen

displays current measuring temperature,

working modes of cooling and heating.

Under normal temperature control mode, w

hen measured temperature

PV ≥ TS

)

+ CD (Cooling Differential Value

), entering into

cooling indicator lamp

on and cooling relay start working; w

hen the

flickering, cooling device is being in the status of compressor delay

hen measured temperature

PV ≤ TS (

Temperature Set Value

off, cooling relay stop wor

king.

When measured temperature

PV ≤TS (Temperature Set Value)-

HD (Heating

, entering into

heating mode with heating indicator

light

heating relay start working; when measured temperature

PV ≥ TS (

Temperature Set

light

off, heating relay stop working.

For example, Set TS=25.0 , CD=2.0 , HD=3.0 : if measured temperature ℃ ℃ ℃

≥27.0 (TS+CD), cooling will turn on; if measured temperature ≤25.0 , cooling will turn ℃ ℃

If measured temperature ≤22.0 (TS℃

-HD), heating

will turn on; if measured temperature

≥25.0 , heating will turn off.℃

hen TR=0, under plug in or exit setting mode, no need to compare the current measured

temperature with the heating or cooling differential values but only compare directly with

For example, when plug in or exit setting mode, Set TS=25.0

℃, CD=2.0℃

, HD=3.0

TS(25.0

℃

), cooling will turn on; if measured temperature ≤25.0

cooling will turn off and then return to normal temperature control mode.

<

TS(22.0℃

), heating will turn on; if measured temperature

, heating will turn off and then return to normal temperature control mode.

When TR=1 (Continuous Timer mode)

With this setting, the TS(temperature set value) will be

invalid and the controller will work

based on the setting values of S01~S12, H01~H12 and U01~U12.

For example, when periods of time within the range of the control duration of H01, if

measured temperature PV≥(Temperature Set Value )TS1+(Cooling Differenti

then cooling on with cooling indicator light on and cooling relay start working.

About the condition that the interval time between two refrigeration operations shorten

than PT(compressor delay time), please note 6.2.3.

er mode)

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

displays current measuring temperature,

PV ≥ TS

), entering into

cooling

hen the

Cooling

, cooling device is being in the status of compressor delay

Temperature Set Value

), cooling

HD (Heating

light

on and

Temperature Set

For example, Set TS=25.0 , CD=2.0 , HD=3.0 : if measured temperature ℃ ℃ ℃

≥27.0 (TS+CD), cooling will turn on; if measured temperature ≤25.0 , cooling will turn ℃ ℃

will turn on; if measured temperature

hen TR=0, under plug in or exit setting mode, no need to compare the current measured

temperature with the heating or cooling differential values but only compare directly with

, HD=3.0

℃: if

), cooling will turn on; if measured temperature ≤25.0

℃,

), heating will turn on; if measured temperature

, heating will turn off and then return to normal temperature control mode.

invalid and the controller will work

For example, when periods of time within the range of the control duration of H01, if

measured temperature PV≥(Temperature Set Value )TS1+(Cooling Differenti

al Value) CD,

then cooling on with cooling indicator light on and cooling relay start working.

About the condition that the interval time between two refrigeration operations shorten

Inkbird Tech. Co., Ltd. www.ink

With this setting, the TS(temperature set value) will be out of action and the controller will

work based on the setting values of S01~S12, H01~H12 and U01~U12.

For example, when periods of time within the range of the control duration of H01, if

measured temperature PV≥Temperature Set Value )TS1+(Cooling Differential Value) CD,

then cooling on with cooling indicator light on and cooling relay start working.

NOTE: The control duration of each stage start timing only when the current temperature

rea

ch or drop to the setting temperature in current stage.

About the condition that the interval time between two refrigeration operations shorten

than PT(compressor delay time), please note 6.2.3.

About how to set the timer and control temperature, please no

About the difference between TR=1 and TR=2, please refer to the chart below with 3

stages of the temperature:

Stage X(N=1~12)

STX(X=1~12)(

Stage1

Stage2

Stage3

The difference of the action time as the chart below:

Continuous Timer mode

Time

[minutes]

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

14

With this setting, the TS(temperature set value) will be out of action and the controller will

work based on the setting values of S01~S12, H01~H12 and U01~U12.

For example, when periods of time within the range of the control duration of H01, if

measured temperature PV≥Temperature Set Value )TS1+(Cooling Differential Value) CD,

then cooling on with cooling indicator light on and cooling relay start working.

NOTE: The control duration of each stage start timing only when the current temperature

ch or drop to the setting temperature in current stage.

About the condition that the interval time between two refrigeration operations shorten

than PT(compressor delay time), please note 6.2.3.

About how to set the timer and control temperature, please no

te 6.2.6.

About the difference between TR=1 and TR=2, please refer to the chart below with 3

STX(X=1~12)(

℃)

HTX(X=1~12)(Minutes)

UAX(X=1~12)

20.0 10

30.0 7

35.0 12

The difference of the action time as the chart below:

TR = 1

Continuous Timer mode

TR = 2

Target Timer mode

Temp

[°C] Stage Temp

[°C]

10

1

10

12

1

12

14

1

14

16

1

16

18

1

18

20

1

20

20

1

20

20

1

20

20

1

20

20

1

20

20

1

20

22

2

20

24

2

20

26

2

20

28

2

20

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

With this setting, the TS(temperature set value) will be out of action and the controller will

For example, when periods of time within the range of the control duration of H01, if

measured temperature PV≥Temperature Set Value )TS1+(Cooling Differential Value) CD,

then cooling on with cooling indicator light on and cooling relay start working.

NOTE: The control duration of each stage start timing only when the current temperature

About the condition that the interval time between two refrigeration operations shorten

About the difference between TR=1 and TR=2, please refer to the chart below with 3

UAX(X=1~12)

n

n

n

TR = 2

Target Timer mode

Stage

1

1

1

1

1

1

1

1

1

1

Inkbird Tech. Co., Ltd. www.ink

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

15

30

2

22

30

2

24

30

2

26

32

3

28

34

3

30

35

3

30

35

3

30

35

3

30

35

3

30

35

3

30

35

3

30

35

3

32

35

3

34

35

3

35

35

3

35

35

35

35

35

35

35

35

35

35

35

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

3

3

3

Inkbird Tech. Co., Ltd. www.ink

Above chart is the difference between the continuous timer mode and target timer mode,

can be shown as below graph:

The graph show when TR=1, the continuous timer mode as blue line: the current stage

control time of H01~H03 is counted continu

18~29 is 29 minutes; when TR=2, the target timer as red line: the current stage control

time od H01~H03 will only start to count down when the current measured temperature

has been reached the set temperature of curr

32~35 is 39 minutes.

6.2.2 Alarm High/Low Limit Setting (AH, AL)

When measured temperature

temperature <

AH or press any button, then will close the buzzer.

When

measured temperature

temperature >

AL or press any button, then will close the buzzer.

When the buzzer alarming, output of heating or cooling will keep working follow the

settings.

6.2.3

Compressor Delay (PT

Under cooling mode, first time to power on, when measured temperature PV ≥ TS

(Temperature Set Value) + CD (Cooling Differential Value), device won’t start cooling

immediately, but waiting for a delay time

When the interval time between two refrige

device will start cooling immediately

operations is

shorter than the delay time, device will start working until there is no delay

time left.

0

5

10

15

20

25

30

35

40

0123456789

1011

Temperature

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

16

Above chart is the difference between the continuous timer mode and target timer mode,

can be shown as below graph:

The graph show when TR=1, the continuous timer mode as blue line: the current stage

control time of H01~H03 is counted continuously and total time of 0~10, 11~17 and

18~29 is 29 minutes; when TR=2, the target timer as red line: the current stage control

time od H01~H03 will only start to count down when the current measured temperature

has been reached the set temperature of current stage and total time of 5~14, 19~25 and

6.2.2 Alarm High/Low Limit Setting (AH, AL)

When measured temperature

PV ≥ AH, alarm with “BI-BI-

BIII” sound until the

AH or press any button, then will close the buzzer.

measured temperature

PV ≤ AL, alarm with “BI-BI-

BIII” sound until the

AL or press any button, then will close the buzzer.

When the buzzer alarming, output of heating or cooling will keep working follow the

Compressor Delay (PT

)

Under cooling mode, first time to power on, when measured temperature PV ≥ TS

(Temperature Set Value) + CD (Cooling Differential Value), device won’t start cooling

immediately, but waiting for a delay time

(PT).

When the interval time between two refrige

ration operations is

longer than the delay time,

device will start cooling immediately

.

When the interval time between two refrigeration

shorter than the delay time, device will start working until there is no delay

1011

1213141516171819202122232425262728293031323334353637383940

41

Time [min]

Timer mode CS

Continuous vs. Target mode

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

Above chart is the difference between the continuous timer mode and target timer mode,

The graph show when TR=1, the continuous timer mode as blue line: the current stage

ously and total time of 0~10, 11~17 and

18~29 is 29 minutes; when TR=2, the target timer as red line: the current stage control

time od H01~H03 will only start to count down when the current measured temperature

ent stage and total time of 5~14, 19~25 and

BIII” sound until the

BIII” sound until the

When the buzzer alarming, output of heating or cooling will keep working follow the

Under cooling mode, first time to power on, when measured temperature PV ≥ TS

(Temperature Set Value) + CD (Cooling Differential Value), device won’t start cooling

longer than the delay time,

When the interval time between two refrigeration

shorter than the delay time, device will start working until there is no delay

41

CS = C

CS = T

Inkbird Tech. Co., Ltd. www.ink

Delay time will

be calculated right after the moment when device stop working.

6.2.4

Temperature Calibration (CA)

When there is

temperature off

user can set

CA for calibration

temperature value.

The calibrated

temperature = the

(positive value, 0 or negative value)

6.2.5

Display in Fahrenheit or Centigrade unit (CF)

Users can select

the temperature reading

the default setting is in

Centigrade.

Fahrenheit, then

set CF to F.

Attentions: when CF value changed, all the setting will be recovered to factory d

setting.

6.2.6 Timer-

Temperature Set Values

U01~U12)

TR:

a value to set timer, set to 0, timer off and set to 1, timer on. When TR=0, timer

function will be off, there will not display the other set values follow TR and no need to set

t

hem; when TR=1 or TR=2, timer function will be activated, user can set the time and the

control temperature values as required, with these settings, TS will be invalid and the the

controller will work based on the set temperature of the timer stages.

UT: a

value to set the time unit, can be set to day, hour or minutes as required.

STT:

a value to set stages of controlled temperature, can be set to max 12 stages: 12

temperature set values and each temperature set value respectively corresponded to a

continuo

us periods of time; when need to control different temperature in different time,

SST can be set to max 12 stages with 12 temperatures as required.

SST:

a value to set start stage to control temperature, can be set to the required stage to

start the temper

ature control.

S01~S12:

values to set the desired controlled temperature, when TR=1, the values of

S01~S012 will replace the TS value as the temperature control values.

H01~H12:

values to set continuous timer, if UT (time unit) set to hour and set H01 to 1

then the controller will control the set temperature of S01 for 12 hours.

U01~U12:

values to set the alarm, set to n=NO Alert; A=Alert; C=Confirm and S=Stop

Program.

UX=n:

if set to n in current stage, when completed the continuous timer, the controlli

will go to the next stage without alarming.

UX=A:

if set to A in current stage , when completed the continuous timer, there will be

alarming with PV screen displaying the current stage value UX(X=01~12) and SV screen

displaying the A in 1Hz flickering.

go to next stage control.

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

17

be calculated right after the moment when device stop working.

Temperature Calibration (CA)

temperature off

between measured temperature and actual

temperature,

CA for calibration

to get the measured temperature value

same

temperature = the

measured temperature value

+ calibration value

(positive value, 0 or negative value)

Display in Fahrenheit or Centigrade unit (CF)

the temperature reading

in Fahrenh

eit or Centigrade temperature value

Centigrade.

If need to change

the temperature reading in

set CF to F.

Attentions: when CF value changed, all the setting will be recovered to factory d

Temperature Set Values( TR, UT, STT, SST, S01~S12, H01~H12,

a value to set timer, set to 0, timer off and set to 1, timer on. When TR=0, timer

function will be off, there will not display the other set values follow TR and no need to set

hem; when TR=1 or TR=2, timer function will be activated, user can set the time and the

control temperature values as required, with these settings, TS will be invalid and the the

controller will work based on the set temperature of the timer stages.

value to set the time unit, can be set to day, hour or minutes as required.

a value to set stages of controlled temperature, can be set to max 12 stages: 12

temperature set values and each temperature set value respectively corresponded to a

us periods of time; when need to control different temperature in different time,

SST can be set to max 12 stages with 12 temperatures as required.

a value to set start stage to control temperature, can be set to the required stage to

ature control.

values to set the desired controlled temperature, when TR=1, the values of

S01~S012 will replace the TS value as the temperature control values.

values to set continuous timer, if UT (time unit) set to hour and set H01 to 1

then the controller will control the set temperature of S01 for 12 hours.

values to set the alarm, set to n=NO Alert; A=Alert; C=Confirm and S=Stop

if set to n in current stage, when completed the continuous timer, the controlli

will go to the next stage without alarming.

if set to A in current stage , when completed the continuous timer, there will be

alarming with PV screen displaying the current stage value UX(X=01~12) and SV screen

displaying the A in 1Hz flickering. Buzzer will be alarm shortly in every 2 seconds and then

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

be calculated right after the moment when device stop working.

temperature,

same

as the actual

+ calibration value

eit or Centigrade temperature value

,

the temperature reading in

Attentions: when CF value changed, all the setting will be recovered to factory d

efault

( TR, UT, STT, SST, S01~S12, H01~H12,

a value to set timer, set to 0, timer off and set to 1, timer on. When TR=0, timer

function will be off, there will not display the other set values follow TR and no need to set

hem; when TR=1 or TR=2, timer function will be activated, user can set the time and the

control temperature values as required, with these settings, TS will be invalid and the the

value to set the time unit, can be set to day, hour or minutes as required.

a value to set stages of controlled temperature, can be set to max 12 stages: 12

temperature set values and each temperature set value respectively corresponded to a

us periods of time; when need to control different temperature in different time,

a value to set start stage to control temperature, can be set to the required stage to

values to set the desired controlled temperature, when TR=1, the values of

values to set continuous timer, if UT (time unit) set to hour and set H01 to 1

2,

values to set the alarm, set to n=NO Alert; A=Alert; C=Confirm and S=Stop

if set to n in current stage, when completed the continuous timer, the controlli

ng

if set to A in current stage , when completed the continuous timer, there will be

alarming with PV screen displaying the current stage value UX(X=01~12) and SV screen

Buzzer will be alarm shortly in every 2 seconds and then

Inkbird Tech. Co., Ltd. www.ink

UX=C:

if set to C in current stage, when completed the continuous timer, there ill be

alarming with PV screen displaying the current stage value UX(X=01~12) and SV screen

di

splaying the A in 1Hz flickering. Buzzer will be alarm shortly in every 2 seconds but still

controlling the temperature of current stage, only by pressing any button will go to the

next stage control.

UX=S:

if set to S in current stage,when completed the

alarming with PV screen displaying the current stage value UX(UX=01~12) and SV screen

displaying the A in 1Hz flickering. Buzzer will be alarm shortly in every 2 seconds with all

output control turned off, only by pressing an

6.2.7 Cycle and Auto Mode (MD, AT)

MD: value to set

the operation time of timer and temperature set values, 00:

1~999

: specific time of operation. The default value is 1, means the controller will st

running after a one time operation with the set values.

AT:

value to set the operation mode when re

the controller will stop working when re

setting values by enterin

g the menu, the controller will restart working after re

AT=1: Auto mode. When

there

; when re-plug in, the

controller

plug based on the

operation

rresponding stage.

For example, set

S01(Stage

=0 or A; if there is a 3

hours

hours, in this case, the

controller

re-

plug in, if U01=n or A, the

controller

stop working on Stage 1

with

7.

Error Description

Sensor fault alarm:

when temperature sensor being in short circuit or open loop, the

controller will initiate the mode of sensor fault, and cancel all the

alarming with displaying

ER

normal working mode after remove the sensor fault.

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

18

if set to C in current stage, when completed the continuous timer, there ill be

alarming with PV screen displaying the current stage value UX(X=01~12) and SV screen

splaying the A in 1Hz flickering. Buzzer will be alarm shortly in every 2 seconds but still

controlling the temperature of current stage, only by pressing any button will go to the

if set to S in current stage,when completed the continuous timer, there ill be

alarming with PV screen displaying the current stage value UX(UX=01~12) and SV screen

displaying the A in 1Hz flickering. Buzzer will be alarm shortly in every 2 seconds with all

output control turned off, only by pressing any button will go to next stage control.

6.2.7 Cycle and Auto Mode (MD, AT)

the operation time of timer and temperature set values, 00:

: specific time of operation. The default value is 1, means the controller will st

running after a one time operation with the set values.

value to set the operation mode when re

-

plug after power off. AT=0: Manual mode,

the controller will stop working when re

-

plug after power off; user need to reset the

g the menu, the controller will restart working after re

there

is a power failure or outage,the timer will

continue

controller

will automatically count the time during

power

operation

time and status of H01~H12 and U01~U12,

then

S01(Stage

1)=25.0C℃, H01=4H, S02(Stage 2) =30.0℃

,

hours

power failure when the controller has worked

controller

will default the 2+3=5 hours to the

operated

controller

will work on Stage 2, if U01=C or S,

the

with

alarming.

Error Description

when temperature sensor being in short circuit or open loop, the

controller will initiate the mode of sensor fault, and cancel all the operations

ER

code. Press a

ny keys can stop the alarm, and return to the

normal working mode after remove the sensor fault.

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

if set to C in current stage, when completed the continuous timer, there ill be

alarming with PV screen displaying the current stage value UX(X=01~12) and SV screen

splaying the A in 1Hz flickering. Buzzer will be alarm shortly in every 2 seconds but still

controlling the temperature of current stage, only by pressing any button will go to the

continuous timer, there ill be

alarming with PV screen displaying the current stage value UX(UX=01~12) and SV screen

displaying the A in 1Hz flickering. Buzzer will be alarm shortly in every 2 seconds with all

y button will go to next stage control.

the operation time of timer and temperature set values, 00:

infinite cycle;

: specific time of operation. The default value is 1, means the controller will st

op

plug after power off. AT=0: Manual mode,

plug after power off; user need to reset the

g the menu, the controller will restart working after re

-plugged.

continue

to work

power

off and re-

then

run to the co

,

H02=6H, U02

on Stage1 for 2

operated

time; when

the

controller will

when temperature sensor being in short circuit or open loop, the

operations

. Buzzer

ny keys can stop the alarm, and return to the

Inkbird Tech. Co., Ltd. www.ink

8.

Technical Assistance

8

.1 Technical Assistance

If you have any problems installing or using this thermostat, please carefully and

thoroughly review the instruction manual. If you require assi

We will reply your emails in 24 hours from Monday through Saturday.

You can also visit our web site

technical questions.

8.2 Warranty

INKBIRD TECH. C.L. warrants this thermostat for one years from

when operated under normal condition by the original purchaser (not transferable), against

defects caused by INKBIRD’s workmanship or materials. This warranty is limited to the

repair or replacement, at INKBIRD’s discretion, of all or

original receipt is required for warranty purposes.

INKBIRD is not responsible for injury property damage or other consequential damages or

damages of third parties arising directly from an actual or alleged in mater of workman

of the product.

There are no representations, warranties, or conditions, express or implied, statutory or

otherwise, other than herein contained in the sale of goods act or any other statue.

ITC-

310T

Inkbird Tech. Co., Ltd. www.ink

19

Technical Assistance

and Warranty

.1 Technical Assistance

If you have any problems installing or using this thermostat, please carefully and

thoroughly review the instruction manual. If you require assistance, please write us to

We will reply your emails in 24 hours from Monday through Saturday.

You can also visit our web site

www.ink-bird.com to find the ans

wers of the common

INKBIRD TECH. C.L. warrants this thermostat for one years from

the date of purchase

when operated under normal condition by the original purchaser (not transferable), against

defects caused by INKBIRD’s workmanship or materials. This warranty is limited to the

repair or replacement, at INKBIRD’s discretion, of all or

part of the thermostat. The

original receipt is required for warranty purposes.

INKBIRD is not responsible for injury property damage or other consequential damages or

damages of third parties arising directly from an actual or alleged in mater of workman

There are no representations, warranties, or conditions, express or implied, statutory or

otherwise, other than herein contained in the sale of goods act or any other statue.

Business Contact:

sales

Technical Support:

cs@

Business Hours: 09:00-

18:00(GMT+8) from Monday to Friday

URL:

www.ink

310T

User Manual

Inkbird Tech. Co., Ltd. www.ink

-bird.com

If you have any problems installing or using this thermostat, please carefully and

stance, please write us to

We will reply your emails in 24 hours from Monday through Saturday.

wers of the common

the date of purchase

when operated under normal condition by the original purchaser (not transferable), against

defects caused by INKBIRD’s workmanship or materials. This warranty is limited to the

part of the thermostat. The

INKBIRD is not responsible for injury property damage or other consequential damages or

damages of third parties arising directly from an actual or alleged in mater of workman

ship

There are no representations, warranties, or conditions, express or implied, statutory or

otherwise, other than herein contained in the sale of goods act or any other statue.

Contact Us

sales

@ink-bird.com

cs@

ink-bird.com

18:00(GMT+8) from Monday to Friday

www.ink

-bird.com

Table of contents

Other Ink Bird Thermostat manuals