Integra LifeSciences MAYFIELD A1115 User manual

EN –ENGLISH...............................................................................

FR –FRANÇAIS..............................................................................

IT –ITALIANO................................................................................

DE –DEUTSCH .............................................................................

ES –ESPAÑOL...............................................................................

NL –NEDERLANDS......................................................................

MAYFIELD®

Modified

Swivel Adaptor

( A1115)

Instruction Manual

Manufacturer:

Integra LifeSciences Corporation

4900 Charlemar Drive, Building A

Cincinnati, OH 45227, USA

Tel: 513-533-7979

Fax: 513-271-1915

integralife.com

Integra LifeSciences Services

Immeuble Séquoïa 2

97 allée Alexandre Borodine

Parc Technologique de la Porte des Alpes

69800 Saint Priest – France

Tel: 33 (0) 4 37 47 59 10

2

This page is intentionally le blank

3

2

MAYFIELD®

Modified

Swivel Adaptor

( A1115)

Instruction Manual

EN – ENGLISH

4

Meaning Of Symbols Used In This Manual - ENGLISH

CAUTION!

Hazards which could result in equipment or property damage

WARNING!

Hazards which could result in severe personal injury or death

Caution

Product complies with the requirements of MDR 2017/745

Manufacturer

Authorized Representative in the European Community

Consult Instructions for Use

Caution: Federal (USA) law restricts this device to sale by or on the

order of a licensed healthcare practitioner.

This device is not indicated for use in the MR environment

Catalog number

Date of manufacture (YYYY-MM-DD)

Lot number

Serial number

Medical Device

5

ENGLISH

Description

The MAYFIELD® Modified Swivel Adaptor (REF A-1115) is designed to provide all the

functionality of the standard swivel adaptor, and in addition offers a feature to tighten the

fit of the ratchet extension to the body of the skull clamp, when the adaptor is used with a

skull clamp. The tightened fit of the ratchet extension reduces motion that might be caused

by the tolerance differences of these two components, thereby minimizing movement of

the skull clamp during a surgical procedure. (In procedures such as image-guided surgery, or

procedures under a microscope, minimal or no movement of the skull clamp is desired.)

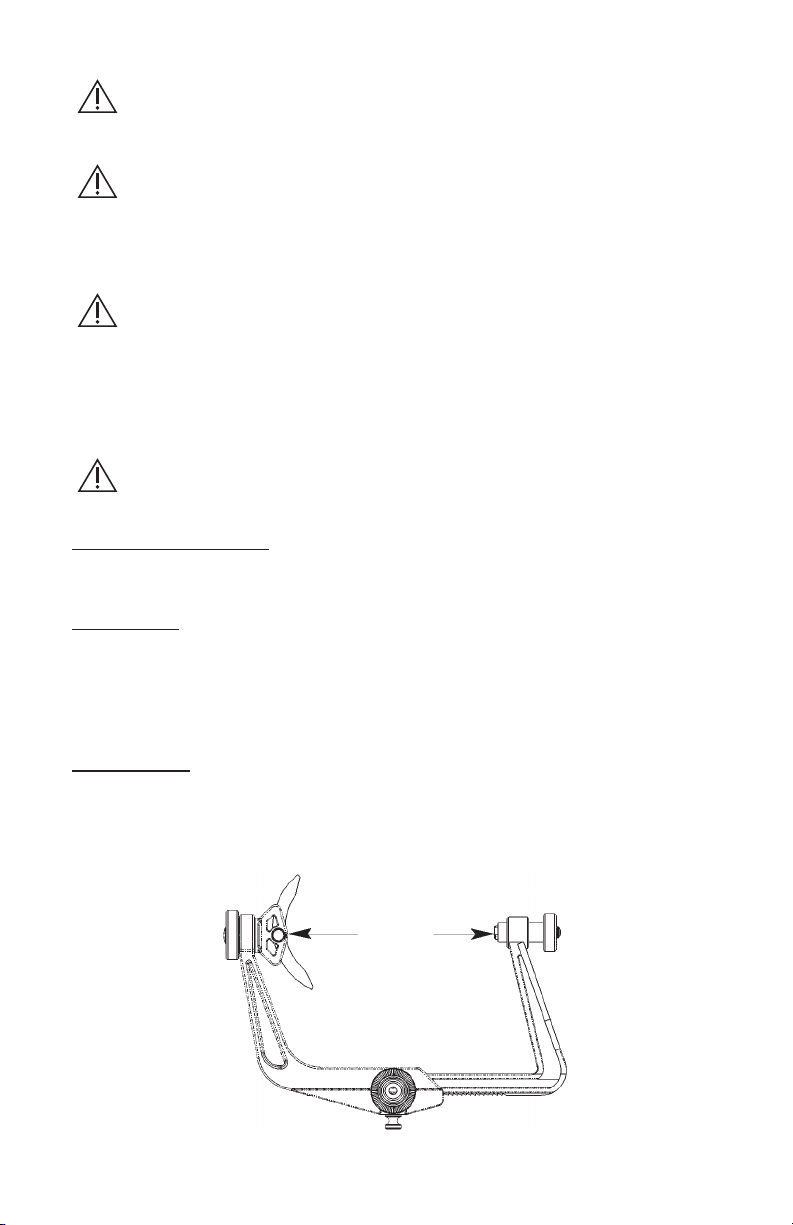

Section 1

1

2

3

4

5

6

7

8

Illustration 1

1. Torque Screw

2. Small Starburst

3. Swivel Sleeve

4. Swivel Base

5. Torque Screw with Pin

6. Adjustment screw

7. Large Starburst

8. Pin

Indications for Use/Intended Purpose

The MAYFIELD Modified Swivel Adaptor aaches to the MAYFIELD Base Unit to support

skull clamps and headrests (A-1011, A-1051, A-1012, A-1059, A-1108, and A-2000). It provides

optimal positional flexibility via 360-degree rotation as well as supplementary stability of

the skull clamp ratchet extension.

WARNING:

This device is not intended for use in or near the vicinity of a strong magnetic field.

(MRI)

WARNING:

Failure to properly position patient and to fully tighten and secure all adjustable

portions of this or any similar device may result in skull pin slippage and serious

patient injury, such as scalp laceration, skull fracture, or even death.

6

EN – ENGLISH

WARNING:

Do not alter the design of the device in part or whole as serious patient injury could

result.

WARNING:

Failure to read and follow instructions furnished in this product insert may result in

skull pin slippage and serious patient injury, such as scalp lacerations, skull fracture,

or even death.

Make certain to securely aach the base unit to the operating room table.

WARNING:

If the Modified Swivel Adaptor Torque Screw becomes tight before the starburst

is properly meshed, the knob is incorrectly adjusted for this skull clamp. Use a

5/64” hex wrench to turn the adjustment screw counter clockwise four full turns to reset

the screw. See Illustration 1 for adjustment screw location. If the starburst fails to mesh

correctly aer the screw is reset, the Modified Swivel Adaptor may be incompatible with

this particular clamp. See Section 2 for details.

WARNING:

The Modified Swivel Adaptor may be incompatible with earlier skull clamps made

with a two piece base design. See Section 2 to recognize incompatible conditions.

Intended Population

MAYFIELD Skull Clamp fixation devices are not recommended for use on children under five (5) years of

age. Extreme caution should be exercised in pediatric cases because of the thin skull.

Inspection

Always inspect instruments before and aer use. If a component appears damaged and/

or does not seem to function properly, do not use the device and immediately send the

instrument to an authorized Integra repair center for evaluation, repair or replacement.

Allow your Integra Representative to inspect this device a minimum of two times per year to

assist you in its proper function.

Adjustment

Before its first use, the Modified Swivel Adaptor should be adjusted to ensure optimal

performance with your specific skull clamp.

1. Obtain the skull clamp with which the swivel adaptor will be used and position the

ratchet extension to approximately half its travel. See Illustration 2:

7-8"

Illustration 2

7

EN – ENGLISH

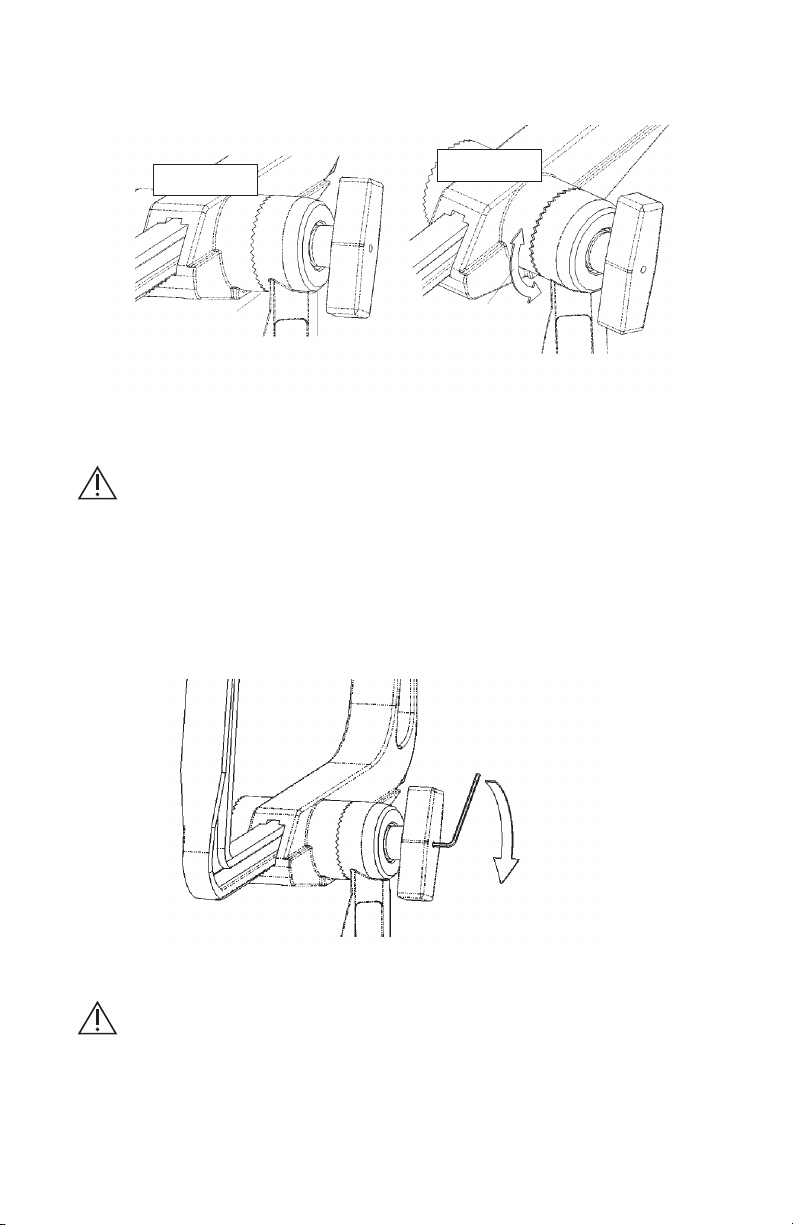

2. Apply the Modified Swivel Adaptor to the skull clamp and carefully inspect the starburst

connection to see that it is properly meshed and secure. See Illustration 3.

Good starburst

connection

Clamp/Swivel

movement from

incomplete

starburst mesh

Incorrect

Correct

Illustration 3

WARNING:

If the Modified Swivel Adaptor Torque Screw becomes tight before the starburst is

properly meshed, the knob is incorrectly adjusted for this skull clamp. Use a 5/64”

hex wrench to turn the adjustment screw counter clockwise four full turns to reset the

screw. See Illustration 1 for adjustment screw location.

If the starburst fails to mesh correctly aer the screw is reset, the Modified Swivel Adaptor

may be incompatible with this particular clamp. See Section 2 for details.

3. With the adapter securely applied to the skull clamp, use a 5/64” hex wrench to turn

the adjustment screw clockwise until it is tight. See Illustration 4. Check the ratchet

extension for movement.

Use 5/64" hex wrench

Illustration 4

WARNING:

This seing is optimized for use on that skull clamp to which it is adjusted. A single

seing may be effective on several skull clamps but it may also be over-adjusted for

some other clamps.

During the preoperative equipment check, verify that the starburst teeth fully engage

on the skull clamp that will be used. It is important for patient safety to perform this

inspection before the equipment is used for patient support.

8

EN – ENGLISH

Instructions for Use

1. Mount the Base Unit with the Transitional Member onto the operating table.

2. Aach the Modified Swivel Adaptor to the Transitional Member of the Base Unit by

inserting the adaptor’s small starburst torque screw into the threaded hole on the

transitional member as shown in Illustration 5:

Turn torque screw clockwise

to secure. Inspect starburst

teeth to confirm correct

engagement.

Illustration 5

CAUTION:

Always confirm the starburst teeth mesh properly (as shown in Illustration 3) Failure

to do so may result in damage to the device

3. Mount the headrest or skull clamp on the swivel adapter by inserting the large starburst

Torque Screw into the threaded hole in the skull clamp or headrest. See Illustration 6:

Turn torque

screw clockwise

to secure.

Inspect starburst

teeth to confirm

correct engagement.

Illustration 6

4. The position of the headrest may be adjusted at the swivel adapter and the base unit to

improve patient comfort or accomodate the surgeon’s preference.

CAUTION:

Stabilize the patient’s head or the headrest equipment until all the connections are

secured against movement.

9

EN – ENGLISH

To change the position at the swivel adapter, loosen the appropriate Torque Screw by

turning the screw counter clockwise two full turns to assure clearance for the starburst

teeth.

Once the desired position is achieved, lock the joint by turning the torque screw clockwise.

Verify that the starburst teeth are correctly engaged at both locations and that the torque

screws are fully tightened.

IMPORTANT:

A correctly adjusted modified swivel adapter will behave as a lock knob in securing

the ratchet extension against movement.

RELEASE

PROCEDURE

2. PULL PLUNGER

1. UNLOCK

SWIVEL ADAPTER

Illustration 7

The Torque Screw at the large starburst connection must be loosened (typically two full

turns) before pulling the plunger on the skull clamp will release the ratchet extension.

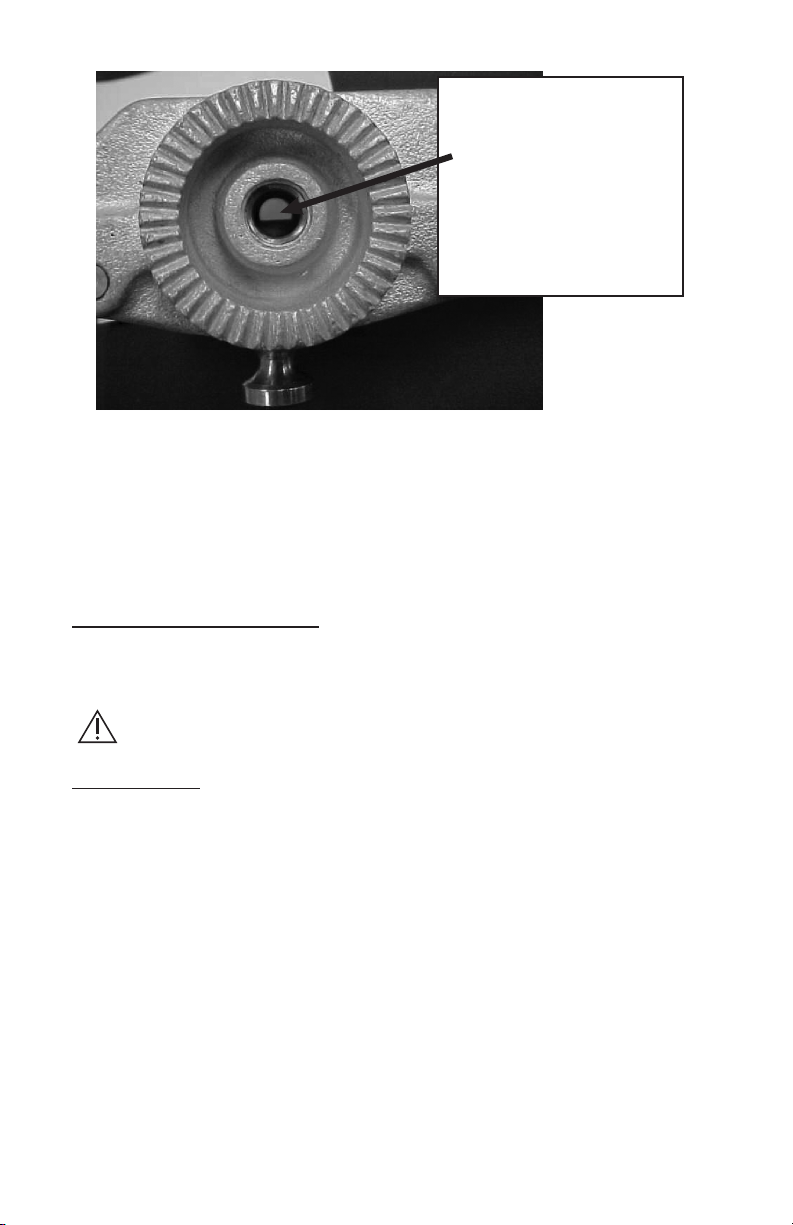

Section 2

Recognizing Incompatible Equipment

Older model skull clamps fabricated using the two-piece, machined race lock in the body

of the skull clamp will not accept the extended stud that is part of the Modified Swivel

Adaptor. Access to the ratchet arm is partially obstructed, causing the Modified Swivel

Adaptor Torque Screw to stop before the starbursts can properly engage. Compatibility can

be readily determined by looking through the threaded hole on the skull clamp base.

Look for a

two piece

base design,

indicated by

the fasteners.

10

EN – ENGLISH

A close inspection of

the hole will reveal the

obstruction that

prevents the Modified

Swivel Adaptor from

operating with this

clamp.

It is possible to convert some of these older model clamps to accept the longer post of the

Modified Swivel Adaptor. Evaluations on suitability for conversion are made by the Service

Department.

Phone: 877-444-1114 (USA only) or (513) 533-7979

Integra LifeSciences Corporation

4900 Charlemar Drive, Building A

Cincinnati, Ohio 45227

Cleaning and Sterilization

The Modified Swivel Adaptor should be thoroughly cleaned aer each use. Scrub with a

so brush and use pH-neutral detergent. Clean thoroughly to prevent traces of blood or

debris from interfering with movement. Wipe down with an antiseptic solution

DO NOT STEAM STERILIZE!

Plastic components may be damaged by the heat.

Manual Wash

CAUTIONS

• Alkaline and highly acidic detergents and solutions cause damage to the devices.

• Channels and crevices found on this device require particular aention during cleaning.

• Pay special aention to the water quality used throughout reprocessing. Hard water can

damage the surface of the equipment. Avoid using hard water. Instead use purified water

unless otherwise specified.

Limitations on reprocessing

• Repeated processing has minimal effects on these devices. Product life is normally

determined by wear and damage due to use.

• It is important to have Integra NeuroSpecialists perform routine inspections (twice yearly

is recommended). See contact information below.

INSTRUCTIONS

Containment/Transportation

• Follow health care facility protocol for safe containment and transport to the

decontamination environment.

• It is recommended that devices are cleaned immediately aer use.

11

EN – ENGLISH

Preparation for Cleaning

• Disassembly is required.

Disassembling Equipment Inspecting for Cleanliness

Completely remove the swivel adaptor

from any components. The swivel adaptor

itself cannot be disassembled any further.

Inspect the teeth of the starbursts, the area

around the locking screw, and the base of

the swivel adaptor for organic debris.

Cleaning – Manual Equipment: Water, Neutral pH Detergent, So Bristle Brush, Towels

Method

1. Prepare neutral pH enzymatic detergent solution (e.g. Endozime® AW Triple Plus with APA

(Ruhof), 1:128 ratio) according to detergent manufacturer’s instructions using lukewarm

tap water.

2. Prepare equipment for soaking by disassembling removable parts and loosening

connections.

3. Rinse equipment in warm water before placing into bath.

4. Completely soak equipment in water/detergent solution for 30 minutes maximum.

5. Clean thoroughly with a so nylon bristle brush. NOTE – If possible, use a disposable

brush.

6. Rinse in warm purified water until all visible substances and residual detergent are

removed. NOTE – Make sure to give special aention to hard-to-reach areas.

7. Thoroughly dry equipment with so clean towels and use medically compressed air if

needed, to dry channels, crevices and lumens.

8. Inspect the equipment to make sure there is no visible organic debris or residue from

cleaning agent.

Repeat process if any soil is detected.

Drying

• Products should be dry at this point. If wetness or excess liquid is detected, dry with a

so clean towel.

• Medically compressed air can be used if needed.

Optional Automatic Wash / Disinfect

CAUTIONS

• Alkaline and highly acidic detergents and solutions cause damage to the devices.

• Channels and crevices found on these devices require particular aention during

cleaning.

• Pay special aention to the water quality used throughout reprocessing. Hard water can

damage the surface of the equipment. Avoid using hard water. Instead use purified water

unless otherwise specified.

Limitations on Reprocessing

• Repeated processing has negative effects on these devices and is not recommended for

routine use.

• It is important to have Integra NeuroSpecialists perform routine inspections (twice yearly

is recommended).

See contact information.

INSTRUCTIONS

Cleaning - Automated Equipment: Neutral pH Detergent

Method

1. Prepare equipment for cleaning by disassembling removable parts and loosening

connections.

12

EN – ENGLISH

2. Rinse equipment in warm water before placing into washer.

3. Load device into the washer and place small parts in container or tray inside the washer

unit in order to avoid losing small components.

NOTE – Load devices carefully into washer in order to avoid collision.

4. Follow the instructions listed below and set washer machine to these exact parameters:

Phase Time (Min.) Water Temperature Detergent and Concentration

Pre-wash 1 4:00 Cold water N/A

Enzyme

Wash 4:00 Hot water Neutral pH enzymatic (e.g. Endozime®

AW Triple Plus with APA, Ratio 1:128)

Wash 1 10:00 60.0ºC (140º F) Neutral pH detergent

(e.g. Renu-Klenz™ , Steris, Ratio 1:256)

Rinse 1 0:30 Hot water N/A

Thermal

Rinse** 2:00 82.2ºC (180º F) N/A

** Optional phase for disinfection of components – minimum water temperature as

indicated or per worker manufacturer specifications for the thermal rinse cycle.

NOTE – Any deviation from this guideline could result in damage to the equipment as well

as improper cleaning results.

Rinse with purified water. Do not perform if parameters cannot be achieved.

5. Remove from washer and dry completely if needed.

6. Inspect equipment to make sure there is no visible organic debris or residue from

cleaning agent.

Repeat process if any visible soil is detected.

The life expectancy of the MAYFIELD products is expected to be as long as 7 years.

Maintenance and Care

To ensure proper function and to extend the life and performance of the equipment, Integra

LifeSciences recommends the following:

Recommended Action Recommended Frequency

Return the device to the Integra LifeSciences Repairs

department for detailed inspection and servicing.

Once / year

Request that Integra NeuroSpecialists perform routine

inspections of the device

Twice / year

In the absence of proper care and servicing of the device, negative effects may be seen aer

repeated processing over time which may lead to reduced performance.

Contact information: See the Service and Repair section for contact information on how to

return your device for periodic servicing and to request periodic inspections.

See Inspection and/or Service notes section for routine checks to be performed on the device.

13

EN – ENGLISH

NOTE – Any serious incident that has occurred in relation to the device for the user and/

or the patient should be reported to the manufacturer and the competent authority of the

member state in which the user and/or patient is established.

Device Disposal

NOTE: Follow hospital procedures for disposal of this device.

Integra LifeSciences Warranty Statement

INTEGRA LIFESCIENCES CORPORATION (“INTEGRA”) warrants to the original purchaser only that each

new MAYFIELD product is free from manufacturing defects in material and workmanship under normal

use and service for a period of one year (except as otherwise expressly provided as to accessory items)

from the date of delivery by INTEGRA to the first purchaser, but in no event beyond the expiration date

stated on any product labeling.

• Surgical instruments are guaranteed to be free from defects in material and workmanship when

maintained and cleaned properly and used normally for their intended purpose.

• Any covered product that is placed by INTEGRA under a lease, rental or installment purchase

agreement and that requires repair service during the term of such placement agreement shall be

repaired in accordance with the terms of such agreement.

If any covered defect occurs during the warranty period or term of such placement agreement, the

purchaser should communicate directly with INTEGRA’s home office. If purchaser seeks to invoke the

terms of this warranty, the product must be returned to INTEGRA at its home office. The defective

product should be returned promptly, properly packaged and postage prepaid. Loss or damage in return

shipment to INTEGRA shall be at CUSTOMER’s risk. INTEGRA’s sole responsibility under this warranty

shall be repair or replacement, at INTEGRA’s sole discretion at INTEGRA’s expense, subject to the terms

of this warranty and applicable agreements.

IN NO EVENT SHALL INTEGRA BE LIABLE FOR ANY INCIDENTAL, INDIRECT, CONSEQUENTIAL OR

PUNITIVE DAMAGES IN CONNECTION WITH THE ACQUISITION OR USE OF ANY INTEGRA PRODUCT.

Further, this warranty shall not apply to, and INTEGRA shall not be responsible for, any loss arising in

connection with the purchase or use of any INTEGRA product that has been repaired by anyone other

than an authorized INTEGRA service representative or altered in any way so as, in INTEGRA’s judgment,

to affect its stability or reliability, or which has been subject to misuse, negligence or accident, or

which has been used otherwise than in accordance with the instructions furnished by INTEGRA.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON INTEGRA’S PART, AND INTEGRA

NEITHER ASSUMES NOR AUTHORIZES ANY REPRESENTATIVE OR OTHER PERSON TO ASSUME FOR IT

ANY OTHER LIABILITY IN CONNECTION WITH INTEGRA’S PRODUCTS.

INTEGRA DISCLAIMS ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION

OR WARRANTY OF QUALITY AS WELL AS ANY EXPRESSED OR IMPLIED WARRANTY TO PATIENTS.

No warranty or guarantee may be created by any act or statement nor may this Standard Warranty be

modified in any way, except as a result of a writing signed by an officer of INTEGRA. These limitations on

the creation or modification of this warranty may not be waived or modified orally or by any conduct.

Service and Repair

For service and repairs outside the United States, contact your local authorized Integra representative.

Inside the United States, send all instruments for service or repair to:

Integra LifeSciences Corporation

4900 Charlemar Drive, Building A

Cincinnati, Ohio 45227

(Always include the purchase order number and a wrien description of the problem).

Phone: 877-444-1114 (USA only) or (513) 533-7979

14 15

EN – ENGLISH

Integra and the Integra logo are registered trademarks of Integra LifeSciences Corporation in the

United States and/or other countries. MAYFIELD is a registered trademark of SM USA, Inc. and

is used by Integra under license. Endozime is a trademark of Ruhof Corporation. Renu-Klenz is a

trademark of Steris Corporation.

2021 Integra LifeSciences Corporation. All Rights Reserved.

451A1115 Rev DA 2021-01 0845510-2

14 15

Adaptateur pivotant

modifié MAYFIELD®

( A1115)

Mode d’emploi

FR – Français

16 17

Aention

Ce produit est conforme aux exigences de la RDM 2017/745

Fabricant

Représentant autorisé dans la Communauté européenne

Consulter le mode d’emploi

Aention : Conformément à la loi fédérale américaine, ce

dispositif ne peut être vendu que par ou sur ordonnance d’un

professionnel de santé agréé.

Il est déconseillé d’utiliser cet appareil pour la résonance

magnétique

Référence catalogue

Date de fabrication (JJ-MM-AAAA)

Numéro de lot

N° de série

Dispositif médical

Signification des symboles utilisés dans ce manuel - FRANÇAIS

ATTENTION!

Dangers pouvant causer des dommages au matériel ou aux biens

AVERTISSEMENT!

Dangers pouvant causer des blessures personnelles graves, voire fatales

16 17

FRANÇAIS

Description

L’adaptateur pivotant modifié MAYFIELD® (REF A-1115) est conçu pour offrir toute la fonctionnalité

de l’adaptateur pivotant standard avec en plus une fonction pour serrer davantage la fixation

de l’extension à cliquet sur le corps du clameau crânien quand l’adaptateur est utilisé avec un

clameau crânien. La fixation plus serrée de l’extension à cliquet réduit le mouvement qui peut être

produit par les différences de tolérance de ces deux composants, ce qui minimise le mouvement

du clameau crânien au cours d’une intervention chirurgicale. (Lors d’interventions comme une

chirurgie sous imagerie ou des interventions sous microscope, il est souhaitable d’avoir un

mouvement minimal ou aucun mouvement du clameau crânien.)

Section 1

1

2

3

4

5

6

7

8

Illustration 1

1. Vis de serrage

2. Petit élément à dentures radiales

3. Gaine pivotante

4. Base pivotante

5. Vis de serrage avec tige

6. Vis de réglage

7. Grand élément à dentures radiales

8. Tige

Indications d’utilisation/Utilisation prévue

L’adaptateur pivotant modifié MAYFIELD se raccorde à l’unité de base MAYFIELD pour soutenir

les clameaux crâniens et les têtières (A-1011, A-1051, A-1012, A-1059, A-1108 et A-2000). Il procure

une souplesse de positionnement optimale grâce à sa capacité de rotation sur 360° ainsi qu’une

stabilité supplémentaire pour l’extension à cliquet du clameau crânien.

AVERTISSEMENT :

Ce dispositif n’est pas conçu pour être utlisé à proximité d’un champ magnétique

puissant. (IRM)

AVERTISSEMENT : Si le patient n’est pas correctement positionné et si toutes les parties

réglables de ce dispositif ou de tout dispositif similaire ne sont pas bien fixées, la tige

métallique permeant de maintenir le crâne pourrait glisser et le patient pourrait subir de

graves blessures, telles que des lacérations du cuir chevelu, une fracture du crâne, voire la mort.

AVERTISSEMENT : Ne pas modifier, toute ou une partie de la conception du dispositif

sous peine d’exposer le patient à des blessures graves.

18 19

FR –FRANÇAIS

AVERTISSEMENT : Si les instructions fournies avec la notice qui accompagne le

produit ne sont pas lues ni suivies, la tige métallique permeant de maintenir le

crâne pourrait glisser et le patient pourrait subir de graves blessures, telles que des

lacérations du cuir chevelu, une fracture du crâne, voire la mort.

Veiller à fixer fermement l’unité de base sur la table d’opération.

AVERTISSEMENT :

Si la vis de serrage de l’adaptateur pivotant modifié devient serrée avant que l’élément

à dentures radiales ne soit correctement engagé, la molee est mal ajustée pour le

clameau crânien en question. Utiliser une clé hexagonale de 5/64 po. pour tourner la vis de

réglage de quatre tours complets dans le sens antihoraire pour rectifier la vis. Voir l’illustration

1 pour l’emplacement de la vis de réglage. Si l’élément à dentures radiales ne s’engage pas

correctement après que la vis est rectifiée, il est possible que l’adaptateur pivotant modifié soit

incompatible avec le clameau en question. Voir la section 2 pour des détails.

AVERTISSEMENT :

L’adaptateur pivotant modifié peut être incompatible avec les clameaux crâniens de

fabrication antérieure avec une base en deux parties. Voir la section 2 pour savoir

reconnaître les conditions incompatibles.

Population prévue

L’utilisation des dispositifs de fixation du clamp crânien MAYFIELD est déconseillée pour

les enfants de moins de cinq (5) ans. Faire preuve d’une prudence extrême dans les cas

infantiles à cause de la minceur du crâne.

Inspection

Toujours vérifier les instruments avant et après leur utilisation. Si un élément semble

endommagé et/ou ne pas fonctionner correctement, ne pas utiliser le dispositif et l’envoyer

immédiatement à un centre de réparation Integra agréé où il sera évalué, réparé ou

remplacé. Faire vérifier ce dispositif par votre représentant Integra au moins deux fois par an

pour veiller à son fonctionnement correct.

Réglage

Avant la première utilisation, l’adaptateur pivotant modifié doit être réglé pour assurer une

performance optimale avec le clameau crânien qu’il est prévu d’utiliser.

1. Se procurer le clameau crânien avec lequel il est prévu d’utiliser l’adaptateur pivotant et

positionner l’extension à cliquet à mi-chemin de sa course. Voir l’illustration 2 :

7-8"

Illustration 2

18 19

FR –FRANÇAIS

2. Appliquer l’adaptateur pivotant modifié sur le clameau crânien et vérifier avec soin le

raccordement de l’élément à dentures radiales pour s’assurer qu’il est correctement engagé et

fixé. Voir l’illustration 3 :

Bonne connexion

de l’élément radial

Mouvement

pivotant du

clameau en raison

d’un mauvais

engagement

de l’élément radial

Incorrect

Correct

Illustration 3

AVERTISSEMENT :

Si la vis de serrage de l’adaptateur pivotant modifié devient serrée avant que l’élément à

dentures radiales ne soit correctement engagé, la molee est mal ajustée pour le clameau

crânien en question. Utiliser une clé hexagonale de 5/64 po. pour tourner la vis de réglage

de quatre tours complets dans le sens antihoraire pour rectifier la vis. Voir Illustration 1 pour

l’emplacement de la vis de réglage. Si l’élément à dentures radiales ne s’engage pas correctement

après que la vis est rectifiée, il est possible que l’adaptateur pivotant modifié soit incompatible

avec le clameau en question. Voir la section 2 pour des détails.

3. Avec l’adaptateur solidement appliqué au clameau crânien, utiliser une clé hexagonale de

5/64 po. pour tourner la vis de réglage dans le sens horaire jusqu’à ce qu’elle soit serrée. Voir

l’illustration 4. Vérifier qu’il n’y a pas de mouvement au niveau de l’extension à cliquet.

Utiliser une clé

hexagonale de 5/64 po.

Illustration 4

AVERTISSEMENT :

Ce réglage est optimisé pour l’utilisation sur le clameau crânien en question auquel il est

réglé. Un réglage unique peut être efficace avec plusieurs clameaux crâniens, mais peut

également avoir un réglage excessif pour d’autres clameaux.

Au cours de la vérification préopératoire du matériel, vérifier que les dentures radiales s’enga-

gent complètement dans le clameau crânien qu’il est prévu d’utiliser. Pour assurer la sécurité du

patient, il est important d’effectuer cee vérification avant que le matériel ne soit utilisé pour

soutenir le patient.

20 21

FR –FRANÇAIS

Mode d’emploi

1. Monter l’unité de base avec la pièce de transition sur la table d’opération.

2. Fixer l’adaptateur pivotant modifié sur la pièce de transition de l’unité de base en insérant

la petite vis de serrage à dentures radiales de l’adaptateur dans le trou fileté de la pièce de

transition, tel qu’indiqué dans l’illustration 5 :

Tourner la vis de serrage dans le sens

horaire pour serrer. Examiner les

dentures radiales pour confirmer

qu’elles sont correctement engagées.

Illustration 5

ATTENTION :

Toujours confirmer que les dentures radiales s’engagent correctement (tel

qu’indiqué dans l’illustration 3). Tout manquement à cet avertissement risque

d’endommager le dispositif.

3. Monter la têtière ou le clameau crânien sur l’adaptateur pivotant en insérant le grand

élément à dentures radiales. Visser la vis dans le trou fileté du clameau crânien ou de la

têtière. Voir l’illustration 6 :

Tourner la vis de serrage

dans le sens horaire pour

serrer. Examiner les dentures

radiales pour confirmer

qu’elles sont correctement

engagées.

Illustration 6

4. La position de la têtière peut être ajustée au niveau de l’adaptateur pivotant et de l’unité

de base de sorte à améliorer le confort du patient ou pour accomoder les préférences du

chirurgien.

ATTENTION :

Stabiliser la tête du patient ou le matériel de la têtière jusqu’à ce que toutes les

connexions soient sûres pour empêcher un mouvement.

Table of contents

Languages:

Other Integra LifeSciences Receiver manuals