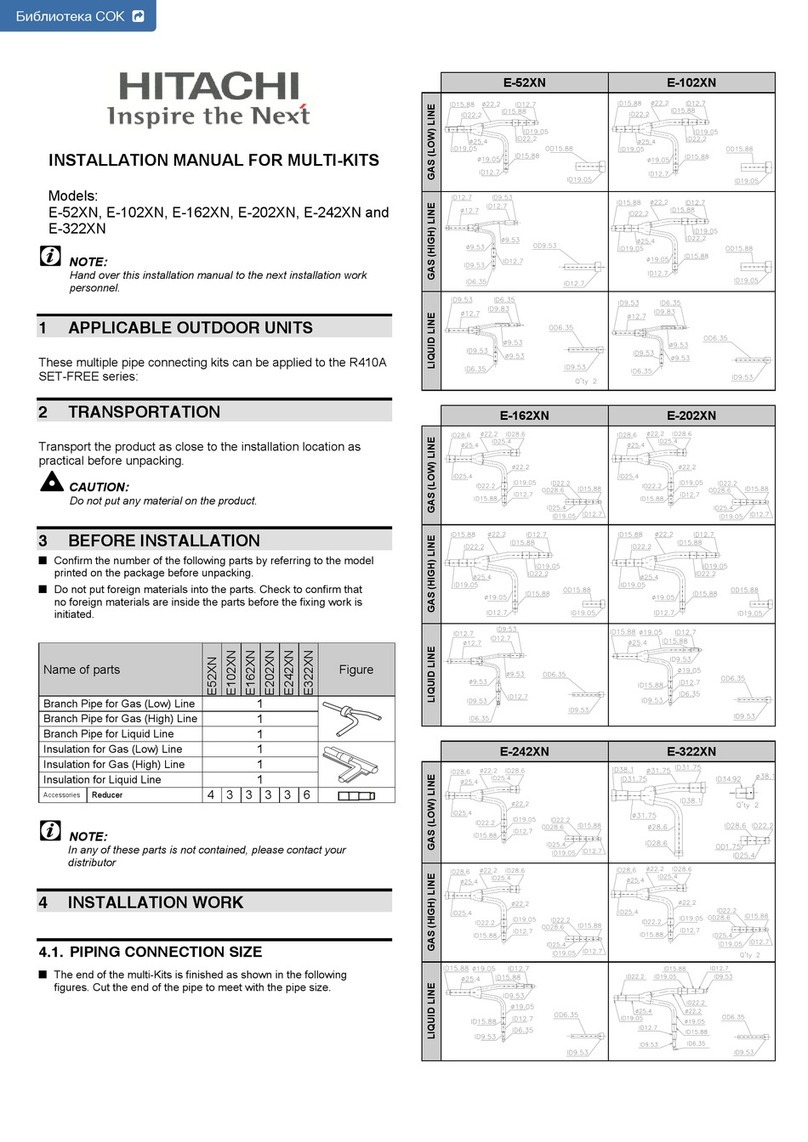

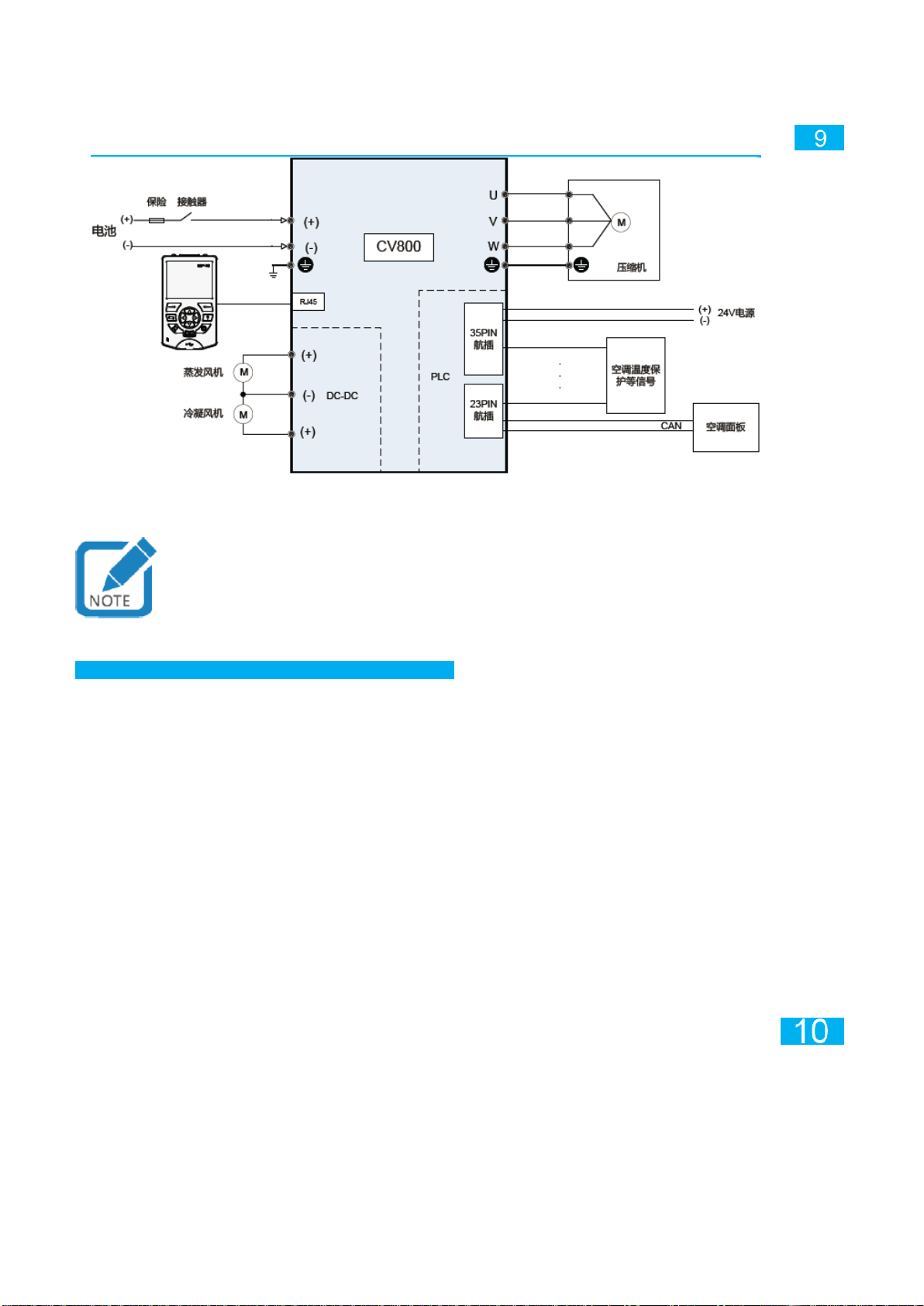

Insurance Contactor

Battery Compressor

24V power supply

35PIN aviation plug

Evaporating fan

Air-conditioning temperature protection signal etc.

Condensate fan 23PIN aviation plug Air conditioner panel

• Brush fan: regulate speed directly with internal voltage regulation instructions.

• Brushless fan: please fix DCDC output voltage, and regulate speed with AI port or PWM port of brushless fan

Fig. 5 CV800 system wiring diagram

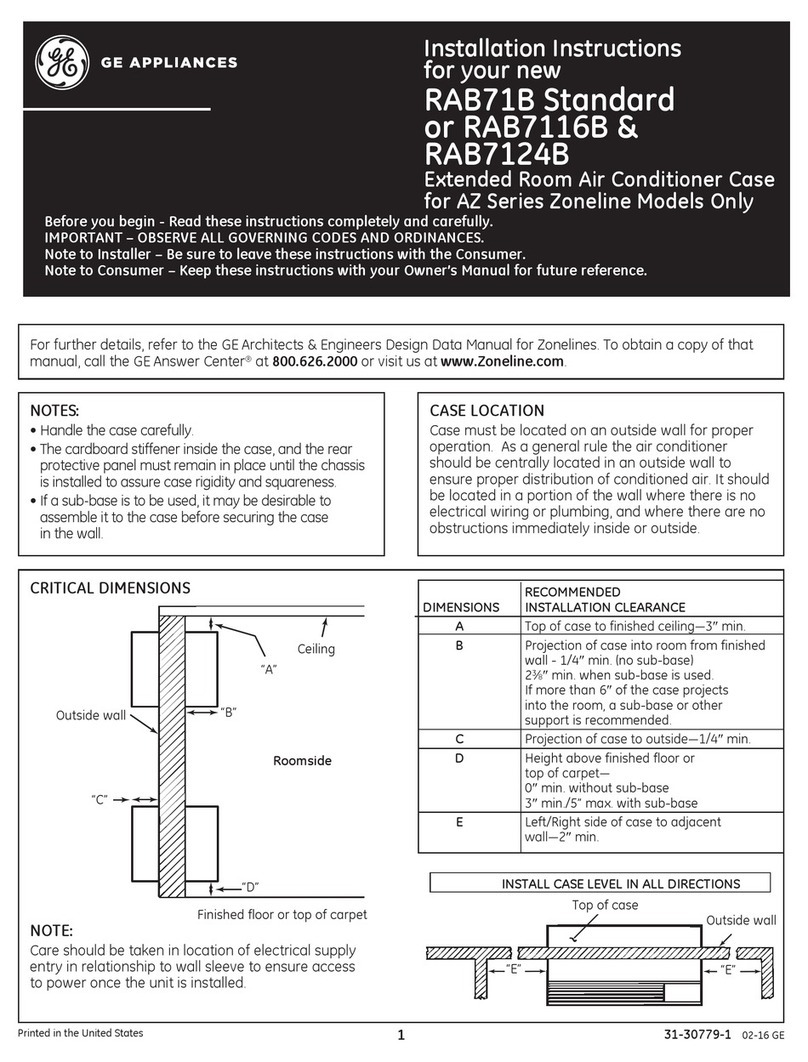

● Waterproof plugs at DC-DC side should be tightened in turn, otherwise, the middle one will interfere

with the two beside it.

a) Connect the compressor and fan, and input the high voltage into DC power supply;

b) To use external keyboard for debugging, please connect SOP-20-810 keyboard;

c) Debug the inverter and change its parameters;

d) Debug DC-DC, and change DC-DC parameters;

e) Write PLC program, and debug PLC;

f) Start running the air conditioner;

g) After confirming that everything is OK, confirm whether CAN pull-up resistor is correct, and lock the

keyboard cover and main power wiring cabin cover.

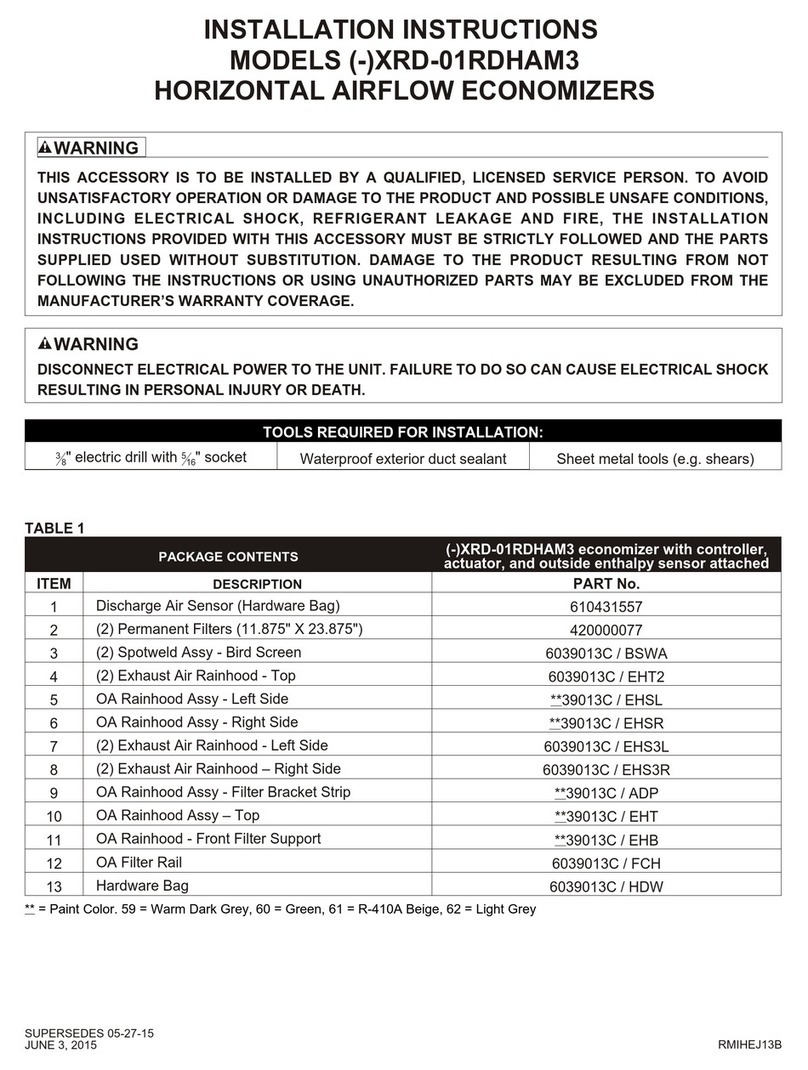

☞Operation and speed regulation of inverter

F0-02 Select command source

0: LCD keyboard/background software command channel;

2: communication command channel (CAN), by default.

F0-03 Select frequency source

0: digital setting (F0-08), not saved after power failure;

1: digital setting (F0-08), saved after power failure;

9: communication setting (CAB), by default; other options of the two sets of function codes are not

available. When using PLC to control the inverter, set F0-02 to be 2, and F0-03 to be 9.

☞DC-DC startup and voltage regulation

F4-00: Select startup mode

1: EN enabled to startup, and EN disenabled to shut down the device;

2: EN enabling and CAN sending startup command to start the device simultaneously, and

correspondingly, EN disenabled or CAN sending shutdown command to shut down the device. Default;

3: SOP-20-810 keyboard and DI enabled startup and stop.

F4-01: Voltage regulation mode

1: Voltage regulation, refers to adjust the output voltage with keyboard (default value 27.5V)

2: control source for voltage regulation is CAN, by default

Voltage regulation range is 14-27.5, where the keys F4-11 on the keyboard are used for regulating

voltage of the first module, and the keys F4-12 are used for regulating voltage of the second module.

☞DC-DC parallel connection

The single output of DC-DC is not greater than 65A, and the total output of two channels is not greater

than 110A, where parallel connection mode is available, i.e. positive terminals of two output channels

are short-connected to form one channel output power. Please contact us at this time to apply for short