Interroll AdControl User manual

INSPIRED BY EFFICIENCY

Operating Manual

Interroll AdControl

Manufacturer details

Interroll Engineering GmbH

Höferhof 16

42929 Wermelskirchen, Germany

Tel.: +49 (0) 2193 23 0

Fax: +49 (0) 2193 2022

www.interroll.com

Content

We strive for the accuracy, timeliness and completeness of the information and have carefully prepared the contents

in this document. Regardless of this, errors and changes are expressly reserved.

Copyright/industrial property rights

Any texts, images, graphics and the like, as well as their arrangement, are subject to protection under copyright and

other laws of protection. The reproduction, modication, transmission or publication of any part of this document or of

the entire document in any form is prohibited.

The document serves the exclusive purposes of information and of operation in accordance with the regulations and

does not justify any counterfeiting of the products concerned.

All signs contained in this document (protected marks, such as logos and trade names) are the property of Interroll

Holding AG, CH or of third parties and must not be used, copied or distributed without prior written consent.

Online version - only suitable for color printing!

Version 2.0 (12/2019) Online

Translation of the original operating manual 3 von 38

Inhalt

1 About this document 5

1.1 Information about this operating manual 5

1.2 Warning notices in this document 6

1.3 Symbols 7

2 Safety-related information 8

2.1 State of the art 8

2.2 Proper use 8

2.3 Improper use 8

2.4 Qualicationofpersonnel 9

2.5 Dangers 10

Injury to persons 10

Electricity 10

Work environment 10

Faults in operation 10

Maintenance 10

Unintentional start-up 10

2.6 Interface to other devices 11

2.7 Operating modes/operating phases 11

Standard operation 11

Special operation 11

2.8 Applicable documentation 12

3 Product information 13

3.1 Product description 13

Functions 13

Energy feedback 13

Temperature protection 14

3.2 Components 15

3.3 Typenschild 15

3.4 Technical data 16

3.5 Dimensions 16

3.6 DIP-Schalter 17

3.7 Meaning of the LED 18

3.8 Comparison RollerDrive EC310 and EC300 19

4 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

Inhalt

4 Transport and storage 24

4.1 Transport 24

4.2 Storage 24

5 Assembly and installation 25

5.1 Warning notices for installation 25

5.2 Assembling the AdControl 25

5.3 Warning notices for electrical installation 26

5.4 Electrical installation 27

5.5 Eingänge und Ausgänge 27

6 Initial startup and operation 28

6.1 Commissioning 28

Pre-commissioning checks 28

Inspection before each commissioning 28

6.2 Operation 28

7 Maintenance and cleaning 29

7.1 Maintenance 29

Checking the AdControl 29

Replacing the AdControl 29

7.2 Cleaning 30

8 Troubleshooting 31

8.1 Troubleshooting 31

9 Decommissioning and disposal 32

9.1 Decommissioning 32

9.2 Disposal 32

10 Appendix 33

10.1 Replacing a RollerDrive EC200 33

10.2 Electrical data of connectors 33

RollerDrive connector 33

Controller Connection 35

10.3 Translation of the original Declaration of Conformity 37

Version 2.0 (12/2019) Online

Translation of the original operating manual 5 von 38

About this document

1 About this document

1.1 Information about this operating manual

The operating manual is part of the Interroll product(s) named on the title and contains important notes and

information on the various operating phases of the product(s) named.

As with all our products, the operating instructions are subject to constant monitoring and will be adapted if necessary.

The current version of these operating instructions can be found on the Internet at www.interroll.com/support/

All information and notes in these operating instructions have been compiled in accordance with the applicable

standards and regulations as well as the state of the art.

For special versions, special contractual agreements and technical documents apply in addition to these operating

instructions.

¾Toensuresafeandfaultlessoperationandtofullanywarrantyclaimsthatmayapply,readthisoperating

manualrstandobserveitsinstructions.

¾Keep this operating manual within close reach of the product(s) named.

¾Pass this operating manual onto every subsequent owner or user.

The manufacturer assumes no liability for damage and malfunctions that occur as a result of non-

compliance with this operating manual.

Should you still have any unanswered questions after reading this operating manual, please contact Interroll

customer service. Contact details for your region can be found online at www.interroll.com/contact/

6 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

About this document

1.2 Warning notices in this document

Warning notices are provided in the context in which danger can occur and describe the nature of the danger in

question. They are structured according to the following examples:

SIGNAL WORD

Type and source of hazard

Consequence(s) in the event of non-compliance

¾Measure(s) for avoiding hazard

Signal words indicate the type and severity of the consequences if measures to avoid the hazard are not observed.

DANGER

Denotes an imminent hazard.

If measures to avoid the hazard are not observed, death or severe injury will occur.

¾Preventive measures

WARNING

Denotes a potentially hazardous situation.

If measures to avoid the hazard are not observed, death or severe injury may occur.

¾Preventive measures

CAUTION

Denotes the possibility of a hazardous situation.

If measures to avoid the hazard are not observed, minor or moderate injury may occur.

¾Preventive measures

Version 2.0 (12/2019) Online

Translation of the original operating manual 7 von 38

About this document

NOTE

Denotes a situation that can lead to material damage.

¾Preventive measures

1.3 Symbols

This symbol indicates useful and important information.

üThissymbolindicatesarequirementthatmustbefullledbeforecarryingoutassemblyorrepairwork.

This symbol indicates general information relating to safety.

¾This symbol indicates an action that needs to be performed.

•This symbol indicates a listed item.

8 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

Safety-related information

2 Safety-related information

2.1 State of the art

The Interroll AdControl has been constructed with respect to applicable standards and the current state of the art and

has been delivered in a condition that is safe to operate. Nevertheless, hazards can occur as a result of use.

Non-compliance with the instructions in this operating manual can result in life-threatening injuries.

In addition, the applicable local accident prevention regulations for the area of application and general safety

regulations must be adhered to.

2.2 Proper use

The AdControl may only be used in an industrial environment for industrial purposes within the stipulated performance

limitsthataregiveninthetechnicalspecications.

TheAdControlmayonlybeusedinanindustrialenvironmentforindustrialpurposeswithinthedenedperformance

limitsspeciedinthetechnicaldata.

The AdControl can be used if a RollerDrive EC300 (predecessor of the EC310) is to be replaced by a RollerDrive

EC310. The AdControl has a short connection cable with plug. The plug corresponds to that of the EC300 and is

connected to the existing DriveControl EC200/EC300 or extension cable.

By using AdControl a RollerDrive EC310 can be used without changing the existing wiring.

Depending on the gear ratio, the AdControl can also be used when replacing an EC200 with an EC310.

2.3 Improper use

Any use that goes beyond the proper use is considered improper, unless this has been authorised by Interroll

Engineering GmbH where applicable.

The equipment must not be installed in areas in which substances could form explosive atmospheres/dust atmospheres

or for application in the medical/pharmaceutical sector.

It is considered improper use to install the equipment in exposed spaces that are open to potentially adverse weather

conditions,orareasinwhichthetechnologywouldsuerfromtheprevailingclimacticconditionsandcouldpotentially

malfunction as a result.

The AdControl is not intended for use by private end users. The equipment must not be used in a residential

environment without further examination and without the use of EMC protective measures that have been adapted

accordingly.

It must not be used as a safety-relevant component or for performing safety-relevant functions.

Version 2.0 (12/2019) Online

Translation of the original operating manual 9 von 38

Safety-related information

2.4 Qualication of personnel

Non-qualiedpersonnelareunabletoidentifyrisksandarethereforeexposedtohigherlevelsofdanger.

¾Onlyqualiedpersonnelmaybeassignedwiththetasksoutlinedinthisoperatingmanual.

¾The operating company is responsible for ensuring that personal adhere to the locally valid rules and

regulations for working in a safe and risk-aware manner.

This operating manual is intended for the following target audiences:

Operators

Operators are trained in how to operate and clean the Interroll AdControl unit and follow the safety regulations.

Service engineers

The service engineers have a specialist technical education or have successfully completed a training course from the

manufacturer. They carry out repair and maintenance work.

Qualied electricians

Qualiedelectricianshaveaspecialisttechnicaleducation.Moreover,duetotheirknowledgeandexperienceaswell

as knowledge of applicable regulations, they are able to carry out work on electrical equipment in an appropriate

manner. They are able to identify hazards independently and prevent electrical damage to persons and property.

Allworkonelectricalequipmentmustgenerallyonlybeperformedbyaqualiedelectrician.

10 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

Safety-related information

2.5 Dangers

Here,youwillndinformationaboutthedierenttypesofdangersordamagethatcanoccurin

connection with the operation of the AdControl.

Injury to persons

¾ Maintenance, installation and repair work on the unit must only be carried out by authorised technical personnel

in compliance with the applicable provisions.

¾ Before switching on the AdControl, ensure that no unauthorised personnel are situated in the vicinity of the

conveyor/conveying system.

Electricity

¾ Installation and repair work must only be carried out when the system has been disconnected from the power

supply.SwitchothepowertotheAdControlandensurethatitcannotbeunintentionallyswitchedonagain.

Work environment

¾ Remove any materials and objects that are not required from the working area.

Faults in operation

¾ Regularly check the AdControl for visible damage.

¾ Ifsmokedevelops,immediatelyswitchothepowertotheAdControlandensurethatitcannotbe

unintentionally switched on again.

¾ Immediately contact specialist personnel to determine the cause of the malfunction.

Maintenance

¾ Sincetheproductinquestionrequiresnomaintenance,itissucienttosimplyexaminetheAdControlforvisible

damage on a regular basis.

¾ Never open up the AdControl.

Unintentional start-up

¾ Ensure that the connected RollerDrive/motors cannot start up unintentionally, particularly during assembly and

maintenance work or in the event of a fault.

Version 2.0 (12/2019) Online

Translation of the original operating manual 11 von 38

Safety-related information

2.6 Interface to other devices

The integration of the AdControl into a conveyor system can create additional potential hazards. Such potential

hazards are not covered by this operating manual and must be analysed during the development, installation and

commissioning of the conveyor system as a whole.

¾Following the integration of the AdControl into a conveyor system, the entire system must be checked for any

new potential hazards that may be present before the conveyor is switched on.

2.7 Operating modes/operating phases

Standard operation

Operation in the installed condition at the end customer as a component in a conveyor in an overall system.

Special operation

Special operation encompasses all operating modes/operating phases that are necessary to guarantee and maintain

safe standard operation.

Special operating mode Comments

Transport/storage -

Assembly/commissioning In de-energised state

Cleaning In de-energised state

Maintenance/repair In de-energised state

Fault location In de-energised state

Troubleshooting In de-energised state

Decommissioning In de-energised state

Disposal -

12 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

Safety-related information

2.8 Applicable documentation

In order to ensure proper use of the RollerDrive, additional operating manuals/documentation relating to the

following must be consulted:

• Power supply unit

• RollerDrive

• Description of the conveyor system/unit

Also ensure that you adhere to the information given in the operating manuals of the connected devices.

Version 2.0 (12/2019) Online

Translation of the original operating manual 13 von 38

Product information

3 Product information

3.1 Product description

TheAdControlservesasaninterfacemodicationbetweenaDriveControl200/DriveControl300andaRollerDrive

EC310. If the RollerDrive EC300 of a conveyor is replaced with a RollerDrive EC310, but the DriveControl 200/300

is to remain, the AdControl ensures that the signals (speed and direction of rotation) of a DriveControl 200/300

are converted in such a way that a RollerDrive EC310 can be connected that behaves in exactly the same way as a

RollerDrive EC300. The AdControl can also be used if the RollerDrive EC300 has been actuated without DriveControl.

Functions

Regenerative breaking

When the RollerDrive motor brakes, it acts as a generator and feeds energy back into the power supply. The

AdControl has a built in brake chopper (load resistor) to limit the DC voltage on the connection to a stable level.

Diagnostics

LEDs indicate the operating condition of the AdControl and the RollerDrive as well as the operating voltage (see

„Meaning of the LED”, page 20). An error signal can also be output.

Speed conversion

Because the RollerDrive EC310 has other gear phases just like the RollerDrive EC300, the RollerDrive EC310

wouldrotateatadierentspeedwhenactuatedinthesameway.TheAdControlconvertsthespeedsignalofthe

DriveControl 200/300 in such a way that the RollerDrive EC310 rotates at the same speed as a previously used

RollerDrive EC300.

Energy feedback

When the speed of a rotating RollerDrive is abruptly reduced (e. g. by removing or reducing the start signal at the

DriveControl),theRollerDrivecontinuestorotatebriey(dependingontheweightoftheconveyedgoodsbeing

stopped) and thus functions as a generator. The voltage generated in this way increases the supply voltage of the

RollerDrive. This increased voltage is partly fed to the DC supply (to max. 30 V) and partly converted to heat via a

brake chopper resistance on the DriveControl. The regenerated power is then available for other consumers. The

more precisely 24 V are complied to in the voltage supply the greater the voltage range in which the DC network can

be fed back to.

14 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

Product information

Temperature protection

Thebrakechopperresistoristemperature-controlled.If,duetospecicapplicationproperties(e.g.highconveying

weight or high conveying speed), the brake chopper resistance is frequently switched, the DriveControl switches

owhenitbecomestoohot(approx.90°Cinnertemperature).Iftemperatureprotectionisactivated,thisstateis

indicated by the LEDs and no start signal will be transmitted to the RollerDrive. When the DriveControl has cooled

down, the RollerDrive restarts automatically when a signal is pending. The DriveControl cools down quicker if it is

mountedonaatsurface,ideallymetal.

NOTE

DriveControl failure from overheating

¾Do not perform a voltage reset when temperature protection is active.

Version 2.0 (12/2019) Online

Translation of the original operating manual 15 von 38

Product information

3.2 Components

1 RollerDrive connector 4 Marker (changeable)

2 Mounting link with hole for countersunk screw 5 Cover for DIP switches

3 LED Ready und Fault 6 Controller connection

3.3 Typenschild

1 Product name 4 Manufacturer’s address

2 Manufacturer 5 Week and year of production

3 Serial number 6 Article number

16 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

Product information

3.4 Technical data

Rated voltage 24 V DC, protected extra-low voltage (PELV)

Voltage range 19 bis 26 V DC (max. reverse polarity protection 30 V)

Current consumption with RollerDrive: up to 5 A

without RollerDrive: 0,5 A

Protectionclassication IP 20

Cooling Convection

Ambient temperature in operation 0°Cto+40°C(32°Fto104°F)

Ambient temperature during transport and

storage

-40°Cto+85°C(-40°Fto185°F)

Air humidity 5 to 95 %, condensation not permissible

condensation not permissible Max. 1000 m (max. 3300 ft)

3.5 Dimensions

Version 2.0 (12/2019) Online

Translation of the original operating manual 17 von 38

Product information

3.6 DIP-Schalter

The DIP switches are used to select the gear ratio of the previously used RollerDrive EC300 and RollerDrive EC310 to

be used in the future. Based on these values, the AdControl determines the necessary change that has to be made to

the speed signal.

In its as-delivered state, the gear ratio EC300 13:1 and EC310 16:1 are set.

DIP switches Meaning

7,85:1 / 13:1 Gear ratio of the RollerDrive EC300

Bit 0, Bit 1, Bit 2, Bit 3 Gear ratio of the RollerDrive EC310 (see below)

Reserve Not occupied

Gear ratio

RollerDrive EC310

DIP switches

Bit 3 Bit 2 Bit 1 Bit 0

9:1 OFF OFF OFF OFF

12:1 OFF OFF OFF ON

16:1 OFF OFF ON OFF

20:1 OFF OFF ON ON

24:1 OFF ON OFF OFF

36:1 OFF ON OFF ON

48:1 OFF ON ON OFF

64:1 OFF ON ON ON

96:1 ON OFF OFF OFF

IfadierentDIPswitchcombinationissetthantheonelistedinthetable,theRollerDrivespeedofrotation

will be set to 0 RPM.

18 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

Product information

DIP switches

1 Bit 3 4 Bit 0

2 Bit 2 5 7,85:1 / 13:1

3 Bit 1 6 Reserve

3.7 Meaning of the LED

The LEDs indicate the operating state of the AdControl and the RollerDrive and provide information about the

operating voltage.

LED green Meaning Operating voltage

On steady AdControl ready for operation 19 to 26 V

Flashing RollerDrive rotating/is activated 19 to 26 V

O AdControl not ready for operation

LED green Meaning Operating voltage

On steady fuse in AdControl defective

Flashing slowly 1) • Operating voltage too low or too high

• RollerDrive Error

• RollerDrive faulty or not connected

unter 18 V oder über 26 V

Flashing quickly 2) Abschaltung wegen erhöhter Temperatur

im Chopperwiderstand

1)LEDashingslowly=0,5son-1,5so

2)LEDashingquickly=0,5son-0,5so

Version 2.0 (12/2019) Online

Translation of the original operating manual 19 von 38

Product information

3.8 Comparison RollerDrive EC310 and EC300

Replacing a RollerDrive EC300 with a RollerDrive EC310 changes the torque and maximum speed.

Gear ratio DIP switches Nominal

torque [Nm]

Max. torque

[Nm]

Max. speed

[m/s]

EC300 EC310 Bit 3 Bit 2 Bit 1 Bit 0 7,85:1

/ 13:1 EC300 EC310 EC300 EC310 EC300 EC310

13:1 12:1 OFF OFF OFF ON ON 0,90 0,61 1,60 1,46 1,27 1,31

13:1 16:1 OFF OFF ON OFF ON 0,90 0,81 1,60 1,95 1,27 0,98

13:1 20:1 OFF OFF ON ON ON 0,90 1,01 1,60 2,44 1,27 0,78

7,85:1 9:1 OFF OFF OFF OFF OFF 0,70 0,45 1,00 1,10 2,00 1,75

7,85:1 12:1 OFF OFF OFF ON OFF 0,70 0,61 1,00 1,46 2,00 1,31

7,85:1 16:1 OFF OFF ON OFF OFF 0,70 0,81 1,00 1,95 2,00 0,98

20 von 38

Version 2.0 (12/2019) Online

Translation of the original operating manual

Product information

The following graphs show the conveyor speed as a function of the voltage and of the gear stages.

Abbreviations:

• v [m/s] Conveyor speed in m/s

• U [V] Speed control in volts

EC300 13:1

Table of contents

Other Interroll Controllers manuals

Popular Controllers manuals by other brands

Allen-Bradley

Allen-Bradley CompactLogix 5370 L1 quick start

select solar

select solar EPHC 10A Instruction guide

Yamaha

Yamaha SRCD Series Supporting supplement manual

Mitsubishi Electric

Mitsubishi Electric FX3G-2EYT-BD user manual

FUHR

FUHR SmartConnect easy Operation manual

MDT Technologies

MDT Technologies RF-TA55A2.01 operating instructions

Hitachi

Hitachi EH-150 Series instruction manual

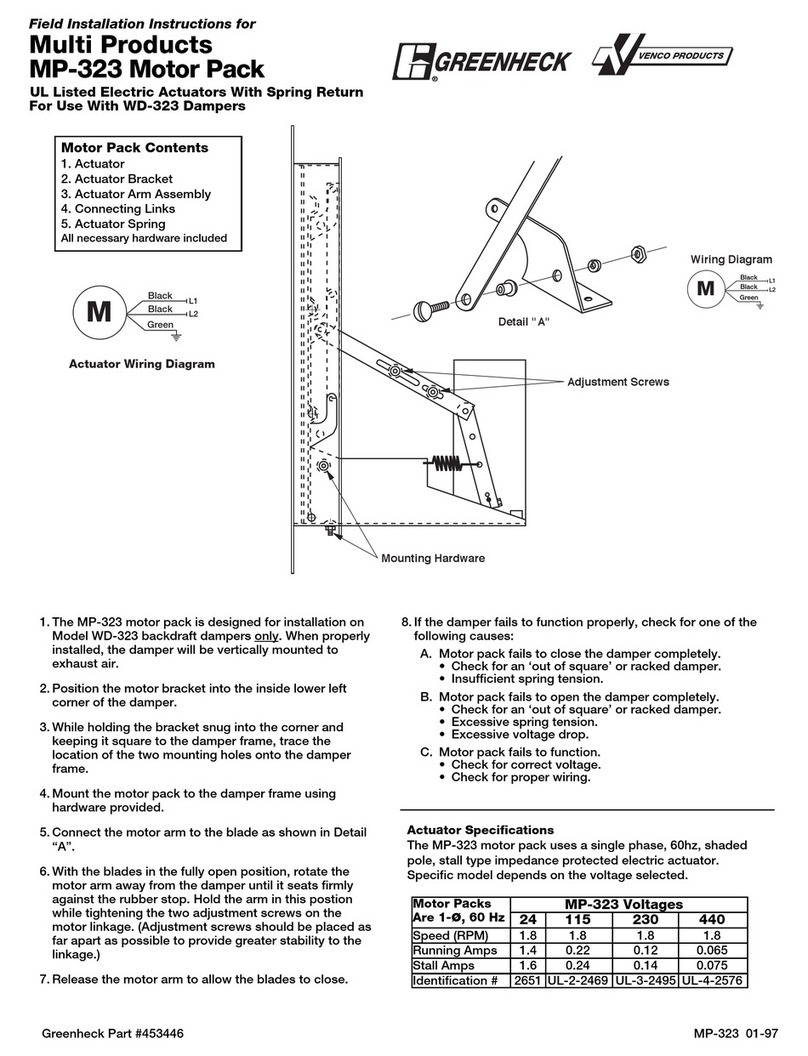

Greenheck

Greenheck MP-323 Field installation instructions

Carrier

Carrier XCT 7 40VCI67FQEE Installation and owner's manual

Lab.gruppen

Lab.gruppen NLB 60E supplementary guide

HIFEI Technology

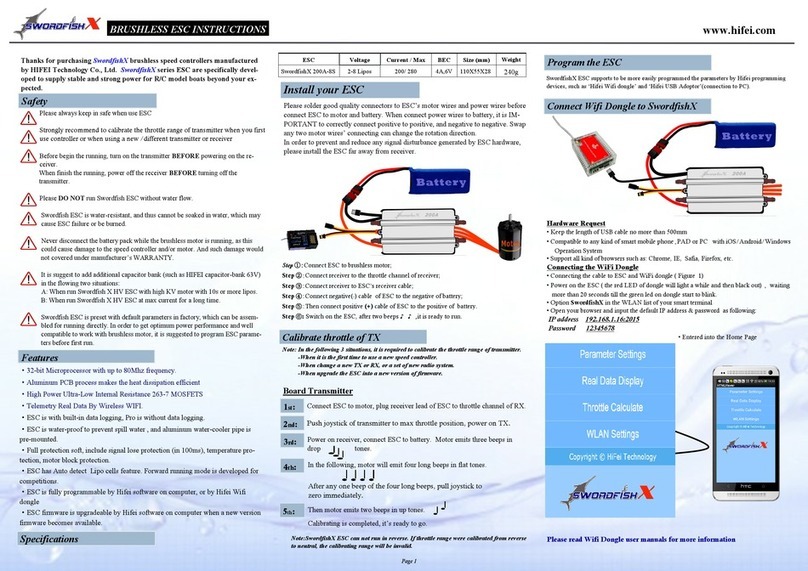

HIFEI Technology SwordfishX 200A-8S instructions

Matrox

Matrox QuadHead2Go Q2G-DP4K Configuration guide