Innovista Sensors CROUZET TNi21 Series Instruction Manual

WWW.CROUZET-MOTORS.COM

TNi21 DCMIND BRUSHLESS

MOTORS

USER AND SAFETY MANUAL

07 April 2016 Page 1/38

TNi21 DCmind brushless motors

User and safety manual

Important notes

This manual is part of the product.

Read and follow the instructions in this manual.

Keep this manual in a safe place.

Give this manual and any documents relating to the product to anyone using the product.

Read and follow closely all the safety instructions in the "Before you start - Safety information"

section.

Please see the current catalogue for the product's technical specification.

We reserve the right to make modifications without prior notice.

Unless otherwise stated in writing by Crouzet Automatismes, any use of the products described

herein automatically signifies unconditional acceptance by the user of our general conditions of sale

and the waiver of any stipulations which might be printed on its orders or correspondence. Crouzet

Automatismes accepts no liability for any malfunction or damage caused by the user, due to the use

of this manual or the instructions herein.

TNi21

07 April 2016 Page 2/38

Table of contents

1. Introduction................................................................................................................................................5

1.1. Motor family.......................................................................................................................................5

1.2. Features............................................................................................................................................5

1.3. Options..............................................................................................................................................5

1.4. Identification label .............................................................................................................................5

1.5. Product coding ..................................................................................................................................6

2. Before you start - Safety information.........................................................................................................7

2.1. Qualification of personnel..................................................................................................................7

2.2. Use for intended purpose..................................................................................................................7

2.3. Basic information...............................................................................................................................8

2.4. Standards and concepts ...................................................................................................................9

3. Precautions for use at a mechanical level...............................................................................................10

3.1. Data specific to the motor shaft ......................................................................................................10

3.1.1. Force applied when pushing items on to the shaft.................................................................10

3.1.2. Radial load on the shaft..........................................................................................................10

3.2. Options............................................................................................................................................11

3.2.1. Holding brake .........................................................................................................................11

3.2.2. Gearboxes..............................................................................................................................11

3.2.3. Others.....................................................................................................................................11

4. Installation................................................................................................................................................12

4.1. Snapshot of the installation procedure............................................................................................14

4.2. Electromagnetic compatibility, EMC ...............................................................................................14

4.3. Before fitting....................................................................................................................................15

4.4. Fitting the motor ..............................................................................................................................16

4.5. Electrical installation........................................................................................................................17

4.5.1. Connecting the holding brake (option) ...................................................................................19

4.6. Production connector ......................................................................................................................20

5. Switching on.............................................................................................................................................21

5.1. Preparations for switching on..........................................................................................................21

6. Product presentation................................................................................................................................23

6.1. Description of the product...............................................................................................................23

6.2. TNI21 control electronics ................................................................................................................23

7. Technical characteristics .........................................................................................................................24

7.1. Electrical data..................................................................................................................................24

7.2. Generic data....................................................................................................................................24

7.3. Control logic bundle ........................................................................................................................25

7.4. Power supply cable.........................................................................................................................26

8. Motor electrical connection......................................................................................................................27

TNi21

07 April 2016 Page 3/38

8.1. Power connection............................................................................................................................27

8.1.1. Ballast circuit ..........................................................................................................................27

8.1.2. Protection for EMC.................................................................................................................29

8.2. Protective devices...........................................................................................................................30

8.2.1. Voltage protection...................................................................................................................30

8.2.2. Temperature protection..........................................................................................................30

8.2.3. Current limiting .......................................................................................................................31

8.3. Connecting inputs/outputs...............................................................................................................31

8.3.1. Equivalent inputs diagram......................................................................................................31

8.3.2. Equivalent outputs diagram....................................................................................................32

9. Operating mode.......................................................................................................................................33

9.1. Preliminaries ...................................................................................................................................33

9.2. Functions associated with inputs ....................................................................................................33

9.2.1. Function E1 - On / Off ............................................................................................................33

9.2.2. Function E2 - Direction of rotation..........................................................................................33

9.2.3. Function E3 - Speed set-point................................................................................................33

9.2.4. Function E4 - Torque limiter set-point....................................................................................34

9.3. Functions associated with outputs..................................................................................................34

9.3.1. Function S1 - Encoder output.................................................................................................34

9.3.2. Function S2 - Torque limiter output........................................................................................34

9.3.3. Function S3 - Actual direction of rotation output ....................................................................34

9.4. SAFE mode.....................................................................................................................................35

10. Diagnostics and troubleshooting .........................................................................................................35

10.1. Mechanical faults ............................................................................................................................35

10.2. Electrical problems..........................................................................................................................35

11. Service, maintenance and problem solving ........................................................................................36

11.1. Addresses of after-sales service points ..........................................................................................36

11.2. Storage............................................................................................................................................36

11.3. Maintenance....................................................................................................................................36

11.4. Replacing the motor........................................................................................................................37

11.5. Shipping, storage, disposal.............................................................................................................37

11.6. Terms and abbreviations.................................................................................................................38

TNi21

07 April 2016 Page 4/38

About this manual

This manual applies to TNI21 DCmind brushless products:

801400TNI21, 801495TNI21, 801496TNI21, 801410TNI21,

801800TNI21, 801896TNI21, 801897TNI21, 801810TNI21,

802800TNI21, 802896TNI21, 802897TNI21, 802810TNI21,

Reference source for manuals

Manuals are available to download from the Internet at the following address

http://www.crouzet.com/

Units

By default, units rotate anti-clockwise.

Risk categories

In this manual, safety instructions are identified by warning symbols.

Safety instructions are divided into three risk categories, depending on the gravity of the situation.

DANGER

DANGER indicates an immediately dangerous situation, which, if

instructions are not followed, would inevitably result in a serious or

fatal accident.

WARNING

WARNING indicates a potentially dangerous situation which, if

instructions are not followed, could in certain cases result in a serious

or fatal accident or cause damage to equipment.

CAUTION

CAUTION indicates a potentially dangerous situation which, if

instructions are not followed, could in certain cases result in an

accident or cause damage to equipment.

TNi21

07 April 2016 Page 5/38

1. INTRODUCTION

1.1.Motor family

TNI21 DCmind brushless motors are direct current brushless motors with a built-in electronic control board.

1.2.Features

TNI21 DCmind brushless motors are intelligent servomotors for speed and torque control applications.

They are fitted with two unscreened cables as standard, one for power and one for control.

1.3.Options

Motors may be supplied with options such as:

a range of gearboxes

a holding brake in the event of loss of current

various motor output shaft versions

1.4.Identification label

The label carries the following information:

Figure 1

1. Product family code

2. Product reference

3. Reserved area

4. Area reserved for special customer markings

5. Date manufactured: week/year

6. Operating voltage

7. The motor's rated speed at 24V

8. The motor's rated current

9. Gear ratio (for versions with gearboxes)

10. Maximum nominal torque applicable to gearboxes (for versions with gearboxes).

11. Motor approvals.

12. Insulation system temperature class.

13. Degree of protection (sealing) of the product during operation (apart from the output shaft).

14. Country of manufacture

TNi21

07 April 2016 Page 6/38

1.5.Product coding

80 XX XX TNI21: Product family based on TNI21 electronics

PRODUCT REFERENCE

8

0

X

X

X

X

X

X

Motor

Type of stator:

14: 30 mm brushless stator

18: 50mm brushless stator

28: 50mm brushless stator

high torque

Gearboxes fitted:

00: no gearbox

10: RAD10 gearbox

95: P52 gearbox

96: P62 gearbox

97: P81 gearbox

Incrementing numbers

TNi21

07 April 2016 Page 7/38

2. BEFORE YOU START - SAFETY INFORMATION

2.1.Qualification of personnel

Only qualified personnel, familiar with and understanding the contents of this manual, are authorised to work

on and with this product.

Qualified personnel should have a sound knowledge of current standards, regulations and requirements with

regard to accident prevention, when carrying out work on or with the product.

Those personnel must have undergone safety training, so that they are able to detect and prevent any

associated danger.

By virtue of their professional training, knowledge and experience, these qualified personnel should be able

to provide warning or recognise potential dangers, that could be caused by use of the product, modifying its

settings or those of mechanical, electrical and electronic equipment in the installation in general.

2.2.Use for intended purpose

As stated in these instructions, this product is a component intended for use in an industrial environment

The safety instructions in force, specified conditions and technical characteristics must be respected at all

times.

Before using the product for the first time, a risk analysis should be carried out on its use in practice.

Depending on the result, any necessary safety measures should be taken.

Since the product is used as a component in an overall system, it is the user's responsibility to ensure the

safety of persons through the design of the overall system, e.g. machine design.

Use only original spare parts and accessories.

The product must not be used in an explosive atmosphere (Ex zone).

Any other use is considered as non-compliant and could cause danger.

Only duly qualified personnel are authorised to install, operate, maintain and repair electrical devices and

equipment.

TNi21

07 April 2016 Page 8/38

2.3. Basic information

DANGER

DANGER DUE TO ELECTRIC SHOCK, EXPLOSION OR EXPLOSION DUE TO AN

ELECTRICAL ARC

• Only qualified personnel, familiar with and understanding the contents of this

manual, are authorised to work on and with this product. Only qualified personnel

are authorised to install, adjust, repair and maintain it.

• The person/entity constructing the installation is responsible for compliance with

all applicable requirements and regulations concerning the earthing of the drive

system.

• It is the user's responsibility to determine whether it is necessary to earth the

motor, depending on its use.

• Do not touch unprotected live parts.

• Use only electrically insulated tools.

• AC voltages may flow along unused conductors in the motor cable. Isolate unused

conductors at both ends of the motor cable.

• The motor produces a voltage when the shaft rotates. Isolate the motor shaft from

any external power supply, before carrying out any work on the drive system.

–Switch off all connections

–Attach a "DO NOT SWITCH ON" sign on all switches.

–Prevent all switches from being re-engaged.

–Wait for the motor's internal capacitors to discharge.. Measure the voltage in the

power cable and check that it is less than 12V DC.

• Fit and close all protective covers before re-applying power..

Failure to take these precautions could result in death or serious injury.

TNi21

07 April 2016 Page 9/38

WARNING

LOSS OF CONTROL

• When designing the control of the installation, the manufacturer should keep in

mind the implications of a potential failure in control paths and, for certain critical

functions, provide a method for returning to a safe state during and after the failure

of a control path.

Examples of critical control functions are:

EMERGENCY STOP, restricting the final position, network interruption and re-

starting.

• Separate or redundant control paths must be available for critical functions.

• Follow accident prevention instructions and all applicable safety directives.

• Any installation in which the product described in this manual is used must be

carefully and minutely checked to ensure that it is operating correctly, before it is

switched on.

If these precautions are not taken, the result could be death or serious injury.

WARNING

UNBRAKED MOVEMENT

In the event of a loss of power to the power stage, the motor is no longer braked in

a controlled way and could cause damage.

• Prevent access to the risk area..

• If necessary, use a damped mechanical stop or a service brake.

If these precautions are not taken, the result could be death, serious injury or

damage to equipment.

2.4.Standards and concepts

This product complies with European ROHS Directive 2011/65/EC and is CE marked.

The product's electrical design complies with standards IEC 60335-1 and IEC 60950-1.

TNi21

07 April 2016 Page

10/38

3. PRECAUTIONS FOR USE AT A MECHANICAL LEVEL

3.1.Data specific to the motor shaft

3.1.1. Force applied when pushing items on to the shaft

WARNING

MECHANICAL CHARACTERISTICS OF THE MOTOR

Exceeding the maximum permitted force on the shaft will result in rapid

wearing of the bearings, a broken shaft or the deterioration of any

accessories (encoder, brake, etc.)

• Never exceed the max. permissible radial or axial forces on the

motor.

• Protect the shaft against impacts.

• When pushing items in to the shaft, do not exceed the maximum

permitted axial force.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

The maximum force when pushing items on to the shaft is limited by the maximum permitted axial force

acting on the ball bearings.

This maximum axial force is given in the motor's data sheet.

Alternatively, the item to be attached can be secured by clamping, bonding or binding.

3.1.2. Radial load on the shaft

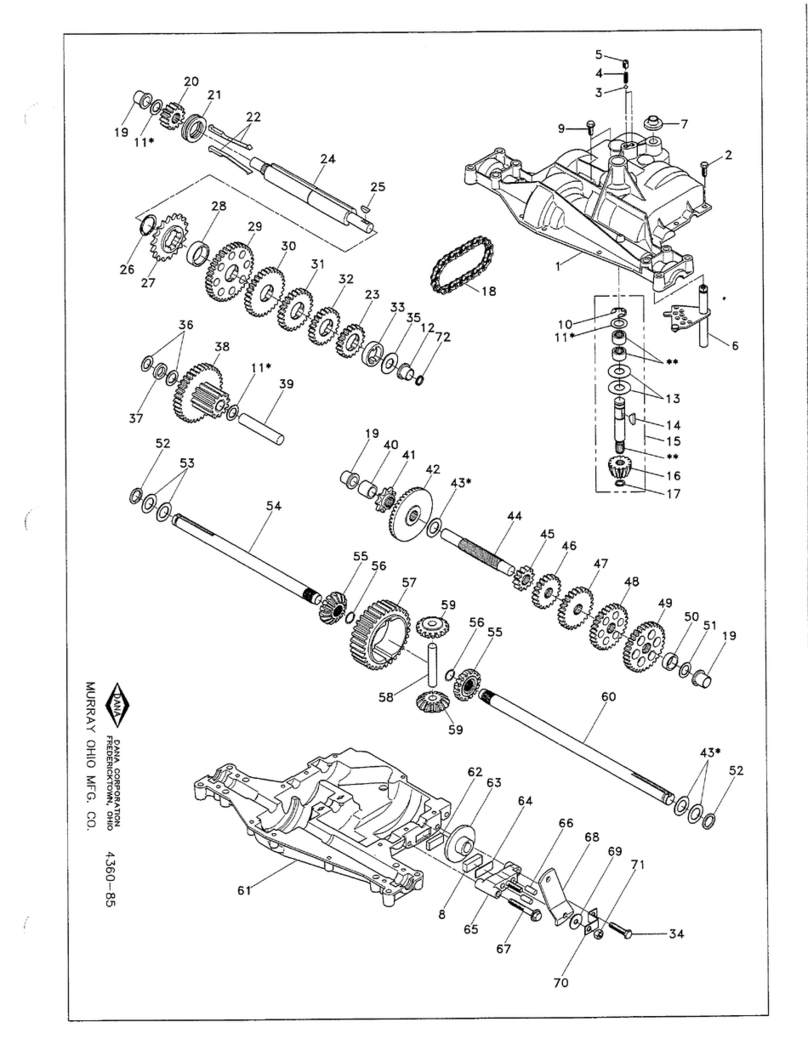

Figure 2

The point of application Xof the radial force Fdepends on the size of the motor.

This information is shown in the motor's data sheet.

The maximum radial and axial loads should not be applied simultaneously, so as to maximise the motor's

service life.

F

X

TNi21

07 April 2016 Page

11/38

3.2.Options

3.2.1. Holding brake

TNI21 DCmind brushless motors can be fitted with a fail safe electromechanical brake.

The holding brake is designed to prevent the shaft from rotating when there is no power to the motor.

The holding brake has no safety function.

The "Connecting a holding brake" section describes how it should be controlled.

3.2.2. Gearboxes

TNI21 DCmind brushless motors may be fitted with various types of gearbox.

The gearboxes offered in the standard catalogue are planetary gearboxes, combining compactness with

strength, and worm gearboxes that provide output from the shaft at right angles to the motor shaft.

3.2.3. Others

Other types of adaptation are possible upon request. Please contact our sales department.

TNi21

07 April 2016 Page

12/38

4. INSTALLATION

In a general sense, motors should be installed in line with good industrial practice.

WARNING

CONSIDERABLE WEIGHT AND FALLING PARTS

The motor can weigh a lot.

• Take the motor's weight into consideration when fitting it.

• Fit the motor (tightening torque of screws) in such a way that it

cannot come adrift, even in the event of high levels of acceleration or

permanent vibration.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

WARNING

STRONG ELECTROMAGNETIC FIELDS

Motors can generate powerful local electrical and magnetic fields.

They can cause sensitive equipment to fail.

• Keep persons wearing implants such as heart pacemakers away

from the motor.

• Do not position sensitive equipment in the immediate proximity of the

motor.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

WARNING

UNEXPECTED BEHAVIOUR AS A RESULT OF DETERIORATION OR

FOREIGN BODIES

As a result of deterioration of the product, the presence of foreign

bodies or deposits or penetration by fluids, unexpected behaviour can

occur.

• Do not use damaged products..

• Do not allow any foreign body to enter the product.

• Check that seals and power cable glands are correctly fitted.

• Check that the plug protecting the motor's internal connector is fitted

correctly.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

TNi21

07 April 2016 Page

13/38

WARNING

HOT SURFACES

The metal surface of the product can reach more than 70°C during

use.

Avoid all contact with the metal surface.

• Do not position inflammable or heat-sensitive components in

immediate proximity.

• Try to achieve an assembly that allows heat to dissipate efficiently.

If these precautions are not taken, the result could be injury or

damage to equipment.

WARNING

DETERIORATION OR DESTRUCTION OF THE MOTOR DUE TO OVER-

STRESSING

The motor is not designed to withstand loads. If the motor is stressed,

it could be damaged or even fall.

• Do not stand on the motor.

• Prevent the motor being used in any other way than its intended

purpose by taking protective measures and following the safety

instructions.

If these precautions are not taken, the result could be injury or

damage to equipment.

CAUTION

OVER-VOLTAGES

During braking phases, the motor generates over-voltages.

• Check that these over-voltages are acceptable to other equipment

connected to the same power supply.

• Preferably, use an external circuit, to limit over-volting

In cases where braking is used intensively.

If these precautions are not taken, the result could be injury or

damage to equipment.

TNi21

07 April 2016 Page

14/38

4.1.Snapshot of the installation procedure

The installation procedure is described in the follow sections:

Electromagnetic compatibility, EMC

Before fitting

Fitting the motor

Electrical installation

Check that these sections have been read and understood and that, subsequently, the motor has been

installed correctly.

4.2.Electromagnetic compatibility, EMC

DANGER

INTERFERENCE AFFECTING SIGNALS AND EQUIPMENT

Interference with signals can cause equipment to behave

unpredictably

• Wiring should be done in accordance with the EMC

recommendations specific to each device.

• Ensure that these EMC recommendations are followed correctly.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

Recommendations with regard to EMC: installing the motor's power supply wiring.

At the wiring planning stage, consider that the motor's power supply wiring must be installed isolated from

network or signal transmission cables.

Take the following measures with regard to EMC.

EMC measures

Effect

Keep cables as short as possible.

Do not install loops of unused cable.

Reduce interference, capacitive and inductive

couplings.

Earth the product.

Reduce emissions; increase immunity to

interference,

Where shielded cables are used, the cable

shielding should be fitted to the widest possible

surface area. Use cable clamps and earth bands.

Reduce emissions.

Position the motor's power supply wires separate

from cables that carry signals or use screening

plates.

Reduce mutual interference

If screened cables are used, fit them without an

isolation point. 1)

Reduce radiating interference.

1) Where the installation requires a cable to be cut, cables must be connected at the isolation point via a shielded cable inside a

metal enclosure.

Equipotential link conductors

Where screened cables are used, differences in voltage can cause currents not permitted in screened

cables. Fit equipotential link conductors to reduce current in screened cables.

TNi21

07 April 2016 Page

15/38

4.3.Before fitting

Look for damage

Damaged drive systems should not be fitted or used.

Check the drive system before fitting and look for visible signs of damage.

Cleaning the shaft

On leaving the factory, the ends of the motor shafts are coated with film of oil.

Where transmission devices are to be fitted by bonding, it may be necessary to remove that oil film and

clean the shaft. Where necessary, use degreasing products recommended by the manufacturer of the

bonding adhesive.

Avoid all contact between the skin and sealing materials and the cleaning product used.

Fitting surface for the flange

The fitting surface must be stable, flat and clean.

On the installation side, ensure compliance with all dimensions and tolerances.

Specification for power supply wires.

The power supply wires for the motor and its accessories must be selected with care according to their

length, the motor's supply voltage, the ambient temperature, the current passing through them and their

environment.

WARNING

DETERIORATION AND FIRE FOLLOWING INCORRECT INSTALLATION

Forces and movement in cable glands can damage cables.

• Comply with the stated bend radius

• Avoid subjecting cable glands to forces or movement.

• Secure supply cable close to cable glands using a strain relief clamp.

If these precautions are not taken, the result could be injury or

damage to equipment.

TNi21

07 April 2016 Page

16/38

4.4.Fitting the motor

DANGER

HOT SURFACES

The surface of the motor can reach more than 70°C during use.

• Avoid contact with hot surfaces.

• Do not position inflammable or heat-sensitive components in

immediate proximity.

• Try to achieve an assembly that allows heat to dissipate efficiently.

• Run a test to check the temperature.

If these precautions are not taken, the result could be injury or

damage to equipment.

WARNING

In rare cases, electrostatic discharges (ESD) on the shaft can cause

faults in the encoding system and unexpected movements of the

motor.

• Use conductive components, e.g. anti-static belts or other

appropriate measures to prevent any static charge due to movement.

WARNING

UNINTENDED BEHAVIOUR DUE TO MECHNANICAL DETERIORATION OF

THE MOTOR

Exceeding the maximum permissible forces on the shaft will result in

rapid wear of the bearings, a broken shaft or damage to the internal

encoder.

• Never exceed the max. permissible radial or axial forces on the

motor.

• Protect the shaft against impacts.

• When pushing items on to the shaft, do not exceed the maximum

permitted axial force.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

TNi21

07 April 2016 Page

17/38

Installation position

The motor can be installed in any position.

Installation

When fitting the motor on the flange, it must be aligned precisely, both axially and radially. All securing

screws must be tightened to the torque prescribed by the application, taking care not to cause any warping.

Fitting transmission devices

Fitting transmission devices incorrectly could damage the motor.

Transmission devices such as pulleys and gears must be fitted with reference to the maximum axial and

radial forces specified in the data sheet for each motor.

Follow the manufacturer's fitting instructions for each transmission device.

The motor and transmission device must be aligned accurately, both radially and axially. Any failure to do so

will result in erratic operation, damage to bearings and a high level of wear.

4.5.Electrical installation

These motors are not designed to be connected directly to the electrical system.

It is the installer's responsibility to specify the electrical protection to be deployed with regard to the

regulations applicable to the field of use of the final product.

For the supply to the power part, we recommend the use of a stabilised double-insulated power supply unit.

The motor's power stage is not protected against reversed polarity.

The motor is said to be regenerative, i.e. it can feed back energy to the power supply during braking phases.

Voltage surges created in this way can reach levels that risk damaging the motor itself or to devices

connected to the same power supply.

DANGER

ELECTRIC SHOCK

High voltages can occur unexpectedly at the motor connection.

• The motor produces a voltage when the shaft rotates. Isolate the

motor shaft from any external driving force before doing any work on

the drive system.

• The system's manufacturer is responsible for complying with all the

rules applicable to the earthing of the drive system.

Failure to take these precautions could result in death or serious

injury.

WARNING

UNEXPECTED MOVEMENT

Drives may move unexpectedly, due to an incorrect connection or

some other error.

• Only start the installation if there is no person or obstacle inside the

danger zone.

• Make initial test movements with no load connected.

• Do not touch the motor shaft or connected drive components.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

TNi21

07 April 2016 Page

18/38

WARNING

OVER-VOLTAGES

During braking phases, the motor generates over-voltages.

• Check that these over-voltages are acceptable to other equipment

connected to the same power supply.

• Preferably use an external circuit, to limit over-volting

In cases where braking is used intensively.

If these precautions are not taken, the result could be

death, serious injury or damage to equipment.

CAUTION

FIRE DUE TO POOR CONTACT

The connection terminals to the motor could heat up and the contacts

melt due to electrical arcing, if the connector is not properly plugged in.

• Poor connections can cause heating due to electrical arcing.

If these precautions are not taken, the result could be injury or

damage to equipment.

CAUTION

REVERSED POLARITY COULD DESTROY THE PRODUCT

Incorrectly connecting the power can result in reversed polarity and the

destruction of the electronic board inside the motor.

• Check that the power connection is correct.

If these precautions are not taken, the result could be injury or

damage to equipment.

Connecting the protective conductor

It is the installer's responsibility to determine the necessity to earth the motor.

This must be done via the mounting flange.

Under no circumstances connect or disconnect the product's power supply wires while they are live.

TNi21

07 April 2016 Page

19/38

4.5.1. Connecting the holding brake (option)

WARNING

LOSS OF BRAKING FORCE DUE TO WEAR OR HIGH TEMPERATURE

Application of the holding brake while the motor is rotating can cause

rapid wear and loss of braking force.

• Do not use the brake as a service brake.

• Note that an "emergency stop" can also cause wear.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

WARNING

UNEXPECTED MOVEMENT

Releasing the holding brake can cause unexpected movement in the

installation.

• Take care that this does not cause any damage.

• Only run tests if there is no person or obstacle inside the danger

zone.

If these precautions are not taken, the result could be death,

serious injury or damage to equipment.

CAUTION

MALFUNCTION OF THE HOLDING BRAKE DUE TO AN INAPPROPRIATE

VOLTAGE

• If the voltage is too low, the holding brake cannot release itself and

that will cause wear.

• If voltages are higher than specified, the holding brake will suffer

excessive heating.

If these precautions are not taken, the result could be injury or

damage to equipment.

A motor with a holding brake requires a suitable control logic which releases the brake when rotational

movement starts and which grips the motor shaft in time when the motor stops.

This manual suits for next models

12

Table of contents

Other Innovista Sensors Engine manuals

Popular Engine manuals by other brands

Continental Refrigerator

Continental Refrigerator IO-240-A Installation and operation manual

DLA

DLA 32cc instruction manual

Rotax

Rotax 914 series Maintenance manual

Vetus

Vetus VF4.145 Operation manuals

MTU

MTU 20 V 4000 M73 x operating instructions

Toshiba

Toshiba Stainless Steel Washdown Duty Motor Toshwash... Brochure & specs