InoTec inoMIX S16 Installation instructions

EN

Read this entire original operating manual before starting work.

Original Operating Manual

inoMIX S16 continuous mixer

EN

Page 2 Page 3

Thank you for trusting INOTEC. By purchasing you have opted for a quality product.

If you have any suggestions or any issues, we would be delighted to hear your suggestions for improvement

and your feedback. Speak to the sales representative assigned to you or, in urgent cases, contact us directly.

We work constantly to further develop our products and reserve the right to make changes for technical reasons

relating to building legislation.

Yours faithfully

INOTEC GmbH

Legal notice

Address: INOTEC GmbH

Daimlerstraße 9-11

79761 Waldshut-Tiengen

Germany

Tel.: +49 (0)7741 6805 666

Fax: +49 (0)7741 6805 665

Web: www.inotec-gmbh.com

Last updated: August 2021

Document number: 10039462-OBA-EN

Contents

1 General information.................................................................................................................................. 5

1.1 Information about this manual ........................................................................................................................5

1.2 Symbol explanation ..........................................................................................................................................5

1.3 Information about this manual ........................................................................................................................5

1.3.1 Purpose of this operating manual...................................................................................................................................5

1.3.2 Disclaimer ......................................................................................................................................................................5

1.3.3 Warranty........................................................................................................................................................................5

1.3.3.1 Exercising claims .........................................................................................................................................................5

1.3.3.2 Warranty claims ..........................................................................................................................................................6

1.3.4 Carrying out repairs .......................................................................................................................................................6

2 Safety.......................................................................................................................................................... 6

2.1 Intended use ......................................................................................................................................................6

2.2 General risk sources...........................................................................................................................................6

2.2.1 Notices in the operating manual.....................................................................................................................................7

2.2.2 Performing checks before starting work .........................................................................................................................7

2.2.3 Conversions and changes...............................................................................................................................................7

2.2.4 Cleaning and maintaining the machine ..........................................................................................................................7

2.2.5 Changing the location of the machine ...........................................................................................................................7

2.3 Notices on the machine ....................................................................................................................................8

2.4 Personnel qualification......................................................................................................................................8

2.5 Responsibility of the operator..........................................................................................................................8

2.6 Personal protective equipment (PPE) ...............................................................................................................8

3 Technical data............................................................................................................................................. 9

3.1 Rating plate .......................................................................................................................................................9

3.2 Electrical control system, mixing rate, weight, dimensions ...........................................................................9

3.3 Water measuring system...................................................................................................................................9

3.4 Material hopper .................................................................................................................................................9

3.5 Motor..................................................................................................................................................................9

3.6 Metering shaft ...................................................................................................................................................9

3.7 Mixing shaft .......................................................................................................................................................9

3.8 Noise emissions..................................................................................................................................................9

3.9 Operating conditions.........................................................................................................................................9

4 Assembly and function ........................................................................................................................... 10

4.1 Scope of delivery of inoMIX S16 (item no. 10039462) ..................................................................................10

4.2 Functionality ....................................................................................................................................................10

4.3 Components .....................................................................................................................................................10

4.3.1 Description of the components ....................................................................................................................................10

4.3.1.1 Main frame with material hopper incl. metering shaft and wheels.............................................................................10

4.3.1.2 Control system..........................................................................................................................................................10

4.3.1.3 Water measuring system ...........................................................................................................................................11

4.3.1.4 Motor .......................................................................................................................................................................11

4.3.1.5 Mixing pipe and mixing shaft with mixing pipe cover ................................................................................................11

4.4 Displays and controls ......................................................................................................................................11

4.4.1 Water measuring system ..............................................................................................................................................11

4.4.2 Installing the water measuring system..........................................................................................................................11

4.4.3 Metering shaft ............................................................................................................................................................11

4.4.4 Mixing pipe and mixing shaft .......................................................................................................................................12

4.4.5 Motor ..........................................................................................................................................................................12

4.5 Connections......................................................................................................................................................12

4.5.1 Power connection (230 V) ...........................................................................................................................................12

4.5.2 Power connection of the motor....................................................................................................................................12

4.5.3 Water fitting connections.............................................................................................................................................12

4.6 Operating modes .............................................................................................................................................12

4.7 Accessories .......................................................................................................................................................13

4.8 Spare parts and diagrams ...............................................................................................................................14

4.8.1 Overview of inoMIX S16...............................................................................................................................................14

4.8.2 Water measuring system spare parts list .......................................................................................................................15

4.8.3 Metering shaft .............................................................................................................................................................16

4.8.4 Mixing pipe with mixing shaft and mixing pipe cover (item no. 10039949)...................................................................16

Page 5

EN

Chapter 1 General information

EN

Page 4

1 General information

1.1 Information about this manual

• This manual helps to ensure safe and efficient use of

the machine.

• Operating personnel must have carefully read through

and understood this manual before starting any work.

• Compliance with all the specified safety instructions is

a basic prerequisite for working safely.

• This manual is a component of the machine and must

be stored within direct proximity of the machine, acces-

sible to operating personnel at all times.

• In addition to the notices in these instructions, the local

accident prevention guidelines and national occupa-

tional health regulations also apply.

1.2 Symbol explanation

Hazard notices feature symbols to make them easier to

identify. These indicate the severity of the hazard.

• You must observe this information.

!

DANGER DANGER indicates an immediate hazard.

Death or serious injuries may result from non-compliance.

!

WARNING WARNING indicates a potentially dangerous

situation. Death or serious injuries may result from a failure

to avoid these situations.

!

CAUTION CAUTION indicates a potentially dangerous

situation. Minor or slight injuries may result from failure to

avoid these situations or damage to the machine or some-

thing in its vicinity.

NOTE

NOTICE draws your attention to useful tips for

effectively handling the machine.

1.3 Information about this manual

1.3.1 Purpose of this operating manual

The operating manual is used to provide information to the

operating manager, assembly fitters and machine operators

on the construction site. It contains important instructions

for safe use, optimum results and a long service life.

!

DANGER Risk of incorrect operation

Failure to observe the operating manual could put the

operator’s life and health at risk and damage the ma-

chine.

• Read this operating manual carefully before passing it

on to your assembly fitters or operators.

• Please ensure that assembly fitters and operators read

this operating manual carefully before they start install-

ing and commissioning the machine.

• Always keep the operating manual to hand and in a leg-

ible condition.

1.3.2 Disclaimer

All technical information, data and instructions for use con-

tained in this operating manual reflect the state of the art at

the time of printing and are based on our experience thus

far and the best of our knowledge.

The manufacturer cannot be held liable for any damages as

a result of:

• Failure to comply with this manual

• Improper use

• Assignment of non-trained personnel

• Unauthorised alterations

• Technical changes

• Use of non-approved spare parts

1.3.3 Warranty

Statutory warranty periods of 12 months from the date of

purchase/the date of invoice of the industrial end customer

apply to our machinery.

1.3.3.1 Exercising claims

In the event of a warranty claim, send the entire machine,

along with the invoice, to our headquarters in Wald-

shut-Tiengen.

Contact our free INOTEC service

hotline beforehand on +49 7741 6805 777.

4.8.5 Mixing pipe cover for mixing pipe (item no. 10039950)................................................................................................17

4.8.6 Mixing shaft for mixing pipe (item no. 10039948)........................................................................................................17

4.8.7 Drive unit (item no. 10039958) ....................................................................................................................................18

5 Transport and storage ............................................................................................................................. 19

5.1 Safety notices for transport............................................................................................................................19

5.2 Transport inspection........................................................................................................................................19

5.3 Damage report.................................................................................................................................................19

5.4 Complaints .......................................................................................................................................................19

5.5 Packaging .........................................................................................................................................................19

5.6 Transport of the used machine in vehicle......................................................................................................19

5.7 Storage .............................................................................................................................................................19

6 Installation ............................................................................................................................................... 20

6.1 Delivery condition of the machine .................................................................................................................20

6.2 Connecting the metering shaft and motor....................................................................................................20

6.3 Assembling the mixing pipe and mixing shaft..............................................................................................20

6.4 Connecting the electrical control system.......................................................................................................21

6.5 Installing the water measuring system..........................................................................................................21

7 Commissioning ....................................................................................................................................... 22

7.1 Adding material to the material hopper........................................................................................................22

7.2 Opening and emptying bags of material.......................................................................................................22

7.3 Commissioning inoMIX S16 ............................................................................................................................22

7.4 Function after commissioning ........................................................................................................................22

7.5 Changing material ...........................................................................................................................................22

7.6 Change of location on the construction site .................................................................................................22

8 Operation, use.......................................................................................................................................... 23

8.1 Checking operating performance...................................................................................................................23

8.2 Checking the consistency of the material......................................................................................................23

8.3 Correcting flow fluctuations...........................................................................................................................23

8.4 Work break.......................................................................................................................................................23

8.5 End of work......................................................................................................................................................24

8.5.1 Switching off the machine ...........................................................................................................................................24

8.5.2 Dismantling and cleaning the mixing pipe and mixing shaft..........................................................................................24

8.5.3 Dismantling the motor und metering shaft...................................................................................................................24

9 Cleaning and decommissioning ............................................................................................................. 24

9.1 Cleaning process ..............................................................................................................................................24

9.2 After cleaning ..................................................................................................................................................25

9.3 Decommissioning.............................................................................................................................................25

9.3.1 Running the machine until it is empty and switching it off............................................................................................25

9.3.2 Mixing pipe and mixing shaft with mixing pipe cover ...................................................................................................25

9.3.3 Water measuring system ..............................................................................................................................................25

9.3.4 Dismantling the motor and metering shaft...................................................................................................................25

10 Maintenance........................................................................................................................................... 26

10.1 Maintenance plan ..........................................................................................................................................26

10.2 Dirt trap sieve in the water inlet ..................................................................................................................26

10.3 Dirt trap sieve in the pressure reducing valve.............................................................................................26

10.4 Wear limit for metering shafts .....................................................................................................................27

10.5 Wear limit for mixing shafts .........................................................................................................................27

11 Faults, causes and solutions ................................................................................................................. 27

12 Dismantling and disposal ..................................................................................................................... 29

12.1 Safety..............................................................................................................................................................29

12.2 Dismantling ....................................................................................................................................................29

12.3 Disposal ..........................................................................................................................................................29

13 Systems................................................................................................................................................... 30

13.1 EC declaration of conformity ........................................................................................................................30

13.2 General Terms of Business of the company INOTEC GmbH........................................................................31

13.3 Circuit diagram for inoMIX S16 ...................................................................................................................32

14 Order form.............................................................................................................................................. 33

15 Index ....................................................................................................................................................... 34

16 Locations ................................................................................................................................................ 35

Page 6 Page 7

EN EN

Chapter 2 Safety Chapter 2 Safety

1.3.3.2 Warranty claims

Claims apply only where material or manufacturing faults

exist and where machinery has been used properly. Wear

parts are not covered by the warranty. All claims shall be-

come void if third-party parts are installed, where the ma-

chinery has been improperly used or stored and in the event

of obvious non-compliance with the operating manual. In

this connection, we refer you to our General Terms of Busi-

ness.

1.3.4 Carrying out repairs

Repairs may only be carried out by employees at our

INOTEC service centres.

2 Safety

2.1 Intended use

You may only operate this machine if the following

conditions are met:

• The inoMIX S16 is suitable for processing all factory

pre-mixed and machine-compatible dry mortars. Load

the continuous mixer only with dry goods (e.g. bagged

goods).

• Only use the machine within its limits of application

and according to the technical data.

• Pay particular attention to the safety and warning

notices outlined in this original operating manual.

!

DANGER Failure to use the inoMIX S16 properly

could put the user’s life and limb at risk and damage

the inoMIX S16 or other assets.

!

WARNING Danger due to misuse!

Improper use of the inoMIX S16 can lead to hazardous

situations.

• Never use the inoMIX S16 continuous mixer to create

other products, such as food.

• Never operate the inoMIX S16 continuous mixer us-

ing values out of the ranges specified in the “Technical

Data”.

2.2 General risk sources

!

DANGER Electrical voltage.

Danger of death due to electric shock.

• Work on the electronic control system may only be per-

formed by a qualified electrician.

• Switch off the machine and pull out the mains plug.

• Secure the machine against unexpectedly being switched

back on.

!

DANGER Rotating shaft.

Danger of death due to being pulled into the machine

and crushed.

When the motor is running, the metering shaft ro-

tates, even if the mixing pipe has been removed with

the mixing shaft!

• Do not reach into the rotating shaft.

• Do not place any objects into the rotating shaft.

1. Before working on the metering and mixing shaft, inter-

rupt the external power supply.

2. To do this, press the red pushbutton.

3. Pull out the mains plug.

4. Secure the machine against unexpectedly being switched

back on.

!

WARNING Water jet.

Risk of injury and risk of property damage due to es-

caping water.

1. Interrupt the external water supply by closing the water

valve.

2. In order to release the pressure (approx. 2 bar), open the

water drainage valve on the water measuring system.

3. Remove the hose from the external water supply.

4. Do not point the water jet at other people or yourself.

2.2.1 Notices in the operating manual

!

CAUTION Safety notices in the operating manual

alert the operating personnel to any immediate dan-

ger. Please observe all the technical and hazard notic-

es in this operating manual.

2.2.2 Performing checks before starting work

!

WARNING Defects or damage can put the safety of

operating personnel at risk and impair the functional-

ity of the machine.

• Before commencing work, check the machine for any

obvious external damage or defects.

• Do not commission the machine if you notice any dam-

age to or defects in the machine.

• Ensure that the damage and/or defects are rectified.

2.2.3 Conversions and changes

!

DANGER Conversions or changes can put the safe-

ty of operating staff at risk and impair the functional-

ity of the machine.

• Do not make any changes, additions or conversions to

the machine without first consulting Inotec GmbH and

obtaining its written approval. Otherwise, the operat-

ing license will become void.

2.2.4 Cleaning and maintaining the machine

!

WARNING Cleaning and maintenance work can put

the safety of operating staff at risk and impair the

functionality of the machine.

1. Switch off the machine and pull out the mains plug.

2. Secure the machine against unexpectedly being

switched back on.

3. Before cleaning with the water jet, cover all the open-

ings that water must not penetrate into for safety and

functional reasons.

4. After cleaning, remove all the covers which were at-

tached to protect against the water.

2.2.5 Changing the location of the machine

!

CAUTION Changing location can put the safety of

operating staff at risk and impair the functionality of

the machine.

1. Switch off the machine and pull out the mains plug.

2. Lift the machine up using the mixing pipe and place it

in a new location on the building site.

3. Always install the machine in such a way that it is level

and stable.

4. Secure the machine against undesirable movements.

5. Reconnect the machine to the external power supply

before restarting the machine.

Page 8 Page 9

EN EN

Chapter 2 Safety Chapter 3 Technical data

2.4 Personnel qualification

INOTEC offers training sessions on operating the inoMIX

S16. Use INOTEC service for the initial commissioning of

the machine; this also serves as an opportunity to provide

operators with training on how to operate the mixer.

!

DANGER If the inoMIX S16 is operated by unqual-

ified individuals, this could put the life and health of

the operating staff at risk and cause property damage

to the inoMIX S16 or other assets.

2.5 Responsibility of the operator

• Only task trained or instructed staff with operating the

inoMIX S16.

• Define employees’ responsibilities for operating, setting

up, maintaining and servicing the machine clearly.

• Only task untrained staff or individuals who have not re-

ceived any instruction with operating the machine when

there is a trained or instructed specialist available to su-

pervise them.

• Work on the electronic control system may only be per-

formed by a qualified electrician.

2.6 Personal protective equipment (PPE)

!

CAUTION PPE – particularly gloves, safety boots, a

safety helmet and safety goggles and respiratory pro-

tection – must be used.

2.3 Notices on the machine

!

DANGER Safety notices on the machine make oper-

ating staff aware of imminent danger.

The following warning notices are affixed to the inoMIX

S16:

• WARNING. Do not reach into the machine (1).

• If there is a risk of frost, drain the water (2).

• This QR code will take you to the original operating man-

ual of the mixer (3).

• The machine may only be operated via a connector pro-

tected with an RCD (FI) IΔn ≤ 30 mA (4).

• Observe all the safety and hazard notices that are at-

tached to the machine.

• Always keep the safety and hazard notices in a clearly

legible condition.

Safety notice to

the right of the

GEKA coupling

Safety notice

under the rating

plate

1

QR code

on the

motor side

3

Safety note on the

power input

2

4

3 Technical data

3.1 Rating plate

1

5

4

23

Item Component Value

1 Manufacturer, address and contact

details, CE marking

-

2 Name and type of machine -

3 Machine’s year of construction -

4 Machine number -

5Technical data

- Voltage

- Current

- Output

230 V

16 A

1.1 kW

You must always state the machine number if you would

like to order spare parts, have any queries or would like

to make a complaint. You will find this information on the

rating plate or on the delivery note.

3.2 Electric control system, pump output, particle size,

weight, dimensions

Mains voltage 230 V, 50 Hz

Mains supply line (CEE plug) 16 A (to be supplied by

customer)

Output 1.1 kW

Fuse min. 16 A

Mixing capacity max. 16 l/min.*

Weight approx. 58 kg

Dimensions:

Length without mixing pipe 1,030 mm

Length of mixing pipe 500 mm

Width 600 mm

Height 890 mm

* Material-dependent – observe the material manufacturer’s instructions.

3.3 Water measuring system

Pressure being too low From 2 to 6 bar

Pressure reducer

ex-works setting

2.5 bar

Solenoid valve 230 V, 50 Hz

Supply line ¾ inch water pipe

(to be supplied by

customer)

3.4 Material hopper

Fill quantity max. 45 l

3.5 Motor

Output/rotation speed 1.1 kW, 387 U/min-1

Installation position Motor horizontal

Electrical data f = 50 Hz , I = 7 A,

U = 230 V, IP 55

Insulation class F, ED = S1

Colour unvarnished

3.6 Metering shaft

Diameter 51 mm

Diameter

(wear limit)

45 mm

3.7 Mixing shaft

Maximum height of mixer

blades:

55 mm

Minimum height of mixer

blades

(wear limit)

50 mm

3.8 Noise emissions

Guaranteed sound power

level LWA

78 dB (A)

3.9 Operating conditions

Temperature range 2 - 45 °C

Relative humidity, maximum 80 %

Page 10 Page 11

EN EN

Chapter 4 Assembly and function Chapter 4 Assembly and function

4 Assembly and function

4.1 Scope of delivery of inoMIX S16 (item no. 10039462)

The scope of delivery is generated using the components

ordered and can be checked using the delivery note.

• Frame

• 2 running wheels

• Material hopper

• Gear motor

• PU mixing pipe

• Mixing shaft

• metering shaft

• Water fitting

• Operating manual

4.2 Functionality

The continuous mixer is filled with bagged goods as stan-

dard. The mixing and metering shafts are directly driven by

a gear motor. During operation, the dry material is con-

veyed from the material hopper into the mixing pipe via the

metering shaft. In the mixing pipe, the dry material − with

the addition of water − is mixed using the mixing shaft, to

form a homogeneous, paste-like product, and is conveyed

out of the mixing pipe.

NOTE

Note the optimum assembly sequence.

1. Push the metering shaft into the main frame.

2. Attach the motor to the material hopper by means of

the quick-release fastener, and ensure that the metering

shaft is connected to the motor via the motor bracket.

3. Insert the motor plug into the machine’s socket.

4. Assemble the mixing pipe by using both eccentric fas-

tenings on the main frame and push the mixing shaft

with the mixing pipe cover into the mixing pipe. En-

sure that the mixing shaft is connected to the metering

shaft.

5. To lock the mixing pipe cover, turn it clockwise so that

both ball heads lock in the recesses provided in the steel

frame.

6. Connect the main switch to the external power supply

(230 V / 16 Hz)

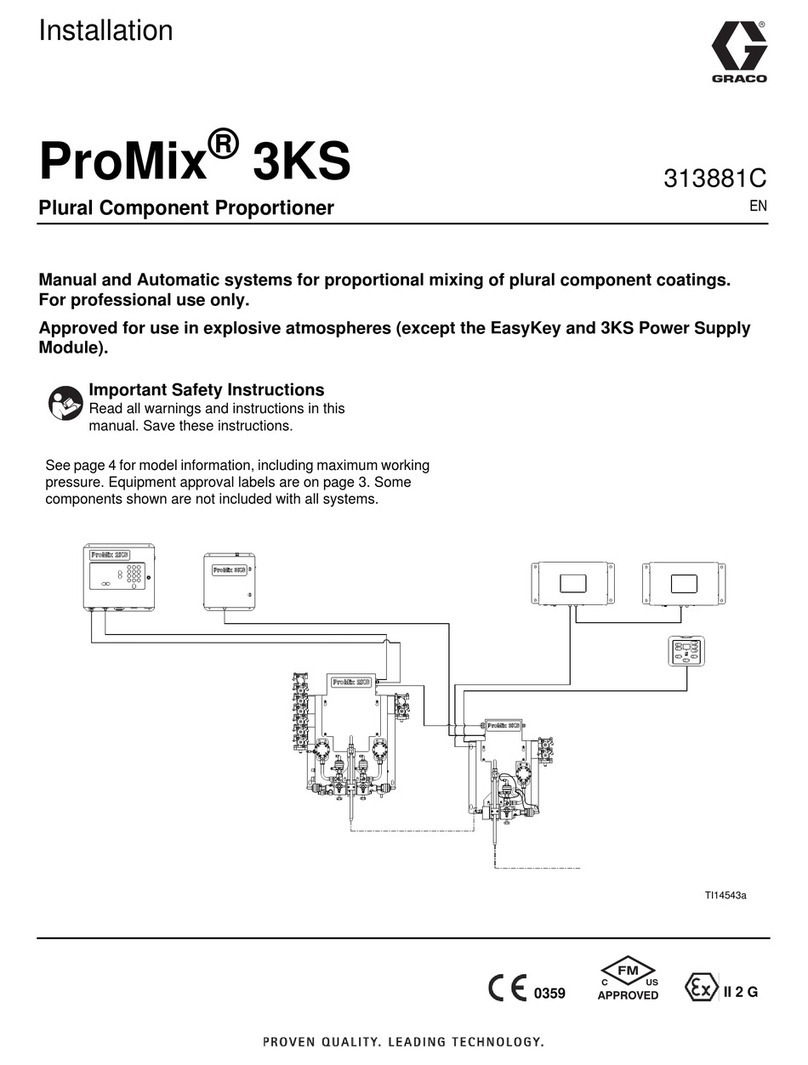

4.3 Components

1

2

3

4

5

4.3.1 Description of the components

Item Component

1 Main frame with material hopper

incl. metering shaft and wheels

2 Control system

3 Water measuring system

4 Motor with motor covering

5 Mixing pipe incl. mixing shaft

4.3.1.1 Main frame with material hopper incl. meter-

ing shaft and wheels

The socket for the motor, main switch and water measuring

system are attached to the main frame. Push the metering

shaft into the main frame. The motor is attached to the

main frame by the quick-release fastener and the mixing

pipe by two eccentric fastenings. Finally, push the mixing

shaft with the mixing pipe cover into the mixing pipe. To

lock the mixing pipe cover, turn it clockwise so that both

ball heads lock in the recesses provided in the steel frame.

Material hopper with hopper mesh, toothed rail and

metering shaft

4.3.1.2 Control system

Connect the main switch to the external power supply (230

V / 50 Hz). The cross-section of the supply cable must be

at least 2.5 mm2! The inoMIX S16 may only be run with an

approved FI circuit breaker (30 mA) (RCD).

4.3.1.3 Water measuring system

The water measuring system is attached to the main frame.

The optimum water quantity is set by opening and closing

the needle valve.

4.3.1.4 Motor

The motor is attached to the main frame together with the

motor cover by a quick-release fastener. The CEE plug of

the motor is plugged into the socket on the main frame.

The metering shaft previously pushed into the main frame

is connected to the motor bracket attached to the motor.

4.3.1.5 Mixing pipe and mixing shaft with mixing pipe

cover

Assemble the mixing pipe by using both eccentric fasten-

ings on the main frame and push the mixing shaft with

the mixing pipe cover into the mixing pipe. Ensure that the

mixing shaft is connected to the metering shaft. To lock the

mixing pipe cover, turn it clockwise so that both ball heads

lock in the recesses provided in the steel frame.

4.4 Displays and controls

1

2

Electronic fitting with green pushbutton (1) to switch on the

machine, and red pushbutton (2) to switch off the machine

4.4.1 Water measuring system

43

16

25

Description of the components in the diagram

Item Component

1 Water drainage valve

2 Needle valve

3 Pressure reducer

4 GEKA coupling with sieve insert

(external water connection)

5 Solenoid valve

6 Pressure gauge

WARNING Water jet.

Risk of injury and risk of property damage due to es-

caping water.

• Do not point the water jet at other people or yourself.

4.4.2 Installing the water measuring system

1. Connect the supply hose to the external water supply.

2. Open the water valve until a steady water jet comes out

of the hose in order to both clean the water hose of dirt

and ventilate it.

3. Then close the valve on the external water supply.

4. Connect the external water hose to the GEKA coupling

of the water fitting.

5. Connect the water drainage valve to the water fitting.

6. Connect the internal water hose to the mixing pipe.

4.4.3 Metering shaft

The metering shaft is connected to the motor via motor

bracket and rotates during operation in the main frame.

The mixing shaft is also connected to the metering shaft via

a plug-in connection. The metering shaft can be pulled out

for cleaning and maintenance work.

This image illustrates the connection from the motor

(right) to the metering shaft, and from the metering shaft

to the mixing shaft.

Page 12 Page 13

EN EN

Chapter 4 Assembly and function Chapter 4 Assembly and function

4.4.4 Mixing pipe and mixing shaft

The mixing shaft is firmly screwed to the mixing pipe cov-

er. The mixing shaft is connected to the metering shaft via

a plug-in connection. The mixing shaft in the mixing pipe

rotates during operation. It is protected from tampering

by the mixing pipe cover. The mixing shaft alongside the

mixing pipe cover can be pulled out of the mixing pipe for

cleaning and maintenance work.

!

DANGER Rotating shaft.

Danger of death due to being pulled into the ma-

chine and crushed.

When the motor is running, the metering shaft ro-

tates, even if the mixing pipe has been removed with

the mixing shaft!

• Do not reach into the rotating shaft.

• Do not place any objects into the rotating shaft.

1. Before working on the metering and mixing shaft, inter-

rupt the external power supply.

2. To do this, press the red pushbutton.

3. Pull out the mains plug.

4. Secure the machine against unexpectedly being switched

back on.

4.4.5 Motor

!

DANGER Electrical voltage

Danger of death due to electric shock.

1. Work on the electronic control system may only be per-

formed by a qualified electrician.

2. Switch the machine off. To do this, press the red push-

button.

3. Pull out the mains plug.

4. Secure the machine against unexpectedly being switched

back on.

4.5 Connections

4.5.1 Power connection (230 V)

AC (alternating current) connection (230 V).

4.5.2 Power connection of the motor

CEE plug of the motor in the socket

4.5.3 Water fitting connections

1

2

Connection of the external water supply (1), connection of

the mixing pipe to the water supply (2).

4.6 Operating modes

The ready-mixed material can be filled into any container

(bucket, wheelbarrow, etc.).

4.7 Accessories

The following accessories can be supplied for the inoMIX S16.

230 V extension cable, 3 x 2.5 mm², length 10 m,

16 A, Schuko plug and socket

Item no.

10015208

PU mixing pipe for inoMIX S16

Including mixing shaft, mixing pipe cover and holders

Mixing shaft

Complete metering shaft with two dowel pins (M8 x 50)

Item no.

10039949

10039948

10039947

Water metering pipe with holder for inoMIX S16

For visual control of the water quantity

Water quantity

litres per hour

100 - 1,000 l

Item no.

10040799

Page 14 Page 15

EN EN

Chapter 4 Assembly and function Chapter 4 Assembly and function

4.8 Spare parts and diagrams

The spare parts for the inoMIX S16 are designated with

numbers in the following images. The individual items are

described in the table under the respective diagrams.

Description of the table columns:

Item: Corresponds to the number in the drawing

designating a spare part.

Item no.: INOTEC item number.

Installation

quantity: number of parts of this item when installed

in the original inoMIX S16.

UQ: Unit of quantity of this item.

Name: Name of the spare part.

4.8.2 Water measuring system spare parts list

7

8

3

2

14

15

4

5

9

6

1

13

12 11

10

Item Item no. Installation

quantity

UQ Name

1 10006499 1 Units Needle valve, 1/2” connection

2 10036240 1 Units Pressure reducer D06F-1/2”, with transparent sieve cup

3 10017821 1 Units Pressure gauge 0 - 10 bar, 1/4” at back

4 10022373 1 Units GEKA coupling, 1/2”, ET

5 10006007 1 Units Brass sieve insert

6 10006470 2 Units Hose nozzle, 1/2” ET x 13 mm nozzle

7 10021968 1.0 Meter Black rubber water hose, 1/2” with yellow stripes

8 10006471 1 Units Angular, 1/2”, 90°, galvanised, IT

9 10022443 2 Units Hose clamp, 1-ear, 19.2 - 21.8, (1/2”)

10 10023112 1 Units Solenoid valve 1/2”, 230 V, type 6213A

11 10022156 1 Units Galvanised bend, DN 15, 1/2”, IT/ET

12 10006493 1 Units T-piece, 1/2” ET x 1/2” IT x 1/4” IT

13 10022166 1 Units Double nipple, 1/2“, galvanised

14 10017912 1 Units Mini ball valve, 1/4”, IT + ET

15 10022372 1 Units GEKA coupling, 1/2”, IT

NOTE

Use the order form at the end of this op-

erating manual to order spare parts.

4.8.1 Overview of inoMIX S16

65

1

3

2

7

4

Item Item no. Installation

quantity

UQ Name

10039462 1 Units inoMIX S16 continuous mixer for bagged goods,

1.1 kW 230V / 50Hz

1 10039946 1 Units Complete main switch for inoMIX S16

2 10011185 2 Units Wheel (puncture-free)

3 10006192 2 Units Starlock cap, d = 20 mm

4 10039962 1 Units CEE socket

5 10039958 1 Units Complete drive unit for inoMIX S16

6 10039949 1 Units Mixing pipe complete with GEKA coupling, mixing pipe cover and

mixing shaft

7 10039460 1 Units Water measuring system

Page 16 Page 17

EN EN

Chapter 4 Assembly and function Chapter 4 Assembly and function

4.8.3 Metering shaft

2

1

Metering shaft

Item Item no. Installation

quantity

UQ Name

1 10039947 1 Units Complete metering shaft

2 10004698 2 Units Dowel pins, M8 x 50

4.8.4 Mixing pipe with mixing shaft and mixing pipe cover (item no. 10039949)

4

2

5

6

3

1

7

Mixing pipe

Item Item no. Installation

quantity

UQ Name

1 10039134 1 Units Transparent mixing pipe insert

2 10039951 1 Units Mixing pipe frame/mixing pipe holder

3 10039948 1 Units Mixing shaft

4 10039950 1 Units Complete mixing pipe cover

5 10017068 2 Units Eccentric lock, size 0 with drawbar eye

6 10036239 1 Units Clamping plug G1/2 for plastic mixing pipe

7 10022373 1 Units GEKA coupling, 1/2”, ET

4.8.5 Mixing pipe cover for mixing pipe (item no. 10039950)

1

2

3

4

5

Mixing pipe cover

Item Item no. Installation

quantity

UQ Name

1 10039950 1 Units Complete cover for mixing pipe (incl. items 2 + 3)

2 10039952 2 Units Ball head for mixing pipe cover

3 10006175 1 Units Plastic transfer for the mixing shaft

4 10040694 1 Units Allen screw, M8 x 12, left-hand thread

5 10040419 1 Units Splash guard washer, 8.4 x 35 x 1.5

4.8.6 Mixing shaft for mixing pipe (item no. 10039948)

Mixing shaft

Item Item no. Installation

quantity

UQ Name

1 10039948 1 Units Mixing shaft

Page 18 Page 19

EN EN

Chapter 4 Assembly and function Chapter 5 Transport and storage

4.8.7 Drive unit (item no. 10039958)

2

3

1

4

5

8

7

6

9

Motor

Item Item no. Installation

quantity

UQ Name

1 10007515 1 Units Gear motor, 1.1 kW

2 10039953 1 Units Complete motor flange (incl. items 7, 8, 9 and 10)

- 10039955 1 Units Motor flange without attachments

3 10041323 1 Units CEE plug 3 x 16 A, IP 44

4 10039956 1 Units Tappet bracket with paddles

4.1 10039933 1 Units Radial shaft seal

5 10016644 1 Units Bow handle

6 10039944 2 Units Centring bolt

7 10039945 2 Units Eccentric bushes

8 10039954 1 Units Clamping lever for quick-release fastener

9 10041184 1 Units Motor flange seal

NOTE

Use the order form at the end of this operating manual to order spare parts.

5 Transport and storage

5.1 Safety notices for transport

!

DANGER Slipping machine

Danger of death for drivers and transport users.

• Ensure that the machine is in a secure position during

transport.

• Secure the machine against slipping.

!

WARNING Risk of injury posed by carrying or lifting

machine

• The machine weighs 58 kg. To prevent overloading and

damaging the spine, at least 2 people must lift or carry

the machine.

5.2 Transport inspection

NOTE

Check the machine to ensure that all

components are present and for transport damage

immediately upon receipt.

• Do not leave any parts in the packaging.

5.3 Damage report

Proceed as follows in the event of externally visible

transport damage:

1. Write a damage report with the following details:

- Your client address

- Name of the transport company and the driver

- Date and time of the delivery

- Order number and machine name

according to the delivery note

- Description of the damage

- Signature of the driver

- Signature of the recipient at the customer’s premises

2. Have the transport damage confirmed by means of the

driver’s signature.

3. Send one copy of the damage report to

the transport company and another to

Inotec GmbH.

4. And clarify the possible ways in which the damage

could be remedied with one of our service centres (see

second last page)

5.4 Complaints

Claims for compensation relating to transport damage can

only be made if the delivery company is informed of the

same without undue delay.

5.5 Packaging

The new machine will be shipped cellophane-wrapped on

a Euro pallet.

• Dispose of the packaging material as required by law.

5.6 Transport of the used machine in vehicle

!

DANGER Slipping machine.

Danger of death for drivers and transport users.

1. Ensure that the machine is stored securely during trans-

port.

2. Secure the machine against slipping.

NOTE

Leaking material residue

• Clean the machine before transport.

• Secure the machine in the vehicle using suitable fixing

materials.

5.7 Storage

If the machine is not likely to be used for an extended

period of time, thorough cleaning will be required.

Store the machine under the following environmental

conditions:

• Dry

• Frost-free

• Protected from dust

• Protected against corrosion (e.g. salt water)

Page 20 Page 21

EN EN

Chapter 6 Installation Chapter 7 Commissioning

6 Installation

Observe the following notices when assembling and posi-

tioning the machine:

Installation location requirements

• Ensure that there is enough space around the machine

to enable filling of the material hopper and machine op-

eration.

• Install the inoMIX S16 on an even and horizontal surface.

• Prevent the machine from sliding by locking the wheels.

The mixing pipe points downwards.

• Cover the floor underneath the machine with a plastic

sheet, if it is not on a firm, tarmacked surface.

• Keep the machine in a dry, protected area in wet weather.

• Prevent direct exposure to sunlight, especially while in

continuous operation, in order to prevent the motor

from overheating.

6.1 Delivery condition of the machine

The inoMIX S16 is shipped with the metering shaft inserted

and motor flanged on. The mixing pipe and mixing shaft

still have to be attached.

6.2 Connecting the metering shaft and motor

1. Push the metering shaft into the main frame.

2. Attach the motor to the (1) main frame by means of

the quick-release fastener, and ensure that the meter-

ing shaft is connected to the motor.

3. Insert the CEE plug of the motor into the socket on the

main frame.

1

6.3 Assembling the mixing pipe and mixing shaft

1. Assemble the mixing pipe by using both eccentric fas-

tenings on the main frame.

2. Push the mixing shaft with the mixing pipe cover into

the mixing pipe. Ensure that the mixing shaft is con-

nected to the metering shaft.

3. To lock the mixing pipe cover, turn it clockwise so that

both ball heads lock in the recesses provided in the steel

frame.

!

DANGER Rotating shaft.

Danger of death due to being pulled into the machine

and crushed.

When the motor is running, the metering shaft ro-

tates, even if the mixing pipe has been removed with

the mixing shaft!

• Do not reach into the rotating shaft.

• Do not place any objects into the rotating shaft.

1. Before working on the metering and mixing shaft, inter-

rupt the external power supply.

2. To do this, press the red pushbutton.

3. Pull out the mains plug.

4. Secure the machine against unexpectedly being switched

back on.

6.4 Connecting the electrical control system

1. Connect the inoMIX S16 only to regulation 230 V con-

struction site power distribution points with FI circuit

breakers (30 mA) (RCD).

2. Ensure that the connection is protected by a 16A fuse

and that the cross-section of the supply cable is at least

2.5 mm2.

3. Connect the supply cable to the connector plug on the

On/Off switch.

Connector plug on the On/Off switch

6.5 Installing the water measuring system

1. Connect the supply hose to the external water supply.

2. Open the water valve until a steady water jet comes out

of the hose in order to both clean the water hose of dirt

and ventilate it.

3. Then close the valve on the external water supply.

4. Connect the external water hose to the GEKA coupling

of the water fitting (1).

5. Connect the water drainage valve to the water fitting

(2).

6. Connect the internal water hose to the mixing pipe (3).

7. Open the valve on the external water supply.

1

32

!

WARNING Water jet.

Risk of injury and risk of property damage due to es-

caping water.

1. Interrupt the external water supply by closing the water

valve.

2. In order to release the pressure (approx. 2 bar), open

the water drainage valve on the water measuring sys-

tem.

3. Remove the hose from the external water supply.

4. Do not point the water jet at other people or yourself.

Page 22 Page 23

EN EN

Chapter 7 Commissioning Chapter 8 Operation, use

7 Commissioning

7.1 Adding material to the material hopper

Warning Risk to health due to dust.

When cleaning the machine, inhaled dust can cause

long-term lung damage or other adverse health ef-

fects.

• The machine operator or people working in the dust area

must each wear a dust mask when cleaning the machine.

• Find out about the technical rules for hazardous sub-

stances (TRGS 559) “Mineral dust” on the homepage of

the German Social Accident Insurance Institution (www.

bgbau.de).

Warning Risk of injury due to powdery material

When adding bagged goods to the material hopper,

swirling material may pose a risk of injury, especially in the

region of the eye and face.

• Always wear safety goggles.

7.2 Opening and emptying bags of material

Warning Observe the applicable occupational safety

regulations (e.g. respiratory protection)

To clean the bags of material, proceed as follows:

1. Place the bag of material on the hopper mesh with the

tooth rail.

2. Tear open the bag of material by using short forward and

backward movements.

3. Move the bag sideways and upwards and then empty

the contents into the material hopper.

4. Observe the applicable occupational safety regulations

(e.g. respiratory protection, etc.).

5. Dispose of the empty bags of material and other pack-

aging material in an environmentally friendly manner in

accordance with the instructions provided by the packag-

ing manufacturer.

7.3 Commissioning inoMIX S16

1. Connect the inoMIX S16 only to regulation 230 V con-

struction site power distribution points with FI circuit

breakers (30 mA) (RCD).

2. Ensure that the connection is protected by a 16A fuse

and that the cross-section of the supply cable is at least

2.5 mm2.

3. Connect the supply cable to the connector plug on the

On/Off switch.

4. Fill the material hopper with bagged goods.

5. Open the valve on the external water supply, and check

the water inlet pressure on the pressure gauge (2 bar).

6. Press the green pushbutton.

7. Turn the needle valve of the water fitting. This allows

you to change the flow volume of the water and thus

precisely determine the material consistency.

7.4 Function after commissioning

The motor starts up, the dry material from the material

hopper is transported into the mixing pipe via the meter-

ing shaft. At the same time, the solenoid valve opens and

allows the water to flow into the mixing pipe. The material

is moistened by the inflowing water and homogeneously

mixed by the mixing shaft, and conveyed to the downpipe

section of the mixing pipe.

7.5 Changing material

1. Run the inoMIX S16 until it is empty and dry.

2. Clean the material hopper, metering shaft, mixing pipe

and mixing shaft.

7.6 Change of location on the construction site

The inoMIX S16 is equipped with two wheels, and a han-

dle is attached to the hopper. The mixer can therefore be

moved on the construction site easily. Its mixing pipe can

also be used to lift and move the inoMIX S16 around. To

do this, disconnect the mixer from the electricity and water

supply.

NOTE

This QR code will take you to the original

operating manual of the mixer.

8 Operation, use

8.1 Checking operating performance

1. If you notice any deviations in the operating behaviour,

decommission the inoMIX S16 immediately.

2. Ensure that the damage and/or defects which led to the

deviating operating behaviour are rectified.

8.2 Checking the consistency of the material

Ensure an even, paste-like material consistency during

operation.

• The viscosity may change, especially in warm weather

conditions.

Material too rigid Increase the water supply

by re-adjusting it on the

needle valve of the water

fitting

Material too runny Reduce the water supply by

re-adjusting it on the nee-

dle valve of the water fitting

8.3 Correcting flow fluctuations

1. Check the water inlet screen and clean it if it is dirty.

2. Check the water pressure at the supply line and regulate

it accordingly, if necessary.

3. Check the pressure reducer and regulate it, if necessary.

8.4 Work break

If the duration of a work break exceeds the setting time of

the material to be processed, there is a risk of the material

setting during the break.

1. Stop the mixer by pressing the red pushbutton.

2. Pull out the mains plug.

3. Pull out the plug of the motor from the socket.

4. Use an external water hose for cleaning.

5. Remove the internal water hose that connects the mix-

ing pipe to the water valve.

6. Pull the mixing shaft (screwed to the mixing pipe cover)

out of the mixing pipe. To do this, turn the mixing pipe

cover anti-clockwise to the left.

7. Open both eccentric fastenings to separate the mixing

pipe from the main frame.

8. Clean the mixing shaft and mixing pipe with water over

a suitable drip tray or bucket.

NOTE

Carry out this cleaning process before any

longer breaks from work (> 0.5 hours). Do not operate

the mixing pipe forcibly from the outside (e.g. by hit-

ting it with a hammer).

!

DANGER Rotating shaft.

Danger of death due to being pulled into the machine

and crushed.

When the motor is running, the metering shaft ro-

tates, even if the mixing pipe has been removed with

the mixing shaft!

• Do not reach into the rotating shaft.

• Do not place any objects into the rotating shaft.

1. Before working on the metering and mixing shaft, inter-

rupt the external power supply.

2. To do this, press the red pushbutton.

3. Pull out the mains plug.

4. Secure the machine against unexpectedly being switched

back on.

!

WARNING Water jet.

Risk of injury and risk of property damage due to es-

caping water.

1. Interrupt the external water supply by closing the water

valve.

2. In order to release the pressure (approx. 2 bar), open

the water drainage valve on the water measuring sys-

tem.

3. Remove the hose from the external water supply.

4. Do not point the water jet at other people or yourself.

Page 24 Page 25

EN EN

Chapter 9 Cleaning & decommissioning Chapter 10 Maintenance

8.5 End of work

8.5.1 Switching off the machine

1. Stop filling with bagged goods in sufficient time.

2. Empty the material hopper of the main frame and the

mixing pipe.

3. Stop the mixer by pressing the red pushbutton.

4. Pull out the mains plug.

5. Pull out the plug of the motor from the socket.

8.5.2 Dismantling and cleaning the mixing pipe and

mixing shaft

1. For cleaning, connect a water hose to the GEKA cou-

pling (left) provided for this purpose on the water valve.

2. Remove the internal water hose that connects the mix-

ing pipe to the water valve.

3. Pull the mixing shaft (screwed to the mixing pipe cover)

out of the mixing pipe. To do this, turn the mixing pipe

cover anti-clockwise to the left.

4. Open both eccentric fastenings to separate the mixing

pipe from the main frame.

5. Clean the mixing shaft and mixing pipe with water over

a suitable drip tray or bucket.

6. Interrupt the external water supply by closing the water

valve.

7. In order to release the pressure (approx. 2 bar), open

the water drainage valve on the water measuring sys-

tem.

8. Remove the supply and cleaning hose from the water

valve.

8.5.3 Dismantling the motor and metering shaft

1. Remove the motor by opening the quick-release fasten-

er that connects the motor to the main frame.

2. Pull out the metering shaft from the main frame.

3. Remove dry residual material by using a suitable broom.

Use a suitable container to collect the residual material.

9 Cleaning & decommissioning

9.1 Cleaning process

1. Stop filling with bagged goods in sufficient time.

2. Empty the material hopper of the main frame and the

mixing pipe.

3. Stop the mixer by pressing the red pushbutton.

4. Pull out the mains plug.

5. Pull out the plug of the motor from the socket.

6. Remove the internal water hose that connects the mix-

ing pipe to the water valve.

7. Pull the mixing shaft (screwed to the mixing pipe cover)

out of the mixing pipe. To do this, turn the mixing pipe

cover anti-clockwise to the left.

8. Open both eccentric fastenings to separate the mixing

pipe from the main frame.

9. Clean the mixing shaft and mixing pipe with water over

a suitable drip tray or bucket.

10. Interrupt the external water supply by closing the water

valve.

11. In order to release the pressure (approx. 2 bar), open

the water drainage valve on the water measuring sys-

tem.

12. Remove the supply and cleaning hose from the water

valve.

13. Remove the motor by opening the quick-release fasten-

er that connects the motor to the main frame.

14. Pull out the metering shaft from the main frame.

15. Remove dry residual material by using a suitable broom.

Use a suitable container to collect the residual material.

!

DANGER Rotating shaft.

Danger of death due to being pulled into the ma-

chine and crushed.

When the motor is running, the metering shaft ro-

tates, even if the mixing pipe has been removed with

the mixing shaft!

• Do not reach into the rotating shaft.

• Do not place any objects into the rotating shaft.

1. Before working on the metering and mixing shaft, inter-

rupt the external power supply.

2. To do this, press the red pushbutton.

3. Pull out the mains plug.

4. Secure the machine against unexpectedly being switched

back on.

!

WARNING Water jet.

Risk of injury and risk of property damage due to es-

caping water.

1. Interrupt the external water supply by closing the water

valve.

2. In order to release the pressure (approx. 2 bar), open

the water drainage valve on the water measuring sys-

tem.

3. Remove the hose from the external water supply.

4. Do not point the water jet at other people or yourself.

9.2 After cleaning

Note the optimum assembly sequence:

1. Insert the metering shaft.

2. Attach the motor to the main frame by using the

quick-release coupling.

3. Mixing pipe and mixing shaft with mixing pipe cover.

4. Connect the water and electricity supply.

9.3 Decommissioning

9.3.1 Running the machine until it is empty and

switching it off

1. Stop filling with bagged goods in sufficient time.

2. Empty the material hopper of the main frame and the

mixing pipe.

3. Stop the mixer by pressing the red pushbutton.

4. Pull out the mains plug.

5. Pull out the plug of the motor from the socket.

9.3.2 Mixing pipe and mixing shaft with mixing pipe

cover

1. Remove the internal water hose that connects the mix-

ing pipe to the water valve.

2. Open both eccentric fastenings to separate the mixing

pipe from the main frame.

9.3.3 Water measuring system

1. Interrupt the external water supply by closing the water

valve.

2. In order to release the pressure (approx. 2 bar), open

the water drainage valve on the water measuring sys-

tem.

3. Remove the supply hose from the water valve.

9.3.4 Dismantling the motor and metering shaft

1. Remove the motor by opening the quick-release fasten-

er that connects the motor to the main frame.

2. Pull out the metering shaft from the main frame.

3. Remove dry residual material by using a suitable broom.

Use a suitable container to collect the residual material.

Page 26 Page 27

EN EN

Chapter 10 Maintenance Chapter 11 Faults, causes and solutions

10 Maintenance

Have the machine inspected once a year by a specialist

workshop. Replace parts which are subject to wear as soon

as the wear limits have been reached. Portable machines,

like the inoMIX S16, must be subject to an annual elec-

trical inspection according to the implementing regulation

for electrical plant and operating resources (DGUV V3). This

inspection may only be carried out by a qualified electrician

(e.g. electrical engineer, electrical technician, master electri-

cian, senior electrician, foreman electrician or assistant elec-

trician). Electrical specialists work at all INOTEC service cen-

tres, conducting electrical inspections in line with DGUV V3.

To arrange an inspection, call the INOTEC service hotline on

+49 7741 6805 777.

WARNING Cleaning and maintenance work can put

the safety of operating staff at risk and impair the

functionality of the machine.

1. Stop the mixer by pressing the red rotary switch on the

main switch.

2. Pull out the mains plug.

3. Disconnect the 5-pole plug of the motor from the up-

per socket on the switching cabinet.

4. Secure the machine against unexpectedly being

switched back on

5. Before cleaning with the water jet, cover all the open-

ings that water must not penetrate into for safety and

functional reasons.

6. After cleaning, remove all the covers which were at-

tached to protect against the water.

10.4 Wear limit for metering shafts

(Item no. 10039947)

The metering shafts are subject to wear. The entire meter-

ing shaft must be replaced if the minimum height of the

augur blades is either reached or not quite reached.

Diameter 51 mm

Wear limit:

Diameter

45 mm

10.5 Wear limit for mixing shafts

(Item no. 10039948)

The mixing shaft is subject to wear. The entire mixing shaft

must be replaced if the minimum height of the mixing

blades is either reached or not quite reached.

Maximum height of mixer

blades

55 mm

Wear limit:

Minimum height of mixer

blades

50 mm

11 Faults, causes and solutions

The inoMIX S16 is designed for fault-free operation. How-

ever, should a fault occur, please follow the instructions

below on analysing, checking and remedying the fault or

contact the Inotec Service team (see the address list for INO-

TEC service centres at the end of the document) or call the

INOTEC service hotline on: +49 7741 6805 777.

WARNING Faults can put the safety of operating staff

at risk and impair the functionality of the machine.

Proceed as follows where a fault occurs:

1. Cut off the power supply in the event of any faults

which pose a direct risk to people or material assets. To

do this, press the red pushbutton.

2. Pull out the mains plug.

3. Secure the machine against unexpectedly being

switched back on

4. Determine the cause of the fault.

5. Report the fault to the responsible person on site.

6. Depending on the type of fault you can either rectify

this yourself or have it rectified by a qualified electrical

specialist.

10.1 Maintenance plan

Have the machine inspected

at a specialist workshop or at

an INOTEC service centre

Once a year

(Recommended)

Electrical inspection (DGUV

V3) by a qualified electri-

cian or at an INOTEC service

centre

Once a year

(Mandatory, stipulated

by DGUV V3)

The dirt trap sieve in the

water inlet is to be cleaned/

replaced by the operator

Daily

The dirt trap sieve in the

pressure reducer is to be

cleaned/replaced by a service

technician

Monthly

10.2 Dirt trap sieve in the water inlet

(Brass sieve insert, item no. 10006007)

1

1. Remove the dirt trap sieve (1) from the GEKA coupling.

2. Clean the dirt sieve trap daily.

3. Replace the dirt trap if it is very dirty.

4. Re-install the dirt trap sieve.

10.3 Dirt trap sieve in the pressure reducing valve

(replacement strainer for pressure reducer item no.

10006518)

1

2

1. Unscrew the sieve cup (1) from the pressure reducer.

2. Remove and clean the dirt trap sieve (2) once a month.

3. Replace the dirt trap if it is very dirty.

4. Install a new dirt trap sieve and screw the sieve cup onto

the pressure reducer.

Page 28 Page 29

EN EN

Chapter 11 Faults, causes and solutions Chapter 12 Dismantling and disposal

The faults listed below feature recommendations as to who is authorised to rectify the fault.

Symptom Potential cause Check / solution Personnel

qualification

If the machine will not

start.

Power supply is

cut off.

• Check the power supply (power distribution points, socket,

power cable, cable reel).

Machine

operator

No input voltage

available.

• Have the voltage supply checked at the worksite distribution

board, supply cables and cable reels.

• Have the voltage supply restored if it was interrupted.

Qualified

electricians

Blockage due to

foreign bodies or

hardened material in

the mixing pipe

• Remove the foreign bodies and clean the mixing pipe Machine

operator

The machine has

stopped.

The overcurrent

protection device has

tripped.

• Check the metering shaft and mixing shaft. Machine

operator

• Have the motor checked.

• Have the fault remedied if necessary.

Service

technician/

qualified

electrician

The machine has

stopped.

Metering shaft me-

chanically blocked.

• Check whether any foreign bodies are in the metering shaft;

if necessary, remove the foreign bodies.

Machine

operator

The machine has

stopped.

Mixing shaft mechani-

cally blocked.

• Check whether any hardened material is in the mixing shaft; if

necessary, remove the hardened material.

• Check whether any foreign bodies are in the mixing shaft; if

necessary, remove the foreign bodies.

Machine

operator

Motor will not start or

is spluttering.

Motor or electronic

control is defective.

• Have the motor checked; have the motor replaced if neces-

sary.

• Have the electronic control checked; the electronic control re-

paired if necessary.

Service

technician/

qualified

electrician

Foreign bodies or

hardened material

in metering shaft or

mixing shaft.

• Check whether any hardened material or foreign bodies are

in the pump shaft; if necessary, remove the hardened material

or foreign bodies.

Machine

operator

Only dry material

comes out of the mix-

ing pipe outlet

The water supply has

been interrupted.

• Check whether the hose is connected to the external water

supply; connect the water hose if it has not been connected.

• Check whether the stop cock on the external water supply has

been opened; open the stop cock if it is closed.

Machine

operator

The water supply has

been interrupted and

the solenoid valve is

not opening.

• Check the plug on the solenoid valve; secure the plug if it is

loose.

• Check the coil of the solenoid valve; replace the coil if this is

defective.

• Check the solenoid valve; replace the solenoid valve if there is

a mechanical defect.

Machine

operator

Only water comes out

of the mixing pipe

outlet

The mixing shaft is

not connected to the

metering shaft.

• Check if the mixing pipe is mounted properly.

• Check whether the mixing shaft is connected to the metering

shaft.

Machine

operator

Material

consistency

too thick The amount of water

supplied is too low.

• Increase the flow volume by adjusting it on the needle valve

of the water fitting.

Machine

operator

too thin The amount of

water supplied is too

high.

• Reduce the flow volume by adjusting it on the needle valve of

the water fitting.

Machine

operator

Consisten-

cy fluctua-

tions

The amount of water

supplied is fluctuat-

ing.

• Check the water inlet screen; clean the water screen if nec-

essary.

• Check the water pressure of the supply line; regulate the wa-

ter pressure if necessary.

• Check the setting on the pressure reducer; regulate the set-

ting if necessary.

Machine

operator

12.2 Dismantling

Clean and dismantle the machine before sorting the parts

in compliance with the applicable occupational health and

environmental protection regulations.

12.3 Disposal

According to European Directive 2012/19/EU on waste

electrical and electronic equipment and its implementation

in national law, this machine should not be disposed of in

general household waste, but recycled in an environmental-

ly conscious manner!

The inoMIX S16 consists primarily of high-quality met-

al. Observe the following if you are decommissioning

the inoMIX S16 for the final time:

• Send the metal to a recycling facility.

• Dispose of the inoMIX S16 via a scrap metal dealer or

your local scrap metal collection centre.

Your used INOTEC equipment will be taken back by us and

disposed of in an environmentally conscious manner. Please

contact one of our service centres to arrange this.

12 Dismantling and disposal

After the machine’s period of use has expired, the machine

must be dismantled and sent for environmentally conscious

disposal.

12.1 Safety

• Only task trained or instructed staff with operating the

inoMIX S16.

• Work on the electronic control system may only be per-

formed by a qualified electrician.

WARNING Risk of injury posed by improper disas-

sembly.

Stored residual energy, sharp components, points and

corners on and in the machine can cause injuries.

• Ensure there is enough space for disassembly.

• Wear gloves and safety boots to avoid injuries.

• Handle sharp-edged parts with care.

• Ensure that the workplace is tidy and clean. Loose com-

ponents and tools lying around or on top of each other

can cause accidents.

• Adopt good practice when dismantling the components.

• Note that some individual parts may be very heavy.

• Secure the individual parts to ensure these do not fall

down or topple over.

• In the event of uncertainty, call the INOTEC service hotline

on +49 7741 6805 777.

!

DANGER Electrical voltage

Danger of death due to electric shock.

When switched on, electrical components can cause

uncontrolled movements and lead to serious injury.

1. Switch the machine off. To do this, press the red push-

button.

2. Pull out the mains plug and finally disconnect the ma-

chine from the electrical supply.

Page 30 Page 31

EN EN

Chapter 13 Systems Chapter 13 Systems

13 Systems

The following documents are enclosed as annexes and form part of this operating manual:

13.1 EC declaration of conformity

Name/address of the issuer: INOTEC GmbH

Daimlerstraße 9-11

DE 79761 Waldshut-Tiengen

We hereby declare