www.imshome.com

TM

Excellence in Motion

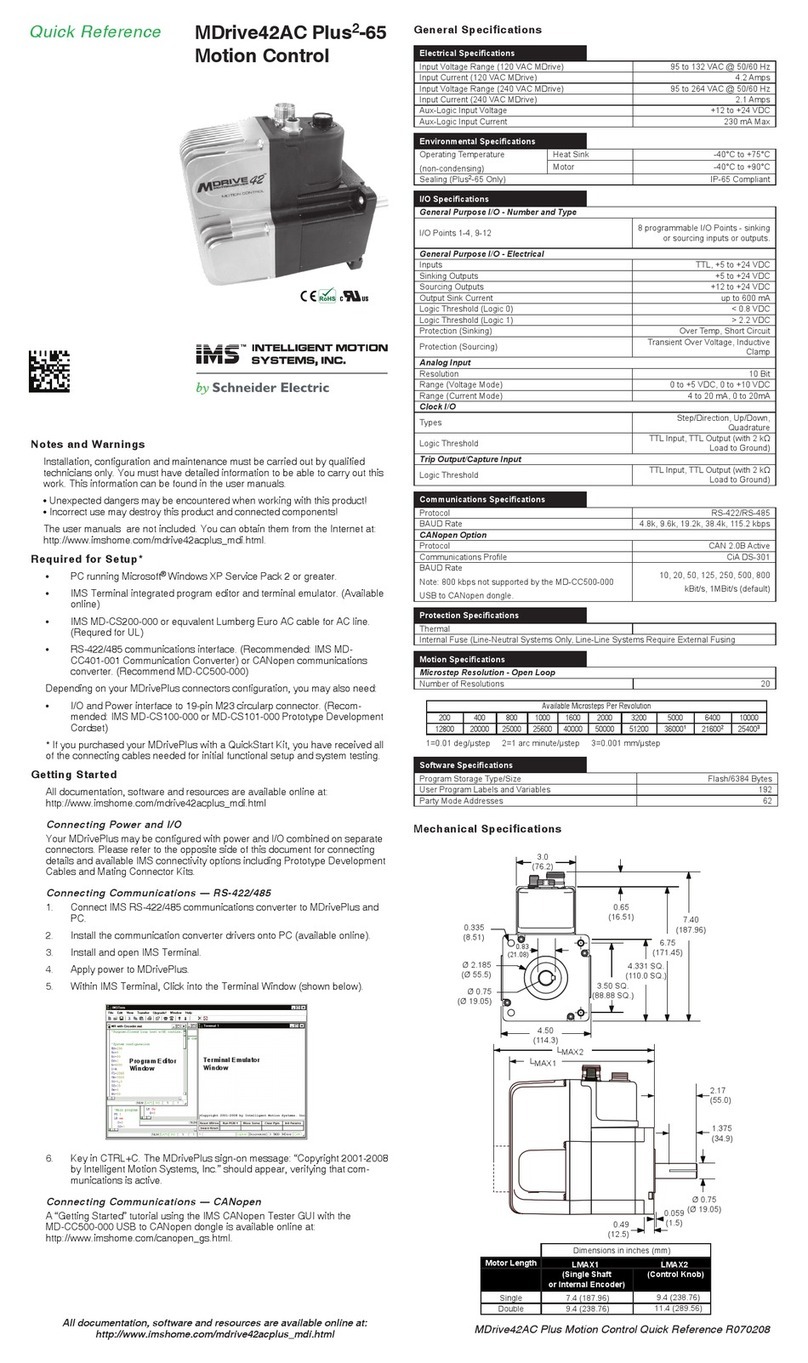

• Highly Integrated Microstepping Driver/

Intelligent Motion Controller with Optional

Encoder/NEMA 34 High Torque 1.8°

Brushless Step Motor

• Advanced 2nd Generation Current

Control for Exceptional Performance

and Smoothness

• Single Supply: 120 or 240 VAC

• Cost Effective

• Extremely Compact

• High Positioning Accuracy

• No Tuning Required

• Stable at Low Speeds

• No Dithering at Zero Speed

• High Starting Torque

• Allows for Greater Inertia Mismatch

• Built-in Regeneration Circuitry

• Available Options:

- Long Life Linear Actuators**

- Integral Optical Encoder for Closed

Loop Control

- External/Remote Encoder (not supplied)

for Closed Loop Control

- Control Knob for Manual Positioning

- Integrated Planetary Gearbox

- IP65 Sealed Configuration

- Linear Slide

• Three Motor Lengths Available

• Auxiliary Logic Power Supply Input

• Up to 5 MHz Step Clock Rate

• 20 Microstep Resolutions up to

51,200 Steps Per Rev Including:

Degrees, Metric, Arc Minutes

• Open or Optional Closed Loop Control

• Programmable Motor Current

• Up to Eight +24 VDC Tolerant I/O Lines,

Sourcing or Sinking

• One 10 Bit Analog Input Selectable: 0 to +5

VDC, 0 to +10 VDC, 0-20 mA, 4-20 mA

• RS-422/485 or Optional CANopen

Communications

• 62 Software Addresses for Multi-Drop

Communications

• High Speed Position Capture Input or Trip

Output

• Electronic Gearing

**Consult Factory for Availability.

Optional communication protocols

include CANopen. The CAN bus is 2.0B

active (11 and/or 29 bit) and is capable

of all standard frequencies from 10 kHz

to 1 MHz. CANopen features include

node guarding, heartbeat producer,

SDOs and PDOs. Highlights include

variable PDO mapping and extended

node identifier.

The MDrive34AC Plus2Motion Control

is available with optional closed loop

control. This increases functionality by

adding stall detection, position mainte-

nance and find index mark.

The closed loop configuration is added

via a 512 line (2048 edge) optical

encoder with index mark, internal to the

MDrive34AC so there is no increase in

length. Or, for an expanded choice of

line counts and resolutions, closed loop

control is available with an interface

to a remotely mounted user-supplied

external encoder.

In addition to encoder options, the

MDrive34AC Plus2Motion Control has

the capability of electronic gearing by

following a rotary or linear axis at an

electronically controlled ratio, or an

output clock can be generated fixed to

the internal step clock.

A sealed version designed to meet

IP65 specifications is also available.

The sealed assembly allows the

MDrive34AC to be used in environ-

ments where exposure to chemical,

dust and liquids may occur.

Three rotary motor lengths are avail-

able as are linear actuators with long

life Acme screw**.

Interface connections are accomplished

using standard industrial circular con-

nectors. And connectivity has never

been easier with options ranging from

all-inclusive QuickStart Kits to indi-

vidual interfacing cables. See pg 4.

FEATURES

34TM

mOTION CONTROL

DESCRIPTION

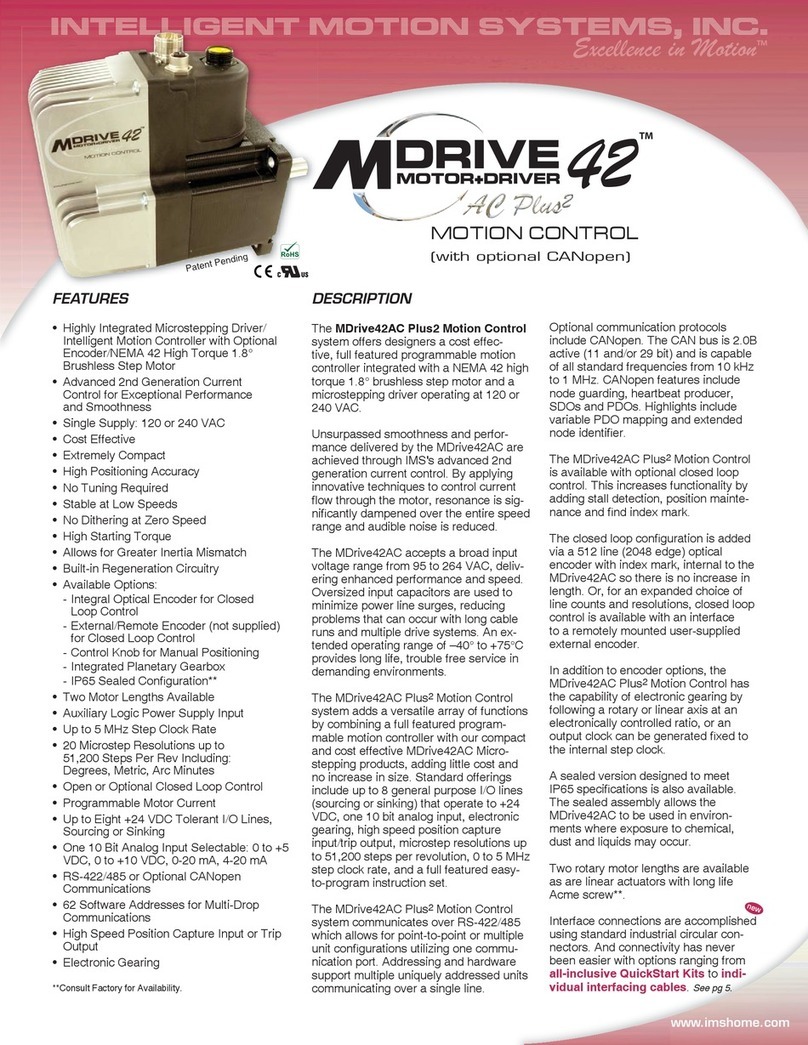

The MDrive34AC Plus2 Motion Control

system offers designers a cost effec-

tive, full featured programmable motion

controller integrated with a NEMA 34 high

torque 1.8° brushless step motor and a

microstepping driver operating at 120 or

240 VAC.

Unsurpassed smoothness and perfor-

mance delivered by the MDrive34AC are

achieved through IMS's advanced 2nd

generation current control. By applying

innovative techniques to control current

flow through the motor, resonance is sig-

nificantly dampened over the entire speed

range and audible noise is reduced.

The MDrive34AC accepts a broad input

voltage range from 95 to 264 VAC, deliv-

ering enhanced performance and speed.

Oversized input capacitors are used to

minimize power line surges, reducing

problems that can occur with long cable

runs and multiple drive systems. An ex-

tended operating range of –40° to +75°C

provides long life, trouble free service in

demanding environments.

The MDrive34AC Plus2Motion Control

system adds a versatile array of functions

by combining a full featured program-

mable motion controller with our compact

and cost effective MDrive34AC Micro-

stepping products, adding little cost and

no increase in size. Standard offerings

include up to 8 general purpose I/O lines

(sourcing or sinking) that operate to +24

VDC, one 10 bit analog input, electronic

gearing, high speed position capture

input/trip output, microstep resolutions up

to 51,200 steps per revolution, 0 to 5 MHz

step clock rate, and a full featured easy-

to-program instruction set.

The MDrive34AC Plus2Motion Control

system communicates over RS-422/485

which allows for point-to-point or multiple

unit configurations utilizing one commu-

nication port. Addressing and hardware

support multiple uniquely addressed units

communicating over a single line.

Patent Pending

(with optional CANopen)

new