Inland WizCG User manual

INSTRUCTION MANUAL

WizCG grinder

WizlingCG grinder

2

IMPORTANT! READ FIRST

For your own safety be sure to read, understand and follow all

warnings, safety rules and instructions in this instruction manual

before using this machine. Failure to do so can result in serious

personal injury. This instruction manual is intended for the WizCG

and WizlingCG grinders. Save these instructions.

SAFETY INSTRUCTIONS

Setup

Intended for indoor use only.

Avoid dangerous environments. Do not

use this machine near gasoline or other

Make sure machine is securely placed

on a sturdy, level surface with ample

working area and away from open

electrical outlets.

Do not place grinder in a pan, on a

towel, or on carpeting.

Check for damaged parts. Before use,

always check for any damaged parts to

determine that it will operate properly

and perform its intended function. Check

for proper alignment of moving parts,

binding of moving parts, breakage

of parts, mounting, and any other

conditions that may affect its operation.

A part that is damaged must be properly

replaced through the manufacturer of

this machine to avoid risk of injury.

Use only Inland WizCG and WizlingCG

grinder parts for replacement parts.

Use of any other parts not originally

intended for these machines may create

a hazard or cause product damage.

Know your power tool. Read this

instruction manual carefully. Learn the

correct applications and limitations as

related to this machine.

Usage

Always wear proper eye protection to

out while you’re grinding. We recommend

wearing safety goggles or safety glasses

with side shields. Everyday glasses are

not safety glasses. If anyone is around

the machine while it’s in use, they must

also wear safety glasses.

3

SAFETY INSTRUCTIONS

Always wear proper apparel. Do not

wear any loose clothing, gloves, neckties

or jewelry that can get caught in the

machine’s moving parts. Secure long hair

with a rubber band or hair tie.

Keep work area well lit and clean.

Make sure your work area is not cluttered.

Do not operate unattended. Adult

leave the machine running unattended.

Do not operate this machine while

under the inuence of drugs, alcohol

or any medication.

Never run diamond grinder bits dry.

Diamond grinder bits are designed to

be used with a lubricant, such as water,

and will be ruined immediately if used

dry. Always make sure you are using

the material’s dust doesn’t form. This

dust contains chemicals that can be

hazardous to your lungs if inhaled and is

known to cause cancer, birth defects or

other reproductive harm. To reduce your

exposure to these chemicals, work in a

well ventilated area and wear a face or

dust mask.

Never grind more than one workpiece

at a time.

Some materials contain poisonous

elements. Avoid grinding materials that

contain uranium, mercury, lead, arsenic,

etc. Make sure you know the material you

are grinding.

Do not allow water to run down the

shaft and into the motor. This will cause

the motor to instantly burn out. This

machine is designed in such a way that

this does not occur with normal use.

Do not overll the water reservoir.

and damage the motor.

Do not force the tool or attachment to

do a job it is not designed to do.

Avoid awkward operations and hand

positions. Make sure you have good

balance while working on this machine.

A sudden slip could cause your hand to

move into the moving grinder bit.

Always stay alert. You must be focused

while working on this machine. Your

grinding material can catch on the

grinder bit and eject out of the area.

Maintenance

Always disconnect from power

before servicing. Disconnect machine

from power source before making any

adjustments and when not in use.

Do not abuse the power cord.

carry the machine by the cord or yank it

to disconnect from receptacle. Keep cord

away from heat, oil and sharp edges.

Do not open the motor housing. There

are no user serviceable parts inside.

Clean and dry machine after use.

4

TABLE OF CONTENTS

2

5

6

ASSEMBLY 7

USAGE 9

10

ACCESSORIES 11

Register your product

So that we can offer you the highest

level of service possible, please take

a moment to register your WizCG

or WizlingCG at inlandcraft.com/

product-registration.You can also

register by mailing us the enclosed

registration form. Complimentary

mailing envelope is included for

your convenience. Registration of

your grinder also helps facilitate any

5

WARRANTY INFORMATION

What does this warranty cover?

If your Inland machine fails under appropriate use during the warranty period,

Inland Craft will repair or replace it at our discretion. Inland Craft guarantees

to replace (after receipt and inspection) your included grinder bit, if the

diamond cutting surface peels off due to any manufacturing defect.

What does this warranty not cover?

This warranty does not cover problems resulting from abuse, misuse,

machine or improperly following the instructions.

Who is covered under this warranty?

non-transferable.

Whom should I contact if I need a warranty service?

Contact Inland Craft directly by phone at (248) 583-7150 or by email at

You must prove that you are under warranty by providing us with the

original invoice of your machine or by registering your product in order

to receive our warranty service.

WizCG and WizlingCG grinders are covered by a 5-year warranty

from the date of purchase. Registering your grinder machine helps

facilitate any warranty-related requests.

6

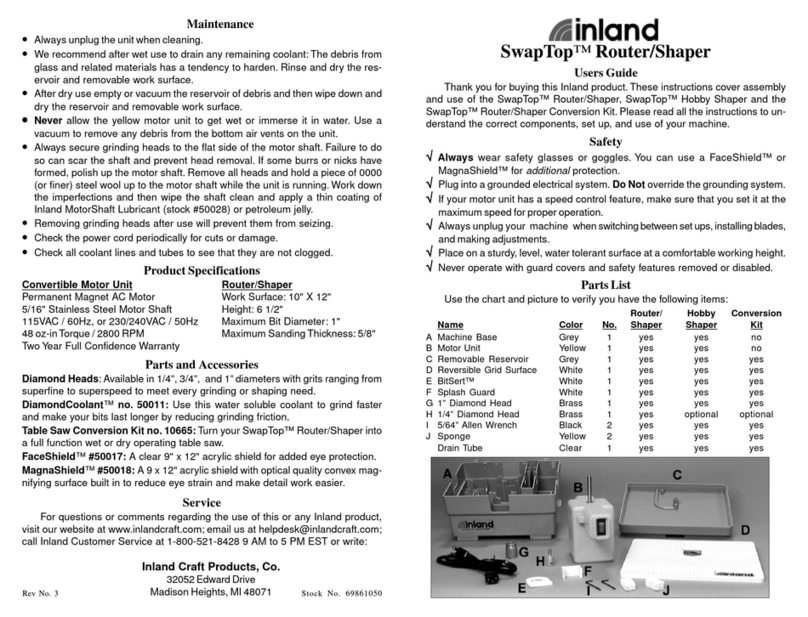

MACHINE DETAILS

The image below shows parts included with your grinder machine

(WizCG grinder pictured)

1

2

3

4

9

8

1. Grinder housing

2. Coolant reservoir tray

*WizlingCG reservoir is maroon color

3. Work surface

4. 3/4" grinder bit

5. 1/4" grinder bit

*Included with WizCG ONLY

6. BitSert

7. Splash guard

8. Coolant sponge (2)

9. Allen wrench (2)

56

7

*WizCG only

7

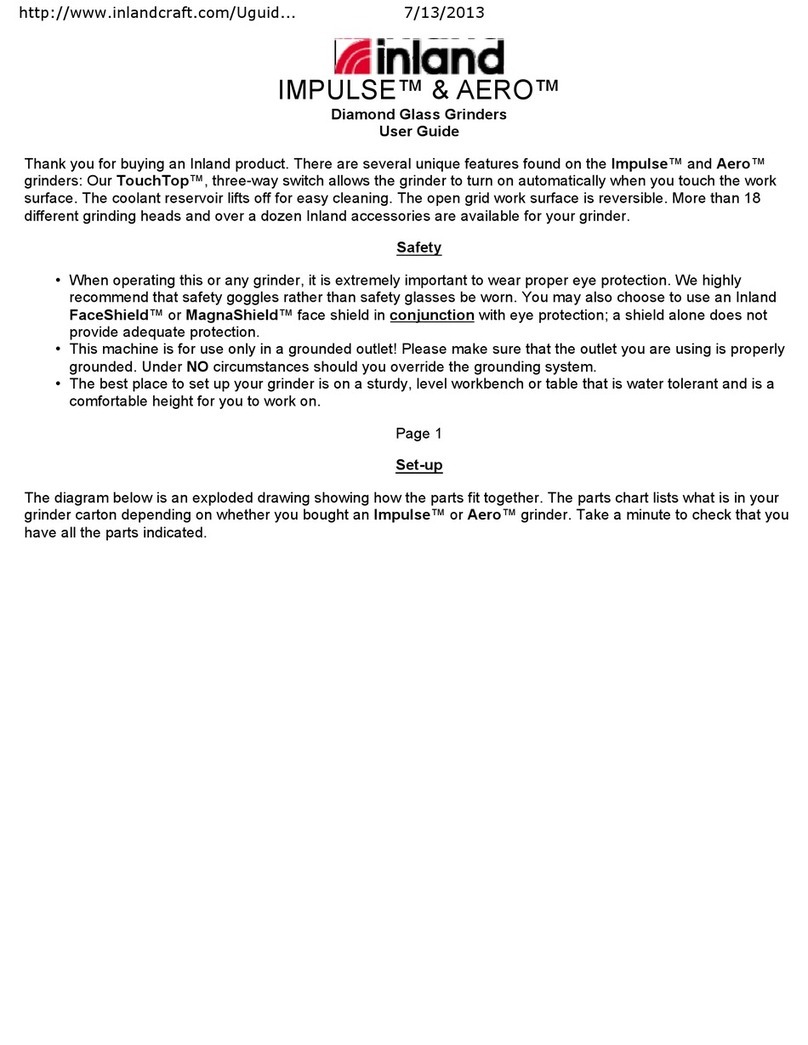

Filling the coolant

reservoir

A water/coolant mixture prevents

airborne glass dust, increases grinding

speed, and prolongs the life of the

diamond surface on the grinder bits.

diamond tool. Remove the work surface,

then pour 12 ounces (1½ cups) of clean

to the ridge on the coolant level indicator

located in the middle of the reservoir

(Fig. A). Optionally, you can add a capful

of Inland Craft diamond coolant (not

included) to increase diamond bit life

and grinding speed. Replace the work

surface.

*IMPORTANT NOTES: Never pour

water directly onto the grinder bit or

down the motor shaft. Do not overll

the coolant reservoir; overlling

can create an electrical shock and

damage the motor. Do not use

antifreeze as a coolant.

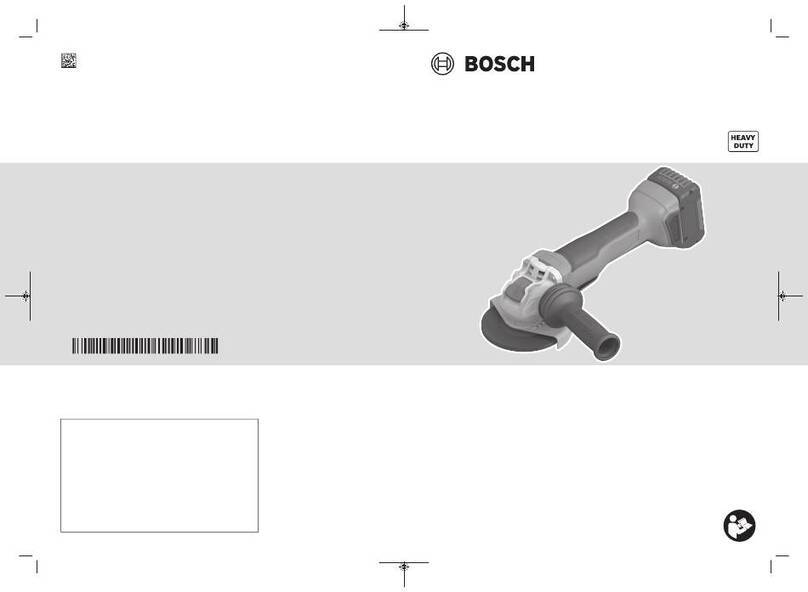

ASSEMBLY

Installing the grinder bit

In chronological order, install the grinder

bit according to the steps below and

Fig. B on page 8.

1Insert the BitSert into the work

surface.

2Insert the splash guard into the

installed BitSert.

3Before installing the grinder bit,

apply a thin coat of Inland Craft

motor shaft lubricant (not included) to

the motor shaft. This is to prevent the set

screw from seizing to the motor shaft.

Metal against metal, under pressure and

over time can bond. Loosening the set

screw between uses also prevents this. If

you do not have the Inland Craft motor

shaft lubricant, use a small amount of

Vaseline.

4Take the included 3/4" grinder bit

and loosen the set screw using

the included Allen wrench, turning

counterclockwise.

5Slide the 3/4" grinder bit onto the

motor shaft, positioning the set

shaft. Bits should slide onto the motor

shaft easily, do not force!

6Lower the bit until just over 1/8" of

the diamond is exposed above the

work surface. Secure the bit using the

Allen wrench, turning clockwise.

Fig. A

*WizCG reservoir is pictured,

WizlingCG reservoir is maroon

Fill to

here

Sponge placement

The included yellow sponge is what feeds

the coolant to the grinding bit while you

work. It is held in place by the BitSert. To

under clean water. Insert the sponge into

the rectangular hole behind the BitSert,

so that the bottom of the sponge makes

contact with the coolant in the reservoir,

and the top of the sponge makes contact

with the diamond surface of the bit

(Fig. C). The sponge must always have

contact with the bit while grinding. If a

white paste develops on the head or

on your glass while grinding, either the

sponge is not properly positioned or the

water/coolant level in the reservoir is low.

Periodically rinse out the sponge to remove

accumulated grinding residue. When the

sponge becomes worn, replace it.

Fire it up!

Make sure the power cord is plugged into

a grounded electrical outlet. Put on safety

goggles (not included) and turn on power

located on the right side of the machine.

8

ASSEMBLY

Fig. C

*IMPORTANT NOTE: Always tighten

and secure the grinder bit set screw

to the at side of the motor shaft.

Tightening the grinder bit to the

rounded side can scar the shaft and

prevent bit removal. Never force a

bit onto the motor shaft and never

attempt to pry off a bit. If the bit

is stuck, please review our FAQ at

inlandcraft.com/faq rst. If you still

need assistance, please contact

Inland Craft at (248) 583-7150.

Fig. B

BitSert

Splash guard

Flat side

motor shaft

Grinder bit

set screw

9

USAGE

Grinding

Turn on the machine and start grinding

a piece of scrap glass to get a ‘feel’ for

the grinding action. Begin by pushing

the glass into the grinding bit using light

pressure and moving the glass back and

forth across the bit. Slowly increase the

pressure until you feel comfortable with

the grinding speed and your control.

pressure for the types of glass you

use. When grinding out deep cuts, use

intermittent pressure to allow coolant

to rinse ground glass from the head. If

you ever have a white paste form on

the bit, it is not getting enough coolant.

Stop, turn off the machine, and check

the sponge placement and coolant level.

Grinding without coolant greatly reduces

the life of your grinding heads.

As the diamond surface wears, you will

feel it grind less effectively. When this

happens, it is time to expose a new

portion of the diamond surface. Loosen

the set screw using the included Allen

wrench and move the grinding head up

on the shaft to expose a new 1/8" section

of diamond. Secure the bit back in place

making sure to tighten the set screw

Reposition the sponge if needed. You

have up to 5, 1/8" sections of exposed

diamond on a standard grinding bit

to use before you need to consider

replacing the entire head.

How to drill a hole in glass

The WizCG comes with a 1/4" grinding/

drilling bit. It is not included with the

WizlingCG. This 1/4" grinder bit is useful

for drilling holes and intricate grinding.

The 1/4" bit is placed onto the motor shaft

and sits on top of the 3/4" grinder bit.

Loosen the set screw with the included

Allen wrench, then slide the bit onto the

side of the motor shaft. You need to supply

the coolant to the 1/4" bit while drilling by

using the other included sponge soaked in

coolant. Begin drilling the hole by holding

the front surface of the glass against the

upper edge of the bit at about a 45° angle,

while holding the coolant soaked sponge

against the bit and glass (Fig. D). You will

want to use two hands. Slowly move the

glass down onto the bit in a horizontal

position. Continue to work the glass down

and around the top of the bit in a circular

motion, making sure to keep the glass and

diamond wet at all times. You may need

to stop and soak the sponge with coolant

several times. Reduce pressure as you

Fig. D

begin to see the bit

come through the

back of the glass

to avoid chipping.

Practice before

project.

10

MAINTENANCE

Motor

The motor bearings are permanently

sealed and lubricated. There is no

Motor shaft

Apply Inland Craft motor shaft lubricant

(not included) or a small amount of

Vaseline to the motor shaft whenever

you change or remove the grinding bits.

Remove the bit if you won’t be using the

grinder for more than a week.

Water reservoir

Remove and clean the reservoir every

four hours of use, more often if grinding

heavily. Remove the water reservoir by

the work surface, then lift the reservoir

tray off the grinder housing. Scrape the

glass sludge into the trash and rinse

clean. Reassemble, referring to the

assembly section on page 7.

Work surface

The work surface is reversible. When one

Replacement work surfaces are available

online.

Coolant sponge

Periodically rinse out the coolant sponge

to remove any accumulated grinding

holding the sponge under running water

to rinse and clean it. When the sponge

becomes worn, replace it.

Keep your switch clean

Water and glass slurry may slop over the

sides of the grinder and onto the switch.

Wet hands handling the switch will also

get glass slurry into the switch. Over time,

this glass slurry builds up in the switch

contacts. Because colored glass contains

are there, the dried glass dust will make

a live connection across the switch

contacts.

Maintenance to WizCG and WizlingCG grinders is minimal but important. Follow these

guidelines to prolong the life and performance of your machine.

Check out our YouTube channel for WizCG and WizlingCG grinder

maintenance videos and usage tutorials at youtube.com/ICPVids

11

ACCESSORIES

Optional accessories and additional grinder bits available at inlandcraft.com

Jewelry bit

Use to grind grooves

around the outside of glass,

cabochons, beads and

buttons for wire wrapping

projects. Available in 220#

diamond grit. Choose from

1 mm and 1.4 mm thickness.

SKU

1 mm: 40190, 1.4 mm: 40194

FaceShield

Large, 10" x 8-3/4" acrylic

face shield provides added

protection from grinding

debris. Quick and easy

installation.

SKU

50017

Diamond drill bit

Use to drill precision holes

details in your glass pieces.

Available in 1/8", 1/4" and

the grinding/drilling adapter

on the right.

SKU

1/8": 40318, 1/4": 40314,

3/8": 40338

MagnaShield

Same as the FaceShield

except with a built-in optical

convex magnifying surface

to reduce eye strain, making

it easier to see.

SKU

50018

Grinding/drilling bit

adapter

This adapter is used with

the diamond drill bits. Drill

precision holes and create

having to remove your 3/4"

or 1" grinding head!

SKU

40317

SecondStory work

surface

Elevated work surface that

makes it easier to grind

and drill holes with small

diameter drilling heads.

SKU

50001

Manufactured by

Reentel International Inc.

808 Burr Oak Drive

Westmont, IL 60559

U.S.A.

Phone

(248) 583-7150

Email

Website

inlandcraft.com

Facebook

facebook.com/inlandcraft

Twitter

twitter.com/inlandcraft

YouTube

youtube.com/ICPVids

This manual suits for next models

1

Table of contents

Other Inland Grinder manuals

Popular Grinder manuals by other brands

Milwaukee

Milwaukee M12 FDGS Original instructions

AEG

AEG WS 22-180E Original instructions

Atlas Copco

Atlas Copco LSF19 S300-1 Product instructions

joke

joke JBS 400 instruction manual

Würth

Würth EWS 7-115 BASIC Translation of the original operating instructions

Siegen tools

Siegen tools S0530.V2 instruction manual

Challenge Xtreme

Challenge Xtreme MD3215M Original instructions

Dongcheng

Dongcheng DSM125A Operation instructions

Ingersoll-Rand

Ingersoll-Rand CA series Operation and maintenance guide

DeWalt

DeWalt D28143 instruction manual

Metabo

Metabo FSR 200 INTEC - Original instructions

Makita

Makita 9565PCV01 instruction manual