Ventmatika EKA Instruction manual

Technical data

Mounng

Maintenance

ELECTRICAL CIRCULAR DUCT HEATERS

EKA

e

n

s

t

s

h

C

g

i

l

t

a

r

s

i

s

A

D

The electrical heater's model and serial number are located on the label of the product.

Improper use of this heater can result in serious bodily injury due to hazards of fire and explosion,

burn and electrical shock.

Use only with electrical voltage and frequency specified on model label. Do not perform any service

with heater plugged in. Serious injury or death may occur if personnel come in contact with high

voltage lead.

Parts of the heater become very hot when operang and immediately aer operang. Severe burns

may occur if the heater is not allowed to cool down properly before servicing.

WARNING! SAFETY REQUIREMENTS

All products are packed by producer for normal transporng condions. For unloading and storing

use proper lier to prevent product damage and employees injuries. Do not li product by power

supply cable, connecon box. Avoid impacts and impact loads.

Unl final installaon store products in dry place with humidity not more 70% (20°C), average

ambient temperature must be 5-40°C. Storing place must be covered from water and dirt. Avoid long

term storing. It is not recommended to store products more then 1 (one) year.

TRANSPORTING AND STORING

Inspect heater for any possible shipping damage. Inspect heater element wire for any deformaon

that could cause a short circuit or ground. Make sure that casing of the heater is not damaged.

RECEIVING AND HANDLING

No special service is required for electrical heaters, only to check electrical connecon not less than 1

me per year.

SERVICE

We care about quality. 100% of heaters are tested before shipment.

QUALITY

Important environmental informaon about this product.

This symbol on the device or the package indicates that disposal of the device aer its lifecycle could

harm the environment. Do not dispose of the unit as unsorted municipal waste; it should be taken to a

specialized company for recycling. Respect the local environmental rules.

If in doubt, contact your local waste disposal authories.

DISPOSAL

2

Thank you for your purchase of this product. This manual describes how to use and install the

supplied product. Be sure that you have read and understood its contents before using the heater.

Table of contents

Descripon

Installaon and electrical connecon

Dimensions

Technical data

Model marking

Overheang protecon

Heaters EKA with integrated controller

Descripon of operang EKA NV …

Descripon of operang EKA NI …

Descripon of operang EKA NIS …

Descripon of operang EKA NV … (PTC…PS)

Descripon of operang EKA NI … (PTC…PS)*

Descripon of operang EKA NIS … (PTC…PS)*

Descripon of operang EKA NV … 2NTC*

Descripon of operang EKA NI … 2NTC*

Descripon of operang EKA NV … PTC/2NTC*

Descripon of operang EKA NI … PTC/2NTC*

Service

Troubleshoong

Warranty

3

4

5

7

8

10

11

11

11

11

12

12

12

13

13

13

14

14

15

15

15

Descripon

Electrical duct heaters EKA are designed to heat fresh air in venlaon systems. Casing (EKA protecon class IP

44, except EKA Type NV which protecon class IP 30) is made from Aluzinc coated steel which is high temperature

proof and with rubber seals for duct connecon. Tube of heang element is made from stainless steel AISI 304.

There are 2 protecon thermostats and screw terminals for easy connecon installed in the heaters.

Heaters can be installed horizontally with the electrical connecon box facing upwards or sideways and

vercally (only if the air flow direcon upwards). Heaters can't be installed in explosive and aggressive substances

environment. Heaters can be used only for the clean air heang or preheang. Heaters intended only for inside

installaon. If heater is installed in such way that can be accidental contact with heang elements, protecve grill

must be installed. The air velocity in the duct of the heater must be 1,5 m/s minimum. The maximum temperature

of the output is 50 °C.

Heaters EKA with integrated temperature controller EKR-K… (See Fig. 1) can be controlled in five different ways

depending on control type:

Type EKA NV – potenometer on the lid of the heater (See page 11).

Type EKA NI – external wired remote setpoint knob (TR5K) for temperature control (See page 11).

Type EKA NIS – external wired remote 0…10V signal for temperature control (See page 12).

Type EKA ESKM – external wired remote PWM (ON/OFF: ON(6…24)VDC) signal for temp. control

Electrical duct heaters EKA with integrated temperature controller EKR-K… works by PID regulator. That enable

fine temperature control. Controller EKR-K… controls load by Triacs without moving parts, which causes no-noise

commutaon.

Fig. 1

4

View may vary depending on type EKR-K.

Installaon and electrical connecon

Electrical duct heaters EKA can be installed horizontally in any posion except electrical connecon box

downward and vercally (only if the air flow direcon upwards) (see Fig. 2).

IMPORTANT:

The installaon to the mains power supply may only be wired by a competent electrician. The power

supply cable must be selected in the rao with power of the heater. When installing these heaters, the

standards and regulaons in force in your country must be followed strictly adhered to. Within the installaon

an electrical isolaon automac circuit breaker (not included) must be present, to enable the installer to cut all

power supply lines. Automac circuit breaker must be selected regarding power and nominal current (see the

electrical rang plate on the lid of heater) of the heater and should have characterisc B. Connect the heater to

the mains power supply, check that the voltage, frequency, power and current are the same as those indicated

on the electrical rang plate. The heater must be earthed.

We recommend install supply air temperature sensor in distance mulplied by the heater's diameter (3xD).

For example: heater EKA diameter 200 mm, sensor's installaon distance will be: 3x200=600 mm.

Fig. 3. Mounng example EKA NV/NI…

*- TR5K is used in EKA NI heater version.

**- Temperature set point knob is used in EKA NV heater version.

Fig. 2

Fig. 3

5

Fig. 4. Mounng example EKA NIS/ESKM…

*- External control signal (0…10VDC) is used in EKA NIS type heater.

**- External PWM control signal ON/OFF: ON (6…24VDC) is used in EKA ESKM type heater.

Fig. 5. Mounng example EKA NV/NI…2NTC…

*- Temperature set point knob and TR NTC10 are used in EKA NV 2NTC heater version.

**- TR5K NTC10 is used in EKA NI 2NTC heater version.

Fig. 6. Mounng example EKA NV/NI… (Preheater)

**- TR5K used only in EKA NI pre-heater version.

*- Temperature set point knob used only in EKA NV pre-heater version.

Fig. 4

Fig. 5

Fig. 6

AHU – Air handling unit

6

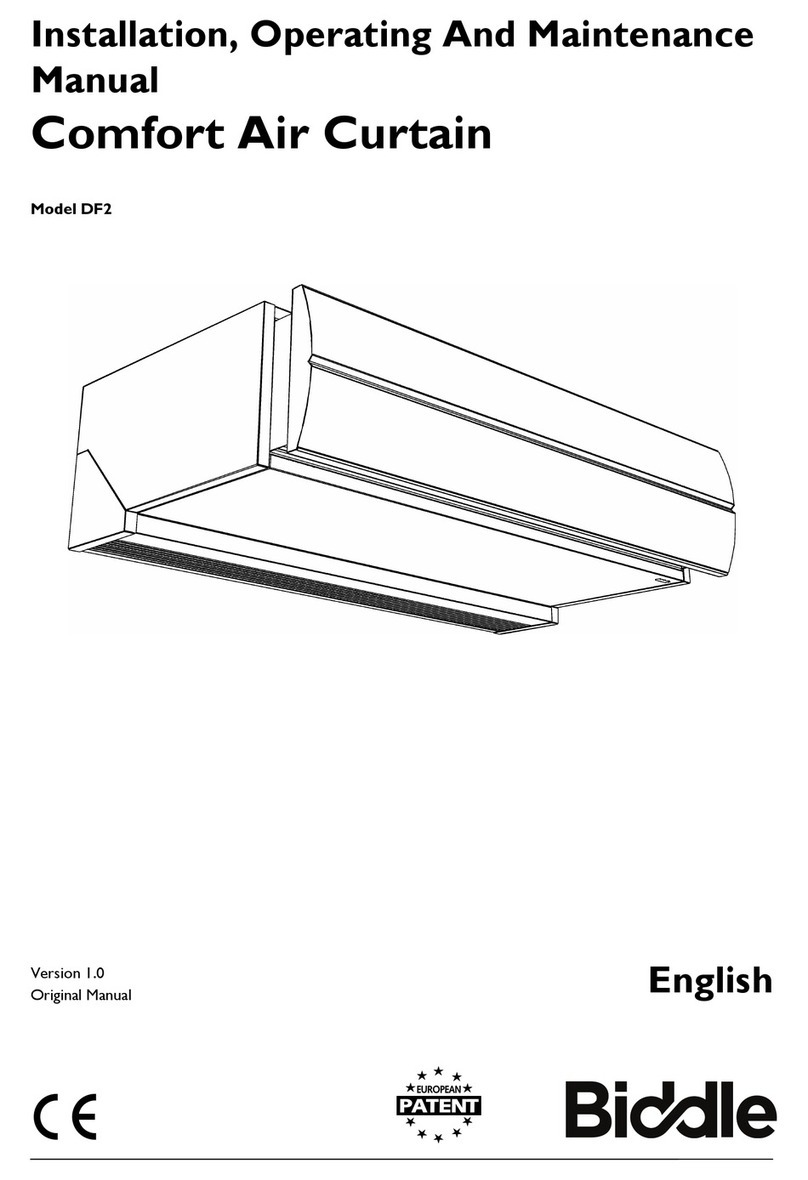

Dimensions

Fig. 7. Mounng example EKA NIS/ESKM… (Preheater)

*- External control signal 0…10VDC (from AHU if possible) is used in EKA NIS type pre-heater.

**- External PWM control signal ON/OFF: ON 6…24VDC (from AHU if possible) is used in EKA ESKM type pre-

heater.

Fig. 7 AHU – Air handling unit

Fig. 8

Type 1 Type 2 Type 3 Type 4

Type 1 – Standard EKA heater dimensions;

Type 2 – EKA heater with external pressure relay dimensions;

Type 3 – EKA heater with external cooling radiator dimensions;

Type 4 – EKA heater with external cooling radiator and pressure relay diemensions.

7

EKA 250-15kW 250 265 3~400 15,0 1,0/1,5

EKA 315 315 425

1~230 0,6...9,0 0,6/1,0/1,2

2~400 1,0...9,0 1,0/1,5

3~400 3,0...9,0 1,0/1,5

EKA 500-15kW 630 532 81 500

EKA 500-18kW 630 532 81 500

EKA 500-21kW 770 672 81 500

EKA 500-24kW 880 782 81 500

Heater type A(mm) B(mm) C(mm) D(mm)

EKA 100 370 276 71 100

EKA 125 370 276 71 125

EKA 150 370 276 71 150

EKA 160 370 276 71 160

EKA 200 370

276

71

200

EKA 250 370

276

71

250

EKA 250-12kW

500

402

71

250

EKA 250-15kW

630

532

71

250

EKA 315 373

276

71

315

EKA 315-12kW

500

402

71

315

EKA 315-15kW

630

532

71

315

EKA 315-18kW

630

532

71

315

EKA 355 373

276 71 355

EKA 355-12kW

500

402 71 355

EKA 355-15kW

630

532 71 355

EKA 355-18kW

630

532 71 355

EKA 400 373

276

81

400

EKA 400-12kW

500

402

81

400

EKA 400-15kW

630

532

81

400

EKA 400-18kW

630

532

81

400

EKA 400-21kW

770

672

81

400

EKA 400-24kW

880

782

81

400

EKA 450 373

276

81

450

EKA 500 373

276

81

500

EKA 500-12kW 500 402 81 500

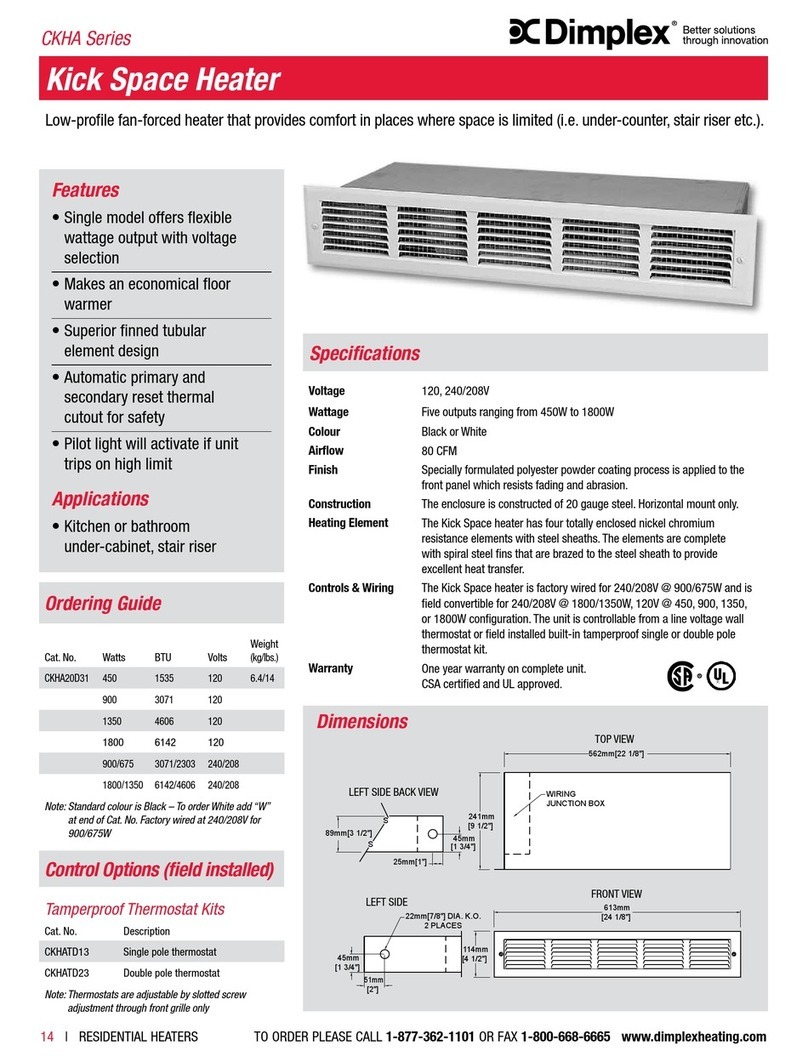

Technical data

EKA ø(mm) Min. airflow

(m³/h)

Power supply

(VAC/50Hz)

Power

(kW)

Available

heatng

elements (kW)

EKA 100 100 45 1~230 0,3...1,8 0,3

EKA 125 125 70 1~230 0,3...3,6 0,3/0,6

EKA 150 150 100 1~230 1,2...3,0 0,6/1,0

EKA 160 160 110

1~230 0,3...7,2 0,3/0,6/1,0/1,2

2~400 1,0...6,0 1,0

3~400 3,0...6,0 1,0

EKA 200

200

170

1~230

0,3...7,2

0,3/0,6/1,0/1,2

2~400

1,0...6,0

1,0

3~400

3,0...9,0

1,0/1,5

EKA 250

250

265

1~230

0,3...7,2

0,3/0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 250-12kW

250

265

3~400

12,0

1,0/1,5

8

EKA 315-12kW 315 425 2~400 12 1,0/1,5

3~400 12 1,0/1,5

EKA 315-15kW 315 425 2~400 15 1,0/1,5

3~400 15 1,0/1,5

EKA 315-18kW

315

425

2~400

18

1,0/1,5

3~400

18

1,0/1,5

EKA 355

355

535

1~230

0,6...9,0

0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 355-12kW

355

535

2~400 12

1,0/1,5

3~400 12

1,0/1,5

EKA 355-15kW

355

535

2~400 15

1,0/1,5

3~400 15

1,0/1,5

EKA 355-18kW

355

535

2~400

18

1,0/1,5

3~400

18

1,0/1,5

EKA 400

400

680

1~230

0,6...9,0

0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 400-12kW

400

680

1~230

9

1,0

2~400

12

1,0/1,5

3~400

12

1,0/1,5

EKA 400-15kW

400

680

1~230

12

1,0

2~400

15

1,0/1,5

3~400

15

1,0/1,5

EKA 400-18kW

400

680

2~400

18

1,0/1,5

3~400

18

1,0/1,5

EKA 400-21kW

400

680

3~400

21

1,0/1,5

EKA 400-24kW

400

680

3~400

24

1,0/1,5

EKA 500

500

1060

1~230

0,6...9,0

0,6/1,0/1,2

2~400

1,0...9,0

1,0/1,5

3~400

3,0...9,0

1,0/1,5

EKA 500-12kW 500 1060

1~230

9

1,0

2~400 12 1,0/1,5

3~400 12 1,0/1,5

EKA 500-15kW 500 1060

1~230 12 1,0

2~400 15 1,0/1,5

3~400 15 1,0/1,5

EKA 500-18kW 500 1060 2~400 18 1,0/1,5

3~400 18 1,0/1,5

EKA 500-21kW 500 1060 3~400 21 1,0/1,5

EKA 500-24kW 500 1060 3~400 24 1,0/1,5

This declaraon is in conformity with the requirements of the standards:

LST EN 60335-2-30:2010+AC:2010+A11:2012+AC:2015 (EN60335-2-30:2009+ AC:2010+ A11:2012+ +AC:2014);

LST EN61000-4-2:2009 (EN61000-4-2:2009);

LST EN 61000-4-3:2006+A1:2008+A2:2010 (EN 61000-4-3:2006+A1:2008+A2:2010);

LST EN 61000-4-4:2013 (EN 61000-4-4:2012);

LST EN 61000-4-5:2014 (EN 61000-4-5:2014);

LST EN 61000-4-11:2004 (EN 61000-4-11:2004);

LST EN 61000-6-2:2005 (EN 61000-6-2:2005);

LST EN 61000-3-2:2014 (EN 61000-3-2:2014);

LST EN 61000-6-3:2007 + A1:2011 (EN 61000-6-3:2007 + A1:2011);

LST EN 61000-3-3:2014 (EN 61000-3-3:2013).

and therefore complies with the essenal requirements and provisions of the (LVD) 2014/35/EC, (EMC) 2014/30 EC,

(RoHS) 2011/65/EU and REACH.

The CE mark is affixed.

9

Model marking

EKA 100-0.3-1f without integrated control

1 2 3

1 – Duct diameter (mm)

100 – 100 mm 160 – 160 mm 355 – 355 mm 450 – 450 mm

125 – 125 mm 200 – 200 mm 400 – 400 mm 500 – 500 mm

150 – 150 mm 315 – 315 mm 450 – 450 mm

2 – Heang power (kW)

0.3 – 0,3 kW ... 24.0 – 24,0 kW

3 – Input voltage:

1f – Single phase 230V

2f – 2-phase 400V

3f – 3-phase 400V

3f – 3-phase 230V (on request)

1B – Duct diameter (mm)

100 – 100 mm 160 – 160 mm 355 – 355 mm 450 – 450 mm

125 – 125 mm 200 – 200 mm 400 – 400 mm 500 – 500 mm

150 – 150 mm 315 – 315 mm 450 – 450 mm

2 – Heang power (kW)

0.3 – 0,3 kW ... 24.0 – 24,0 kW (NV, NI, NIS) >15 kW with mounted addional step

0.3 – 0,3 kW ... 15.0 – 15,0 kW (ESKM)

3

–

Input voltage:

1f

–

Single phase 230V

2f

–

2-phase 400V

3f

–

3-phase 400V

3f

–

3-phase 230V (on request)

4

–

Addional accessories:

PS

–

Differenal

pressure

switch

for

air flow

detecon

PTC

–

Sensor for minimum air velocity detecon

PTC/PS

–

Sensor

for minimum air velocity detecon

and diff. pressure switch for air flow detecon

PTC/K – Sensor for minimum air velocity detecon and contactor for overheang protecon

2NTC – 2 sensors for the air temperature measuring

PTC/2NTC – Sensor for min. air velocity detecon and 2 sensors for the air temperature measuring

EKA NV 100-0.3-1f PTC/2NTC with integrated controller

1A 1B 2 3 4

1A – Control type:

NV – Potenometer for temperature control is on the lid of the heater

NI – External wired remote setpoint knob (TR5K) for temperature control

NIS – External wired remote (0…10) VDC signal for temperature control (analog input)

ESKM – External wired remote PWM (ON/OFF: ON (6…24) VDC) signal for temperature control

10

Overheang protecon

Two overheat protecon thermostats are installed in the electrical circular heater EKA. The first one with

automac reset, turns off the heang when the temperature reaches 50 °C and turns on when the temperature

drops below 50 °C. The second with manual reset, turns off the heang when the temperature reaches 100 °C. In

this case need to figure the cause of the overheang of the heater. Eliminate overheang cause, press „RESET“

buon on heaters cover.

Addional overheang thermostat (with automac reset) is installed in the EKA heater with ESKM to protect

the ESKM controller. This thermostat turns off the heang when the temperature reaches 70 °C and turns on when

the temperature drops below 70 °C.

Heaters EKA with integrated controller

Table 1. Technical characteriscs of controller EKR-K...

Power supply depending on model

single phase 230V / 2 -

phase

400V / 3 -

phase 400V

Power consumpon in standby mode

0,1VA

Ambient temperature

0...50 °C

Relave humidity Max. 90 % RH (non-condensing)

Descripon of operang EKA NV …

Electrical duct heaters EKA NV … are designed with integrated temperature control, one temperature sensor,

setpoint potenometer knob is integrated on the heater lid.

When the heater power supply is switched on, LED 6 on the controller (EKR-K…) PCB (see Fig. 1 on page 4)

flashes once every 8 seconds if setpoint is 0 °C and every second if setpoint is higher than 0 °C. If controller turns on

the heang depending on the demand, LED 5 lights (see Fig. 1 on page 4).

Heaters EKA NV … operates by the supply (TJ-K10K) air temperature sensor. Setpoint temperature (0…30) °C.

There can be set the different desired (setpoint) air temperature by potenometer on the top of the heater

casing.

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

Descripon of operang EKA NI …

Electrical duct heaters EKA NI … are designed with integrated temperature control, one temperature sensor,

wired remote control panel (TR5K) for temperature setpoint.

When the heater power supply is switched on, LED 6 on the controller (EKR-K…) PCB (see Fig. 1 on page 4)

flashes once every 8 seconds if setpoint is 0 °C and every second if setpoint is higher than 0 °C. If controller turns on

the heang depending on the demand, LED 5 lights (see Fig. 1 on page 4).

Heaters EKA NI … operates by the supply (TJ-K10K) air temperature sensor. Setpoint temperature (0…30) °C.

There can be set the different desired (setpoint) air temperature by wired remote control panel.

If LED 6 lights connuously it means that there is a failure of: supply (TJ-K10K) air temperature sensor or wired

remote control panel TR5K.

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

11

Descripon of operang EKA NV … (PTC…PS)

Electrical duct heaters EKA NV … (PTC…PS) are designed with integrated temperature control, PTC (air

velocity), PS (air pressure) and temperature sensors, setpoint potenometer knob is integrated on the heater lid.

When the heater power supply is switched on, controller (EKR-K…) is in preparaon mode for 30 seconds, LED

1 flashes once every 5 seconds. If air velocity is detected by PTC sensor (rapid LED 1 flashes when Min. 1,5 m/s is

detected) and air pressure is greater than min 20kPA aer preparaon mode ends, LED 1 will start to flash once

every second and controller will iniate the heang based on demand, LED 2 is indicang when heang is iniated.

If there is no air velocity detected and or there is not enough pressure in the duct, controller will not iniate the

heang unl air velocity and or pressure is detected. Heaters EKA NV… (PTC…PS) operates by the supply (TJ-K10K)

air temperature sensor.

EKA NV … PTC … setpoint temperature (0…30) °C

EKA NV … PTC/PS setpoint temperature (-10…50) °C

There can be set the different desired (setpoint) air temperature by potenometer on the top of the heater

casing.

Pre-heater casing and air duct before pre-heater should be insulated with rock wool 10cm (R~2,4m²K/W).

Depending on the mounng posion of the heater in the duct relave to the motor (pre- or post-motor), the

pressure hose must be placed on the "-" or "+" pipe, respecvely.

Descripon of operang EKA NIS …

Electrical duct heaters EKA NIS … are designed for the heaters power (0…100) % control by analog signal input

(0…10) VDC.

When the heater power supply is switched on, LED 6 on the controller (EKR-K…) PCB (see Fig. 1 on page 4)

flashes every second. If controller turns on the heang depending on analog signal, LED 5 lights (see Fig. 1 on page

4).

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

Descripon of operang EKA NI … (PTC…PS)*

Electrical duct heaters EKA NI … (PTC…PS) are designed with integrated temperature control, PTC (air velocity)

PS (air pressure) and temperature sensors, wired remote control panel (TR5K) for temperature setpoint.

When the heater power supply is switched on, controller (EKR-K…) is in preparaon mode for 30 seconds, LED

1 flashes once every 5 seconds. If air velocity is detected by PTC sensor (rapid LED 1 flashes when Min. 1,5 m/s is

detected) and air pressure is greater than min 20kPA aer preparaon mode ends, LED 1 will start to flash once

every second and controller will iniate the heang based on demand, LED 2 is indicang when heang is iniated.

If there is no air velocity detected and or there is not enough pressure in the duct, controller will not iniate the

heang unl air velocity and or pressure is detected.

Heaters EKA NI … (PTC…PS) operates by the supply (TJ-K10K) air temperature sensor.

EKA NI … PTC … setpoint temperature (0…30) °C

EKA NI … PTC/PS setpoint temperature (-10…50) °C

There can be set the different desired (setpoint) air temperature by wired remote control panel.

Pre-heater casing and air duct before pre-heater should be insulated with rock wool 10cm (R~2,4m²K/W).

Depending on the mounng posion of the heater in the duct relave to the motor (pre- or post-motor), the

pressure hose must be placed on the "-" or "+" pipe, respecvely.

* - non standard opon. For more informaon please contact sales@ventmaka.lt

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

12

Descripon of operang EKA NIS … (PTC…PS) *

Electrical duct heaters EKA NIS … (PTC…PS) are designed for the heaters power (0…100) % control by analog

signal input (0…10) VDC, with integrated PTC (air velocity) and PS (air pressure) sensors.

When the heater power supply is switched on, controller (EKR-K…) is in preparaon mode for 30 seconds, LED

1 flashes once every 5 seconds. If air velocity is detected by PTC sensor (rapid LED 1 flashes when Min. 1,5 m/s is

detected) and air pressure is greater than min 20kPA aer preparaon mode ends, LED 1 will start to flash once

every second and controller will iniate the heang based on demand, LED 2 is indicang when heang is iniated.

If there is no air velocity detected and or there is not enough pressure in the duct, controller will not iniate the

heang unl air velocity and or pressure is detected.

Pre-heater casing and air duct before pre-heater should be insulated with rock wool 10cm (R~2,4m²K/W).

Depending on the mounng posion of the heater in the duct relave to the motor (pre- or post-motor), the

pressure hose must be placed on the "-" or "+" pipe, respecvely.

* - non standard opon. For more informaon please contact sales@ventmaka.lt

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

Descripon of operang EKA NV … 2NTC*

Electrical duct heaters EKA NV … 2NTC are designed with integrated temperature control, two temperature

sensors, potenometer on the top of the heater casing for temperature setpoint.

When the heater power supply is switched on, LED 6 on the controller (EKR-K…) PCB (see Fig. 1 on page 4)

flashes depending on the operang mode. If controller turns on the heang depending on the demand, LED 5 lights

(see Fig. 1 on page 4).

Heaters EKA NI … 2NTC can operate in two modes:

1. Control by the supply air temperature sensor (TJ-K10K), when the first (1) switch of JP1 -(R37) (see Fig. 1 on

page 4) is in posion ON. LED 6 flashes twice per second. Set point temperature (0…30) °C.

2. Control by the supply (TJ-K10K) and by the room (NTC10) air temperature sensor, when the first (1) switch of

JP1 - (R37) (see Fig. 1 on page 4) is in posion OFF. LED 6 flashes once per second. Setpoint temperature (15…30) °C.

In this mode is preprogrammed the minimum (15°C) and the maximum (45°C) temperatures of supply air. The room

air temperature sensor is mounted in the wired remote control panel TR5K NTC10.

Depending on the operang mode there can be set the different desired (setpoint) air temperature by wired

remote control panel TR5K NTC10.

* - non standart opon. Fore more informaon please contact sales@ventmaka.lt

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

Descripon of operang EKA NI … 2NTC*

Electrical duct heaters EKA NI … 2NTC are designed with integrated temperature control, two temperature

sensors, wired remote control panel (TR5K NTC10) for temperature setpoint.

When the heater power supply is switched on, LED 6 on the controller (EKR-K…) PCB (see Fig. 1 on page 4)

flashes depending on the operang mode. If controller turns on the heang depending on the demand, LED 5 lights

(see Fig. 1 on page 4).

Heaters EKA NI … 2NTC can operate in two modes:

1. Control by the supply air temperature sensor (TJ-K10K), when the first (1) switch of JP1 -(R37) (see Fig. 1 on

page 4) is in posion ON. LED 6 flashes twice per second. Set point temperature (0…30) °C.

13

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

Descripon of operang EKA NV … PTC/2NTC*

Electrical duct heaters EKA NV … PTC/2NTC are designed with integrated temperature control, PTC (air

velocity) and two temperature sensors, potenometer on the top of the heater casing for temperature setpoint.

When the heater power supply is switched on, controller (EKR-K) is in preparaon mode for 30 seconds, LED 1

flashes once every 5 seconds. If air velocity is detected by PTC sensor (rapid LED 1 flashes when Min. 1,5 m/s is

detected) aer preparaon mode ends, LED 1 will start to flash once every second and controller will iniate the

heang based on demand, LED 2 is indicang when heang is iniated. If there is no air velocity detected, controller

will not iniate the heang unl air velocity detected.

Heaters EKA NV … PTC/2NTC can operate in two modes:

1. Control by the supply air temperature sensor (TJ-K10K), when the first (1) switch of JP1 -(R37) (see Fig. 1 on

page 4) is in posion OFF. LED 1 flashes once per second. Setpoint temperature (0…30) °C.

2. Control by the supply (TJ-K10K) and by the room (NTC10) air temperature sensor, when the first (1) switch of

JP1 -(R37) (see Fig. 1 on page 4) is in posion ON. LED 1 flashes twice per second. Setpoint temperature (15…30) °C.

In this mode is preprogrammed the minimum (15°C) and the maximum (40°C) temperatures of supply air. The room

air temperature sensor is mounted in the wired panel TR NTC10.

Depending on the operang mode there can be set the different desired (setpoint) air temperature by

potenometer on the top of the heater casing.

* - non standart opon. Fore more informaon please contact sales@ventmaka.lt

2. Control by the supply (TJ-K10K) and by the room (NTC10) air temperature sensor, when the first (1) switch of

JP1 -(R37) (see Fig. 1 on page 4) is in posion OFF. LED 6 flashes once per second. Setpoint temperature (15…30) °C.

In this mode is preprogrammed the minimum (15°C) and the maximum (45°C) temperatures of supply air. The room

air temperature sensor is mounted in the wired remote control panel TR5K NTC10.

Depending on the operang mode there can be set the different desired (setpoint) air temperature by wired

remote control panel TR5K NTC10.

* - non standart opon. Fore more informaon please contact sales@ventmaka.lt

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

Electrical duct heaters EKA NI … PTC/2NTC are designed with integrated temperature control, PTC (air velocity)

and two temperature sensors, wired remote control panel (TR5K NTC10) for temperature setpoint.

When the heater power supply is switched on, controller (EKR-K…) is in preparaon mode for 30 seconds, LED

1 flashes once every 5 seconds. If air velocity is detected by PTC sensor (rapid LED 1 flashes when Min. 1,5 m/s is

detected) aer preparaon mode ends, LED 1 will start to flash once every second and controller will iniate the

heang based on demand, LED 2 is indicang when heang is iniated. If there is no air velocity detected, controller

will not iniate the heang unl air velocity detected.

Heaters EKA NI … PTC/2NTC can operate in two modes:

1. Control by the supply air temperature sensor (TJ-K10K), when the first (1) switch of JP1 -(R37) (see Fig. 1 on

page 4) is in posion OFF. LED 1 flashes once per second. Set point temperature (0…30) °C.

2. Control by the supply (TJ-K10K) and by the room (NTC10) air temperature sensor, when the first (1) switch of

JP1 -(R37) (see Fig. 1 on page 4) is in posion ON. LED 1 flashes twice per second. Setpoint temperature (15…30) °C.

In this mode is preprogrammed the minimum (15°C) and the maximum (40°C) temperatures of supply air. The room

air temperature sensor is mounted in the wired remote control panel TR5K NTC10.

Depending on the operang mode there can be set the different desired (setpoint) air temperature by wired

remote control panel TR5K NTC10.

Descripon of operang EKA NI … PTC/2NTC*

14

IMPORTANT: If failure appears, power supply must be switched off and only then performed fault

eliminaon works.

No special service is required for electrical heaters, only to check electrical connecon not less than 1 me per

year.

Service

* - non standart opon. Fore more informaon please contact sales@ventmaka.lt

Troubleshoong

No heang from

heater

1. If the manual protecon is acvated, check for a fault before pressing the RESET

buon. If the fault is idenfied aer it has been recfied, press the RESET buon

using a screwdriver or similar object.

2. No power supply to heater – check all external electrical connecon components

(relays, switches).

3. Temperature sensor fault. Check sensor resistance, it must be 10kΩ at 25°C.

4. Pressure switch fault. Check if pressure in system is set correctly (check the

pressure when air flow is not less than 1,5m/s).

5. If LED 1 lights connuously it means that there is a failure of: PTC (air velocity)

sensor, supply (TJ-K10K) or room (NTC10) air temperature sensor, potenometer on

the top of the heater casing, wired remote control panel TR5K.

6. When the heater power supply is switched on, aer power supply interrupon or

aer any failure, controller is in preparing mode for 30 seconds.

7. PCB fault. Contact: quality@ventmaka.lt

Heater gives full

output, not by set

point

1. Temperature sensor fault. Check sensor resistance, it must be 10kΩ at 25°C.

2. Air flow sensor fault. Check sensor resistance. It must be 22Ω between X15…X16

and 10Ω between X15...X18. Sensor must be clear.

3. When the heater power supply is switched on, aer power supply interrupon or

aer any failure, controller is in preparing mode for 30 seconds.

4. Triacs fault. Contact: quality@ventmaka.lt

5. PCB fault. Contact: quality@ventmaka.lt

Automac circuit

breaker switching off

1. Check circuit breakers data, it must correspond to heaters electrical data.

2. Check isolaon of connecon cables, wires, check is heater grounded.

3. Check power supply source data, it must correspond to heaters electrical data.

Protecon thermostat

cut off

1. Low air flow speed through heater. Check filters, fans, ducts of system.

2. Pressure switch fault. Check if pressure in system is set correctly (check the

pressure when air flow is not less than 1,5m/s).

Warranty

1. Manufacturer declares 2 years warranty term from the date of manufacturer's invoice. Warranty is applied

in case if all requirements of transporng, storing, installaon and electrical connecon are fulfilled.

2. In case of damaged or faulty product during warranty term customer must inform producer in 5 days and

deliver product to manufacture as soon as possible at customer's costs. In other case warranty is not valid.

3. Manufacturer is not responsible for damages which occur during transportaon or installaon.

15

Manufacturer:

VENTMATIKA UAB

Metalistu str. 2A -1, 78107 Siauliai

Lithuania

EKA2020EN_002

This manual suits for next models

28

Table of contents