Inorea VFR-091 User manual

FREQUENCY INVERTER VFR-091

QUICK START GUIDE

2

TABLE OF CONTENTS

1. PEOPLE SAFETY.................................................................................................................................................. 3

2. MATERIAL SAFETY ............................................................................................................................................. 3

3. NAME PLATE...................................................................................................................................................... 4

a. Single phase inverters ................................................................................................................................... 4

b. Three phase inverters ................................................................................................................................... 5

4. INVERTER ASSEMBLY IN AN ELECTRIC BOX....................................................................................................... 7

5. TECHNICAL FEATURES ....................................................................................................................................... 7

6. ELECTRICAL DIAGRAM....................................................................................................................................... 8

7. PARAMETER : INDICATOR LIGHT AND BUTTONS............................................................................................ 10

8. INVERTER PARAMETERS.................................................................................................................................. 12

a. Paramters: system y0.................................................................................................................................. 13

b. Parameters: motor b0................................................................................................................................. 13

c. Standard parameters .................................................................................................................................. 14

d. Input settings............................................................................................................................................... 15

e. Table 1: Multi-speed ................................................................................................................................... 18

f. Table 2: Piloted acceleration and deceleration........................................................................................... 18

g. Control modes............................................................................................................................................. 18

h. Output settings............................................................................................................................................ 21

i. Error messages............................................................................................................................................ 22

3

1. PEOPLE SAFETY

RISKS OF ELECTROCUTION OR EXPLOSION

Read carefully this installation guide before using the inverter.

The user has to conform to all the requirements of the international and national regulations about the

earthing of all the equipments.

DO NOT touch the internal parts of the inverter : use only tools isolated electrically

DO NOT touch the terminal blocks when the inverter is supplied.

DO NOT put in short circuit borders DC+1 and DC+2 or condensers of the bus DC. A high tension which

can cause electric shocks remains present in the device after cutting the supply.

DO NOT try to fix the inverter; you should contact your retailer.

Put back in place and close all the lids before putting back the inverter under tension.

The inverter must be carefully fixed before switching it under tension.

Before any intervention on the motor, power supply of the inverter must be turned off.

NON-RESPECT OF THESE RULES MAY BE FATAL: DEATH, SERIOUS INJURIES AND MATERIAL DAMAGES

2. MATERIAL SAFETY

Verify that the inverter VFR-013 is not damaged

Verify that the inverter corresponds to your order and to the delivery note.

Verify that the tension of the electric network corresponds to the supply power of the inverter : 220V

single phase or 400V three phase

Never turn off the supply power if the inverter before the end of the motor operations.

An armored cable must be used for the control circuit, and this one must be taken away as much as

possible from the circuit of power to avoid the disturbances.

When the frequency of hashing is lower than 3 KHz, the distance between the inverter and the motor

must be at the maximum 50 meters.

If the inverter has to start frequently, do not turn off it power supply, but use the starting up at the

terminal blocks, to avoid some damages.

Never connect a supply power on terminals U, V, W of the inverter; otherwise it would be immediately

destroyed.

The inverter capacity in KW and A should always be higher than the motor capacity.

WARNING; IF THE INVERTER IS DAMAGED; DO NOT USE IT

4

From 0.75KW to 5.5KW

3. NAME PLATE

VFR-091T4B-4K0

Motor power in kW

T4 : three phase 400V - M2 : single phase 220V / Ø : standard - B : integrated braking

091 / 092

Frequency inverter

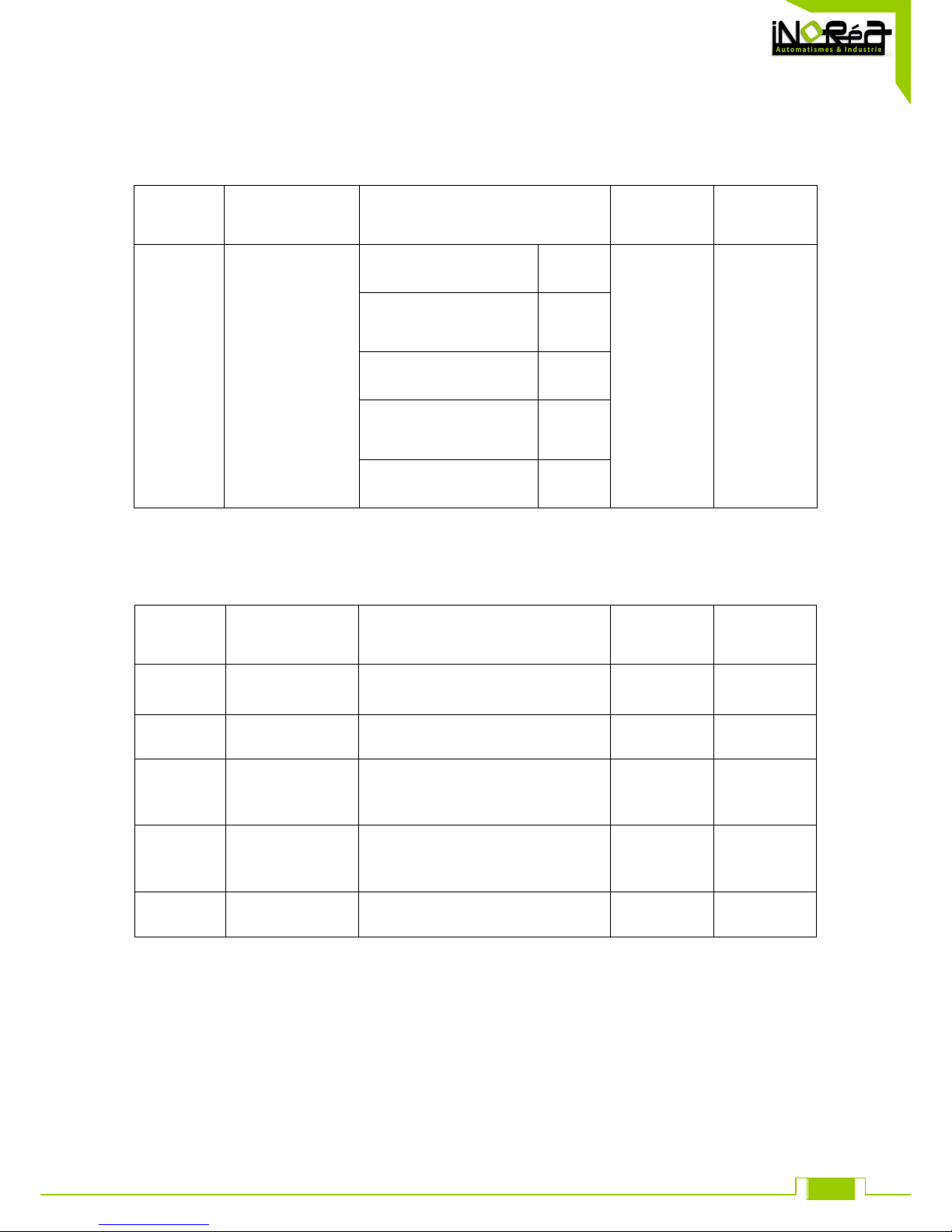

a. Single phase inverters

Reference

Nominal

power

Input

tension

Electrica

l current

input

Protectio

n caliber

Cable

section

input

Electrical

current

output

Cable

section

output

Size

(KW)

(V)

(A)

(A)

(mm²)

(A)

H/L/P (mm)

VFR-091M2-0K75

0.75

220

±10%

5.5

10

1.5

4

1,5

185/120/178,5

VFR-091M2-1K5

1.5

220

±10%

11

16

2.5

7

1,5

VFR-091M2-2K2

2.2

220

±10%

16

20

2.5

10

2,5

220/150/185,5

VFR-091M2-4K0

4

220

±10%

29

32

4

16

2,5

285/180/200

VFR-092M2-5K5

5.5

220

±10%

40

40

6

25

4

360/220/210

5

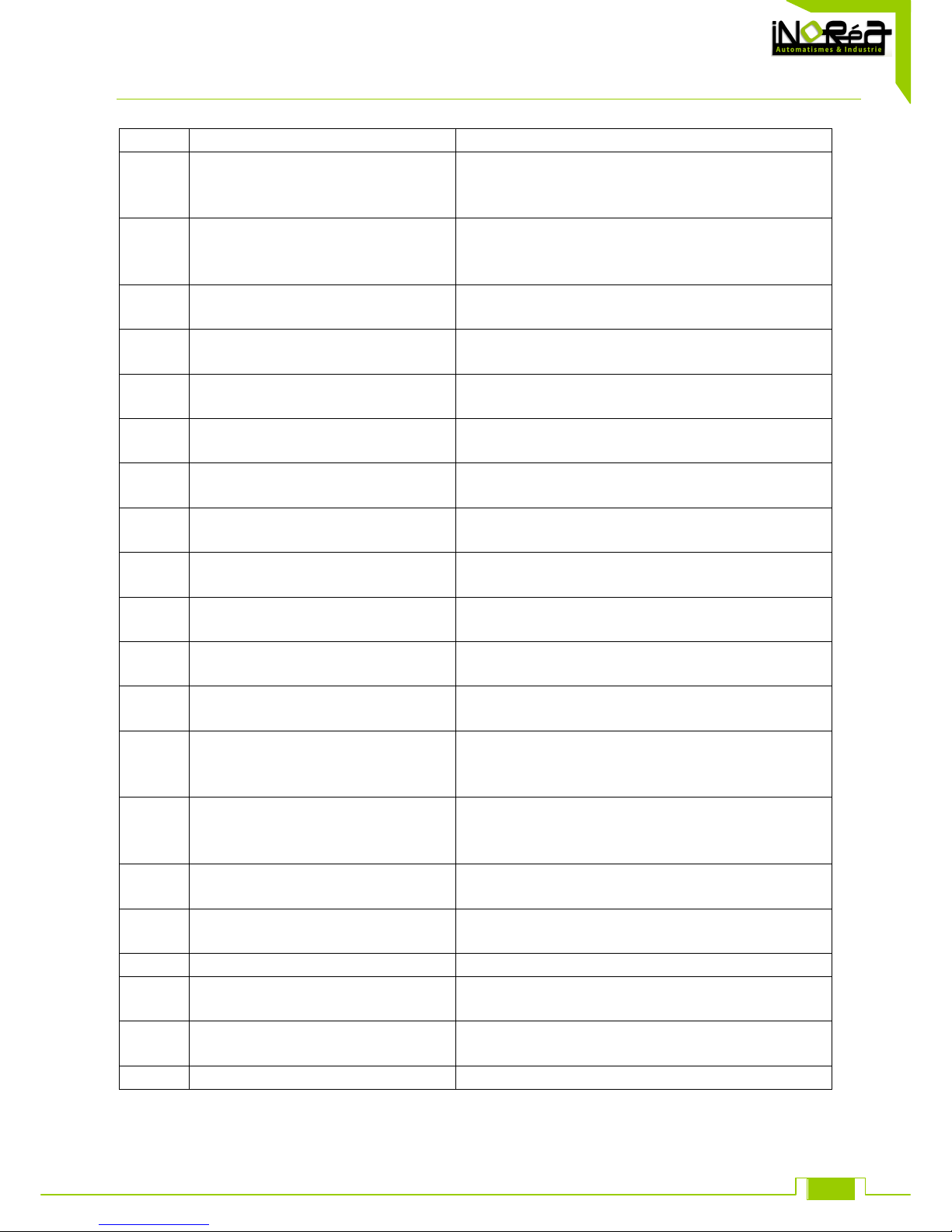

b. Three phase inverters

Reference

Input

tension

Nominal

power

Input current

Output

current

Size

Option

(V)

(KW)

(A)

(A)

H/L/P (mm)

VFR-091T4-0K75

400

0.75

3,4

2,1

185/120/178,5

VFR-091T4B-0K75

Braking

VFR-091T4-1K5

400

1.5

5

3.8

VFR-091T4B-1K5

Braking

VFR-091T4-2K2

400

2.2

5,8

5,1

VFR-091T4B-2K2

Braking

VFR-091T4-4K0

400

4

10,5

9

220/150/185,5

VFR-091T4B-4K0

Braking

VFR-091T4-5K5

400

5.5

14,6

13

VFR-091T4B-5K5

Braking

VFR-091T4-7K5

400

7.5

20,5

17

285/180/200

VFR-091T4B-7K5

Braking

VFR-092T4-11K0

400

11

26

25

360/220/210

VFR-092T4B-11K0

Braking

VFR-091T4-15K0

400

15

35

32

VFR-092T4B-15K0

Braking

VFR-092T4-18K0

400

18,5

38,5

37

432/225/242

VFR-092T4B-18K0

Braking

VFR-092T4-22K0

400

22

46,5

45

VFR-092T4B-22K0

Braking

VFR-092T4-30K0

400

30

62

60

480/296/246

VFR-092T4B-30K0

Braking

VFR-092T4-37K0

400

37

76

75

VFR-092T4B-37K0

Braking

VFR-092T4-45K0

400

45

91

93

660/364/280

VFR-092T4B-45K0

Braking

VFR-092T4-55K0

400

55

112

110

VFR-092T4B-55KO

Braking

VFR-092T4-75K0

400

75

157

150

VFR-092T4B-75K0

Braking

VFR-092T4-90K0

400

90

180

176

710/453/280

VFR-092T4B-90K0

Braking

VFR-092T4-110K0

400

110

214

210

VFR-092T4B-110K0

Braking

VFR-092T4-132K0

400

132

256

253

910/480/323

VFR-092T4B-132K0

Braking

VFR-092T4-160K0

400

160

307

304

VFR-092T4B-160K0

Braking

6

From 11KW to 160KW

7

4. INVERTER ASSEMBLY IN AN ELECTRIC BOX

5. TECHNICAL FEATURES

Input tension

(depending on the model)

Three phase 400V (±10%)

Input frequency

50/60Hz (±5%)

Output frequency

0 to 300Hz in vectorial control, 0 to 3200Hz in V/F

Overload capabilities

150% during 1 min., 180% during 2 sec.

Start-up torque

150% to 0,5Hz

Control methods

V/F, vectorial control in open or closed torque

Inputs

6 ou 8 digitals (depending on the model) , 2 analogs

Outputs

2 analogs, 2 transistors, 1 ou 2 shift (depending on the model)

Communication

RS485/RS232 (additional card in option)

Protection

IP20

WORKING ENVIRONMENT

- Temperature: -10 ℃à 40 ℃.

- Avoid the electromagnetic interferences, and take away sources of

interferences.

- Avoid the penetration of droplets, water vapor, dust, dirt and

metallic dust.

- Avoid the penetration of oils, salt and corrosive gas.

- Avoid the vibrations.

- Avoid high temperatures, moisture and exposition to the rain.

Moisture should be lower than 90% (without condensation).

-Never use the inverter in a dangerous environment; flammable,

combustible, corrosive and explosive gas.

8

6. ELECTRICAL DIAGRAM

380V Three Phase

Inverter

Ground

input

terminal

Ground

output

terminal

Power circuit

Motor

Optional elements

Braking resistor

DC voltage filter

Control circuit

Terminal block

inputs

Output signal 1

Output signal 2

Output signal 3

2-3 utilisation of the COM on DI inputs terminal blocks

2-1 utilisation of the +24V on DI inputs terminal blocks

Connector for

communication

card RS 485

The PLC can be

connected to the

+24V or to the COM or

to an external power

supply (9-30V)

Analog output DA1

Analog output DA2

9

220V Single Phase

DC voltage filter

Braking resistor

Optional elements

Inverter

Output signal 3

Output signal 2

Output signal 1

Analog output DA2

Analog output DA1

Connector for

communication

card RS 485

2-3 utilisation of the COM on DI inputs terminal blocks

2-1 utilisation of the +24V on DI inputs terminal blocks

10

7. PARAMETERS : INDICATOR LIGHT AND BUTTONS

Indicator light

Description

Status of the indicator light

RUN

Indicator ON/OFF

* ON: operating motor (forward)

* OFF: motor switched off

LOCAL/REMOT

Pilotage mode indicator

* ON: pilotage by terminal blocks

* OFF: pilotage by keyboard

*Blinker: pilotage by remote control

FWD/REV

Forward / Reverse

* ON: forward

TUNE/TC

Indicator setting / Defect

* ON: torque control mode

* Slow blink: dans l'état de mise au point

* Fast blink: dans l'état de défaut

Indicateur unités

de combinaison

Hz/A/V

Unit indicator

11

Buttons

Name

Function

Parameters button

/ output

Change the parameter

Back to the display menu or to the functions menu

SHIFT

Select the different types of display of the unit ON or

OFF

Select the characters during the parameter

modification

UP

Data or code of the increasing function

DOWN

Data or code of the decreasing function

RUN

Use to start the motor in mode keyboard piloting

STOP / RESET

Use to stop the motor

Use to reset a defect of the alarm

Button in relation with the F6.00 parameter

ENTER

Use to enter in a parameter

Allows to confirm a parameter modification

Keyboard

potentiometer

If F0.02 is set on 3, the keyboard potentiometer is

used to manage the frequency currently being

implemented

Last display at the extinction

Different groups

Display of the subparameters

Modif. Of the parameter value

Selection of

the setting

group

Selection of the

parameter

group

Change of the

parameter

value

PRG

PRG

PRG

PRG

ENTER

ENTER

ENTER

Touch

Touch

Touch

Touch

Touch

Touch

To confirm

Indicator

12

8. INVERTER PARAMETERS

Code

Parameter name

Description

d0

Display of values surveillance of

measures

Display of: frequency, voltage, electric current etc...

F0

Basic functions

Setting of frequency, control mode, acceleration and

deceleration

F1

Group of input terminals

Analogue functions and digital input

F2

Group of output terminals

Analogue functions and digital output

F3

On and off states control parameters

Choice of on and off states

F4

Control parameters V / F

Control parameters V / F

F5

Vector control parameters

Vector control parameters

F6

Keypad and screen

To define the keypad and screen parameters

F7

Group of auxiliary functions

To define the auxiliary functions parameters

F8

Failure and protection

To define the failure and protection parameters

F9

Communication parameters

To adjust the communication parameters Modbus

FA

Torque control parameters

To define the parameters in mode torque control

FB

Optimization control parameters

To define the parameters of the optimization of the

performances of control

E0

Rebalancing of length and the counting

To define the parameters of rebalancing, length and

the counting

E1

Multi-speed

Multi-speed

E2

Function PID

To define and integrate the parameters PID

E3

DI virtual, DO virtual

Settings of the virtual parameters I/O

b0

Motor parameters

Settings of the motor features

y0

Function codes management

To define a password, installation of the parameters

y1

Error messages

Error messages

13

a. Paramters: system y0

Code

Designation

Range

Factory value

Modification

when the

motor is ON

y0.00

Factory settings

No reset

0

0

No

Reset of the basic

parameters except

parameters motor

1

Historic disappearance

2

Reset of the users

parameters with

parameters motor

3

Saving of the actual users

parameters

4

b. Parameters: motor b0

Code

Designation

Range

Factory value

Modification

when the

motor is ON

b0.01

Nominal power

0,1Kw to 1000,0kW

Depending on

the model

No

b0.02

Nominal voltage

1V to 2000V

Depending on

the model

No

b0.03

Nominal current

electric

0,01A to 655,35A for inverter ≤55kW

Depending on

the model

No

b0.04

Nominal

frequency

0,01Hz to F0.19 (max. frequency)

Depending on

the model

No

b0.05

Nominal speed

1rpm to 3600rpm

Depending on

the model

No

14

c. Standard parameters

Code

Designation

Range

Factory value

Modification

when the

motor is ON

F0.00

Control mode

Vector control without

return coder

0

2

No

Control V/F

1

Torque control

2

F0.01

High limit of

frequency

instruction

0.00Hz to F0.19 (maximum

frequency)

50.00 Hz

No

F0.03

Main piloting of

the frequency

Analog input AI1

2

0

Yes

Analogue input AI2

3

Screen potentiometer

4

Multi-speed

6

F0.11

Start-up mode

RUN/STOP keyboard

(LED Local/Remot Off)

0

0

Yes

Control terminal block

(LED Local/Remote On)

1

Modbus communication

(LED Local/remote)

2

F0.13

0.00s to 6500s

-

Yes

F0.14

Acceleration time

0.00s to 6500s

-

F0.19

Deceleration time

50.00Hz 320.00Hz

50.00Hz

No

F0.21

Maximum limit

output frequency

De F0.23(min) F0.19(max)

50.00Hz

Yes

F0.23

Minimum limit

output frequency

De 0.00Hz F0.21 (max)

0.00Hz

Yes

15

d. Input settings

Code

Designation

Range

Factory value

Modification

when the

motor is ON

F1.00

Input terminal

block DI1

0 to 50

1

No

F1.01

Input terminal

block DI2

0 to 50

2

F1.02

Input terminal

block DI3

0 to 50

8

F1.03

Input terminal

block DI4

0 to 50

9

F1.04

Input terminal

block DI5

0 to 50

12

F1.05

Input terminal

block DI6

0 to 50

13

F1.06

Input terminal

block DI7

0 to 50

0

F1.07

Input terminal

block DI8

0 to 50

Setting

value

Function

Description

0

No function

No action of the inverter

1

Direction of rotation forward( FWD)

Choice of direction of rotation

2

Direction of rotation reverse(REV)

3

Control mode 3 electric wires

For more details look at the instructions of the functions

code F1.10

4

Mode : JOG Forward

Control in JOG mode

5

Mode: JOG Reverse

6

Frequency increase

Change the frequency of the increment/decrement

control when the digital setting is selected as the

frequency control (F0.03=0 or 1)

7

Frequency decrease

8

Stop "Freewheel"

The motor stops on his own.

9

Reset of a defect

To restore an inverter defect

10

Break is functionning

The inverter stops but all the parameters are stored, as

the acceleration/deceleration and instruction frequency.

When the break is over, the inverter restarts.

11

External defect : input open

When the signal is sent to the inverter, it refers to the

Err.15, and it makes the repair according to the chosen

protection action on F8.17

12

Multi-speed : terminal 1

The speed setting can be done by 16 settings predefined

and controlled through 4 input terminals. For more

details, look at the table 1.

13

Multi-speed : terminal 2

14

Multi-speed : terminal 3

15

Multi-speed : terminal 4

16

16

Acceleration / deceleration time:

terminal 1

The selection of the 4 acceleration/deceleration can be

chosen by ON/OFF.

For more details, look at the table 2

17

Acceleration / deceleration time:

terminal 2

18

Tilt of the frequency pilotage

Allows switching between different pilotage modes of the

frequency. The terminal is used to commute between two

frequency mode, depening on the selection of the

frequency source parameter (F0.07)

19

Up/Down setting

When the reference frequency is digital, this terminal is

used to erase the frequency value modified by the

terminal UP/DOWN, in such a way that reference

frequency can recover the instruction value (F0.01)

20

Terminal block control communication

When the control is set on the terminal block (F0.11=1),

the terminal can be used to commute between the

terminal block control and the keyboard control. When

the control is set on the control communication (F0.11=2),

the terminal can be used to switch between the control by

Modbus communication and keyboard control

21

Acceleration / deceleration

prohibited

Make sure that the inverter is free of internal signals. This

function maintain the current output frequency

22

Break of the PID regulation

The PID regulation is temporally desactivated, the inverter

maintain the actual output frequency.

23

Reset of the controller

When the controller stops and starts again, this terminal is

used to reset the inverter.

24

Rebalancing break

When the inverter will give in output the half of the

frequency, the rebalancing will be in break.

25

Counter input

Impulsion input terminal of counting

26

Reset of the meter

Erase the actual value of the counter

27

Counting input of the length

Input terminal of the length of counting

28

Reset length

Erase the actual value of the length

29

Torque control prohibited

When the torque control is prohibited, the inverter switch

in speed control mode.

30

High speed pulse input

(only for DI5)

DI5 is used as pulse inputs terminals.

31

Reserve

32

Immediate release of the DC brake

If the input is activated, the inerverter switch to braking

stage DC.

33

External defect, input closed

When the external defect signal is put in the inverter, the

inverter reports this signal and stops.

34

Validation of the frequency switch

If the input is activated, and if the frequency instructiong

changes, the inverter doesn’t react to these frequency

modifications until the input is no longer activated.

17

35

Reverse effect of the PID action

If the input is validated,the opposite effect of the PID

action will be opposed to the direction set by E2.03

36

External stationing input 1

In mode keyboard control, a terminal block input can be

used to stop the inverter, such as the STOP touch on the

keyboard.

37

Commutator of the terminal 2 control

Allows commuting between the terminal block control

and the Modbus communication. If the control source is

selected by the terminal block, the system will be on

mode control by Modbus communication when the

terminal block input is activated and vice versa.

38

Break of the PID integral

When the input is activated, the integral function of the

PID is on break, but the proportional and differential

changes of the PID are still valuable.

39

Commute between the main

frequency and the preset frequency

When the input is activated, the frequency source A is

replaced by the preset frequency F0.01

40

Commute between the source

frequency and the preset frequency

When the input is activated, the frequency source B is

replaced by the preset frequency F0.01

41

Reserve

42

Reserve

43

Communication of the PID parameters

The DI terminal (E2.19 = 1) is used to commute the PID

parameters. If the terminal is not valid, the PID uses the

the parameters E2.13 to E2.15, and if the terminal is valid,

the PID uses the parameters E2.16 to E2.18

44

Preset defect 1

When the preset defect 1 or 2 is assets, the inverter

performs the alarm defect Err.27 and Err.28.

And depending on the selected mode by the protection

action F8.19

45

Preset defect 2

46

Communication of the speed control /

torque

Commute between the speed control mode and the

torque control mode in mode vectorial control. If the

input is not valid, the inverter works in preset mode by

E0.00, if the input is valid, the inverter will work on an

other mode.

47

Energency stationing

If the input is validated, the inverter is setting at the

maximum speed, and the electric current is maintained at

the upper limit during the stationing time. This function is

used to answer at the requirements that the inverter have

to stops when the system is in emergency state.

48

Terminal stationing 2

In any control mode, the terminal can be used to slow

down the inverter until the stop, the deceleration time is

set on: time 4 (F7.13)

49

Deceleration with injection of the

direct current

When the input is valid, the inverter decelerates at the

initial frequency of braking, and truns automatically on DC

braking.

50

Erasing of the running time

If the inverter input is active, the running time is erased,

this mode have to perform with (F7.42=1) and the the

running time (F7.45)

18

e. Table 1: Multi-speed

K4

K3

K2

K1

Control setting

Parameters

OFF

OFF

OFF

OFF

Speed 0 Setting 0X

E1.00

OFF

OFF

OFF

ON

Speed 1 Setting 1X

E1.01

OFF

OFF

ON

OFF

Speed 2 Setting 2X

E1.02

OFF

OFF

ON

ON

Speed 3 Setting 3X

E1.03

OFF

ON

OFF

OFF

Speed 4 Setting 4X

E1.04

OFF

ON

OFF

ON

Speed 5 Setting 5X

E1.05

OFF

ON

ON

OFF

Speed 6 Setting 6X

E1.06

OFF

ON

ON

ON

Speed 7 Setting 7X

E1.07

ON

OFF

OFF

OFF

Speed 8 Setting 8X

E1.08

ON

OFF

OFF

ON

Speed 9 Setting 9X

E1.09

ON

OFF

ON

OFF

Speed 10 Setting 10X

E1.10

ON

OFF

ON

ON

Speed 11 Setting 11X

E1.11

ON

ON

OFF

OFF

Speed 12 Setting 12X

E1.12

ON

ON

OFF

ON

Speed 13 Setting 13X

E1.13

ON

ON

ON

OFF

Speed 14 Setting 14X

E1.14

ON

ON

ON

ON

Speed 15 Setting 15X

E1.15

f. Table 2: Piloted acceleration and deceleration

Input 2

Input 1

Acceleration and deceleration time

Parameters

OFF

OFF

Time 1

F0.13 and F0.14

OFF

ON

Time 2

F7.08 and F7.09

ON

OFF

Time 3

F7.10 and F7.11

ON

ON

Time 4

F7.12 and F7.13

g. Control modes

Code

Designation

Mode

Range

Factory value

Changing : motor

ON

F1.10

Control by terminal

block

Two electric wires type 1

0

0

No

Two electric wires type 2

1

Three electric wires type 1

2

Three electric wires type 2

3

19

This parameter defines 4 different modes to control the inverter functioning by input terminal blocks.

0: Two electric wires type 1

This mode is the most used. The function FWD / REV of the motor is determined by DI1, DI2.

The terminal function is set like that:

Terminal block input

Value to be chosen

Description

DI1

1

(FWD)

DI2

2

(REV)

DI1 and DI2 are the multifunction input from DI1 to DI6.

Setting:

F0.11=4 (Inverter control by terminal block + keyboard)

F1.10=0 (Two electric wires type 1)

F1.00=1 (DI1 FWR)

F1.01=2 (DI2 REV)

1: Two electric wires type 2

In this case, DI1 allows the rotation and the forward direction, while DI2 is used to activate the reverse direction.

The terminal function is set like that:

Terminal block input

Value to be chosen

Description

DI1

1

(FWD)

DI2

2

(REV)

DI1 and DI2 are the multifunction input from DI1 to DI6.

K1

K2

Control

0

0

Stop

0

1

Stop

1

0

(FWD)

1

1

(REV)

Setting:

F0.11=4 (Inverter control by terminal block + keyboard)

F1.10=0 (Two electric wires type 2)

F1.00=1 (DI1 FWR)

F1.01=2 (DI2 REV)

K1

K2

Control

0

0

Stop

0

1

(FWD)

1

0

(REV)

1

1

Stop

20

2: Three electric wires type 1

In this case, DI2 is used to allow the pilotage by impulsion with DI1 or DI2.

The terminal function is set like that:

Terminal block input

Value to be chosen

Description

DI1

1

(FWD)

DI2

3

authorization of the pilotage by impulsion 3

electric wires type 1

DI3

2

(REV)

To start DI2 must be closed. The forward or reverse rotation is controlled by per pulse on DI1 or DI3.

To stop, you need disconnect DI2 with a pulse.

DI2 and DI3 are the multifunction inputs terminals from DI1 to DI6.

So:

SB1: Stop button

SB2: Forward button

SB3: reverse button

Setting:

F0.11=4 (Inverter control by terminal block + keyboard)

F1.10= 2(Three wires electric type 1)

F1.00=1 (DI1 FWD)

F1.01=3 (DI2 authorization of the pilotage by impulsion)

F1.02=2 (DI3 REV)

3: Three electric wires type 2

In this mode, DI2 is used to allow the pilotage by impulsion with DI1 or DI2.

The terminal function is set like that:

Terminal input

Value to be

chosen

Description

DI1

1

Forward rotation (FWD)

DI2

3

Authorization of the pilotage by impulsion 3 wires type

2

DI3

2

Reverse rotation (REV)

To start, DI2 must be closed. The starting up of the motor is controlled by impulsion on DI1 and the DI3 input

reverse the direction of rotation while the contact is maintained and that DI2 is still closed.

To stop, you have to disconnect DI2 by impulsion.

DI1, DI2 and DI3 are the multifunction inputs terminals from DI1 to DI6.

SB3

Control

0

Forward (FWD)

1

Reverse (REV)

Setting:

F0.11=4 (Inverter control by terminal block + keyboard)

F1.10= 3(Three wires electric type 2)

F1.00=1 (DI1 FWD)

F1.01=3 (DI2 authorization of the pilotage by impulsion)

F1.02=2 (DI3 REV)

FWD

STOP

REV

FWD

STOP

REV

Table of contents

Popular DC Drive manuals by other brands

Danfoss

Danfoss VLT Micro Drive FC 51 Series Design guide

Danfoss

Danfoss VLT FC 103 instruction manual

PR electronics

PR electronics 9107 product manual

SEW-Eurodrive

SEW-Eurodrive Movidrive MDX61B System manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 6000 user manual

Perception

Perception PEDAL DRIVE quick start guide