INTEGRATED PAVING CONCEPTS StreetHeat SR-28 User manual

Updated: April 2010

www.integratedpaving.com

1.800.688.5652

StreetHeat SR-28

Infrared Heater

(With Flint 2000EX Heat Torch)

Operations Manual

2

Contents

1. Safety

2. Main Operating Components

3. Specifications and Dimensions

4. Preparing for Work

5. Operating Procedure

6. Preparing for Transport

3

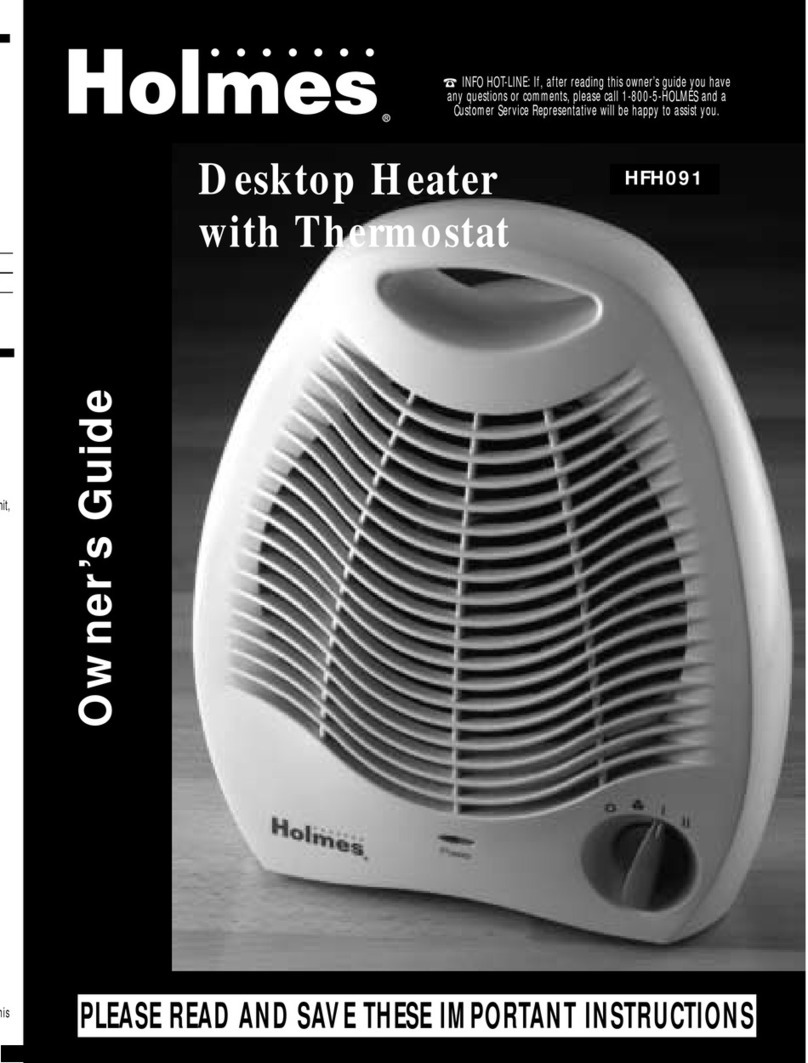

a

b

c

Safety

WARNING: Propane is HIGHLY FLAMMABLE and potentially EXPLOSIVE! Never smoke or allow

an open flame when setting up, dismantling, or switching the propane tank on the equipment.

Ensure that everyone who operates this machine has read and understood this manual.

Safety Wear – To avoid injury, always wear safety glasses, ear protection, long pants and steel toed

boots when operating this equipment. Always keep a fire extinguisher nearby.

Emergency Shutoff (a) – If a fire is present or there is any risk simply let go of the lever and the

safety valve will spring closed and shut off the heaters. Never mechanically fasten the valve

lever in the open position!

Main Propane Shutoff Valve (b) – In case the safety valve lever fails to spring closed there is a

second back up shut off valve on the left side of the handle that will shut off propane to the

burners. This will not shut off the propane to the Flint 2000EX Heat Torch

Flint 2000EX Heat Torch (c) – Read the separate Operations Manual for the torch before

using. To avoid risk of serious injury, take care when lighting the torch that it is pointed away

from other people and the machine, especially the hoses and fittings. When heating the ground

near the machine avoid heating close to the pneumatic tires to avoid overheating and bursting

them.

Risk of burn injuries – the heat generated by the SR28 is enough to cause very serious burns. Use

with extreme care.

Operation – never drive over any area that has just been heated. This could overheat and burst a

tire causing serious injury. Never operate this equipment indoors. When the heaters are lit

never leave the machine standing in one place, but always keep it moving. Rock the machine

back onto its rear wheel when not in use so the heaters are elevated off the ground for cooling.

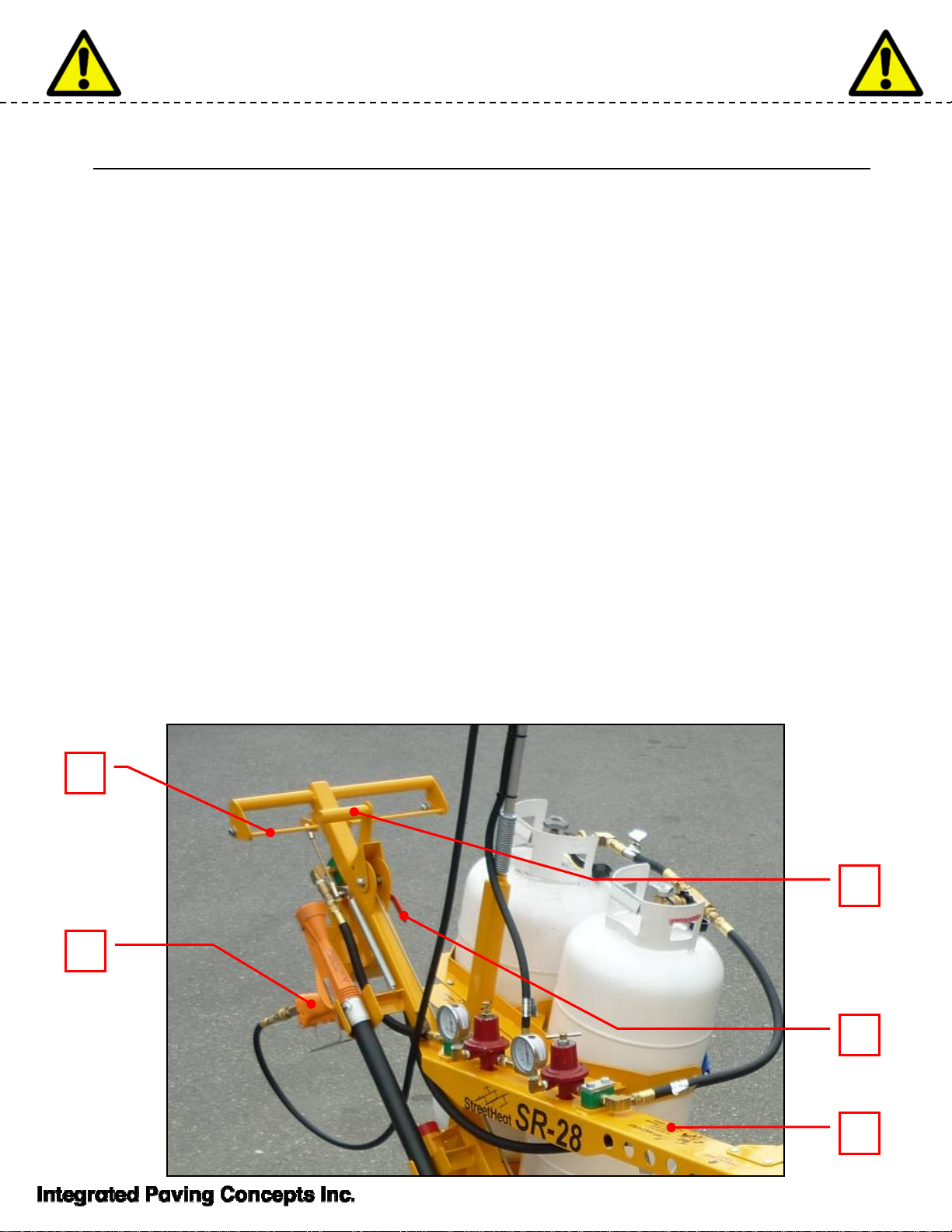

Hand Brake (d) - Always set the hand brake whenever the machine is left unattended. NOTE:

breaking effectiveness is directly related to tire pressure. Always keep the main tires properly

inflated.

Tipping Hazard (e) – The SR28 needs the propane tanks installed to be properly balanced.

CAUTION: Never remove the tanks with the heater bank extended as the machine could tip

over causing damage and potential serious injury (see warning label on the machine)

d

b

4

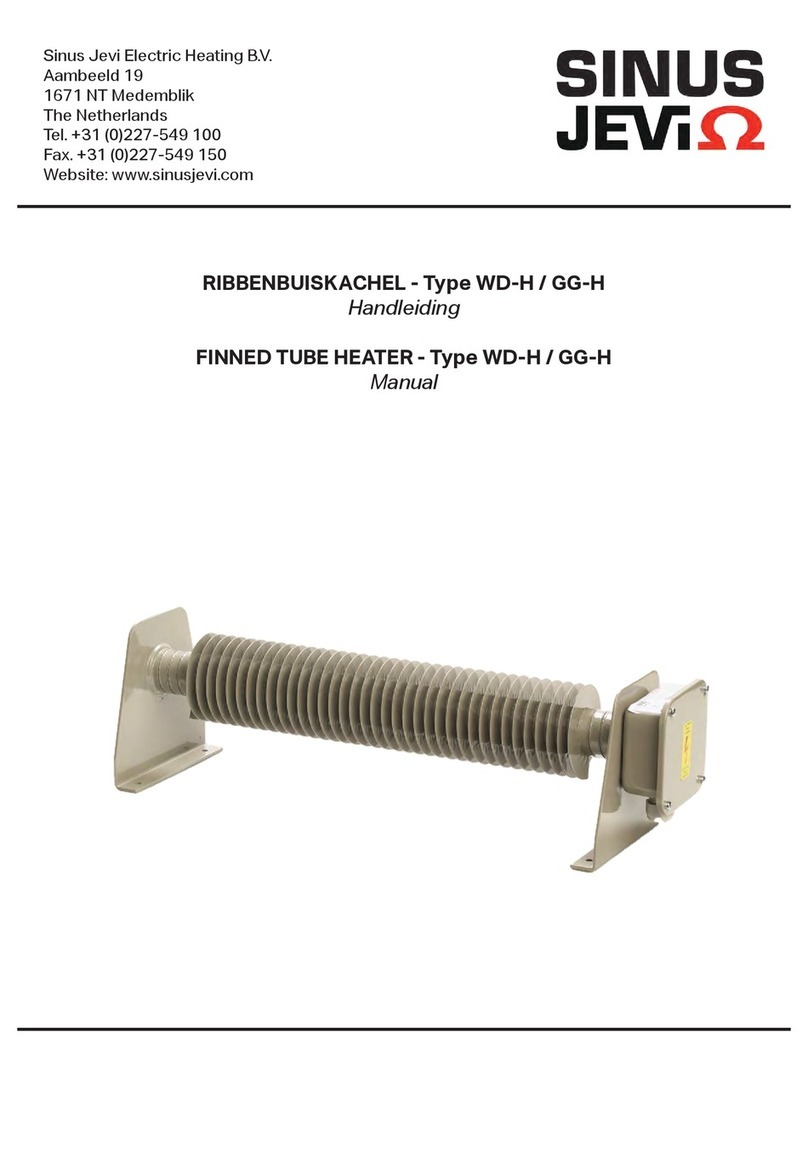

Main Operating Components

Heater Bank

(4 Heaters)

4th Heater Shut-Off

Valve

Front Castering Wheel

with Swivel Lock

Heater Bank

Fold Rotary

Latch

Flint Torch

Regulator and

Gauge

Heater Bank

Regulator and

Gauge

Hand Brake

Standard Vapor

Withdraw 40 lb

Propane Cylinders

Hose “Whip” and Hose

for Flint Torch

Heater Bank Burner

Valve Lever

Flint 2000EX Heat

Torch

Adjustable Stay

(Heater Bank

Camber)

Traction Gas

Spring

Heater Bank

Manual Shut-Off

Valve

OPERATING PRINCIPLE

The StreetHeat SR28 Infrared Heater is a fully self contained infrared heating machine for use

in reheating asphalt, installing preformed thermoplastic, drying and curing on asphalt surfaces,

and other heating jobs. It is designed for maximum heating control because the heating

motion is not static but the operator moves the machine back and forth so that the surface

temperatures can be closely monitored and controlled.

Infrared heat is effective because much of the heat energy penetrates below the surface

making it ideal for its intended use, especially melting and bonding preformed thermoplastic

5

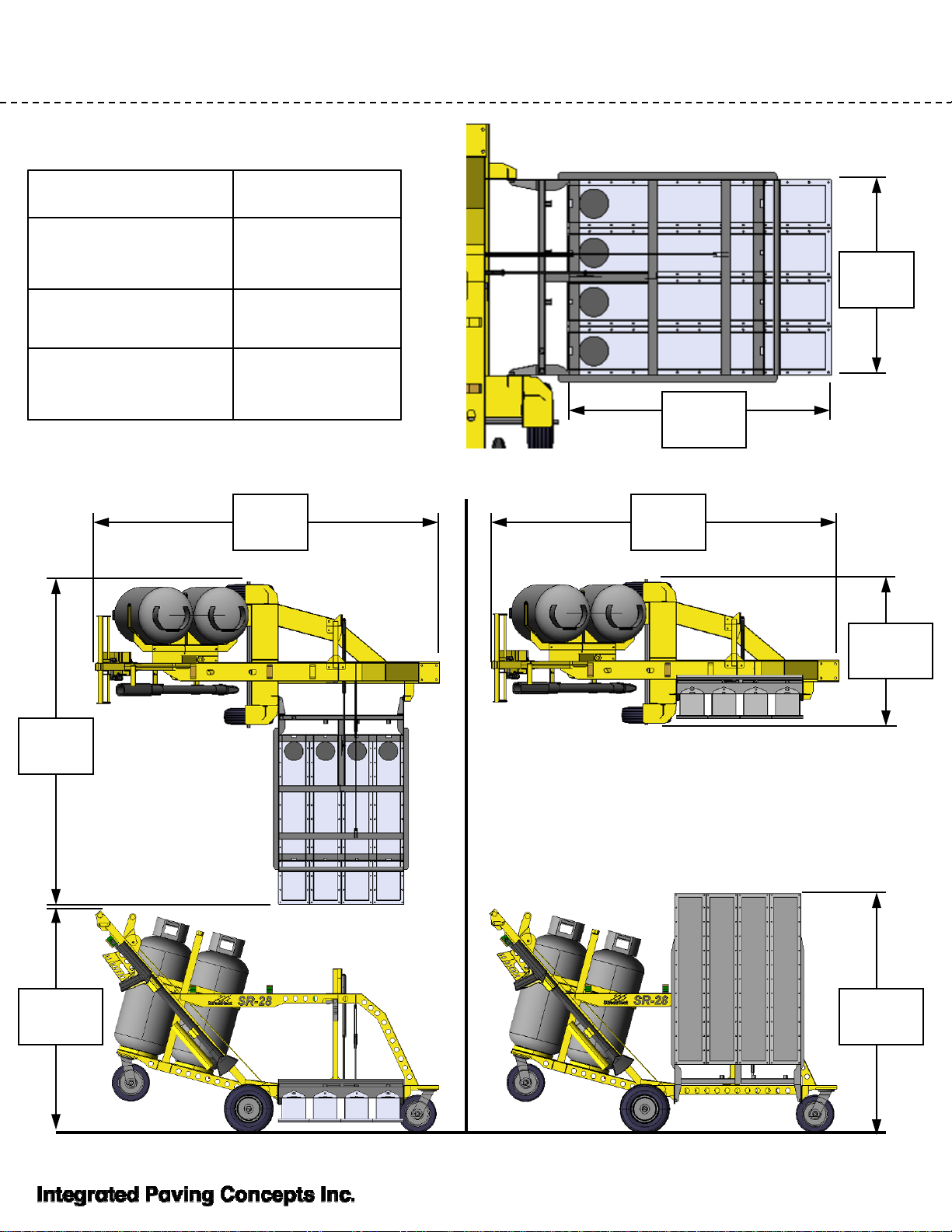

SR28 Specifications

280,000 BTU-Hr

(250 kW-Hr)

Amount of Heat

(SR28) 90,000 - 190,000

BTU-Hr

(27-55 kW-Hr)

Amount of Heat (Flint

2000EX Heat Torch)

260 lbs

(118 kg)

Machine Weight

(Without Propane

Cylinders)

PropaneInfrared Heat Source

Dimensions

with Heater

Bank Extended

Dimensions with

Heater Bank Folded

68.5”

1.74 m

31”

0.79 m

47.5”

1.21 m 50.5”

1.28 m

73.5”

1.87 m

26.5”

0.68 m

36”

0.91 m

73.5”

1.87 m

Heater Bank Dimensions

Specifications and Dimensions

6

Preparing for Work

Propane Tanks

The SR28 requires two standard 40 lb propane

tanks (not included). USE ONLY 40 LB TANKS –

THE MACHINE’S BALANCE IS OPTIMIZED FOR

THIS TANK ALONE. Use only the more common

vaporized propane cylinders. DO NOT USE THE

LIQUID PROPANE TYPE AND NEVER USE

WITH THE TANKS LYING ON THEIR SIDES. It is

advisable to purchase a second set of tanks to

have as back up when needed.

Latch the bottles in place as shown. NEVER USE

OR TRANSPORT THE MACHINE WITHOUT THE

BOTTLES LATCHED SECURELY!.

Attach the propane lines

as shown turning the

hand wheel POL fittings to

the left. Open the tank

valves slowly making sure

there are no leaks

CAUTION:

TIP HAZARD!

Never lower the heater

bank without propane tanks

on board and secured! The

machine is not balanced

without the tanks and could

tip over can cause serious

injury

Make sure the heater

bank is closed and latched

in the up position before

changing propane tanks!

Always set the hand

brake before changing the

propane tanks

7

Preparing for Work – Cont’d

Folding out the Heater Bank

CAUTION:

Always set the brake before raising or

lowering the heater bank!

Never lower the heater bank without the

propane bottles installed!

Never attempt to lower the heaters

when standing on the opposite side of the

machine from the heaters! This could

result in injury or damage the SR28!

Position yourself with one foot on the heater side of

the machine. Straddle the nose of the SR28, hold

the heater bank handle with you left hand and

unlatch the bank with your right hand, letting the

bank down gently. NEVER LET THE HEATER

BANK DROP ON ITS OWN

8

Preparing for Work – Cont’d

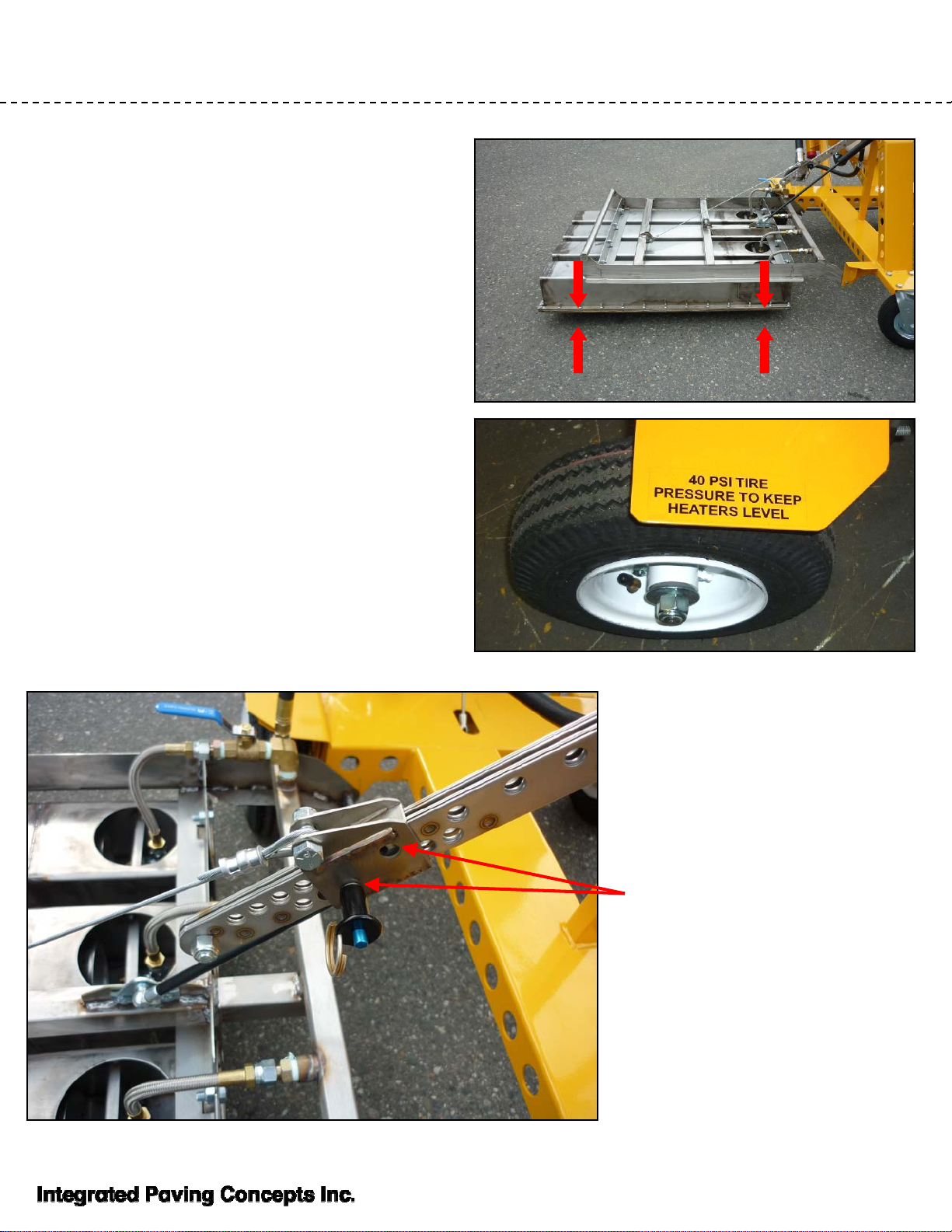

Leveling the Heaters

First, ensure that the pressure on the main

tires is at 40 psi, especially the right hand tire.

(Note: Most of the weight of the entire

machine rests on this wheel)

Then raise or lower the heater by

adjusting the stay. By alternating

inserting the ball lock pin between

the upper and lower holes on the

stay sleeve, the stay length can

be adjusted in ¼” (13 mm)

increments for very precise height

control. Folding the heater bank

makes it easier to make these

adjustments.

Leveling the heaters will ensure that you get

the most effective and even heating results

and at the same time prevent the heaters

scraping the ground

9

Operating Procedure

Lighting the Heaters

Once the propane bottles are installed

and the heater bank lowered and

leveled, open the valves on the propane

tanks. Ensure that the pressure on the

heater regulator (see above) is between

6 and 7 PSI (41 - 48 kPa). Rock the

machine onto its front wheel. Check that

the nearest burner valve is open if you

want all four heaters to light, and that the

main shut off valve to the left of the

handle bar is open.

Open the burner valve by pulling the

valve lever against the handlebar (red

circle at right). While holding the valve

open, light the heaters by waving the

Flint 200EX Heat Torch back and forth

under the heaters for about 5 seconds.

CAUTION: To avoid lighting the heaters internally (which will damage them), always light from

UNDERNEATH the heaters

To shut off the heaters simply let go of the valve lever

Tilt the machine onto its rear wheel to avoid burning the pavement surface as the heaters cool

Flint 2000EX Heat Torch

IMPORTANT: READ THE FLINT 2000EX MANUAL

BEFORE OPERATING. The Flint 2000EX torch is

necessary for both lighting the heaters and to heat areas

which the SR28 cannot reach because of obstacles.

Connect and mount the torch as shown using the quick

connect coupler. Set the torch regulator pressure (see

right) to between 21 and 45 PSI (145 – 310 kPa). There is

no separate shut off valve for the torch, but if the torch is

disconnected, the valve in the quick connect coupling will

shut and prevent any gas flow. Heater Bank

Regulator Flint Torch

Regulator

10

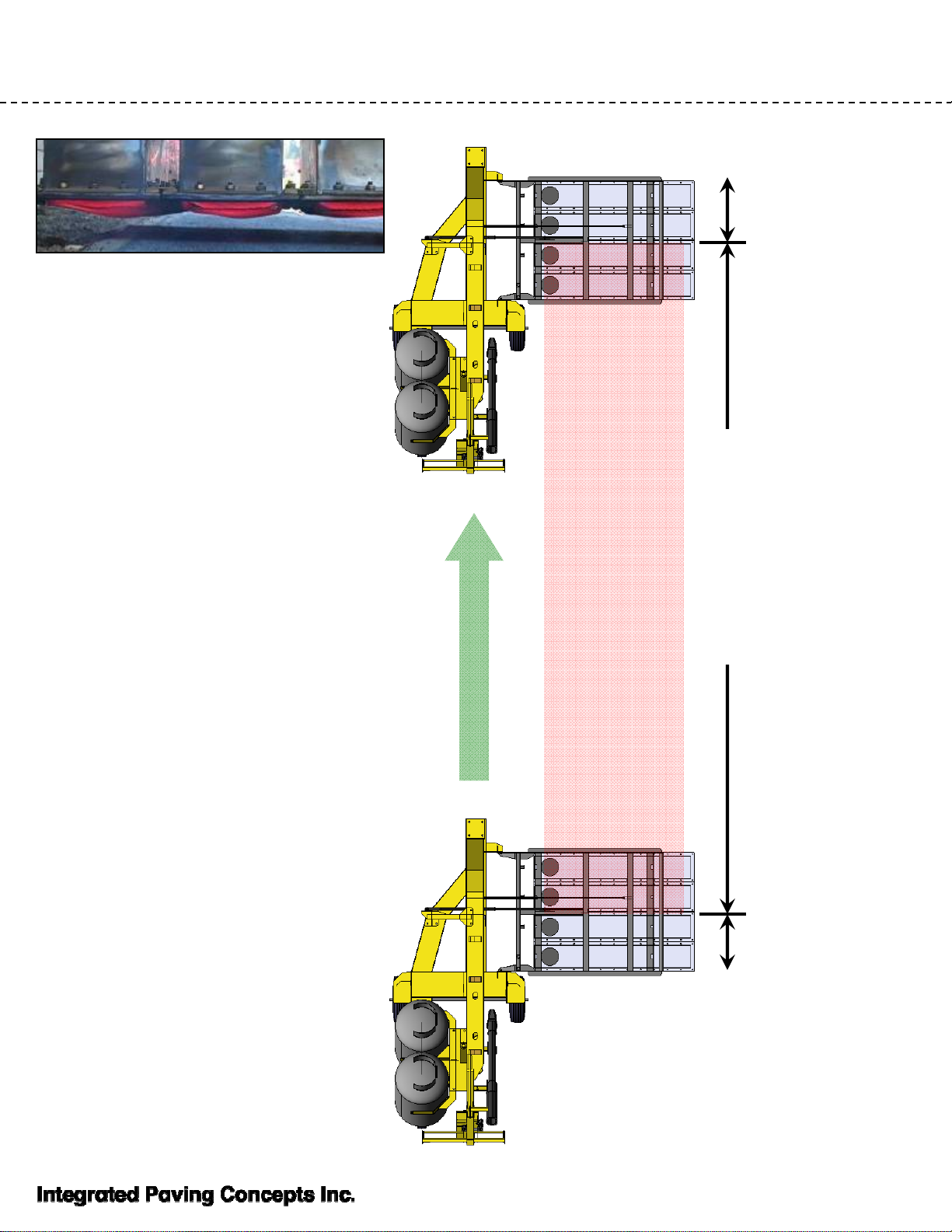

Heating

The advantage of infrared heat is its

ability to penetrate below the surface to

heat at depth without overheating the

surface. To do this effectively, begin

heating by walking VERY SLOWLY

forward (about 10-20 feet per minute).

After one “stroke”, rock the machine

back and return quickly to the start line

and repeat, walking a little faster each

time (as the surface will reach

maximum temperature more quickly)

until the asphalt reaches the desired

depth of heat. (Note: when heating, the

handle height has be optimized for

pushing, not pulling the machine; it is

also easier to maintain a straight line by

pushing the machine.)

Monitor the surface temperature with an

IR thermometer. Try to bring the

surface temperature up as high as

possible with each stroke without

exceeding the maximum allowable

temperature of the material you are

heating and causing it to burn.

To ensure that you have heated

adequately along the entire length, start

and end each stroke at least ½ the

bank width at the start and end of the

desired heating area.

Operating Procedure – Cont’d

Extend Stroke

at least ½ bank

width beyond

desired heating

area

Start Stroke at

least ½ bank

width before

desired heating

area

Desired Heat Area

Optimum heating length is

about 6-12 feet (2-4

meters); if the heat length

is less than 6 feet (2

meters) close the shut-off

valve to the nearest

heater to prevent

overheating the surface

11

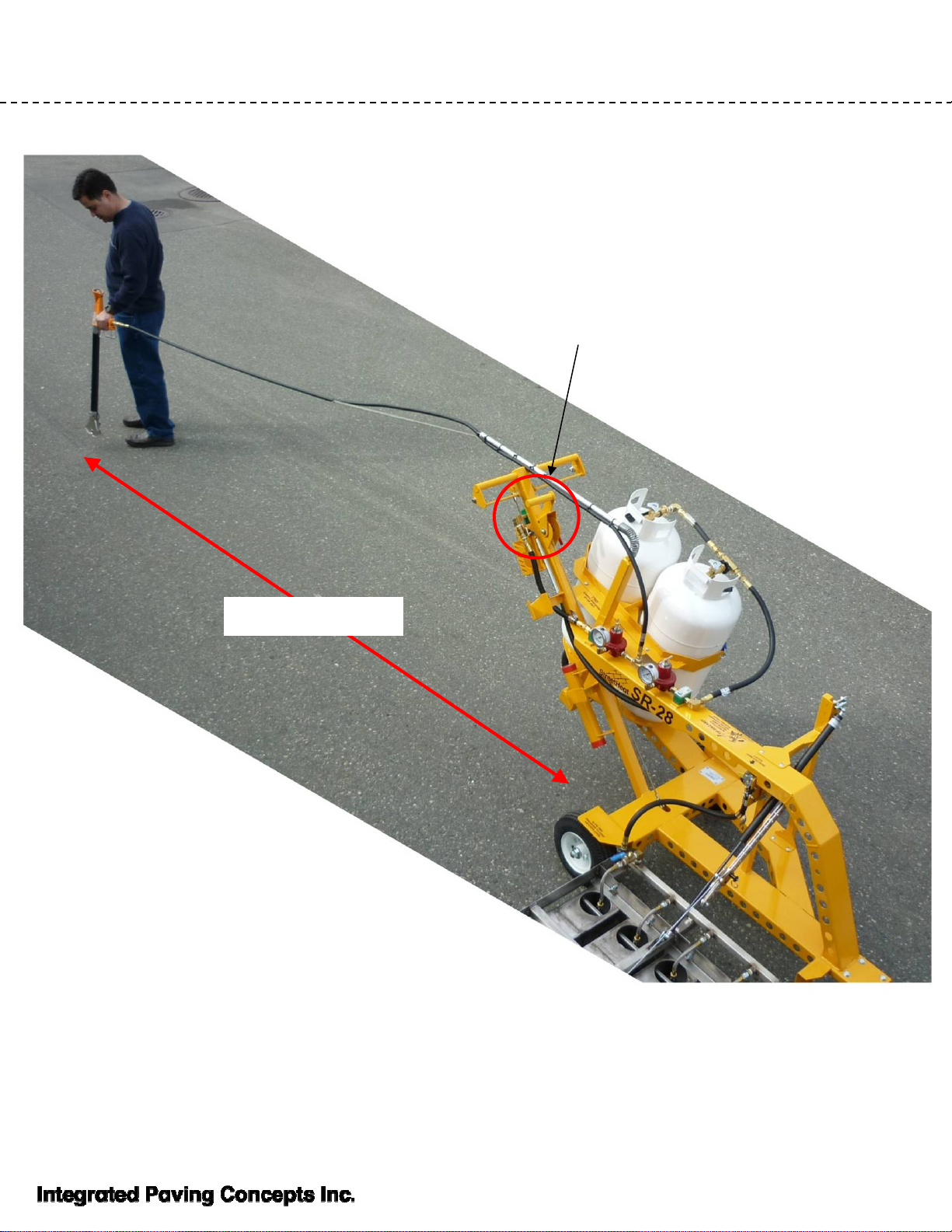

Operating Procedure – Cont’d

12’ Radius

The Flint 2000EX Heat Torch can be operated in a 12’ radius in all

directions from the SR28 if you need to heat those hard-to-get-at

places.

Do not pull too hard on the hose

or it could rupture and cause a

dangerous propane leak.

Always make sure that the hand brake is

set first.

Take care when using the Heat Torch close to the machine

that you do not overheat a tire and cause it to burst

12

Preparing for Transport

1. Propane Tank – Caution EXPLOSION HAZARD! Never transport the SR28 with

the propane hose attached to the tanks! Never transport or store propane

tanks inside an enclosed trailer! Make sure the shut off valve on the tank is

closed tightly and that the tanks are securely latched to the machine or

transport.

2. Fold up the Heater Bank - The heavy duty rotary latch will hold the heater bank in

place securely for transportation. Make sure it is closed securely.

3. Secure the Flint 2000EX Heat Torch – The heat torch should be either removed

from the SR28 and stowed separately or held in its cradle securely using bungee

cords.

4. Brake – When transporting always set the hand brake.

5. Strapping – Strap the SR28 down so that it cannot move in any direction, nor rock

from front to rear wheels. Avoid placing strapping on to or over the heater

bank.

13

Trouble-Shooting and Repair Contents

1. Trouble-Shooting Guide

2. Parts List

3. Parts List Illustrations

4. Removing Traction Spring Cylinder

5. Adjusting Brake

6. Regular Maintenance

7. Service

14

Trouble Shooting

Problem will correct itself when winds subside.This can occur in high winds

Use a pressure washer to clean the screen. Allow

to dry before lighting

Check for build up of dirt or asphalt on the screen

Tighten Bolts. There is a ceramic gasket around

the perimeter that must be sealed

Check that all the nuts and bolts around the

perimeter of each heater are tightened.

Tighten or reseat and tighten flare fittings until leaks

are sealed

Check for leaks in the tube running from the

manifold to the heaters using soapy water and

blowing compressed air into the system (DO NOT

USE PROPANE; EXPLOSION HAZARD!)

Set to between 6 and 7 PSI. Too high pressure can

cause gas to leak out of the bell, fall to the ground

and ignite inside the heater.

Check that the pressure is not set too high

Propane is burning inside the heater: If you hear a continuous “whooshing” sound and

the top of the heater is turning blue, it is because it is burning internally. Here are some

things you can do:

Heater is lit but is not glowing red: Here are some things to check for:

Set between 6 and 7 PSI.2. Check that the pressure is not too low.

If it is still blocked there may be a larger piece that

necessitates the removal of the tip altogether (See the

Maintenance Section of this manual for instructions).

Use the supplied tip cleaner to clean out the orifice.

To do this, blow compressed air into the system and

run tip cleaner in and out while the air is blasting out

(DO NOT USE PROPANE; EXPLOSION HAZARD!)

1. Check that there is no blockage in the orifice

(the tip that injects the propane into the heater).

15

Parts List

(See the Following Page for Illustrations)

1Tip Cleaner Kit (Not Shown)80-0-432A62

1SR-28 Operations Manual (Not Shown)80-0-4500461

OTHER PARTS

1Flint 2000EX Heat Torch80-0-450U37

1- 3/8 Manual Shut off ValveMC-0-0-14136A

1Heater Bank Manifold AssemblyN/A36

4Infrared Heater Assembly (with 8" Braided Hose)80-0-416E35

1POL Propane Hose Sub-Assembly80-0-416N34

1Hose Whip Sub Assembly80-0-416G33

1- Heater Bank Pressure GaugeMC-0-0-13432B

1- StreetHeat Pressure GaugeMC-0-0-13532A

1Regulator Train Sub-Assembly80-0-416C32

1Propane Valve Sub-Assembly80-0-416D31

PROPANE

1Traction Gas Spring PostN/A23

1Heater Bank Frame AssemblyN/A22

1Main Frame AssemblyN/A21

STRUCTURAL

1- Ball Lock PinMC-0-0-27113A

1Heater Stay Sub Assembly80-0-416K13

1Brake Handle Sub Assembly80-0-416P12

1Traction Gas SpringMC-0-0-27511

1Brake Bar (Not Shown)N/A10

1Brake Rod Assembly80-0-416F9

1Rotary Latch Striker StudMC-0-0-2038

1Rotary LatchMC-0-0-2027

1Valve Extension SpringMC-0-0-2016

1Valve Linkage ArmN/A5

1Valve Handle LeverN/A4

18" Pneumatic Swivel Caster with Swivel LockMC-0-0-2003

18" Pneumatic Swivel CasterMC-0-0-1992

310" Pneumatic WheelsMC-0-0-1371

MECHANICAL

Qty Per

SR28

DescriptionPart Number

REF.

No.

16

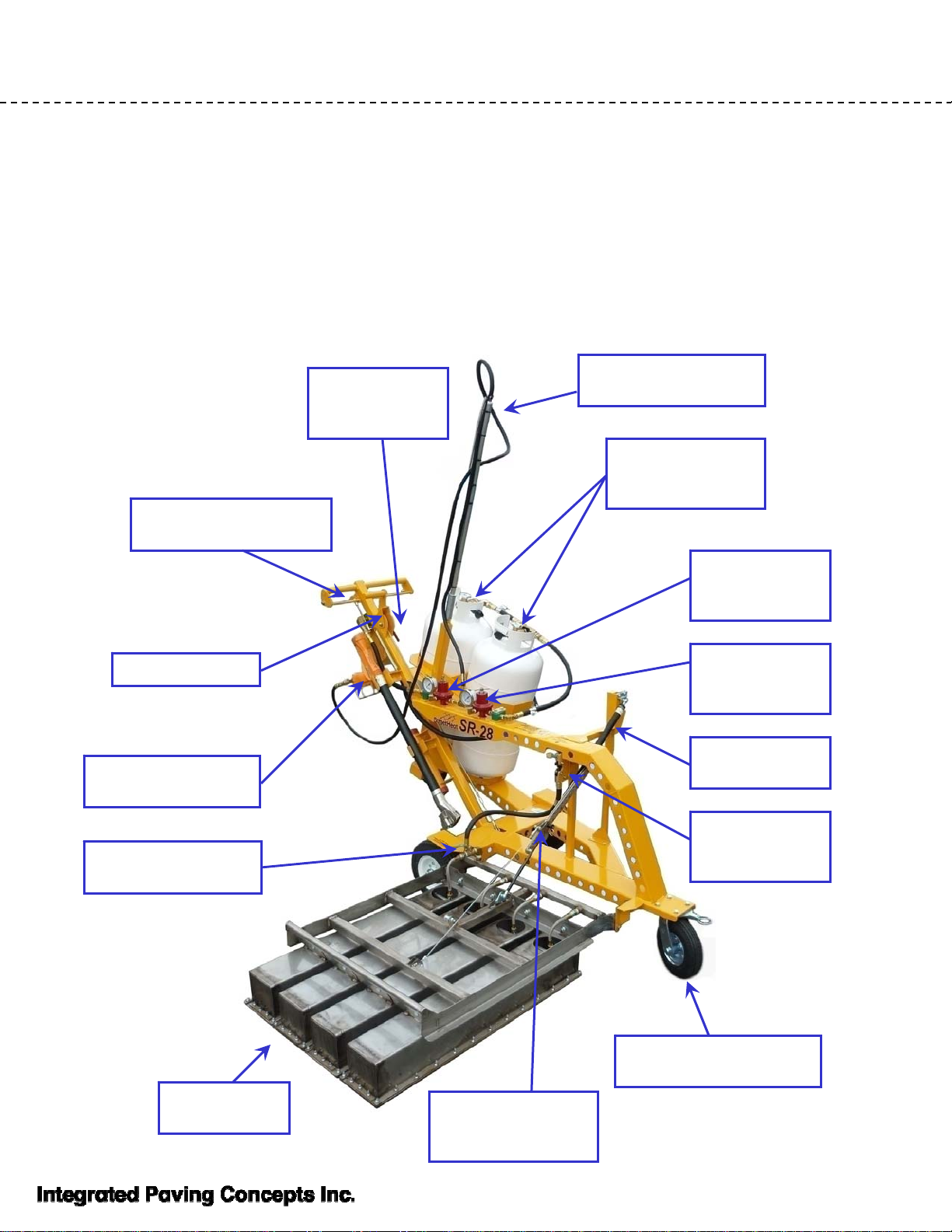

Parts List - Illustrations

1

2

3

4

33

5

7

36

9

13A

22

32

34

32A

31

13

12

35

8

37

32B

36A

611

21

23

17

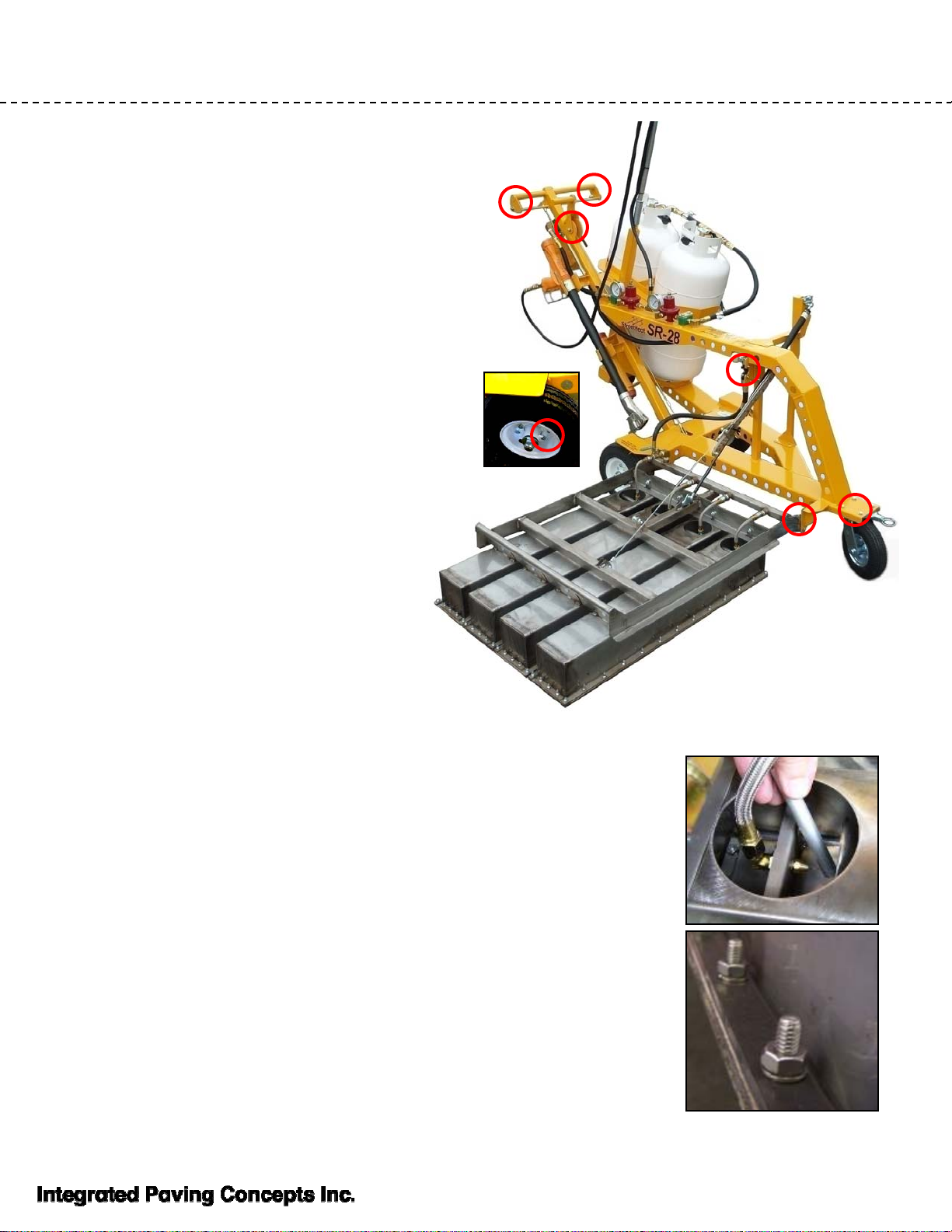

Removing the Traction Gas Spring

VERY IMPORTANT: Disassembling or operating the traction spring cylinder

incorrectly could result in severe injury. Please read these instructions

carefully.

To remove the traction gas spring cylinder, THE

CYLINDER MUST BE RETRACTED COMPLETELY. To

do this, the rotary latch assembly (circled left) will need to

be removed by undoing these two nuts and bolts.

Now the heater bank can be folded until the traction

spring is fully retracted

ONLY WHEN THE CYLINDER IS FULLY RETRACTED

should the clips holding the cylinder to the balls on both

ends be removed. See below.

Reverse the process to reinstall, taking care to line the rotary latch with the rotary latch stud on the

folding bank so that it latches properly.

CAUTION: NEVER OPERATE THE TRACTION GAS SPRING WITHOUT THE CLIPS

PROPERLY ATTACHED ON BOTH ENDS!

18

Adjusting Brake

Once the tire pressure is set properly the brake can be adjusted:

1. Remove the split pin and clevis pin on the Brake Rod

2. Screw Yoke on to tighten brake or off to loosen. Reassemble.

Split Pin

Yoke

Clevis Pin

The brake bar on the SR28 presses

against the tire tread. Therefore brake

effectiveness is related to tire pressure.

Make sure the main wheels are kept at 40

psi pressure.

19

Regular Maintenance

Lubrication

At least once a season apply grease to all

the rotation points on the SR28. Use a

grease gun to apply grease to the grease

nipples on the wheels and caster bearings

and spray white lithium grease to lubricate

the remaining points. (circled at right).

Hoses and Fittings

Do a visual check at least once a month of

all hoses and fittings to make sure there is

no damage or risk of perforation. Replace

any parts BEFORE they fail.

Tires

Check tire pressures frequently. Check the

tread, especially on the right hand 10” wheel

that takes most of the weight of the

machine. Replace the wheel if necessary.

Heaters

Over time the heaters may begin to lose some of their original glow so

that it takes longer to heat the asphalt. One way to prevent this is to

keep the propane tips (orifices) clear of debris. The orifice is the small

tip that injects the propane into the heater. Use the supplied tip cleaner

to clean out the orifice.

To do this, attach compressed air onto the quick coupler on the hose

leading into the heater bank. Run the tip cleaner in and out of the tip

while air is blowing through it. CAUTION: DO NOT USE PROPANE;

EXPLOSION HAZARD!

Once a year, using a 7/16” wrench and ratchet with an extension,

check that all the bolts on the heater perimeter are tight. This will

prevent propane leaking out the sides and causing internal combustion.

20

1. Using a 11/16” wrench,

loosen and disconnect the

braided hose

4. Remove fitting and tip

assembly from burner.

2. Using a 3/4” wrench,

loosen the backing bolt that

keeps the tip assembly in

place.

3. Once the backing nut is

loose, you will be able to

unscrew by hand.

5. Using the tip cleaner or a

welding tip cleaner, clean

the tip. This will dislodge

any debris that may be

clogging the tip.

6. Blow compressed air

through the tip to remove

debris from behind the

orifice.

Reverse steps for re-assembly. When fully assembled, apply soapy water, blow compressed

air through system to check for leaks. Tighten any fitting that leaks.

Regular Maintenance –Cont’d

Heaters (cont’d) - If cleaning the tip still doesn’t restore the glow on the heater, you may need to

remove the whole fitting assembly on which the tip is mounted to dislodge any debris that has

accumulated behind the tip.

Table of contents