Intelligent Lighting Controls, Inc. Light Master User manual

INTELLIGENT LIGHTING CONTROLS, INC.

5229 Edina Industrial Boulevard

Minneapolis. Minnesota 55439

Phone 952 829 1900

FAX 952 829 1901

1-800-922-8004

USER GUIDE

Version 1C

9/20/00

Light Master User Manual

Version 1C 9/20/00

Structure

The major components making up the

controller are:

• enclosure

• control transformer

• CPU I/O board

• additional I/O boards

• programming module

• lighting relays

Enclosure –The enclosure is rated NEMA 1.

It is divided into a line voltage section con-

taining the line voltage side of the control

transformer and lighting relays and a low volt-

age section containing the Class 2 side of the

lighting relays, transformer secondaries and

electronic components. Enclosures are avail-

able in 6 sizes to accommodate 8, 16, 24, 32,

40 and 48 inputs, outputs, and lighting relays.

Transformer –A 40 VA multi-tap control trans-

former (120 or 277/24 VAC) provides the 24

VAC input to power the controller electronics.

CPU I/O Board –The CPU board provides

the controller’s intelligence and memory and

the first eight (8) of the controller inputs and

outputs. Major components include:

•Switch Inputs –can accept input from either

2- or 3-wire momentary or maintained dry

contact devices. Each input has two associ-

ated LEDs (light emitting diodes). The ON

LED lights when a closure is sensed between

the ON and COMMON terminals. The OFF

LED lights when a closure is sensed between

the OFF and COMMON terminals. The inputs

are noise- and surge-resistant. A switch may

be located up to 1500 feet from the con-

troller, provided you use a minimum of 18

gauge wire.

•Relay Outputs –Each output switches its asso-

ciated lighting relay ON and OFF. Each out-

put has an associated LED. The LED lights

when the output switches the relay ON.

•Override Switches –Each relay output is

equipped with an ON and an OFF override

switch. These switches allow you to turn the

associated lighting relay ON or OFF.

•Stagger Start –The controller switches those

relays impacted by the same switch signal

ON/OFF, one at a time.

Overview

The Light Master Programmable Contactor is a microprocessor-based programmable lighting

controller. You can program each of the controller inputs to control any or all of the relay out-

puts. The Light Master is UL and FCC approved for commercial and residential applications.

Section 1 Controller Description

1.0 Section Overview .......................................................................... 1-1

1.1 Controller Architecture ................................................................. 1-2

1.1.1 Enclosure................................................................................ 1-2

1.1.2 Transformer ............................................................................ 1-2

1.1.3 CPU I/O Board....................................................................... 1-3

1.1.4 Additional I/O Boards........................................................... 1-4

1.1.5 Programming Module .......................................................... 1-8

1.1.6 Lighting Relays....................................................................... 1-8

1.2 I/O Options ..................................................................................... 1-9

1.2.1 Telephone Add-On Module ................................................ 1-9

1.2.2 PC Add-On Module ............................................................. 1-9

Section 2 Installation

2.0 Section Overview .......................................................................... 2-1

2.1 Pre-Installation Checks .................................................................. 2-2

2.2 Mounting the Controller................................................................ 2-2

2.2.1 Location ................................................................................. 2-2

2.2.2 Environmental Considerations ............................................ 2-2

2.2.3 Distance From Control Devices .......................................... 2-2

2.3 Wiring the Controller...................................................................... 2-2

2.3.1 Wire the Control Transformer............................................... 2-2

2.3.2 Connect Line and Load ...................................................... 2-2

2.3.3 Wire Switch Inputs ................................................................. 2-2

2.3.4 Set Relay Response .............................................................. 2-2

2.4 Pre-Power Checks.......................................................................... 2-5

2.4.1 Check Controller Power Input............................................. 2-5

2.4.2 Verify Controller’s Supply Voltage....................................... 2-5

2.4.3 Double-Check Connections ............................................... 2-5

2.5 Power-Up and Check Out............................................................ 2-5

2.5.1 Power-Up the Controller ...................................................... 2-5

2.5.2 Verify the Lighting Relays ..................................................... 2-5

2.5.3 Perform Initial Programming Procedures........................... 2-5

2.5.4 Verify the Switching Function .............................................. 2-5

2.5.5 Verify the Timer Functions .................................................... 2-5

2.6 Troubleshooting.............................................................................. 2-6

2.6.1 Controller Will Not Power-Up ............................................... 2-6

2.6.2 Lighting Relay(s) Will Not Function...................................... 2-6

2.6.3 Switch Input Will Not Function............................................. 2-6

2.6.4 Timers Will Not Function Properly ........................................ 2-6

2.6.5 Entire I/O Board(s) Doesn’t Work ........................................ 2-6

Light Master User Manual

Version 1C 9/20/00

Table of Contents

Table of Contents

Light Master User Manual

Version 1C 9/20/00

Section 3 Programming

3.0 Section Overview .......................................................................... 3-1

3.1 Relay Status .................................................................................... 3-2

3.2 Controlling Relays From the Keypad........................................... 3-3

3.3 Relay Output .................................................................................. 3-4

3.4 Set Relay Parameters .................................................................... 3-5

3.5 Switch Status................................................................................... 3-6

3.6 View Current Switch Status........................................................... 3-7

3.7 Switch Input .................................................................................... 3-8

3.8 Programming a Switch Input........................................................ 3-9

3.9 Input/Relay Control ....................................................................... 3-11

3.10 Map a Switch to a Relay Output............................................... 3-12

3.11 Timers ............................................................................................. 3-13

3.12 Define a Timer .............................................................................. 3-16

3.13 Timer/Relay Control ..................................................................... 3-17

3.14 Map the Timer to a Relay Output ............................................. 3-18

3.15 Blink Alerts ..................................................................................... 3-19

3.16 Set Time and Date....................................................................... 3-21

3.17 Set the Controller Clock.............................................................. 3-22

3.18 Set Astro Clock............................................................................. 3-23

3.19 Daylight Savings........................................................................... 3-25

3.20 Serial Interface ............................................................................. 3-27

3.21 Telephone Interface.................................................................... 3-28

3.22 Edit Presets .................................................................................... 3-29

3.23 Capture Preset ............................................................................. 3-31

3.24 Set Open/Close Times................................................................. 3-33

3.24.1 Example: Set Open/Close Times....................................... 3-34

3.24.2 Example: Define the Timers ............................................... 3-35

3.24.3 Example: Map Lighting Relays to Timers.......................... 3-36

3.25 Firmware Revision ........................................................................ 3-37

Section 4 Applications

4.0 Section Overview .......................................................................... 4-1

4.1 Wire and Program a 3-Wire SPDT Momentary Switch to

Control Relays ................................................................................ 4-2

4.1.1 Define the Switch.................................................................. 4-3

4.1.2 Map the Switch to the Relays ............................................. 4-3

4.2 Wire and Program a 2-Wire Maintained Switch

to Control Relays............................................................................ 4-4

4.2.1 Define the Switch.................................................................. 4-5

4.2.2 Map the Switch to the Relays ............................................. 4-5

4.3 Wire and Program a Photocell Controller Contact to

Control Relays ................................................................................ 4-6

4.3.1 Define the Photocell Contact............................................. 4-7

4.3.2 Map the Photocell Contact to the Relays ........................ 4-7

Table of Contents

Light Master User Manual

Version 1C 9/20/00

Section 4 Applications, continued

4.4 Wire and Program an Occupancy Sensor Contact to

Control Relays ................................................................................ 4-8

4.4.1 Define the Occupancy Sensor Contact ........................... 4-9

4.4.2 Map the Occupancy Sensor Contact to the Relays....... 4-9

4.5 Wire and Program a BAS System Contact to

Control Relays ................................................................................ 4-10

4.5.1 Define the BAS System Contact ......................................... 4-11

4.5.2 Map the BAS System Contact to the Relays..................... 4-11

4.6 Control Relays by Time of Day Schedules.................................. 4-12

4.6.1 Set the Light Master Clock to Current Date and Time .... 4-13

4.6.2 Define the Timers .................................................................. 4-14

4.6.3 Map the Timer to the Relays ............................................... 4-15

4.7 Wiring to Field Loads ..................................................................... 4-16

Section 5 Appendix

A. Telephone Add-On Module........................................................... A-1

A.1 Overview .................................................................................. A-1

A.2 Telephone Control Features .................................................. A-2

A.3 Telephone Control Setup ....................................................... A-2

A.4 Remote Modem Programming Control

and Monitoring........................................................................ A-2

A.5 Remote Modem Control Setup............................................. A-2

B. PC Add-On Module ........................................................................ B-1

B.1 Overview................................................................................... B-1

B.2 PC Add-On Setup.................................................................... B-1

D. DMX Control Feature ...................................................................... D-1

D.1 Overview .................................................................................. D-1

D.2 Objectives ................................................................................ D-1

D.3 Programming Example........................................................... D-3

M. MODBUS Communications............................................................ M-1

M.1 Overview ................................................................................. M-1

M.2 Structure................................................................................... M-1

M.3 Transmission Modes ................................................................ M-1

M.4 Transmission Mode Characteristics....................................... M-3

M.5 Hardware Setup...................................................................... M-3

M.6 Required Parameter Entries................................................... M-3

M.7 Framing .................................................................................... M-3

M.8 Additional Information........................................................... M-3

N. N2 Communications ....................................................................... N-1

N.1 Overview .................................................................................. N-1

N.2 Hardware Setup ...................................................................... N-1

N.3 Point Map................................................................................. N-1

Section 1

Controller Description

Light Master User Manual

Version 1C 9/20/00

LIGHT MASTER

WED 10/30/99

07:50:54 AM

EDIT (c) 99 ILC

Section 1 Controller Description

1.0 Section Overview .......................................................................... 1-1

1.1 Controller Architecture ................................................................. 1-2

1.1.1 Enclosure................................................................................ 1-2

1.1.2 Transformer ............................................................................ 1-2

1.1.3 CPU I/O Board....................................................................... 1-3

1.1.4 Additional I/O Boards........................................................... 1-4

1.1.5 Programming Module .......................................................... 1-8

1.1.6 Lighting Relays....................................................................... 1-8

1.2 I/O Options ..................................................................................... 1-9

1.2.1 Telephone Add-On Module ................................................ 1-9

1.2.2 PC Add-On Module ............................................................. 1-9

Controller Description – Table of Contents

Light Master User Manual

Version 1C 9/20/00

Objectives

In this Section you will learn about the struc-

ture and configuration of the Light Master

Controller.

Overview

The Light Master is a microprocessor-based

lighting controller. You can program the

Light Master to control lighting relays in

response to switch signals sensed by its

inputs and/or by time-based scheduling.

The Light Master is UL approved and FCC

certified for both commercial and

residential applications.

Section 1 –Controller Description

Light Master User Manual 1 - 1

Version 1C 9/20/00

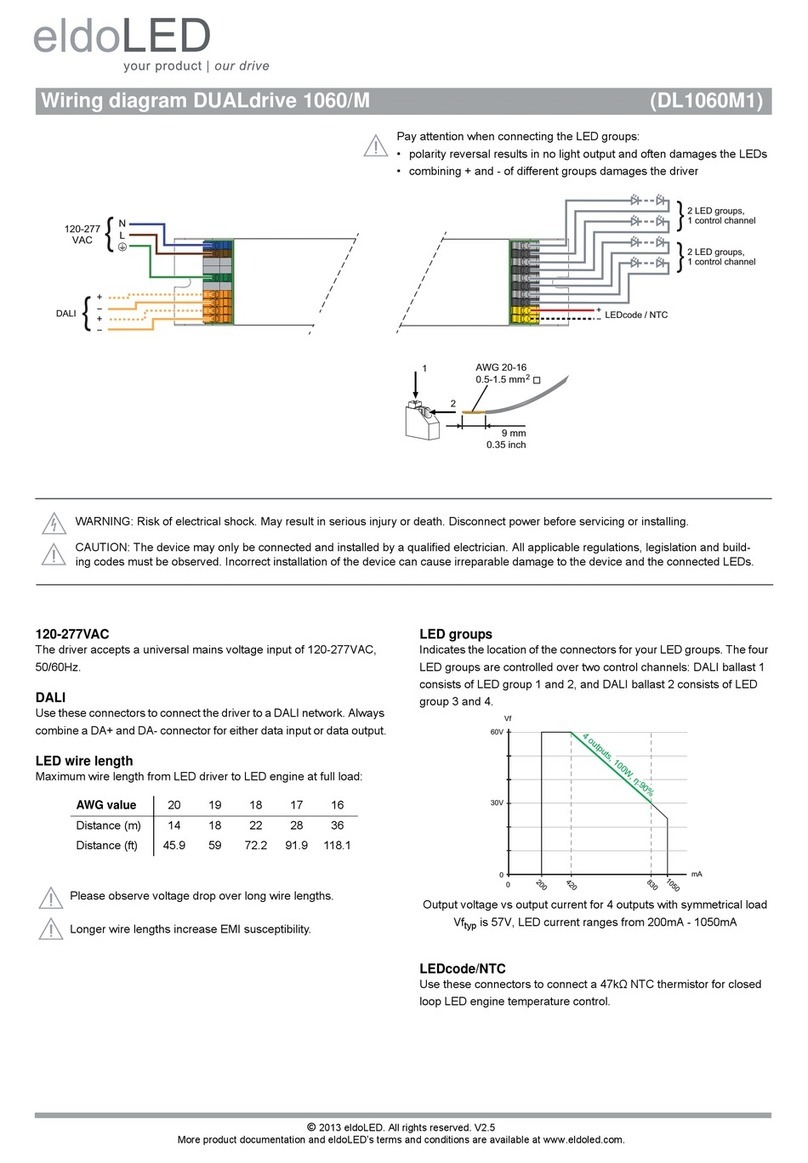

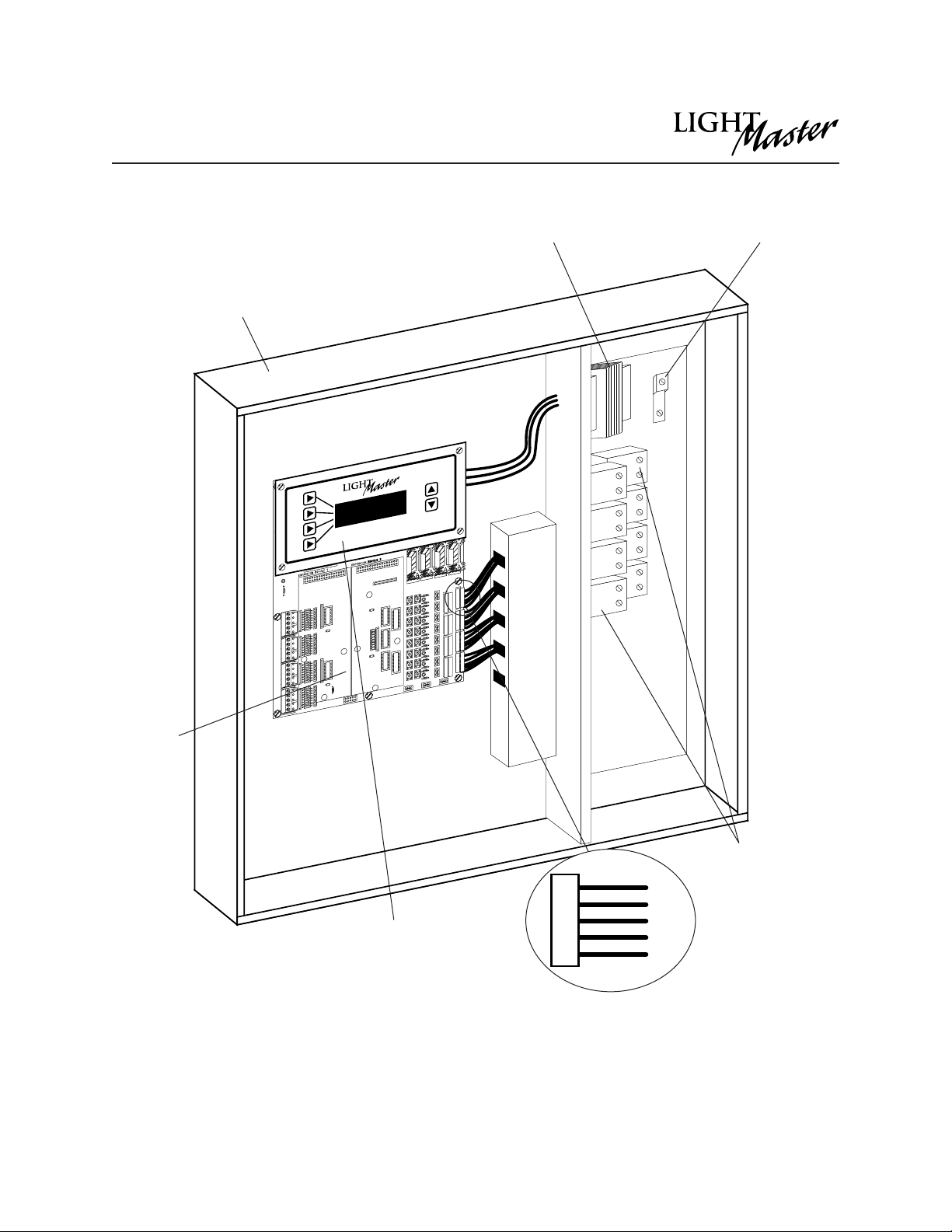

1.1 Controller Architecture

The major components making up the

controller are: (See Figure 1.1.)

•enclosure

•control transformer

•CPU I/O board

•additional I/O boards

•programming

•lighting relays module

1.1.1 Enclosure - The enclosure is rated

NEMA 1. It is divided into a line voltage sec-

tion containing the line voltage side of the

control transformer and lighting relays and

a low voltage section containing the Class 2

side of the lighting relays, transformer sec-

ondary, and electronic components.

Enclosures are available in 6 sizes to accom-

modate 8, 16, 24, 32, 40 and 48 inputs, out-

puts, and lighting relays. See (Table 1-1.) The

Light Master is shipped to the job-site as a

complete assembly. (See Figure 1-1, which

illustrates a Light Master 8.)

1.1.2 Transformer - A 40 VA multi-tap control

transformer (120 or 277/24 VAC) provides

the 24 VAC input to power the controller

electronics.

Controller Description

Light Master User Manual 1 - 2

Version 1C 9/20/00

Model # of Relays

& I/O Points Width Height Depth

Light Master 8 8 18 inches 15 inches 4 inches

Light Master 16 16 24 inches 18 inches 4 inches

Light Master 24 24 24 inches 36 inches 4 inches

Light Master 32 32 24 inches 36 inches 4 inches

Light Master 40 40 24 inches 48 inches 6 inches

Light Master 48 48 24 inches 48 inches 6 inches

Table 1.1 –Light Master Configurations

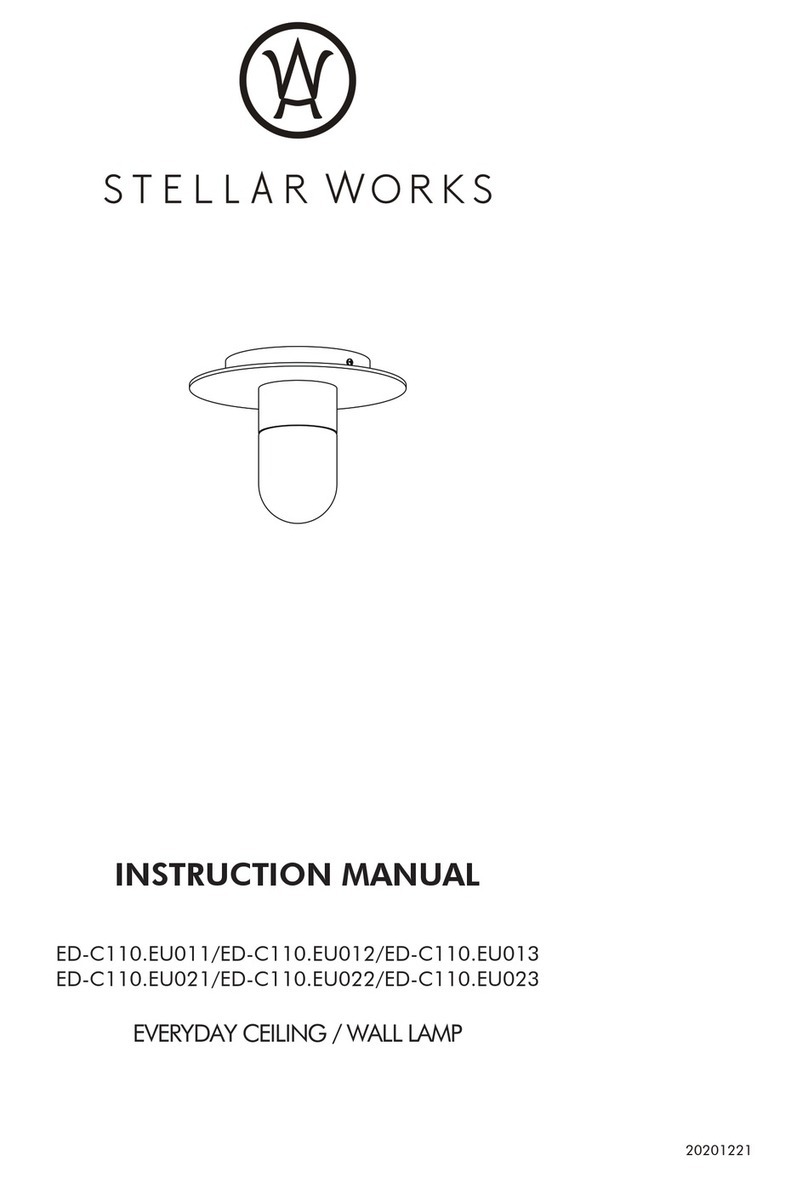

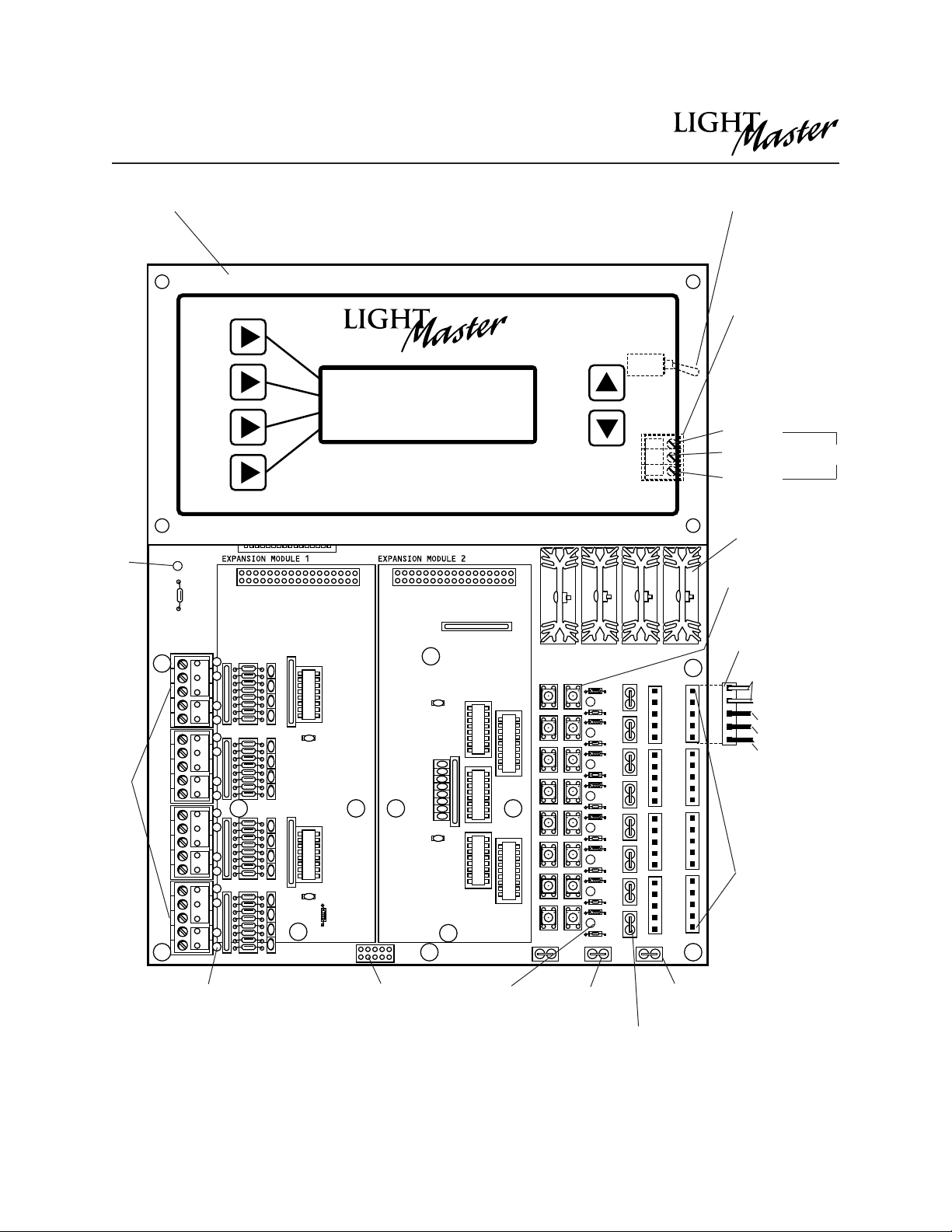

1.1.3 CPU I/O Board –(See Figure 1.2.) The

CPU board provides the controller’s intelli-

gence and memory and the first eight (8) of

the controller inputs and outputs. Major

components include:

•Switch Inputs –The Light Master is designed

to accomplish a wide variety of switch

input types. See the table below for a

description of switch input types.

Controller Description

Light Master User Manual 1-3

Version 1C 9/20/00

Momentary ON/OFF: When

momentary contact is made

between ON and COM, relay

outputs controlled by this input

are turned ON. When momen-

tary contact is made between

OFF and COM, relay outputs

controlled by this input are

turned OFF.

Momentary Pushbutton:

When momentary contact is

made between ON and COM,

relay outputs controlled by this

input are turned ON and OFF

alternately each time contact

is made.

Maintained ON/OFF: When

contact is made between ON

and COM, relay outputs con-

trolled by this input are turned

ON. When contact is broken

between ON and COM, relay

outputs controlled by this input

are turned OFF.

Maintained Multi-Way: When

contact is either made or broken

between the ON and COM, relay

outputs controlled by this input

will be toggled between ON and

OFF conditions. This function is

similar to that of standard 3-

and 4-way switches.

Timed ON: When momentary

contact is made between ON

and COM, relay outputs con-

trolled by this input are turned

ON for a duration of 15 minutes

to 6 hours. At the end of this

time, relay outputs controlled by

this input are turned OFF.

Timer Disable: While contact

is made between ON and

COM, selected timer or timers

will be ignored.

Photo Sensor Inputs:

Light Master controllers can be

connected to either momentary

or maintained output photo

sensors as shown below.

Motion Sensor Inputs:

Light Master controllers can be

connected to either momentary

or maintained output motion

sensors as shown below.

Fire Alarm System Inputs:

Light Master controllers can be

easily connected to building

Fire Alarm Systems to force

selected controlled lighting cir-

cuits to the ON, OFF, or HOLD

state and lock out all other

forms of control when a Fire

Alarm signal is present (con-

tacts CLOSED).

Dry Contact Interface:

Virtually any control system or

device can be interfaced to a

Light Master controller through

the use of a simple dry contact

interface utilizing any of the

available switch types.

Please consult factory for any

special requirements.

ON

COM

OFF

ON

COM

OFF

ON

COM

OFF

ON

COM

OFF

ON

COM

OFF

ON

COM

OFF ON

COM

OFF

ON

COM

OFF

ON

COM

OFF

MAINTAINED

MAINTAINED

Programmed as

“Output Override input”

MOMENTARY

Programmed as “Momentary”

MAINTAINED

Programmed as “Maintained

ON/OFF input”

ON

COM

OFF

ON

COM

OFF

MOMENTARY

Programmed as “Momentary”

MAINTAINED

Programmed as “Maintained

ON/OFF input”

MOMENTARY MOMENTARYMAINTAINED MAINTAINED

MOMENTARY

Controller Description

Light Master User Manual 1 - 4

Version 1C 9/20/00

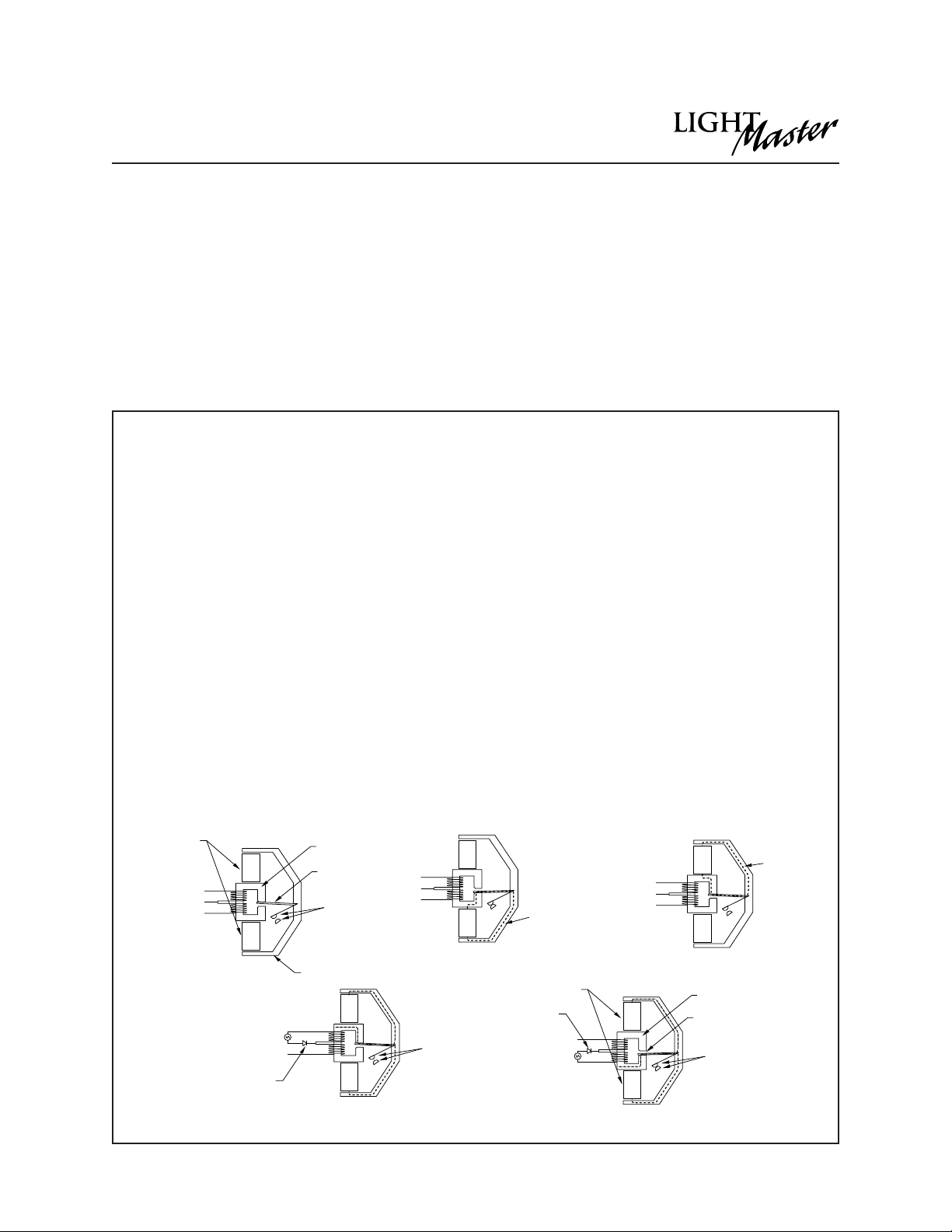

2R9 split coil relay’s unique construction has only one

movable part (the contacts). This reliable relay design

has a proven failure rate of less than 0.001 percent.

The following describes the actual internal operation

of the 2R9 relay.

Figure 1 shows the basic parts of the magnetic circuit.

The leads of the split coil are color coordinated: Red

(ON), Black (OFF), and Blue (COMMON).

The relay section consists of four permanent magnets,

a split coil switching winding, a steel bracket, a mov-

ing armature that supports the moving contacts, and

a set of stationary contacts (90% silver, 10% cadmium).

Figures 2 and 3 show the magnetic activity when no

switching is being applied. As can be observed, the

contacts are held in a steady state condition by the

permanent magnets (during a power failure the relays

will automatically maintain their state).

Magnetism Theory

By convention, magnetism “flows”FROM the north

pole TO the south pole. When a diode is placed

between the switching leads, an electromagnet is

created across the gap. By using two coils in oppo-

site directions to each other, the 2R Relay is able to

create two magnetic polarities opposite to each

other.

Figure 4 shows the magnetism that is applied to the

gap of the core to CLOSE the contacts.

When a half wave rectified source is placed between

the switching leads (current from the Red wire toward

the Blue wire), the flux that is produced sets up a mag-

netic field on both surfaces of the gap (top North and

bottom South). Because the flipper arm is always con-

nected to the North sides of the permanent magnets,

the flipper arm is repelled from the North surface and is

attracted to the South surface. The contact arm is con-

nected to the flipper arm and, therefore, the contacts

will close.

Figure 5 shows the magnetism that is applied to the

gap of the core to OPEN the contacts.

When a half wave rectified source is placed between

the switching leads (current from the Black wire

toward the Blue wire), the flux that is produced sets up

a magnetic field on both surfaces of the gap (top

North and bottom South). Because the flipper arm is

always connected to the North sides of the perma-

nent magnets, the flipper arm is repelled from the

North surface and is attracted to the South surface.

The contact arm is connected to the flipper arm and,

therefore, the contacts will open.

As can be seen by examining Figures 4 and 5, the

electromagnet reverses its polarity to switch the relay

ON and OFF.

OFF

COMM

ON

N

S

S

NMagnetic

Flux

Activity

OFF

COMM

ON

N

S

S

N

Permanent

Magnets Core

Contacts

Bracket

Switching

Leads

Armature

OFF

COMM

ON

N

S

S

N

Magnetic

Flux

Activity

Figure 2 – Magnets holding the contacts closed

Figure 1 –2R9 Relay Figure 3 –Magnets holding the contacts open

OFF

COMM

ON

N

S

S

N

24 VAC Contacts

(open)

Switching

Leads

Diode

N

S

S

N

OFF

COMM

ON 24 VAC

Magnets Core

Contacts

(closed)

Switching

Leads

Diode Gap

Figure 4 –The electromagnet and the permanent magnets

combine to switch the contacts to the closed position.

Figure 5 –The electromagnet and the permanent magnets

combine to switch the contacts to the open position.

•Relay Outputs –Each output switches its

associated lighting relay ON and OFF. Each

output has an associated LED (light emitting

diode). The LED lights when the output

switches the relay ON. The 2R9 split coil

relay’s unique construction has only one

movable part (the contacts). This reliable

relay design has a proven failure rate of less

than 0.001 percent. See below for detail.

•Override Switches –Each relay output is

equipped with an ON and an OFF override

switch. These switches allow you to turn the

associated lighting relay ON or OFF.

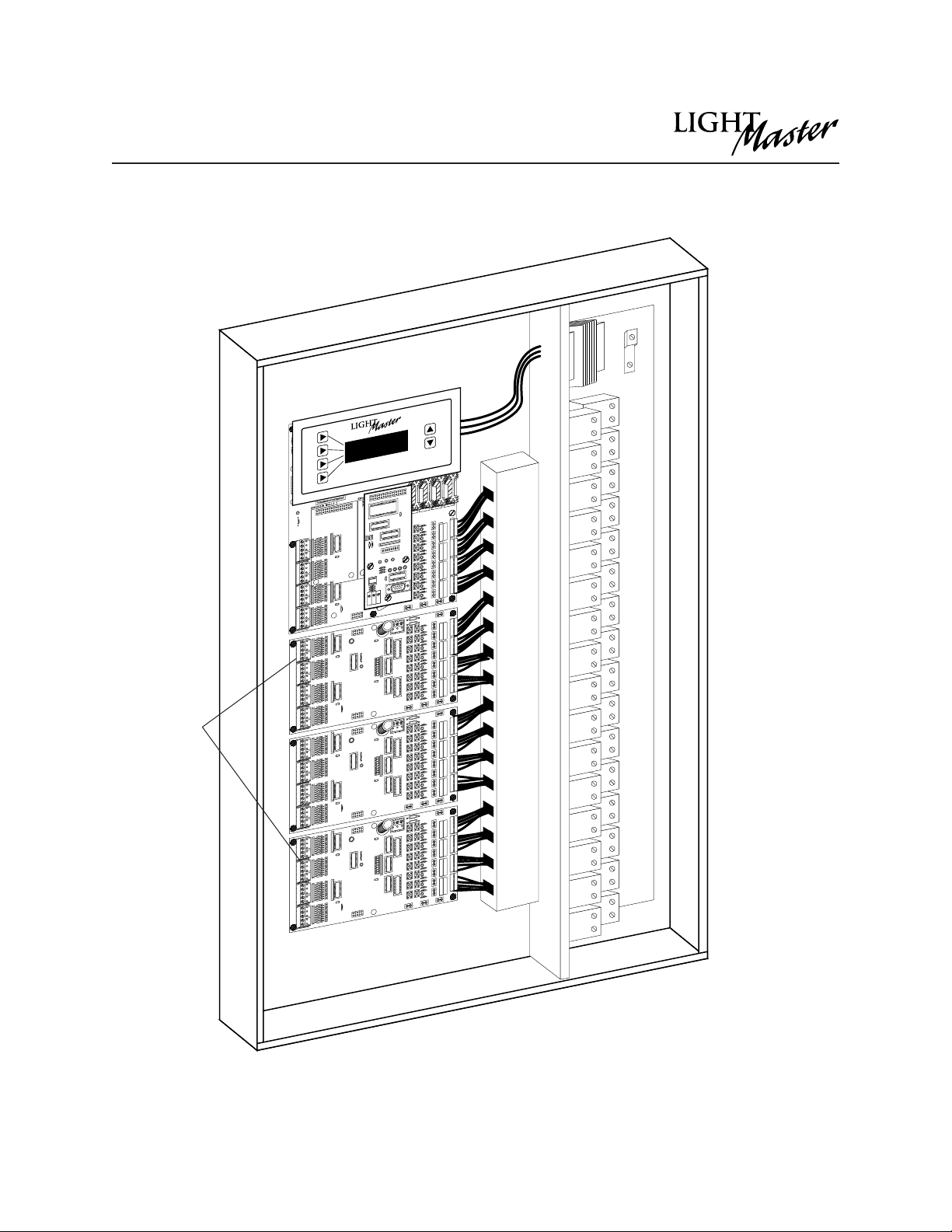

1.1.4 Additional I/O Board(s) –Additional

I/O boards composed of 8 inputs and out-

puts can be added to the appropriate size

enclosure to expand the controller capacity

up to 48 switch inputs and 48 switch relay

outputs. (See Figure 1.3, which illustrates a

Light Master 32.)

Controller Description

Light Master User Manual 1 - 5

Version 1C 9/20/00

12

34

56

78

Enclosure

Lighting relays

Relay termination detail

Programming module

CPU I/O

board

Control transformer

Figure 1.1 –Light Master 8 Controller

ORANGE

CONNECTOR

ORANGE

BLACK (OFF)

STATUS

RED (ON)

BLUE (COM)

}

Grounding Lug

Controller Description

Light Master User Manual 1 - 6

Version 1C 9/20/00

Figure 1.2 –CPU I/O Board

1 OFF

2ON

COM

2 OFF

3 OFF

3 ON

4ON

COM

4 OFF

5 OFF

5 ON

6ON

COM

6 OFF

7 OFF

7 ON

ON

COM

OFF V10

OFF

12

34

56

7

ON

OFF ON

PILOT

COM +

1ON

1

2

3

4

5

6

7

W1

Power

LED

Switch

inputs

I/O mounted

headers for

relay output

connectors

Relay output

connector

Black (OFF)

Red (ON)

Blue (COM)

Orange

(Aux. contacts : not

used on 2R7 relay)

Pilot

COM

Data to

next board

Switch input

status LEDs

Relay output

status LEDs

Power to

next board

Override

switches

Programming

module

12 VAC

Center tap

12 VAC

Main power

switch (under

Keyboard on the

controller board )

Terminal block for

transformer

(under Keyboard

on the controller

board )

LIGHT MASTER

WED 10/30/99

07:50:54 AM

EDIT (c) 99 ILC

Power

supply

ON

OFF

24 VAC

Status terminals

(used with Pilot

Light Switches)

Controller Description

Light Master User Manual 1 - 7

Version 1C 9/20/00

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

Figure 1.3 –Light Master 32

Additional

I/O boards

Controller Description

Light Master User Manual 1 - 8

Version 1C 9/20/00

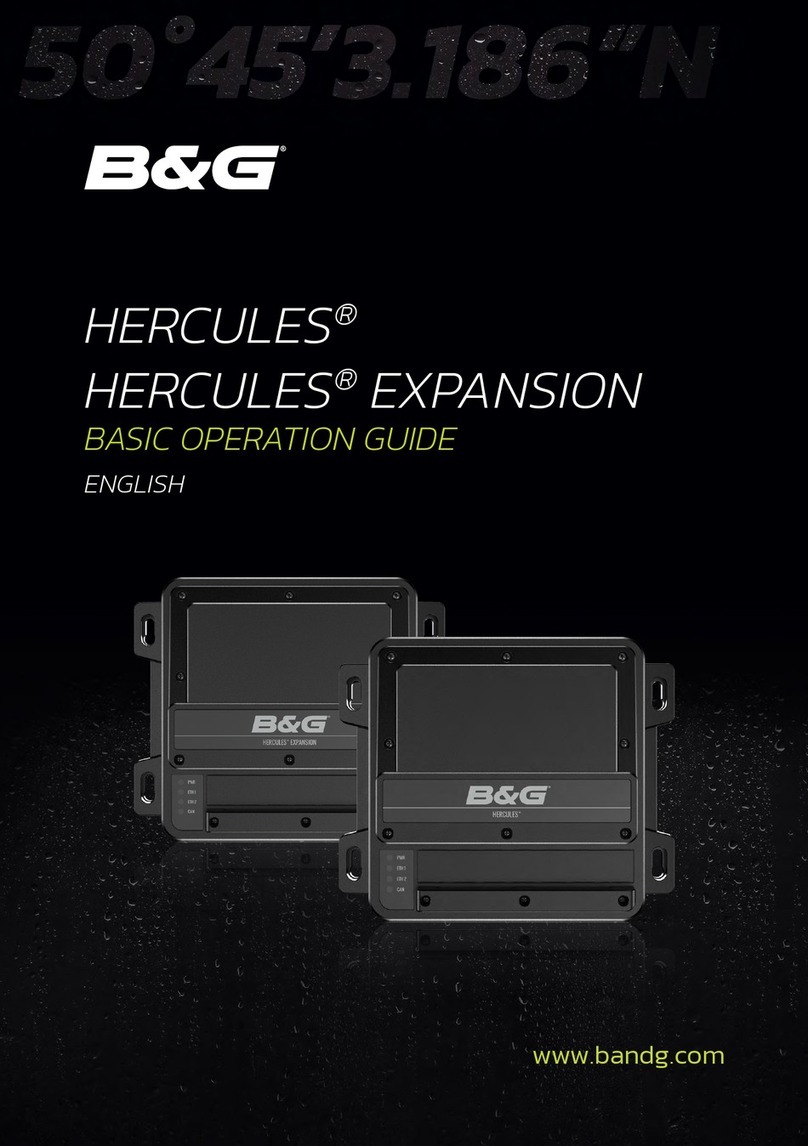

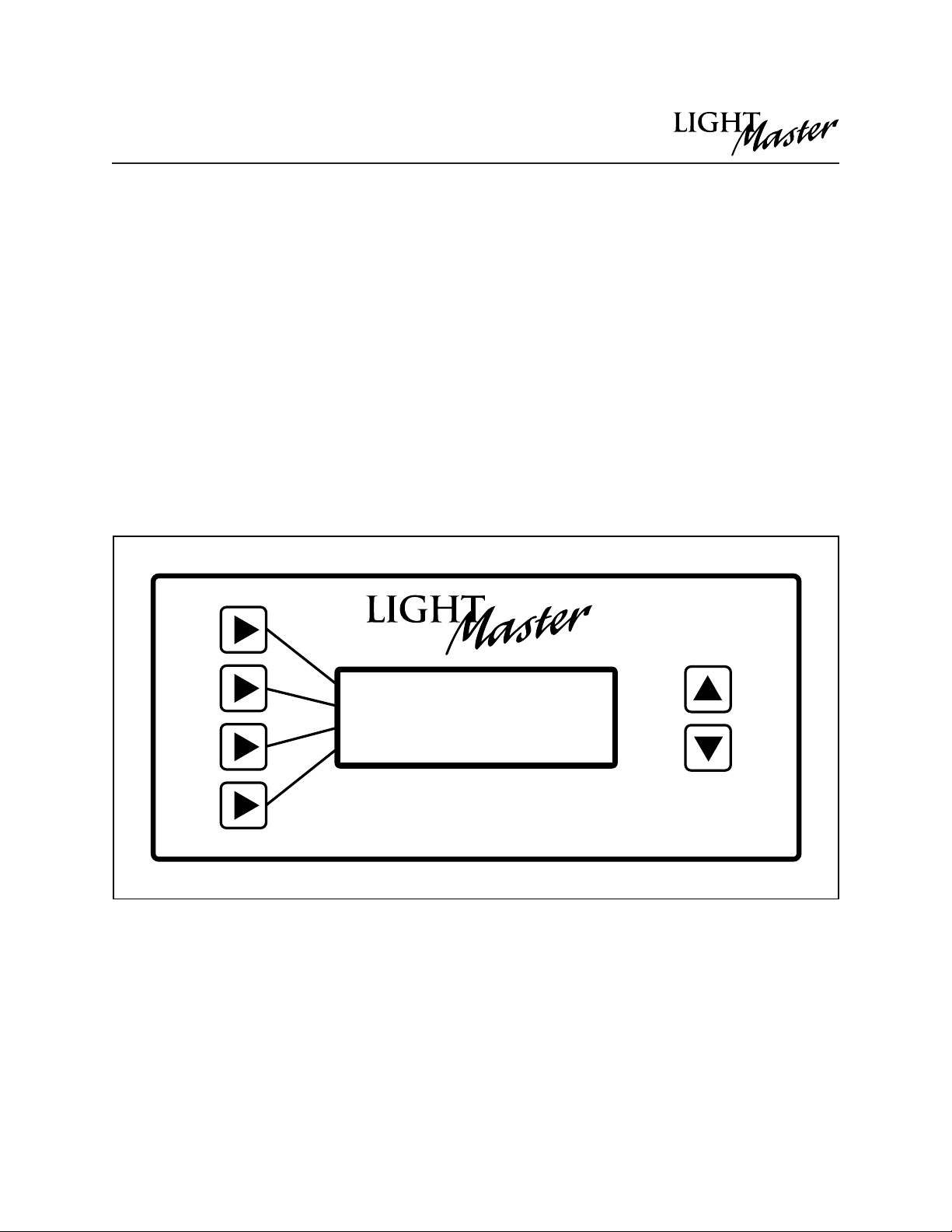

Figure 1.4 –Light Master Keypad and Display

4-line, 32-character Display Screen

Scrolling Pads

Selection Keys

(Used to select

displayed options)

1.1.5 Programming Module - (See Figure

1.4.) The programming module provides you

with access to program and view controller

data. It consists of a tactile response key-

pad and screen. The programming module

is mounted to the CPU I/O board.

1.1.6 Lighting Relays - control the line voltage

loads. The lighting relays can control 120 or

277 VAC loads rated up to 20 amps. The

Class 2 low voltage control part of each relay

is terminated to a relay output on the con-

troller CPU I/O board. (See Figure 1.2.) Each

relay output controls only one lighting relay.

1.2 I/O Options

The Light Master controller can be

equipped with the following add-on

devices:

1.2.1 Telephone Add-On Module –You can

equip the controller with a DTMF (Dual Tone

Multi Frequency) interface, which allows

you to activate switch inputs via commands

from a touchtone telephone. (See

Appendix A.)

1.2.2 PC Add-On Module –Allows for the

connection of a standard Windows-based

PC via an on-board RS232 port for monitor-

ing, control, and programming. (See

Appendix B.)

Controller Description

Light Master User Manual 1 - 9

Version 1C 9/20/00

Light Master User Manual

Version 1C 9/20/00

Section 2

Installation

LIGHT MASTER

WED 10/30/99

07:50:54 AM

EDIT (c) 99 ILC

Section 2 Installation

2.0 Section Overview .......................................................................... 2-1

2.1 Pre-Installation Checks .................................................................. 2-2

2.2 Mounting the Controller................................................................ 2-2

2.2.1 Location ................................................................................. 2-2

2.2.2 Environmental Considerations ............................................ 2-2

2.2.3 Distance From Control Devices .......................................... 2-2

2.3 Wiring the Controller...................................................................... 2-2

2.3.1 Wire the Control Transformer............................................... 2-2

2.3.2 Connect Line and Load ...................................................... 2-2

2.3.3 Wire Switch Inputs ................................................................. 2-2

2.3.4 Set Relay Response .............................................................. 2-2

2.4 Pre-Power Checks.......................................................................... 2-5

2.4.1 Check Controller Power Input............................................. 2-5

2.4.2 Verify Controller’s Supply Voltage....................................... 2-5

2.4.3 Double-Check Connections ............................................... 2-5

2.5 Power-Up and Check Out............................................................ 2-5

2.5.1 Power-Up the Controller ...................................................... 2-5

2.5.2 Verify the Lighting Relays ..................................................... 2-5

2.5.3 Perform Initial Programming Procedures........................... 2-5

2.5.4 Verify the Switching Function .............................................. 2-5

2.5.5 Verify the Timer Functions .................................................... 2-5

2.6 Troubleshooting.............................................................................. 2-6

2.6.1 Controller Will Not Power-Up ............................................... 2-6

2.6.2 Lighting Relay(s) Will Not Function...................................... 2-6

2.6.3 Switch Input Will Not Function............................................. 2-6

2.6.4 Timers Will Not Function Properly ........................................ 2-6

2.6.5 Entire I/O Board(s) Doesn’t Work ........................................ 2-6

Section 2–Table of Contents

Light Master User Manual

Version 1C 9/20/00

Objectives

This section shows you how to install the

Light Master Programmable Contactor

and how to perform required power-up

verification checks.

Overview

This section covers the following topics:

•Pre-installation checks

•Mounting the controller

•Wiring the controller

•Pre-power-up checks

•Power-up and checkout

•Troubleshooting

Section 2 –Installation

Light Master User Manual 2 - 1

Version 1C 9/20/00

This manual suits for next models

6

Table of contents

Popular Lighting Equipment manuals by other brands

ML Accessories

ML Accessories BL01BK Installation & maintenance manual

Epstein-Design

Epstein-Design Sahara E27 manual

SHAFT

SHAFT SHE191 manual

Teknoware

Teknoware ESC 90 Installation and Maintenance

Vision & Control

Vision & Control R-CLR-132x104-G523-SL Installation and operating instructions

SloanLED

SloanLED PosterBOX Mini installation guide