InSystems Pick-to-Light Series User manual

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 2-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

EU Declaration of Conformity

InSystems Automation GmbH, Wagner-Régeny-Straße 16, 12489 Berlin

for the devices:

Pick-to-Light Sensor P2L-Sensor D003 Digital

Pick-to-Light Sensor P2L-Sensor D003 Digital ESD

Pick-to-Light Sensor P2L-Sensor C003 CAN Bus

Pick-to-Light Sensor P2L-Sensor C003 CAN Bus ESD

We herewith confirm the conformity of the above-mentioned products with European laws and standards:

EU Guideline 2004/108/EG –EMV

EU Guideline 2011/65/EU –RoHS

Following harmonized standards are used:

DIN EN 61326-1:2013-07

Electrical Equipment for Measurement, Control and Laboratory Use

EMV Requirements

The measurements were performed by an EMW laboratory; the measurement report can be viewed on

request.

Authorized representative for technical documentation:

Susanne Dannat, technical documentation

InSystems Automation GmbH

Wagner-Régeny-Straße 16

12489 Berlin

Deutschland

Berlin, 18.01.2018

Ort, Datum Dipl. Ing. Henry Stubert, Geschäftsführer

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 3-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

1Preliminary Remarks

1.1 General Remarks

–These operating instructions describe the handling of the Pick-to-Light sensors.

–This guide addresses to especially trained staff only.

–Prior to installation and use of the sensors, every user must have read these instructions.

–The sensors should only be installed and adjusted (teach-in procedure) from qualified staff members.

–InSystems Automation GmbH will not be responsible for damages due to improper use and settings of the

sensors.

–The operating instructions must be available during the whole lifetime of the sensors.

If you have any questions, please contact the customer service at InSystems Automation GmbH.

1.2 Safety Remarks

Please observe the instructions for the assembly procedure and the content of the safety remarks in

chapter „Information to this guide“.

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 4-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

2Table of Contents

EU Declaration of Conformity 2

1Preliminary Remarks 3

1.1 General Remarks 3

1.2 Safety Remarks 3

2Table of Contents 4

3Product Overview 7

3.1 Acronyms / Definitions 7

4Information to this Guide 8

4.1 Coverage and Target Audience 8

4.1.1 Function of this Document 8

4.1.2 Storage of the Instructions 8

4.1.3 Safety Remarks and General Warnings 8

4.2 Safety remarks 9

4.3 Intended Use 9

4.4 Improper Use 9

4.5 Improper Use 9

4.6 Addition, Changes and Modifications 9

5Product Description P2L Sensor 10

5.1 Available Models 11

5.2 General remarks 11

6Initial Start-Up 13

6.1 P2L D003 Digital 13

6.2 P2L C003 CAN Bus 13

6.3 Available on Request 13

6.3.1 Pick-2-Light-Software from InSystems for CAN sensors 13

6.4 Settings 13

6.4.1 LED Brightness 14

6.4.2 Pick Time 14

6.4.3 Pick Type 14

7P2L Sensor Assembly and Coverage Area 14

7.1 Required Tools and Assembly Material 14

7.2 P2L Sensor Coverage 14

7.3 Assembly and Sensor Alignment 15

7.4 Sensor Position on the Box 16

7.4.1 Ideal P2L Sensor Positioning 16

7.4.2 Poor Sensor Positioning 17

7.5 Assembly of ESD Sensors 17

7.6 Assembly Examples 18

8Connection 18

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 5-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

8.1 P2L D003 Digital 18

8.1.1 Connector Plug 19

8.1.2 DIP Switch for Brightness and Pick Time 20

8.2 P2L C003 CAN Bus 21

8.2.1 Variant 1: Connection to USB-CAN bus adapter 21

8.2.2 Variant 2: Connection to PLC 22

8.2.3 Connector Plug 23

8.2.4 CAN bus Addressing 23

9Use in PLC Systems 25

9.1 Start-up Sequence 25

9.2 Start and Process Error 25

10 Teach-in of P2L Sensors 26

11 P2L Sensor Control 28

11.1 Operation Modes 28

11.2 Consequences by Errors during Picking Operations 29

11.3 Signal Processing P2L D003 Digital 29

11.4 Signal Processing P2L C003 CAN Bus 30

11.4.1 CAN –Data Telegram 30

11.4.2 11.4.3Message Protocol 30

11.4.3 Communication with the sensor and functions 31

11.4.4 Sensor answers 32

12 LED Error Codes and Troubleshooting 33

13 Special Issues 34

14 P2L mobile supply unit with Pick-to-light sensor 35

14.1 Station Technical Data 35

15 Service 36

15.1 Downloads and FAQ 36

15.2 Customer Service 36

16 Maintenance 36

16.1 Cleaning 36

17 Dispose of Old Devices 36

18 Technical Data P2L sensors 37

18.1 Measurements and Elements of P2L sensors 38

18.1.1 P2L D003 Digital 38

18.1.2 P2L D003 CAN Bus 39

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 6-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

2.1 Table of Pictures

Picture 1: Supply shelf 10

Picture 2: Protection class IP53 11

Picture 3: Diagram of sensor area 15

Picture 4: Recommended position 15

Picture 5: Sensor field facing upwards 15

Picture 6: Sensor field facing sideways 16

Picture 7: Good sensor position 16

Picture 8: poor sensor position 17

Picture 9: Insufficient P2L positioning 17

Picture 10: Assembly with customer specific bracket 18

Picture 11: Pick-to-light system scheme with P2L digital 18

Picture 12: Socket assignment at P2L digital 19

Picture 13: Schema of DIP switch 20

Picture 14: Bottom of P2L D003 with DIP switch 20

Picture 15: Schema of Pick-to-light system with CAN bus and connection to USB-CAN bus adapter 21

Picture 16: Schema of Pick-to-light system with CAN bus and connection to PLC 22

Picture 17: Socket assignment at P2L CAN Bus 23

Picture 18: Schema of DIP switch 23

Picture 19: Bottom of P2L C003 with DIP switch 23

Picture 20: LED signals during startup sequence 25

Picture 21: LED signals by error during startup sequence 25

Picture 22: LED status after successful teach-in after system start 27

Picture 23: LED status after an error during teach-in procedure 27

Picture 24: Example for succeeded picking operation 28

Picture 25: Example for picking error 28

Picture 26: LED signals during correct picking 29

Picture 27: LED signals by wrong picking 29

Picture 28: PLC signals by correct picking operation 29

Picture 29: PLC signals by picking error 30

Picture 30: CAN data telegram 30

Picture 31: LED while setting brightness 32

Picture 32: LED while setting picking time 32

Picture 33: Mobile P2L station with open fronted container (LF 211 ZW PP) by SSI Schäfer 35

Picture 34: Measurements P2L D003 38

Picture 35: Overview P2L digital 38

Picture 36: Measurements P2L CAN bus 39

Picture 37: Overview P2L CAN bus 39

Copyright © 2018, InSystems Automation GmbH

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 7-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

3Product Overview

General

P2L sensors are designed for assembly or picking systems. The sensors simplify the

assembly or picking processes for the workers by leading them. The sensor recognizes

if they reach in the right shelf and gives a signal immediately

.

Optic signal:

–

A green LED shows from which shelf the next piece should be taken

.

–A red LED communicates an error.

Models

There are different models for Pick to Light sensor:

–P2L D003 digital

–P2L D003 ESD digital

–P2L C003 CAN Bus

–P2L C003 ESD CAN Bus

Model 002 is a further development of model 001. The sensors of 002 series allow

advanced settings and an automatized teaching-in process (adaption to the geometry

of the container and fill height).

Version 003 is a further development of versions 002 and 001. The sensors of the 003

series allow advanced settings and a new housing design.

You can read more details about the sensors in the relevant chapter.

Service

InSystems Automation GmbH allows a free sensor test:

We provide test sensors for a functional test to your conditions. Please contact our

customer service (See chapter 15.2)

3.1 Acronyms / Definitions

CAN

Controller Area Network (serial Fieldbus system)

DIP

Dual in-line package

ESD

Electro static discharge safe device

SLC

Small Load Carrier

MFC

Material Flow Control

P2L

Pick-to-light

PLC

Programmable Logic Controller

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 8-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

4Information to this Guide

4.1 Coverage and Target Audience

The following guide is valid for the described P2L sensor. It describes safety-compliant and efficient handling of

sensors and explains the necessary procedures during installations and operations. Operating instructions

must be read and understood from everyone executing following tasks:

–Installation

–Configuration

–Closing down and removal

4.1.1 Function of this Document

These operating instructions contains all necessary information for proper assembling, electric installation,

putting into operation and operation modus of P2L sensors.

These operating instructions do not refer to the functions of assembly or picking system, which is integrated in

P2L sensors. This information can be found in the operating instructions of the system manufacturer.

4.1.2 Storage of the Instructions

The operating instructions must be always available in the place of use of the described sensors.

4.1.3 Safety Remarks and General Warnings

In these operating instructions, safety remarks and general warnings with following symbols and contents are

used:

Special warning

signs

Safety warnings are provided with an additional symbol when referring to specific

hazards.

Text Layout Remarks

Instructions

Description

Operating instructions are numbered consecutively in the margin column (1,2 etc.)

are structured as follows:

Description of an operating instruction:

This symbol identifies an operating step. An operating instruction contains one

or more consecutive operating steps.

This symbol underlines useful tips and extra information.

This symbol identifies the end of an operating instruction.

Lists

Lists are bulleted.

References to

images

Reference to numbered images are put into brackets:

[Picture 10 / 1]

Position number

Image number

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 9-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

If the same picture or table is quoted more than once in a paragraph, only the first

cross-reference contains the indication of the picture [Picture 10 / 1]. The following

cross-references contain only the position number [2].

4.2 Safety remarks

Follow all safety remarks and warnings in this user manual.

4.3 Intended Use

The P2L sensors are designed with the purpose of supervising manually picking in a box. They should only be

used for this purpose. Other uses than the ones described in this guide are not allowed. For damages after

improper use, InSystems Automation GmbH declines any liability.

4.4 Improper Use

Another use as described in chapter Intended Use is considered improper. During improper use, unpredictable

risks might occur. For damages after improper use, InSystems Automation GmbH declines any liability.

Examples for improper use are:

–Untypical use

–Passing fixed technical limits

–Modification, which are not approved by the manufacturer

–Operations in explosive atmosphere

–Contamination with aggressive chemicals, acids or their vapors.

4.5 Improper Use

Even preventive measurements do not avoid improper use. The following paragraphs describe proper use. All

other uses are defined as improper use.

4.6 Addition, Changes and Modifications

Addition, changes and modifications on the sensors can cause hazards.

–Additions, changes and modifications should be only made after consultation with the manufacturer and

his written approval.

–Unauthorized changes on the sensors or their components invalidate the guarantee and liability by the

manufacturer.

–The CE Definition of Conformity is only valid, if the sensor can be clearly identified. This can only happen if

the manufacturer label is intact. A change or distortion of the manufacturer specification is not allowed

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 10-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

5Product Description P2L Sensor

P2L sensors are designed for assembly and picking systems. The sensors simplify the assembly and picking

procedures for the operators, since the light signals lead each operator. The sensor recognizes if the right or the

wrong shelf is reached and signalizes it immediately

.

Optical signaling:

–

A green LED shows from which shelf the parts should be picked

–A red LED means an error.

The consequences of an error are defined by the customer in the software or the PLC.

Example

Figure 1 shows an error, which is

immediately reported by the red LED. The

green LED lights up on the container, from

where the piece should have been taken

out.

Picture 1: Supply shelf

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 11-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

Process Safety

With P2L sensors, a high process safety in assembly and picking operations can be reached. These represent a

great economic advantage, if a lot of parts and product variants are assembled.

The sensor is teachable and can be fit to different container forms and filling heights. The P2L sensor is

optimized for the current set of containers, materials and filling heights.

The sensor is taught during each sensor startup process. An additional teaching signal can be sent by a

button or integrated in the PLC start routine.

The small construction and the small minimal distance (see chapter 7.2) allow very flat racking levels, which

ensure ergonomic deployment architecture with shorts handling ranges.

A removal from a compartment does not have to be confirmed, because the P2L sensor recognizes it

automatically.

For big assembly systems with lots of sensors, the use of P2L sensors with CAN bus is recommended,

because the wiring is less time-consuming: all P2L C003 are wired in series and only one supply line to

the USB-CAN adapter or the PLC is required.

With P2L C003 sensor the LEDs over the CAN Bus can be individually controlled, depending on the

process requirements.

5.1 Available Models

Type

Digital

Can Bus

Standard

P2L D003

P2L C003

ESD

P2L D003 ESD

P2L C003 ESD

Technical Data see chapter 18

5.2 General remarks

Der P2L-Sensor is designed to fulfill the requirements of the protection class IP53.

Picture 2: Protection class IP53

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 12-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

–Keep the sensor away from moisture, since it might lead to corrosion of the electric components in the

casing

–Keep the recommended operating temperature (-10 until +50 °C) and don’t expose the sensor to extreme

temperature differences, since this might lead to dysfunction and shorten the lifetime of the sensor.

–

Avoid violent impacts and electric discharges that can damage the P

2L sensor.

–

Do not open the casing of a P2L sensor. The device contains high-precision electronic components, which

might be damaged

.

For damages resulting from non-compliance with the present instructions, we do not grant any warranty.

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 13-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

6Initial Start-Up

6.1 P2L D003 Digital

With following steps the P2L D003 will be installed and launched:

Assembly the sensor in the racking levels where the material is stored see chapter 7.

Connect the sensors to the PLC see chapter 8.1.

Turn on the PLC.

The teach-in procedure of container geometry and filling heights runs automatically see chapter 10.

6.2 P2L C003 CAN Bus

With following steps the P2L D003 will be installed and launched:

Set a serial connection between sensors and a connection to the USB-CAN bus adapter see chapter 8.2.1

or the PLC see chapter 8.2.2.

Assembly the sensor in the racking levels where the material is stored see chapter 7.

Set the sensor addresses at the DIP switches see chapter 9.

Open the P2L-Software or turn on the PLC.

The teach-in procedure of container geometry and filling heights runs automatically see chapter 10.

6.3 Available on Request

The process workflow (pick-sequence and reaction by errors) is defined in the USB-CAN bus adapter or the

PLC. A material and assembly workflow manager, the visualization of assembly steps, as well as the saving of

process parameters can be performed by extra PC software.

InSystems Automation GmbH offers a special software for using the CAN bus sensors with the CAN bus

adapter "USB-CAN PLUS ISO" from VSCOM, see chapter 6.3.1.

6.3.1 Pick-2-Light-Software from InSystems for CAN sensors

InSystems Automation offers a user-friendly Pick-2-Light software to configure an assembly assistance system

with P2L sensors without any programming skills. Following the selection of the product, Pick-2-Light software

triggers the Pick-2-Light sensors in the right order and secures a correct process of assembly and

commissioning. The software allows to store and manage any desired assembly recipes.

For more information about the Pick-2-Light software, please visit our website (www.pick-to-light.de).

You are also welcome to contact us by email at P2L@insystems.de

6.4 Settings

Settings at D003 are performed using a DIP switch see chapter 8.1.2 und at C003 using the software or the CAN

bus commands see 11.4.3

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 14-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

6.4.1 LED Brightness

Depending on the working environment and installation (at eye level), the brightness can dazzle and you might

want to dim the lights. You can choose between four brightness levels.

6.4.2 Pick Time

Having small pieces or pieces, which get easily caught (for example coil springs), the pick procedure might take

longer. In this case, the picking time can be extended in the sensor, so that no error message is triggered.

During the selected pick time the green LED of the sensor lights up. If pick time =0ms is selected the green light

is switched off as soon as a pick is registered.

6.4.3 Pick Type

For the P2L sensors with CAN bus can be set two different types for picking (see chapter 11.4.3):

Type 1:

You can reach into the box once, after which the next box is automatically activated (green LED lights up).

Type 2:

One box can be accessed several times. The assembly step does not end until the next box is reached. The

next box is already indicated by the corresponding green LED.

7P2L Sensor Assembly and Coverage Area

P2L sensor is easy to install and can be quickly integrated in existing assembly workplaces.

Customer tailored integration are available on request.

Assembly is done by screwing two screws or brackets on a fitting retaining plate (not included in scope of

delivery). The gripping range must be within the maximum range of 150 mm, optimally at 100 mm.

For a better integration of P2L-sensors in your deployment architecture, CAD data with measurements are

available on our download page, in order for you to find their optimal position.

7.1 Required Tools and Assembly Material

In order to fix a P2L sensor, two M4 screws with a minimal length of 10 Millimeter are needed. For the ESD

variants, two additional external teeth lock washers (DIN 6797) are required.

7.2 P2L Sensor Coverage

Sensor coverage reaches between 20

and

150 mm. Ideal results are reached at a distance between 20 and

100

mm.

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 15-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

Picture 3: Diagram of sensor area

7.3 Assembly and Sensor Alignment

A downward-facing alignment is recommended. The sensor can also be aligned upward or side-facing, but it

might be become susceptible to failures because of dirt (case-by-case assessment).

Recommended

Installation Position

Standard installation position

Sensor field facing downwards

Less susceptible for

contamination

Less influence by ambient light

Picture 4: Recommended position

Possible Installation

Position (case-by-

case assessment)

Standard installation position –Sensor

field facing upwards

Possible, but more susceptible for

contamination:

by dirt deposit on the sensor

by ambient light

Picture 5: Sensor field facing upwards

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 16-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

Possible Installation

Position (case-by-

case assessment)

Standard installation –Sensor field facing

sideways

Possible, but more susceptible for

contamination:

by dirt deposit on the sensor

by ambient light

Picture 6: Sensor field facing sideways

7.4 Sensor Position on the Box

7.4.1 Ideal P2L Sensor Positioning

Example for

an ideal position of

P2L sensor

Picture 7: Good sensor position

The range of the P2L sensor covers the whole box.

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 17-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

7.4.2 Poor Sensor Positioning

Example for

a poor positioning

of P2L sensor

Picture 8: poor sensor position

The sensor just covers a corner of the box. Errors during teach-in and picking procedures may occur.

The sensor range is too far from the box and can supervise only a part of it. The procedure might not be

recognized or the next box might be supervised instead.

Example for

a non-optimized

position of P2L

sensor

Picture 9: Insufficient P2L positioning

The sensor just covers a corner of the box. Errors during teach-in and picking procedures may occur.

7.5 Assembly of ESD Sensors

The P2L ESD sensor is already grounded through the connecting plug. However, we recommend to ground the

housing during the assembly procedure with external teeth lock washers, in order to provide maximal safety.

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 18-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

7.6 Assembly Examples

Demo of a C003 P2L sensor, which is mounted over Bosch grip plates with an angled bracket. The sensor is

fastened to the bracket with two M4 screws.

Picture 10: Assembly with customer specific bracket

8Connection

8.1 P2L D003 Digital

Each digital P2L sensor is connected by a separate cable with the PLC.

P2L sensors are supplied with power by the PLC.

Picture 11: Pick-to-light system scheme with P2L digital

1. Digital P2L-Sensors

2. PLC with E/A (I/O)

3. MFR for

- Control of assembly sequence

- Control of the containers

- Visualizing etc.

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 19-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

8.1.1 Connector Plug

Picture 12: Socket assignment at P2L digital

Documentation

Created:

19.01.18

Printed:

19.01.18

File:

BA_P2L-003_V2.3_EN

InSystems Automation GmbH Wagner-Régeny-Straße 16 Tel.: +49-30-639 225 10 20-40

12489 Berlin, Germany Fax: +49-30-639 225 16

www.insystems.de Email: info@insystems.de

Der Inhalt dieser Betriebsanleitung obliegt dem Kopierschutz. Er

darf nicht, auch nicht auszugsweise, ohne vorheriges

Einverständnis der InSystems Automation GmbH vervielfältigt

oder an Dritte weiter gegeben werden. Alle technischen

Angaben, Zeichnungen usw. unterliegen dem Gesetz zum Schutz

des Urheberrechts.

8.1.2 DIP Switch for Brightness and Pick Time

LED brightness and picking time can be set with the DIP switch on the bottom.

Four brightness levels and picking times from 0 to 8000 ms can be configured.

Picture 13: Schema of DIP switch

Picture 14: Bottom of P2L D003 with DIP switch

DIP Switch

1

2

Brightness

Status

OFF

OFF

25%

Status

ON

OFF

50%

Status

OFF

ON

75%

Status

ON

ON

100%

DIP Switch

3

4

5

6

Picking

Time

Status

OFF

OFF

OFF

OFF

0 ms

Status

ON

OFF

OFF

OFF

1000 ms

Status

OFF

ON

OFF

OFF

1500 ms

Status

ON

ON

OFF

OFF

2000 ms

Status

OFF

OFF

ON

OFF

2500 ms

Status

ON

OFF

ON

OFF

3000 ms

Status

OFF

ON

ON

OFF

3500 ms

Status

ON

ON

ON

OFF

4000 ms

Status

OFF

OFF

OFF

ON

4500 ms

Status

ON

OFF

OFF

ON

5000 ms

Status

OFF

ON

OFF

ON

5500 ms

Status

ON

ON

OFF

ON

6000 ms

Status

OFF

OFF

ON

ON

6500 ms

Status

ON

OFF

ON

ON

7000 ms

Status

OFF

ON

ON

ON

7500 ms

Status

ON

ON

ON

ON

8000 ms

The other DIP switches are not used.

Upon delivery of the P2L sensors all DIP switches are set to OFF.

This manual suits for next models

4

Table of contents

Other InSystems Accessories manuals

Popular Accessories manuals by other brands

llaza

llaza MOONBOX 400 Assembly manual

Redsbaby

Redsbaby Bassinet Stand Product guide

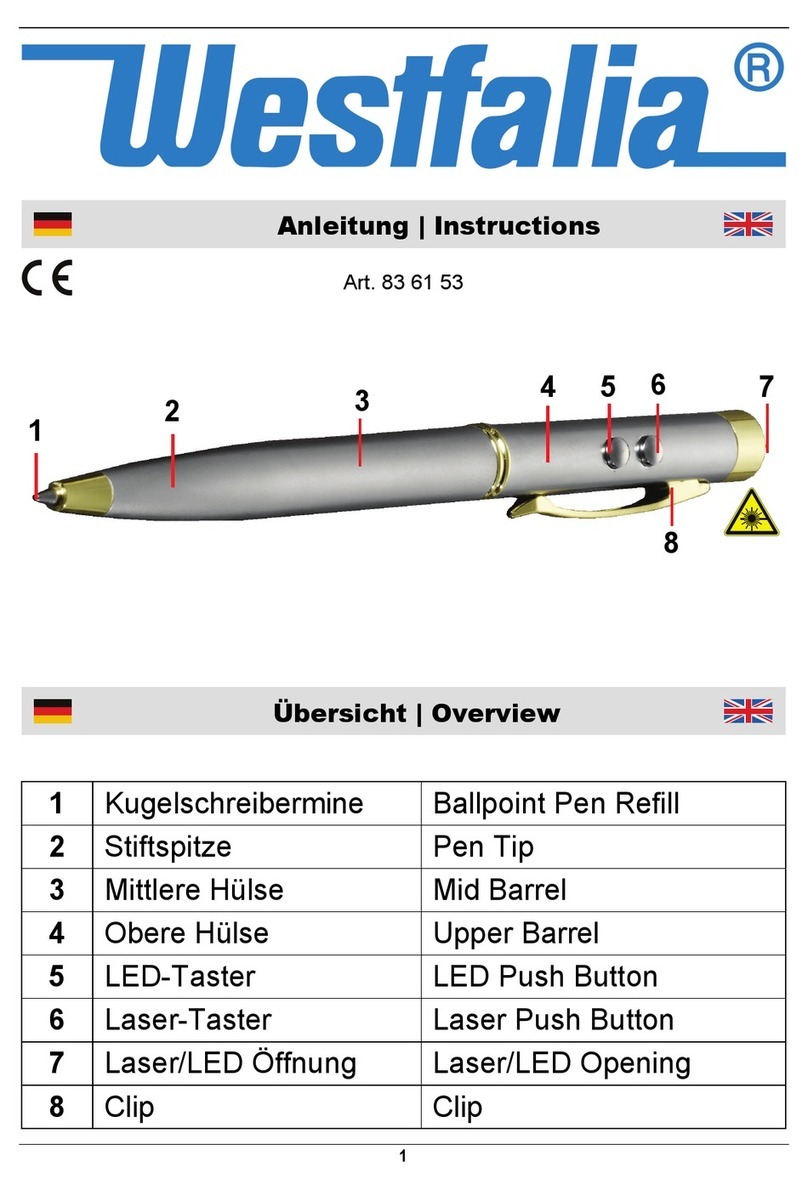

Westfalia

Westfalia 83 61 53 instructions

La Crosse Technology

La Crosse Technology TX12U instruction manual

Action Sports Equipment

Action Sports Equipment Junior Jumper Assembly, Installation, Care, Maintenance, and Use Instructions

SEELEY INTERNATIONAL

SEELEY INTERNATIONAL Climate Wizard Multi-Magic CW-H10 Installation & operation manual