INOV8 F240 User manual

INOV8 Model F240 – Edited September 2008

i

INTERNATIONAL INCORPORATED

ASSEMBLY, INSTALLATION, MAINTENANCE

AND OPERATING INSTRUCTIONS

INOV8 F240 Multi-fueled Unit Heater & Furnace

Save These Instructions! This manual must be kept near the furnace!

Control No. 3120734

INOV8 Model F240 – Edited September 2008

ii

BL

SECTION 1 – GENERAL GUIDELINES...........................................................................................0

Codes & Regulations........................................................................................................................................................ 0

U.S. EPA Regulations & Used oil Burning........................................................................................................................ 0

Listing Agencies ............................................................................................................................................................... 1

Fuels- general information................................................................................................................................................ 1

Special Precautions!......................................................................................................................................................... 1

Warranty is void if … ........................................................................................................................................................ 2

Disposal............................................................................................................................................................................ 2

Unpacking & Inspecting.................................................................................................................................................... 2

Minimum Clearances........................................................................................................................................................ 2

Shipping & parts information ............................................................................................................................................ 3

Figure 1 - Model F240 Dimensions .......................................................................................................................... 4

SECTION 2 – FURNACE INSTALLATION ......................................................................................5

FURNACE LOCATION ................................................................................................................................................ 5

ATTACHING THE BURNER TO THE FURNACE............................................................................................................... 5

Installing the Burner:......................................................................................................................................................... 5

Installing the Electrical Plug.............................................................................................................................................. 6

Electrical Hookup of the Furnace...................................................................................................................................... 6

Attaching the Air Connection ............................................................................................................................................ 7

Attaching the Oil Delivery Line (‘A’ in photo)..................................................................................................................... 6

Attaching the Return Line (‘B’ in photo) ............................................................................................................................ 6

Blocked Vent Switch –supplied with Canadian Furnaces (or optional) ............................................................................. 7

INSTALLATION DETAILS............................................................................................................................................. 7

Air Supply Installation ....................................................................................................................................................... 7

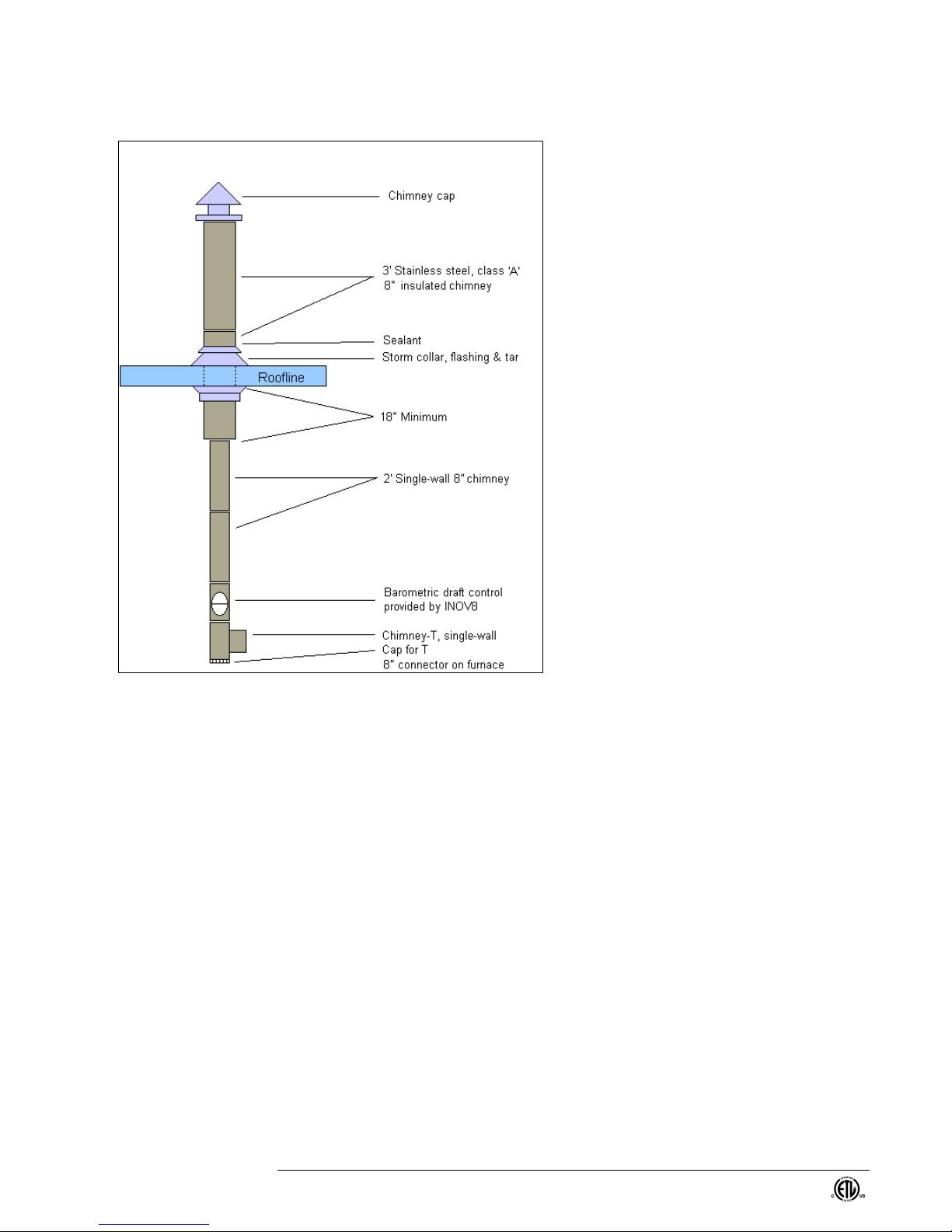

Chimney Installation ......................................................................................................................................................... 8

Installing the Barometric Draft Control.............................................................................................................................. 9

Draft Measurements & Adjustments............................................................................................................................... 10

Installing an Optional Draft Inducer ................................................................................................................................ 10

Installing an Optional Sealed Combustion System ......................................................................................................... 10

Figure 2 - Typical Installation Diagram (without bench tank).................................................................................. 12

Ceiling Mount Installation Considerations....................................................................................................................... 12

Electrical Supply Installation........................................................................................................................................... 12

Fan/Limit control............................................................................................................................................................. 13

TANK &PIPING CONSIDERATIONS........................................................................................................................... 13

Oil Storage Considerations............................................................................................................................................. 13

Additional Oil Storage Consideration.............................................................................................................................. 13

Piping & Fitting Recommendations................................................................................................................................. 13

Tank Filter ...................................................................................................................................................................... 14

Vapor Eliminator Filter / Pressure Relief Assembly ........................................................................................................ 14

Installation of Vent Line from Vapor Eliminator back to the Tank ................................................................................... 14

Vapor Eliminator Filter .................................................................................................................................................... 14

Bench Tank Installation .................................................................................................................................................. 16

Figure 3 - Bench Tank Setup ................................................................................................................................. 16

Boost Pump (optional) .................................................................................................................................................... 18

Figure 4 - Diagram Showing Installation of Suntec Boost Pump, Filter, Check valve, Regulator & Gauges .......... 19

Figure 5 – Burner Diagram .................................................................................................................................... 20

Final Installation Checklist .............................................................................................................................................. 21

SECTION 3 – OPERATING THE FURNACE .................................................................................22

FIRST START-UP OF FURNACE................................................................................................................................22

Priming the Oil System ................................................................................................................................................... 22

Firing up the Furnace the First Time .............................................................................................................................. 22

Ducted Furnace Installation Check (Model F240 SC)..................................................................................................... 23

NORMAL OPERATION OF FURNACE .........................................................................................................................24

FACTORY SETTINGS...............................................................................................................................................25

Figure 6 - Electrode Adjustment Diagram .............................................................................................................. 25

FLAME ADJUSTMENTS ............................................................................................................................................26

Figure 7 – Proper & Improper Flame appearances............................................................................................... 26

MAINTENANCE .......................................................................................................................................................27

INOV8 Model F240 – Edited September 2008 iii

General Information ........................................................................................................................................................ 27

Changing Filters.............................................................................................................................................................. 27

Vacuuming the Combustion Chamber & Heat Exchanger Tubes ................................................................................... 27

Annual Maintenance ....................................................................................................................................................... 28

Chimney Inspection ........................................................................................................................................................ 29

Summer Burner Refurbishing Program........................................................................................................................... 29

SECTION 4 - TROUBLESHOOTING ............................................................................................. 30

General Failure Categories & Potential Causes ............................................................................................................. 30

Using Lights on the Controller to Diagnose Symptoms................................................................................................... 31

SECTION 5 –DETAILED SERVICING PROCEDURES ................................................................. 33

Removing the Module from the Burner ........................................................................................................................... 33

Replacing the Module into the Burner............................................................................................................................. 33

Flushing the Final Delivery.............................................................................................................................................. 33

Checking the Oil Spray ................................................................................................................................................... 34

Checking the Oil System................................................................................................................................................. 34

Checking the Ignition Arc................................................................................................................................................ 35

Checking the Atomizing Air System................................................................................................................................ 35

Checking the Draft & things that can cause it to be wrong.............................................................................................. 36

By-passing the Bimba Cylinder....................................................................................................................................... 36

Replacing the Vapor Eliminator Filter ............................................................................................................................. 37

Cleaning the Nozzle........................................................................................................................................................ 37

Rebuilding the Pump ...................................................................................................................................................... 38

Cleaning the Pump Internal Pressure Regulator............................................................................................................. 39

Oil Temperature Controller: Operation & Settings .......................................................................................................... 39

Oil Temperature & Pressure Settings..................................................................................................................... 40

Adjusting the Temperature Controller..................................................................................................................... 40

Removing Excess Oil from Combustion Chamber.......................................................................................................... 41

PROCEDURE FOR PARTS REPLACEMENT................................................................................................................. 41

ADDENDUM................................................................................................................................... 42

THEORY OF OPERATION......................................................................................................................................... 42

MAIN COMPONENTS &THEIR FUNCTIONS ............................................................................................................... 43

The Fireye Controller ...................................................................................................................................................... 43

The Oil System ............................................................................................................................................................... 44

The Primary (atomizing) Air System ............................................................................................................................... 45

ELECTRICAL DIAGRAMS ......................................................................................................................................... 46

Figure 8 – Basic Wiring Diagram for Furnace with Prop Fan ................................................................................. 46

Figure 9 – Basic Wiring Diagram – for 240v Squirrel Cage Blower ........................................................................ 47

Figure 10 – Burner Electrical Diagram for Prop Fan............................................................................................... 48

Figure 11 – Burner Electrical Diagram for 240v Squirrel Cage Blower................................................................... 49

PARTS LIST &TOOLS............................................................................................................................................. 50

SECTION 6 - GLOSSARY ............................................................................................................. 51

Notations Used in this Manual

RISK OF INJURY OR SYSTEM DAMAGE – Identifies a possible dangerous

situation that can lead to personal injury or physical damage.

NOTICE – This is a tip or notice for optimum use of equipment and

adjustment as well as useful information.

INOV8 Model F240 – Edited September 2008

0

SECTION 1–GENERAL GUIDELINES

Congratulations on your purchase of this INOV8 Multi-fueled Furnace. You have

selected the highest quality, precision-engineered piece of equipment available,

designed specifically to allow you to fully benefit from the used oils generated in your

business. INOV8 has not compromised in engineering this product for high efficiency,

safety, longevity, operating economy, and to allow you a maximum of fuel choices; all

while providing the highest standards of environmental considerations. This manual was

written for the novice technician with detailed instructions for the installation, start-up,

routine operation and maintenance of this furnace. If these instructions and pertinent

local regulations are followed closely you will be assured full satisfaction.

CODES ®ULATIONS

This manual covers installation, maintenance and service of the INOV8 model F240 unit

heater or F240 SC furnace. Both are referred to using the term “furnace” throughout this

manual that covers the installation of the chimney system, fuel storage and piping

connections and electrical work. All work shall be performed by a qualified contractor in

strict accordance with the requirements of state, provincial and local regulating agencies

and codes pertaining to oil-burning equipment installations. After start-up the owner or its

representative should be instructed about the furnace operation and be given this

manual. This equipment must be installed according to these national standards.

For furnace equipment: ANSI/NFPA # 31 – Standard for the Installation of Oil-

Burning Equipment – 2006 Edition, and in Canada to CSA

Standard B139.

For chimney installation: ANSI/NFPA # 211 – Standard for Chimneys, Fireplaces,

Vents, and Solid Fuel Burning Appliance, 2006 Edition

For oil storage installation: NFPA # 31 – Standard for the Installation of Oil-Burning

Equipment – 2006 Edition

For electrical installation: NFPA # 70 – National Electrical Code – 2005

Cleaning and routine maintenance must be carried out at least quarterly during

operation. This shall include an overall check of the heating system. There should be

periodic inspection of the combustion chamber for possible deterioration. Any

discrepancies must be corrected immediately.

NOTE: This manual is for reference only. The manual does NOT purport to address all

design, installation and safety considerations. It is the responsibility of the user of this

manual to determine the applicability and safety of each individual application and ensure

its compliance with local building codes.

U.S. EPA REGULATIONS &USED OIL BURNING

On August 12, 1992 the U.S. Environmental Protection Agency (EPA) announced that it

would not list nor classify as hazardous waste, used oil destined for recycling. They also

affirmed the long-standing regulatory exemption, which allows the operation of used oil-

fired furnaces. Under this exemption, used oil-fired furnaces may operate without a

regulation so long as the owner burns "on-specification used oil". Used oil exceeding

EPA designated levels of contaminants is classified as "off-specification used oil"

which means the owner must comply with three requirements: the heater does not

exceed 500,000 BTU per hour, it is vented to the outside, and burns oil generated on-site

or collected from do-it-yourself oil changers. After years of careful study the EPA

concluded that used oils that are recycled in this manner do not pose a substantial

present or potential hazard to human health or the environment so long as they are

managed properly. To this end, EPA's regulations are designed to provide safe and

environmentally sound used oil management practices.

INOV8 Model F240 – Edited September 2008 1

LISTING AGENCIES

This equipment is tested and listed by Intertek ETL Semko (ETL) - an internationally

recognized third party test agency to UL 296A - Standard for Safety for Waste Oil

Burning Air-Heating Appliances, Edition 2, Revision 2006/03/08 (the U.S. used oil

standard), and to CSA B140.0 General Requirements for Oil Burning Equipment General

Instruction No 2-4 (R1991) Rev: 1991/01/01and is listed with the European Economic

Community with a CE registration number 3884/97. The INOV8 tanks are also tested

and listed by ETL to UL 80 Standard for Steel Tanks for Oil-Burned Fuel.

FUELS-GENERAL INFORMATION

This product is approved to burn the following oils: crankcase oil, crankcase oil with up to

20% gasoline, fuel oils up to #6 heating oil, jet fuel, mineral spirits and transmission oil.

The following additional oils have been tested and passed combustion analysis

requirements but are not approved as fuels due to a lack of standards to define them:

used and crude vegetable oil, and biodiesel. DO NOT attempt to burn other liquids

without written authorization from INOV8 International, Inc. Only used oil generated on

the premises of the owner may be used in this equipment, unless written authorization is

obtained from the regulatory authority.

Caution – used oils may contain gasoline, heavy metallic compounds and foreign

materials. When burned, these compounds are emitted from or deposited within this

furnace and therefore care should be taken when storing these oils or when using,

cleaning and maintaining this equipment.

SPECIAL PRECAUTIONS!

1. This furnace is listed for commercial or industrial use only. It may not be used for

residential or any other unauthorized purpose.

2. All furnaces must be wired strictly in accordance with wiring diagram and

instructions in this manual.

3. Disconnect the power supply before making wiring connections to prevent

electrical shock and equipment damage.

4. Disconnect the power supply before cleaning the furnace.

5. Do not install furnace or chimney connector closer than 18 inches to combustible

materials in any direction, except the louver side of the furnace, which must be

unobstructed.

6. DO NOT add fluids with the classification of a hazardous waste, or fuels with

flash points below 100oF (such as gasoline) to your used oils. (Check your local

codes for restrictions.)

7. For your protection - DO NOT store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

8. Canadian standards allow only used oil generated on the premises of the owner

to be used as fuel, unless permitted by the regulatory authority.

9. Venting - Failure to provide proper venting could result in death, serious injury,

and/or property damage. Units must be installed with a flue connection, draft

regulator and proper vent to the outside of the building. Safe operation of any

gravity vented heating equipment requires a properly operating vent system,

correct provision for combustion air, and regular maintenance and inspection.

10. Hazardous Atmosphere - The INOV8 products are not designed for use in

hazardous atmospheres containing flammable vapors or combustible dust, or

atmospheres containing chlorinated or halogenated hydrocarbons.

INOV8 Model F240 – Edited September 2008

2

WARRANTY IS VOID IF …

1. The heater is not installed in accordance with these instructions and applicable

codes and ordinances.

2. The wiring is not in accordance with drawings in this manual.

3. The Furnace or burner is not maintained in accordance with maintenance

requirements – particularly failure to clean the combustion chamber and heat

exchanger on a regular basis.

4. Other than specified fuel is burned.

5. Fuel input capacity is over the rated condition of maximum flow rate of 1.68 US

gallons or 7.63 liters per hour.

Note: Information on the Limited Warranty was sent along with the sales order.

DISPOSAL

Dispose of packaging in an environmentally responsible manner. Dispose of all heating

system components that have to be replaced at an authorized disposal site. Dispose of

ash in a responsible manner.

UNPACKING &INSPECTING

Immediately upon receipt, check the cabinet and burner for any damage that may have

occurred in shipment. If damage is found, INOV8 or the sales representative must be

notified within two days in order to process shipping damage claims. Prior to shipping, all

components were inspected and the burner test fired, so the burner will still have oil in it.

MINIMUM CLEARANCES

Furnaces must be installed so that the following clearances are provided for proper air

movement, service and distance from combustible materials. In addition to walls and

ceilings, combustibles include rags, paper, or any moveable combustibles like gasoline

or other flammable fluid.

Inches Millimeters Purpose

Cabinet Fan Motor: 6 152 air movement

Chimney connector (flue pipe): 18 457 combustible material

Above Furnace: 24 609 combustible material

Below Furnace: 4 101 combustible material

Burner side: 48 1,219 service access

Outlet Louver: Unobstructed air movement

INOV8 Model F240 – Edited September 2008 3

SHIPPING &PARTS INFORMATION

The INOV8 Waste Oil Furnace is shipped on a pallet with strapping and plastic wrap.

This includes the heat exchanger, fan, and fan motor (mounted and wired). The burner is

packed in a separate box that also contains other parts, based on the following list and

what was purchased. Immediately upon receipt of INOV8 products inspect all parts for

possible shipping damage or missing parts and report any problems within 48 hours.

Check for the items shown in the photos, that they are received:

1. Oil Pickup Assembly, includes these parts from the top down:

a. One ¾” check valve

b. 3/4 “ x 2” black nipple

c. One 90ostreet elbow

d. Filter mount

e. One 90ostreet elbow

f. One ¾” x 12” pipe nipple

g. Double tap bushing, 2” with ¾” x ½”

reducing bushing

h. One primary filter, model Gar-Ber

Spin-on Filter #11V-R2000K with Filter

Restriction Indicator

2. Barometric draft control – 8”

(see photo at right)

The following items are shown in the lower photo:

3. Wall Thermostat - 120 volt (line voltage).

4. Other items include:

a. Instruction Manual

b. Spare vapor eliminator filter

c. Spare 10 amp (brown) & 4 amp

(orange) fuses

d. Burner gasket

5. Air regulator Assembly, includes:

a. Air regulator

b. Air gauge, 0 – 160 psig

c. Plastic nut

d. Bracket and screws

e. ¼” air tube

The following items are not shown in the photos:

6. Squirrel-Cage Blower (optional), mounted

7. Bench Tank - (optional), which includes:

a. 300 gallon bench-type tank

b. Optional stands

c. Tank gauge, oil supply and lines with fittings

2

3

5

4

1

INOV8 Model F240 – Edited September 2008

4

Figure 1 - Model F240 Dimensions

INOV8 Model F240 – Edited September 2008 5

SECTION 2–FURNACE INSTALLATION

FURNACE LOCATION

Furnace location and other installation requirements were covered in the “Pre-installation

Considerations” document that was sent along with the confirmation of order. It is

absolutely essential that you have read that document before proceeding with the

installation. If you don’t have it, contact INOV8 and it will be faxed or e-mailed.

The furnace location is important to the efficient operation of the system. These

abbreviated guidelines will insure the most beneficial location. Further details are found

on subsequent pages.

1. The location of the chimney must be considered before other aspects of the

installation. See the section entitled, “Chimney Installation” for further details

2. Select a location as close as possible to the oil storage tank. The burner pump can

suck laterally easier than it can vertically but there are limits. If the distance from the

tank exceeds 30 feet or when the height exceeds 8 feet, a boost pump may be

necessary.

3. Furnaces hung higher than the standard 8 feet are not recommended. The location

should provide easy access to the furnace for routine servicing and

maintenance and for proper heat distribution.

4. DO NOT attach ducting to furnace (unless the furnace was ordered with the ducting

option that includes the squirrel-cage blower).

5. To prevent premature heat exchanger failure, DO NOT locate in areas where

chlorinated, halogenated or acid vapors or other corrosive contaminants may exist.

6. DO NOT install the furnace outdoors or in excessively wet conditions.

7. DO NOT attach air filters to the furnace.

8. In multiple furnace installations, arrange furnaces so that each supports the air

stream of the next furnace, thus creating circulatory air movement in the area. A

large portion of the heated air should be directed toward the side of the building

exposed to prevailing winds. The INOV8 dealer can provide recommendations for

the most efficient installation of multiple furnaces. These installations will vary

depending upon the unique layout of the facilities.

9. Adequate combustion air is required to maintain combustion. The INOV8 furnace will

not operate in a negative building pressure (see section on sealed combustion if this

exists).

10. Minimum clearances from combustible surfaces must be adhered to. See the

section “Minimum Clearances” for more information.

ATTACHING THE BURNER TO THE FURNACE

Carefully remove the burner and components from the shipping box. Be careful when

handling the burner, as the electrodes and the flame retention head are factory set and if

either are bumped or moved, the operation of the burner could be affected. If the

electrodes get out of adjustment, refer to page 25 for a diagram of the proper electrode

settings. The burner has been pre-fired in the factory prior to shipping and will have oil in

it. A plug has been installed in the pump for shipping and should be removed carefully to

avoid spilling oil.

INSTALLING THE BURNER:

1. Place the burner gasket onto the air tube.

2. Remove the three 3/8”-16 nuts from the burner mounting plate studs.

3. Place burner on mounting plate studs.

4. Now tighten the 3/8” nuts that hold the burner to the mounting plate.

INOV8 Model F240 – Edited September 2008

6

INSTALLING THE ELECTRICAL PLUG

Insert the round burner power plug into the socket provided on the bottom of the

electrical junction box that houses the GFCI outlet.

ELECTRICAL HOOKUP OF THE FURNACE

1. Remove a convenient knock-out from the electrical junction box to allow

connection of your electrical supply conduit.

2. Attach the hot wire (typically black) to the 6” black pigtail that comes off the GFCI

“Line Hot” terminal.

3. Attach the Neutral wire (typically white) to the 6” white pigtail that comes off the

GFCI “Line Neutral” terminal.

4. Attach the earth ground wire to the 6” green pigtail that comes off of the junction

box.

5. If the furnace has a blower fan (like a squirrel cage) hook the other hot wire

(typically red) to the red pigtail that comes off the fan contactor.

ATTACHING THE OIL DELIVERY LINE (‘A’ IN PHOTO)

Specifics on the oil storage and plumbing are covered in the section titled “Tank

& Piping Considerations” starting on page 13. The items in that section must

have been completed in order to have an oil supply line run to the burner at this

time. Assuming the line is in place: the oil supply line will connect to the inlet

port of the pump on the burner. There are two inlet ports: one on the bottom of

the pump and one on the side. Connect to the one on the side. Attach the line

to the pump via a ½” x ¼” NPT flare fitting and use the corresponding female

portion with a barb fitting to attach to a flexible oil line. DO NOT do the

following:

•plumb the line directly into the pump,

•use any compression fittings,

•use rigid line that will be difficult to remove for servicing the burner.

Be sure to seal the ¼” NPT threads of the flare fitting at the pump inlet. ONLY

Use pipe sealant suitable for waste oil, such as Loctite #565.

ATTACHING THE RETURN LINE (‘B’ IN PHOTO)

As noted in the section “Installation of Vent Line from Vapor Eliminator Back to the Tank”

on page 14, a ¼” O.D. (minimum) copper or plastic line must be installed from the burner

back to the tank. This line will connect to the brass elbow on top of the oil pressure

release mechanism via the compression nut and ferrule supplied on that elbow. There

will be no pressure in this line as long as the line is open all the way back to the tank. It

is ABSOLUTELY IMPERATIVE that no valves or other constrictions be placed or allowed

to exist (like crimps) in this line.

B

A

INOV8 Model F240 – Edited September 2008 7

ATTACHING THE AIR CONNECTION

The air regulator assembly is in a plastic bag in the burner box.

1. Remove the screws and all necessary parts from the plastic bag.

2. Mount the ‘L’ shaped bracket to the right side of the burner just above the

end of the motor (as shown in the photo at right).

3. Secure with the two screws that are provided.

4. Then mount the air regulator into the bracket, securing it with the black

plastic ring nut.

5. Connect the ¼” air line into the right-most fitting in the bottom of the module

block. It just slides in and locks. It can be removed by pushing up on the

ring on the fitting and then pulling the line back out.

6. There is a ¼” NPT hole in the regulator into which you can install a quick-

disconnect type of fitting. To this connect the air supply line coming from the

compressor. The regulator will be set during the section on “Operating the

Furnace”.

BLOCKED VENT SWITCH –SUPPLIED WITH CANADIAN FURNACES (OR OPTIONAL)

The Blocked Vent Switch responds to hot flue gases backing up through its heat transfer

tube during a blockage and shuts off the burner. The Backflow Sensor Switch is

supplied with furnaces shipped to Canada (or as an optional purchase) and must be

installed in accordance with these instructions and those that accompany the switch, that

are abbreviated here.

1. Drill or pierce a clean hole (about ¾” diameter) in the vent pipe near the heater

outlet.

2. The heat transfer tube must have the fiber gasket installed against the mounting

plate before attaching the unit to the vent pipe.

3. Insert the heat transfer tube with gasket into the ¾” diameter hole placed in the vent

pipe during step 1.

4. Secure the assembly to the vent pipe with a minimum of 4 sheet metal screws. The

channel must be mounted horizontally.

5. Refer to the electrical diagram in the Addendum for wiring connections – DO NOT

refer to the diagrams that accompany the switch.

This switch requires annual inspection and maintenance to remove any ash buildup on

the thermal switch surface.

INSTALLATION DETAILS

AIR SUPPLY INSTALLATION

There are two air supplies used in the combustion process. Combustion air entering the

chamber through openings in the burner housing, located next to the oil pump, is referred

to as "secondary or combustion air". Air is also supplied to the nozzle under pressure in

order to atomize the oil into small particles for burning. A shop air compressor supplies

this air. This compressor air is referred to as either primary air or atomizing air.

Installation of the primary air is described below:

INOV8 Model F240 – Edited September 2008

8

1. A continuous supply of compressed air (2.0 CFM at 30 psig) is required to operate

the furnace. The furnace includes a factory provided pressure regulator rated at 300

PSIG with a gauge rated to 160 PSIG inlet for shop air. The connection requires 1/4 "

NPTM. The pressure regulator is located on the right side of the burner housing (see

photo on page 7) and controls air for use in atomization.

2. The shop air must be free of dirt and water. A filter should be installed in the line

before attaching to the INOV8 burner. Do not attach the shop air directly to the

burner module as damage will occur from the high pressure.

3. Air may be piped directly from the air compressor supply tank by using 1/4-inch (or

larger) pipe, seamless copper tubing, or air hose. If piping or rigid tubing is used it is

recommended that a short piece of hose be used to connect to the air regulator (on

the burner) in order to swing the burner away for cleaning the combustion chamber.

If air hose is used, it should have a minimum burst pressure rating of 300 psig.

4. Water routinely condenses in the air lines of a shop compressor and must be

removed periodically. Water must be kept to a minimum to prevent component

failure and operating problems.

Note – If there are concerns for leaving the air compressor on during nights and

weekends, INOV8 has a compressor protection device available.

CHIMNEY INSTALLATION

Included in this section are the critical factors involved in the chimney installation. The

complete guidelines can be found in NFPA 211 – Standard for Chimneys, Fireplaces,

Vents, and Solid Fuel Burning Appliance, 2006 Edition, and in NFPA #31 – Standard for

the Installation of Oil-Burning Equipment – 2006 Edition. There may also be local codes

that need to be adhered to. The most critical factor in the installation of your INOV8

furnace is a properly designed and located chimney. A good draft (air movement up the

chimney) is essential to the safe and reliable operation of the furnace. The furnace will

not run with any degree of success when attached to an improperly installed chimney.

The chimney MUST meet these requirements:

1. The chimney must be 8” diameter pipe with a minimum of 12 vertical feet.

2. It must be tall enough and sufficiently clear of wind obstacles at the top to provide

constant, adequate draft to the furnace.

3. It must be free of any horizontal runs in excess of 3 feet. If any section of it must be

run laterally, run that section laterally upward at the sharpest possible angle.

4. Avoid using elbows as much as possible, particularly 90o elbows. An additional 2 feet

of chimney height is required for each elbow.

Most installation standards recommend that an insulated stainless steel chimney be used

from a point 18 inches below the ceiling to the top at the rain cap. The purpose of the

insulated chimney is to protect combustible building materials from high temperature, but

it also supports the chimney draft and prevents harmful condensation within the chimney.

For each gallon of oil burned, there is a gallon of water vapor generated as a product of

the combustion process. This water vapor can condense inside the chimney in extremely

cold weather. Some waste oils contain various ingredients that will form acids when

combined with the condensation. These acids will prematurely corrode non-insulated,

non-stainless steel piping and the furnace heat exchanger.

An ideal chimney is attached to the furnace by a ‘T’ fitting and consists of 8” chimney

pipe going straight up through the roof to sufficient height to provide at least 12 feet

between the furnace flue attachment and the top of the chimney. Other items of

importance include:

INOV8 Model F240 – Edited September 2008 9

1. Each furnace must have a dedicated

chimney.

2. New chimney pipe is recommended. Tying

into old stacks often causes problems

because of soot build-up inside the chimney,

too small of interior pipe, the connection

section is often a horizontal piece, concrete

chimneys are cold and difficult to heat up to

create the draft and additional length is

difficult to add.

3. A barometric draft damper and a clean-out

tee must be installed at the bottom of the

vertical chimney.

4. Single-wall flue pipe may be used for

INTERIOR CHIMNEY ONLY! Stack

temperatures in excess of 500oare common.

5. A metal ventilated, approved thimble must

be used when passing through a combus-

tible wall. Once through the wall, DO NOT

use a single-wall component.

6. Sidewall flue installations are prohibited

without written factory authorization.

7. The last stack section must extend at least 3

feet above the highest point at which it

comes in contact with the roof, and at least 2

feet higher than any ridge, parapet wall or

roof structure within 10 feet of the chimney.

8. Install a non-restrictive stack cap (rain cap). In extremely windy locations, a Breidert

type vent cap is recommended. A screen to restrict birds from access to the

chimney is recommended.

9. It may be necessary to install a draft inducer on chimneys that fall short of providing

sufficient draft for whatever reason. See the following section for more information.

INSTALLING THE BAROMETRIC DRAFT CONTROL

The barometric draft control is intended to provide consistent draft, especially in tall

chimneys where there may be excessive draft that could impact the flame. The best

location for the barometric draft control is in the first vertical section within one to three

feet of the furnace. The flapper on the barometric draft control should be installed so it is

facing away from the fan on the furnace. The flapper must be vertical when closed. Use

a spirit level to make sure the barometric draft control is plumb in all directions,

regardless of whether the flue is horizontal, vertical or sloping. Do not attach the

barometric draft control in a horizontal section of flue pipe or in a room separate from the

furnace. See the photo on page 2. Additional installation instructions are included with

each damper.

Typical Chimney Parts

INOV8 Model F240 – Edited September 2008

10

DRAFT MEASUREMENTS &ADJUSTMENTS

Tools Required: Dwyer Pressure Gauge, Draft Rite or Bacharach Draft Gauge

The barometric draft control must be set to maintain proper draft. Draft measurements

must be re-done any time there is a change in the combustion air adjustment located on

the burner housing (secondary air). Follow these instructions for measuring the draft

over the fire:

1. Check the draft while the burner is up to temperature and the cabinet fan is running.

Insert the draft gauge into the ¼” hole in the 2” view port. The measurement must

indicate a draft of 0.02 to 0.04 inches WC (water column) for newly installed or newly

cleaned furnaces. The furnace will not operate properly with a draft less than 0.01.

2. A draft greater than 0.05 will induce excessive heat up the chimney resulting in low

heat output and abnormally high stack temperature. Make necessary adjustments to

the barometric draft damper, according to the factory instruction sheet found in the

box the damper comes in.

INSTALLING AN OPTIONAL DRAFT INDUCER

A draft inducer is a motor driven fan that attaches to the chimney for the purpose of

augmenting the natural draw of that chimney. It may be necessary to install a draft

inducer on chimneys that fall short of providing sufficient draft for some reason or other,

but a draft inducer is not a cure-all: It provides no relief for resonation problems that can

occur in horizontal runs, for instance, and it cannot overcome the effects of an exhaust

system operating within the building. Should you find that your installation requires the

assistance of a draft inducer, install it according to the following guidelines:

Install it just above the barometric draft control in a vertical section, on the opposite side

of the chimney from where the furnace flue pipe enters. Avoid mounting in horizontal

sections for these reasons: a) ash will accumulate on the blades, b) it will be exposed to

excessive heat, and c) it will need to be supported in some manner. A red wire is

provided in the furnace’s electrical junction box which functions to control a relay that

turns the draft inducer on at the proper time. Wire the draft inducer and relay in

accordance with the electrical wiring diagram. Draft inducers are adjustable and may

need to be adjusted to obtain proper draft.

INSTALLING AN OPTIONAL SEALED COMBUSTION SYSTEM

Refer to the burner diagram on page 20 for identification and location of parts.

1. Remove the oil supply line (item #4 on drawing) from the burner pump.

2. Remove the copper ‘U’ shaped tube just above the pump.

3. Disconnect the pump outlet hose from port ‘C’ under the module. Remove the

other end of the hose from the oil pump.

4. Remove the two bolts that secure the oil pump to the burner casing.

5. Remove the oil pump. (The plastic pump shaft drive coupling is made of three

parts: some, all or none of which might remain on the pump shaft during removal.

Put it back together if necessary and slide it all onto the motor shaft.)

6. Remove the two screws that secure the disk shaped secondary combustion air

bands to the burner casing. The screws are just above and below the pump.

7. Remove the disk shaped air band. (It will not be re-installed.)

8. Loosen the cinching screw that binds the disk shaped secondary combustion air

band to the burner casing and remove the bands. (It will not be re-installed.)

9. Install the provided 450 ‘street’ elbow into the hole in the pump from where the

hose was earlier removed. Use thread sealant and turn it to a position such that

the outlet of the elbow will be horizontal when the pump is remounted.

INOV8 Model F240 – Edited September 2008 11

10. Install the provided sheet metal air boot onto the extended casing of the burner.

The provided sponge rubber gasket will seal the boot to the burner casing. The

two slots in the gasket will line up with the two oil pump bolt holes. (Rotate the

air boot until the left side is essentially vertical.)

11. Using bolts saved in step 4 above, re-install oil pump with coupling connecting

both shafts. Be aware that the flat on the pump shaft must align with the flat side

in the coupling. Don’t tighten the bolts yet

12. Re-attach the copper ‘U’ bend removed earlier.

13. Wiggle the boot to make sure it’s properly seated. Then tighten the pump bolts.

14. Attach the pump hose to the 45o‘street’ elbow. Use thread sealant.

15. Re-attach the other end of the hose to port ‘C’ under the module block.

16. Re-install the oil delivery line to the pump inlet with 1/8-27 NPT 45ostreet elbow.

17. Cut a 4” round hole through the wall near the chimney. The termination of the

vent must be on the same plane as the termination of the chimney.

18. Install the provided air intake mechanism and secure it to the wall.

19. The termination of the vent pipe must be at the same plane as the chimney pipe.

20. Connect the f” port on the intake mechanism to the 4” port on the sealed

combustion boot with solid vent hose (Not provided)

21. Secure the hose at both ends with hose clamps. (Not provided)

22. Set the combustion air adjustment knob in the boot to around 60.

23. Assure that the barometric draft control flapper is sealed shut and can no longer

function.

24. Start the furnace and allow time for the chimney to get hot.

25. Make further adjustment to the combustion air as necessary to produce a good

flame. You want as little combustion air as possible to produce a clean flame.

Check the draft to be sure the setting is proper.

NOTE: It is important that the air brought into the burner through the sealed combustion

adapter boot is allowed to warm up. Cold outside air will cool the preheated oil and

cause combustion problems. Longer lengths of vent pipe and/or running it along side the

furnace are two options for pre-warming. Call the factory for other suggestions.

INOV8 Model F240 – Edited September 2008

12

Figure 2 - Typical Installation Diagram (without bench tank)

NOTE: The above diagram is intended for illustration purposes only.

CEILING MOUNT INSTALLATION CONSIDERATIONS

Be aware that the F240 furnace weighs 500 pounds (186 kg) and the F240 SC weighs

550 pounds (205 kg) when planning its installation. Before suspending the unit, check

the supporting structure to ensure it has sufficient load-carrying capacity. The furnace

comes with 5/8" bolts, lock washers and shackles for suspension purposes. Securely

transfer the furnace weight to the roof/ceiling trusses. Use a proper ceiling mounting

system, such as a 2" x 2" x 1/4" angle iron. Lock all mounting components in place using

lock washers and double nuts. It is important that the furnace be hung level side-to-side

and front-to-back and level with the floor. Never hang the furnace with ropes or chains.

ELECTRICAL SUPPLY INSTALLATION

Installation must be done only by a licensed electrician in accordance with the NFPA 70-

2005, National Electric Code® International Electrical Code® Series. See electrical

diagrams in the Addendum. If the furnace has a propeller fan blower, the furnace

requires a 20 amp, 120 volt service. It will have a maximum draw of 17 amps. If the

furnace has a squirrel cage type blower, the furnace requires a 20 amp, 208/240 volt

service including a neutral line. It will have a maximum draw of 17 amps.

INOV8 Model F240 – Edited September 2008 13

FAN/LIMIT CONTROL

The fan/limit controls the on/off function of the motor

that drives the fan or blower unit. It also shuts down

the burner in the event of excessive heat in the

furnace. This safety control is located in the upper

corner (on the louver side of the furnace). Make

certain that the switch has the proper settings: Fan ON

= 140oF, Fan OFF = 80oF, Limit = 170oF. It should

be on the “AUTO” setting.

TANK &PIPING CONSIDERATIONS

OIL STORAGE CONSIDERATIONS

The proper storage and handling of oil is monitored by the federal EPA and most state

environmental agencies, such as the Department of Natural Resources (DNR), your local

Fire Marshall and/or the Regional Environmental Protection Agency. Some states have

adopted more stringent regulations which must be identified and adhered to. Your

installer is responsible for knowing these regulations and of any pertinent application

and/or approval requirements for your oil storage system.

Federal and some state and local regulations restrict the burning of gasoline, paint

thinners and other volatile (low-flash point) solvents, PCBs, benzenes (carburetor

solvent), and fluorinated hydrocarbons (refrigerants). DO NOT add anti-freeze, oil

additives, or paint as these will not burn and cause operating problems.

The instructions found in this manual are general guidelines; exact local regulations must

prevail. Installation of the oil storage and piping must be done by a licensed or qualified

installer in accordance with the pertinent state and local codes and the nationally

accepted standard, NFPA 31 – Standard for the Installation of Oil-Burning Equipment

2006 Edition.

ADDITIONAL OIL STORAGE CONSIDERATION

Many operational problems can be eliminated if proper care is taken in setting up an oil

storage system. All waste oil contains substantial amounts of water and sludge, both of

which settle to the bottom of a tank over a period of time. A storage system that allows

sufficient settlement time will provide trouble free operation. A two-tank system is

recommended allowing one tank to settle while drawing from the other.

Use a fill pipe when adding oil. This fill pipe should extend to within two inches of the

bottom of the tank to minimize the disturbance of the upper oil that is supplied to the

burner. At least once a year the water and sludge should be drained off the bottom of the

tank. If not drained, the pump will draw the water and sludge into the filters and may

cause a shutdown in operation. The tank should be located in close proximity to the

furnace. Inside, outside or buried tanks must be used in accordance with state and local

installation codes.

PIPING &FITTING RECOMMENDATIONS

Air leaks in the oil line will cause sporadic operation. The pipe or tubing size is important

for the best operation of the pump. The following recommendations will produce airtight

connections and trouble-free operations.

1. If the storage tank is inside the building, use 1/2" i.d. (Up to 30 feet to the furnace).

INOV8 Model F240 – Edited September 2008

14

2. If the tank is more than 30 feet away then 1" i.d. or bigger is required (depending on

the distance).

3. Copper piping or iron piping can be used if care is taken with each joint and the line

has a continuous upward incline of at least 1-inch per 1 foot to vent air to the burner.

Flexible copper tubing may be suitable. When using soft copper tubing or plastic

tubing flare fittings are required. Proper sized copper tubing with proper flare fittings

has the least potential for leaks. DO NOT use numerous short lengths of pipe as

each fitting is a potential source of a leak.

4. At no time should pipe unions or compression fittings be used. Sealant (such

as Locktite #565 or Permatex #2 Non-hardening Gasket Sealer) must be used

on all pipe threads.

TANK FILTER

INOV8 provides an in-line filter assembly to be installed in the oil supply line. This filter

will need to changed every six months or as indicated on the filter restriction indicator; the

frequency depends on the type of oil. This filter is a General Filter, model 11V-R2000K

Gar-Ber Fuel/Water Separator. It has a machined aluminum head. The filter dimensions

are: 9” H x 4-3/4” W. It comes with a 1/8” vacuum bleed port, a 3/8” NPT inlet and outlet,

has 10 micron removal, filtering area of 500 square inches, working pressure of 15 psig

and a flow rate of 90 gph, and is UL listed. Replacement elements require part number

R2000 Epoxy-coated Disposable Spin-On Filter.

VAPOR ELIMINATOR FILTER /PRESSURE RELIEF ASSEMBLY

The vapor eliminator/pressure relief assembly located on the burner (see items #2 and

26 on page 20) serves three functions:

1. It vents any vapors that accumulate in the burner’s oil circulating system back to the

oil supply tank.

2. It filters the oil as it is heated and re-circulated at the burner.

3. It shunts the full volume of the pump back to the tank in the event the vapor

eliminator filter should become totally plugged.

INSTALLATION OF VENT LINE FROM VAPOR ELIMINATOR BACK TO THE TANK

A minimum of ¼” copper line or plastic tubing must be run from the compression fitting on

the pressure relief assembly (see item #13 on page 20) back to the oil supply tank.

There must be no valves or constrictions in this line. See “Burner Ignition Start-up” for

adjustment of the valve controlling flow through this line.

1. Insert one end of the return line into the nut and ferrule (provided) on the pressure

relief valve on the vapor eliminator.

2. Run the line along the oil supply line back to the oil storage tank through an available

opening. Make sure the return line nearly touches the bottom of the tank to prevent

loss of prime in the oil supply line. If no opening is available, use a “T” fitting to share

the opening with the supply or fill opening.

3. While the burner is running there should be a steady rapid drip (not a stream) coming

from the end of the return line. Adjust the valve accordingly. Excessive flow will take

all the hot oil back to the tank, inadequate flow will cause vapor to build in the pump.

VAPOR ELIMINATOR FILTER

The filter element in the vapor eliminator canister can plug up over time due to the normal

collection of debris. When the filter is plugged, an amber light on the burner will come on

while the burner is firing to indicate that the filter should be changed. If the filter is not

changed, the pressure relief assembly will vent the over pressured oil back to the tank

through the ¼” return line.

INOV8 Model F240 – Edited September 2008 15

INOV8 Model F240 – Edited September 2008

16

BENCH TANK INSTALLATION

Tanks are available in a variety of sizes and configurations. Our model

T300 HB, a 300 gallon tank with steel supports, holds the INOV8 furnace

eight feet above the floor. Installations using this bench tank are easier

than those without a bench tank because of the ease in mounting the

furnace versus hanging and the short distance for running the oil supply

line. The bench tank comes fully supplied with all necessary fittings for a

complete installation. Many states and cities have additional regulations

regarding the storage of waste or other fuels that may require stricter

measures. It is very important to check with your local fire inspector, or the

proper authority, or a qualified tank installer regarding the requirements in

your area. Refer to these steps for a basic installation.

Figure 3 - Bench Tank Setup

Table of contents

Popular Heater manuals by other brands

Russell Hobbs

Russell Hobbs RHMFHO1 Installation manual and operating instructions

Toyotomi

Toyotomi Toyoset LC-3010 operating manual

Stelpro

Stelpro SCR series user guide

Webasto

Webasto AirTop 2000 S Operating, and servicing instructions

Purmo

Purmo YALI PARADA PLUS Installation and operating manual

Ayce

Ayce DF-150A7-7 manual

Stanley

Stanley ST-23-240-E instruction manual

Soleus Air

Soleus Air HC1-15-12 operating instructions

Bricoman

Bricoman K3CK145NVGBMAN Assembling instructions

Eterna

Eterna SH3WH installation instructions

Dimplex

Dimplex TDTR 175 W Installation and operating instructions

Linea 2000

Linea 2000 DOMO DO7323F manual