Intersan Wallgate Thrii User manual

Thrii

Installation

Page 1of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

Installation Instructions for models:

THRII –Solid Surface

THRII –Stainless Steel

IMPORTANT

Read instructions entirely prior to installation.

Prior to hooking up the fixture to the water supply

make sure that all the lines are flushed thoroughly.

All wall anchors should have a pull out strength of

1000 lbs. or more.

Units should always be installed according to local

plumbing and/or electrical codes.

Thrii

Installation

Page 2of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

1. Disclaimer & Copyright notice

Every effort has been made to supply information within this manual which is correct. Wallgate Limited and Intersan Mfg.

will not be liable for any damage or loss that arises if the person installing, operating or maintaining the unit has not read

or not complied with the manual

In any event, and without prejudice to any warranties in Wallgate Limited’s and Intersan’s terms and conditions of sale,

Wallgate Limited’s and Intersan’s liability for all damages and losses (including negligence) shall not in any circumstances

exceed the amount paid by the customer for the unit.

Wallgate and Intersan reserve the right to alter, update or improve its product specification at any time without prior

notice. This manual is specific to the product that it has been supplied with at the date of supply.

Without prejudice to any warranties in Wallgate Limited’s and Intersan’s terms and conditions of sale, any warranty will be

null and void if the equipment is installed or serviced by unqualified personnel.

No part of this publication and the information contained may be reproduced, transmitted, stored in a retrieval system,

used or disclosed wholly or partly without prior written permission from Wallgate Limited.

For full warranty details please see Intersan’s Terms and Conditions.

Please ensure this manual is passed to the end user. The manual forms an integral part of the product and should be kept

for its working life. Additional copies of this and other supporting documents are available by contacting Intersan or by

visiting www.intersan.us.

2. Conventions

Certain conventions are used in this manual to make it easier to read and understand. They are shown in the sections

below. It is recommended that you read and understand these warnings before you install and commission the Wallgate

Thrii.

2.1 Warning

A boxed WARNING! is used to give information about hazards associated with electric current and high voltages that can

cause damage, injury or death. Failure to heed these warnings can have serious consequences. Example box:

WARNING! The information contained within this ‘Warning’ box indicates hazards associated with electric

current and high voltages

2.2 Caution

A boxed CAUTION! is used to give information about hazards that can cause damage or injury. Failure to heed these

warnings can have serious consequences. Example box:

CAUTION! The information contained within this ‘Caution’ box indicates hazards that require safety advice for

personnel or potential unit/property damage

2.3 Important

A boxed IMPORTANT: is used to draw your attention to important information on installation, set-up and operation.

Example box:

IMPORTANT: The information contained within this ‘Important’ box gives further useful information.

Thrii

Installation

Page 3of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

2.4 Numbered procedures

Steps in procedures are numbered, starting from 1.

1. This is step 1.

2. This is step 2, etc.

2.5 Bullet lists

A bullet list is used to give information that is not necessarily in sequential order.

2.6 Menu items

Menu items, submenu items and settings, where available, are given in bold.

3. Glossary

The glossary lists all words, abbreviations and technical terminology used in this manual, along with a short description of

these terms.

Term

Description

Thrii®

Hand Wash Unit

Engine Unit

The Engine Unit refers to the complete soap,

water, dryer module mounted on the back of

the fascia.

IR Sensor

The infrared (IR) sensor transmits an invisible

beam into the washbowl area, so that when

interrupted by a person's hand the beam is

rebounded back to the receive sensor. This

creates an electrical signal which rapidly

activates the hand wash cycle.

FNPT

Female National Pipe Thread

Solid Surface

The term Solid Surface refers to the hard

granite-effect or solid color material that is

molded to form the Thrii fascia.

Power up

The external electricity supply is provided to the

Thrii.

Thrii

Installation

Page 4of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

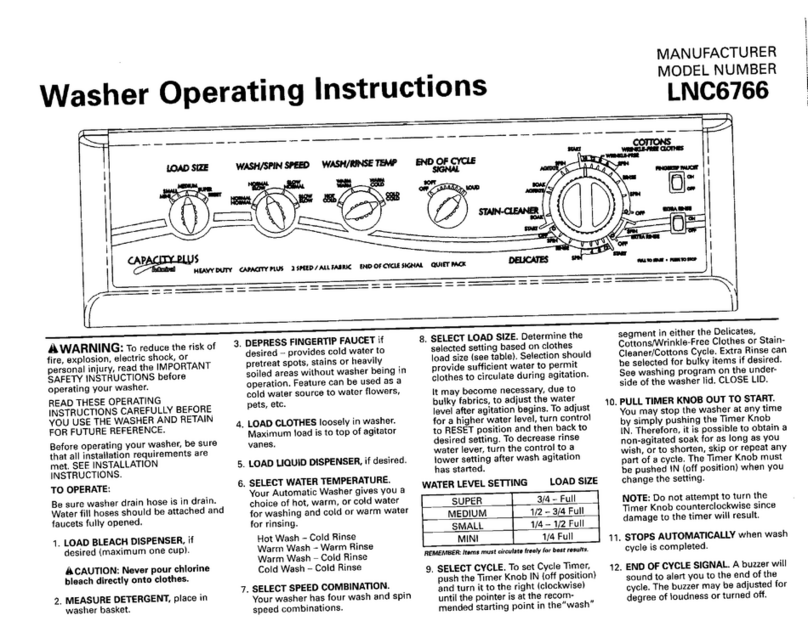

4. Technical Specification

Weight

Item

Fascia

Engine Support

frame, etc. Full

soap container

Total

Solid surface

33.73 lbs.

15.43 lbs.

9.92 lbs.

5.73 lbs.

64.81 lbs.

Stainless Steel

17 lbs.

15.43 lbs.

9.92 lbs

5.73 lbs.

48.06 lbs.

Dimensions

Width

Height

Depth

± 17-3/4”

± 31-1/4”

± 12-1/4”

± 17-3/4”

± 34-1/4”

± 12-1/4”

(9-7/8”behind the panel on all models)

Water Supply

Minimum pressure

Maximum rating

Inlet connection size

Dynamic

14.5 psi / 100 kPa

145 psi / 1000 kPa

½” NPT

Electrical Power requirement

120V AC, 60Hz, 20 Amp

Enclosure IP Rating

IPX4

Regulatory compliance

Complies with:

IAPMO Green Plumbing and

Mechanical Code Supplement

Cal Green

LEED

National Green Building Standard™

Natural Resources Canada R-2000

Standard

Green Building Assessment Protocol

for Commercial Buildings

Solid Surface and Plumbing Code

Compliance

Uniform Plumbing Code (UPC®)

International Plumbing Code (IPC®)

IGC 127-2009

Water heater

Water temperature range

Factory set @ 100°F

*Based on 54°F supply

temperature, 43.5 psi

dynamic pressure & 120V

supply.

86°F to 113°F Flow rate of

0.4 gpm*

Water Resistivity

Water resistivity must not be less than 1300

Ωcm (511.81Ωin) (refer EN603355-2)

Thrii

Installation

Page 5of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

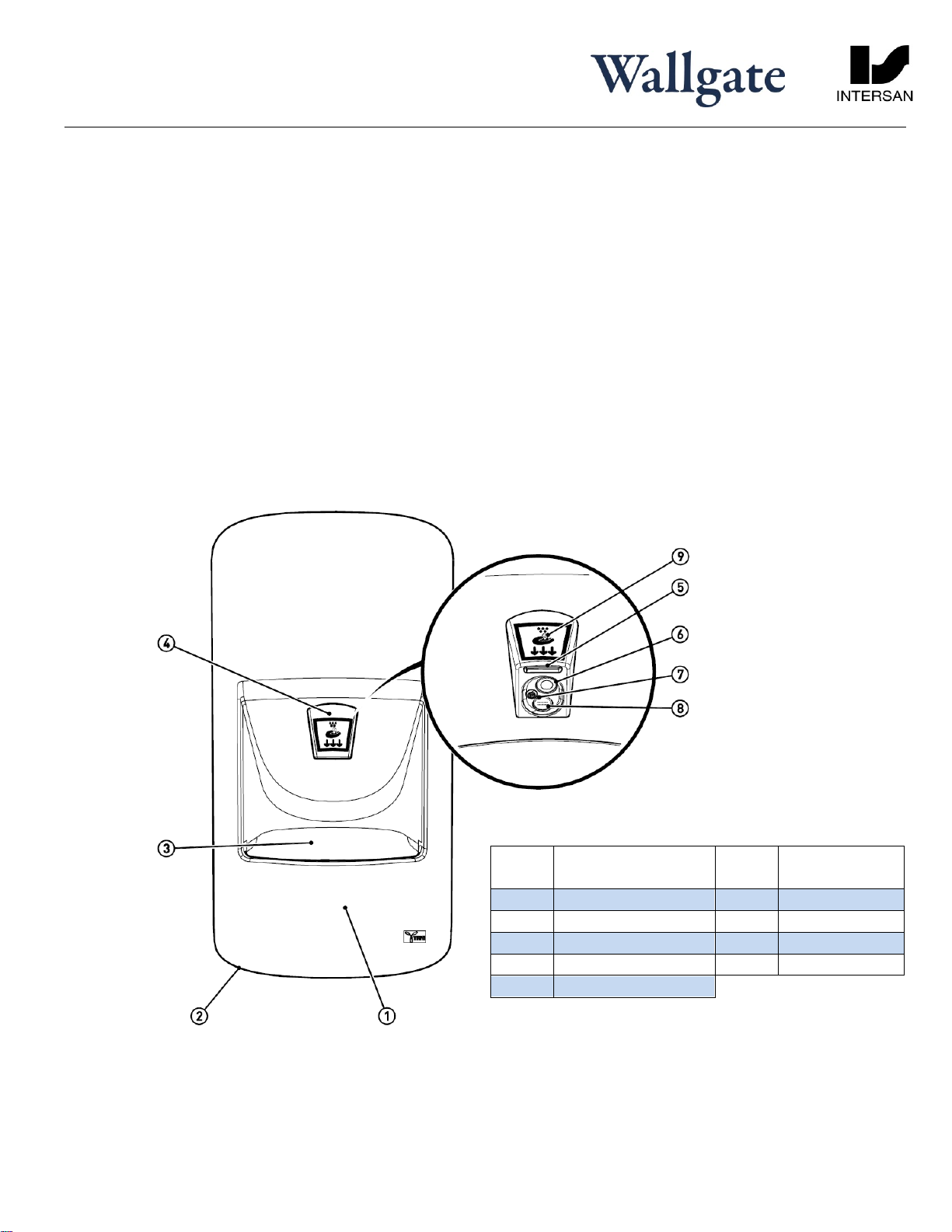

5. Overview

The Thrii is an integrated hand wash dryer unit with automatic infra-red sensor operation. It is available in a

solid surface or stainless steel (grade 304) material.

The unit should only be installed in a frost free environment, to avoid damage.

All models are identical, with the exception of the fascia material & fascia dimensions.

When hands are placed in the center of the wash bowl, an infra-red sensor activates the hand washing and

drying cycle, supplying soap (liquid or foam), warm water and dryer-air in amounts and intervals preset as

required.

The unit can be installed in a variety of wall types, servicing can be carried out either from the front (fascia

unlocks and whole Thrii swings out) or from within an access duct behind the machine.

Item

No.

Description

Item

No.

Description

1

Fascia

6

IR Sensor

2

Fascia Lock (hidden)

7

Soap Outlet

3

Wash Bowl

8

Water Outlet

4

Dispensing Unit

9

Label (optional)

5

Dryer Outlet

Thrii

Installation

Page 6of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

Item

No.

Description

Item

No.

Description

1

Fascia

13

Hinge

2

Container Cap

14

Hinge side lock plate

3

Soap Hose

15

Water (inlet) adapter

4

Soap Container

16

Double Check Valve

5

Container Holder

17

Isolation Tap

6

Engine Cover

18

Water Connection (frame)

7

Locking Bar

19

Engine water supply hose

8

Mounting Frame

20

Engine Cover fixing

9

Clamp bracket

21

Control

10

Fascia Lock

22

LCD Control (see fig. 18)

11

Drain

23

Mains Power socket

12

Waste Outlet

24

Soap Selection switch

Thrii

Installation

Page 7of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

6. Installation and Commissioning

The Wallgate Thrii handwash-drier unit is a three-part assembly consisting of a flush support frame and a hinged fascia and

engine assembly. It is necessary to install the mounting frame and prepare the services (electrical, water and waste) prior

to installing the fascia.

It is important that when selecting a mounting position consideration be given to the suitability of the wall

construction, so that it is able to bear the weight of the assembled unit in both the open and closed positions, and able

to withstand the clamping method as shown in Fig.6

6.1 Package Contents

Before you begin the installation, make sure that you have the following items:

1 Support frame

1 Installation instructions

1 Wall frame waste connector

1 Waste pipe 1-1/4” – 1-1/2” adapter pipe

1 Fascia lock key

1 Mains electrical plug and lead (6-1/2 ft. length)

1 User instruction label

1 Set of mounting brackets and fixings

1 Fascia

1 Engine

1 Container of liquid soap (2/3 gal.)

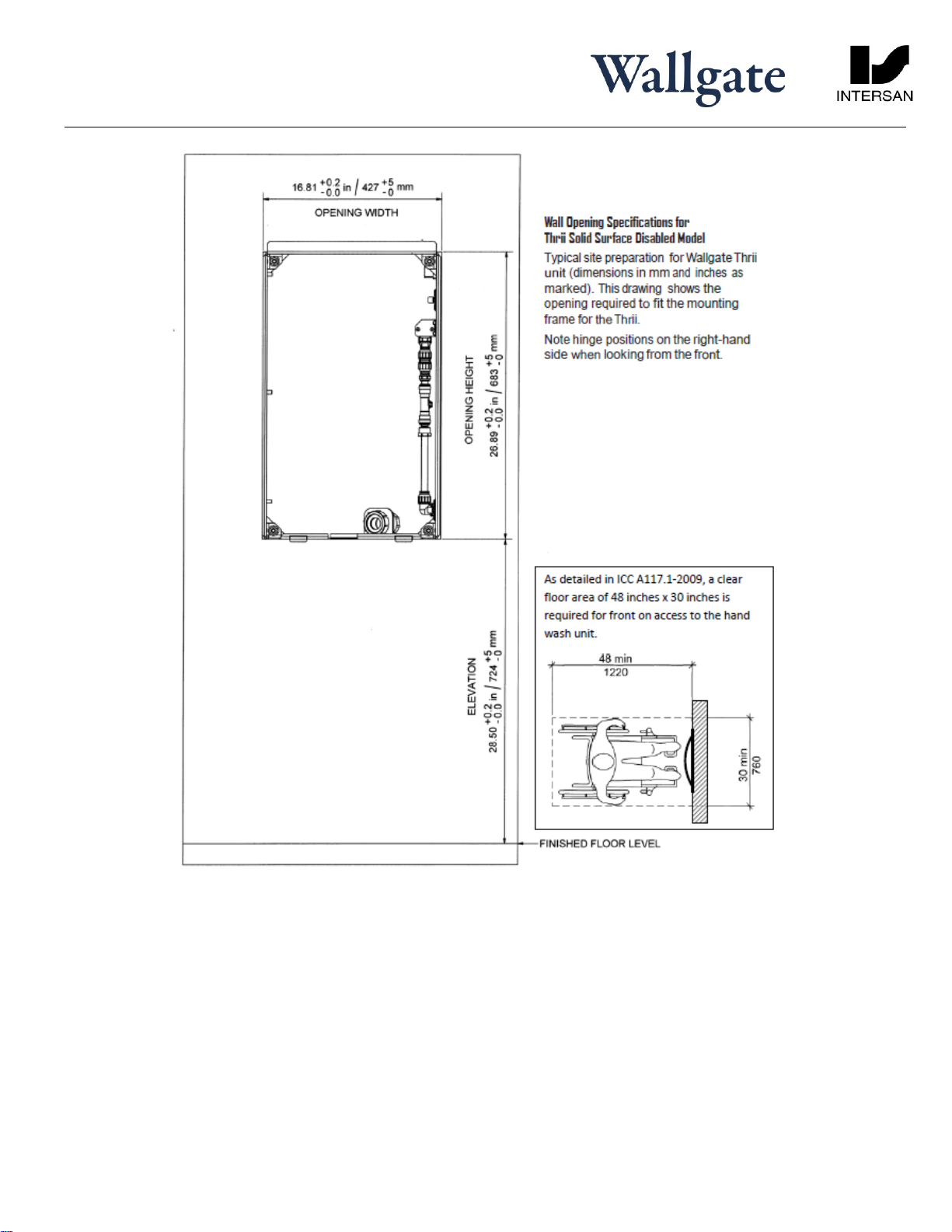

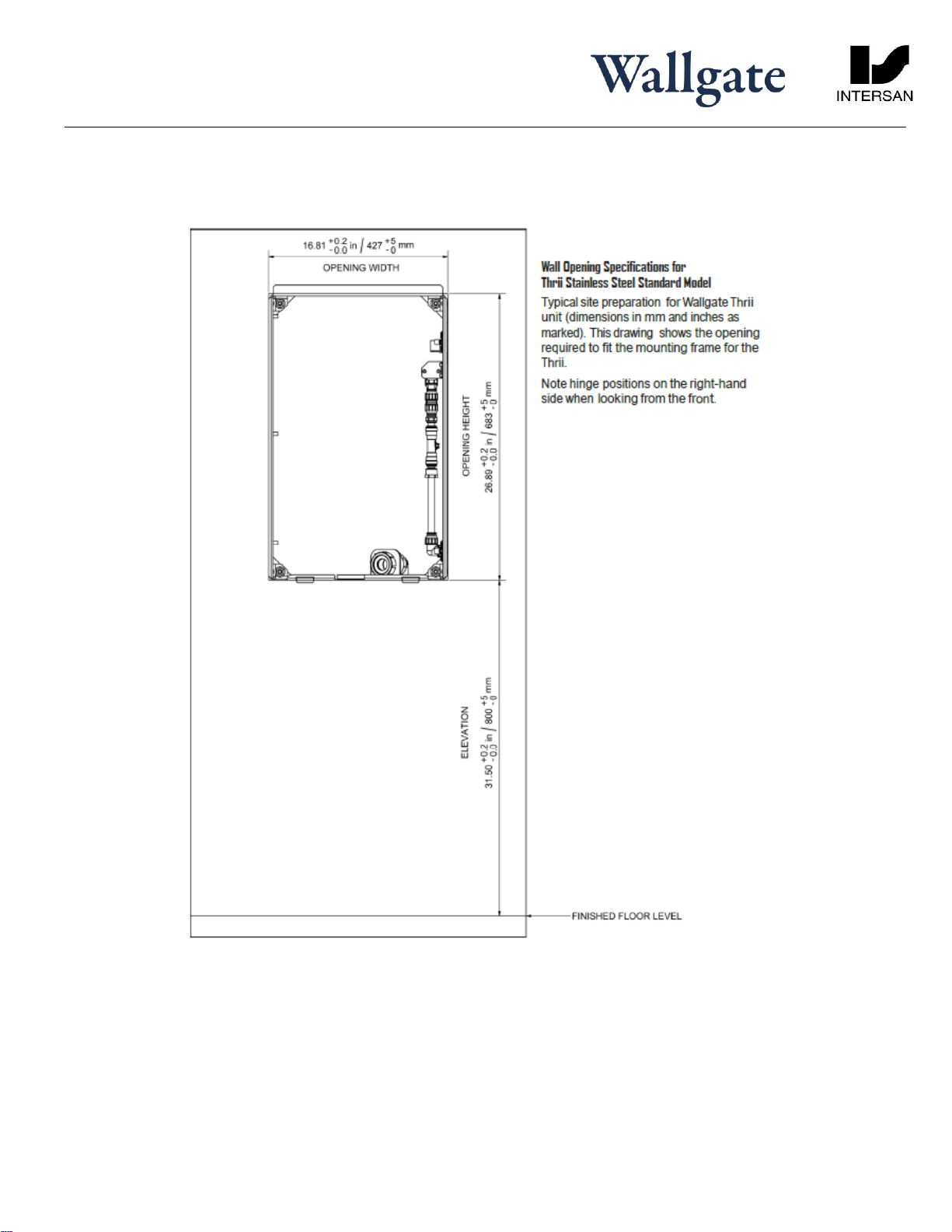

6.2 Site Preparation

6.2.1 Installation guidelines

Looking at the front of the unit the fascia hinges are on the right-hand side. For front access allow for the left-hand

edge of fascia to swing out (120°) to allow full internal access. Water, power and waste water connections are

located on the hinged side of the unit.

Make an opening in the wall surface according to the dimensions shown in drawing Fig.4 noting the appropriate

mounting height as detailed on the drawing table A.

The opening must be according to the dimensions given in fig.4. The aperture must be accurate in order for the

door mechanism to work effectively. The unit will be fitted to the support frame supplied. The frame is fixed to the

sides of the wall opening using the frame fixing brackets provided. The front edge of the frame must be flush with

the finished face of the wall. On IPS panel walls such as trespa or corian the aperture in the panel should be lined

on the rear face with 50mm timber studding.

Complete all surface finishes such as screed, plaster or tiling before attaching the fascia to the support frame.

All electrical work must be carried out by a qualified electrician and should be installed in accordance with the

current Nationally Approved Regulation

Thrii

Installation

Page 8of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

The installer must:

Provide a 120V 50/60Hz single-phase circuit equipped with a 20 Amp circuit breaker. Locate an outlet in close

proximity to the intended location of the Thrii unit. The Thrii unit is equipped with a 6.5 feet long electrical cord.

A GFCI equipped circuit is recommended, and likely required by your applicable regulations. If so, ensure that a

GFCI is present on the circuit that meets your locally applicable electrical/building/plumbing codes.

The circuit must be equipped with a circuit breaker that is accessible without requiring the fascia of the Thrii unit to

be opened first. Be sure to turn off the circuit breaker before working on or installing the Thrii unit.

Provide a cold water supply mounted behind the wall below the ‘hinge’ side of the aperture. Terminate the cold

water supply with a suitable isolating tap. For optimum operation a dynamic water flow pressure of between 14.5

psi and 43.5 psi is required.

If you are planning on connecting your Thrii unit(s) to a gravity-fed water supply, please contact Intersan in advance

for advice and guidance.

Provide a waste pipe with a 1-1/4” or a 1-1/2” connection and suitable deep seal waste trap behind the wall,

below the ‘hinge’ side of the aperture.

6.3 Installing the support frame, water and waste connections and electric

1. Remove the support frame from the packing box.

2. Orientate the frame with hinge plates on the right-hand side and waste outlet parts at bottom and facing away

from you. The frame front edge should now be facing towards you.

3. Place the frame into the front of the aperture, ensuring it is flush fitting with the finished face of the wall, at the

correct height and perfectly level in the horizontal and vertical planes. The hinge-side of the frame should be hard

up against the aperture.

Thrii

Installation

Page 9of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

Thrii

Installation

Page 10 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

Thrii

Installation

Page 11 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

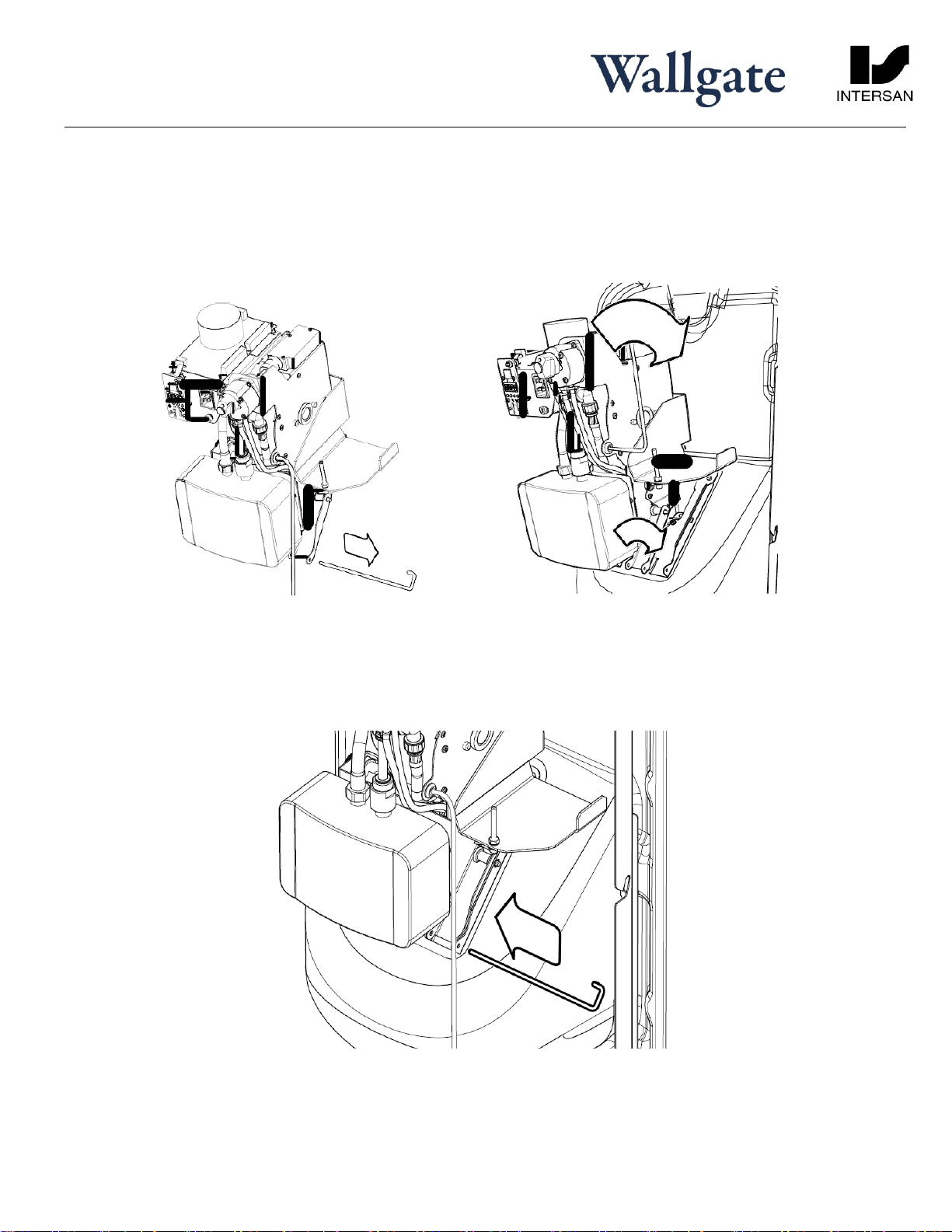

Solid Surface Model Stainless Steel Model

Typical site installation of Thrii unit

showing clamping bracket (view on rear)

Thrii

Installation

Page 12 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

4. Insert the 4 No. M10 x 150mm (6”) threaded rods through the corner angles on the support frame and into the

brackets as shown in figure above.

5. Tighten all four (4) brackets until the wall frame is held securely in place in the wall opening. It is important that

the frame side members are not distorted when tightening to the wall, as this may prevent the hinge and catch

mechanisms from working properly.

6. Once the frame is securely attached to the wall, if necessary make good any excessive gaps between the frame

and the wall that may not be covered by the fascia.

7. Install the waste connector to the frame as shown in figure below along with the pipe adapter which then is

terminated to the deep seal waste trap as detailed in section 6.2 site preparation.

8. Provide a cold water supply pipe to connect to the inlet connector on the support frame. Note that the water

inlet connector is ½” copper fitting on the main water supply.

If pipe sealing compound is used, avoid applying excessive amounts as particles of sealant can block water

filters and impede valve operation.

Before carrying out the following steps, flush the main water supply pipes to remove any debris and trapped

air. Failure to do so may result in damage and failure of the unit.

9. Connect the deep seal waste trap to the outlet fitting on the support frame.

10. Connect the supplied electrical cable to a 20 amp circuit equipped with an accessible circuit breaker and GFC�if

required per locally applicable code requirements.

6.4 Mounting the fascia

Ensure that the fascia is fully supported until both hinges are fully engaged. Failure to do so may damage the

hinges

For ease of installation it is recommended to have at least two people carry out this operation

Ø1-1/4”

Thrii

Installation

Page 13 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

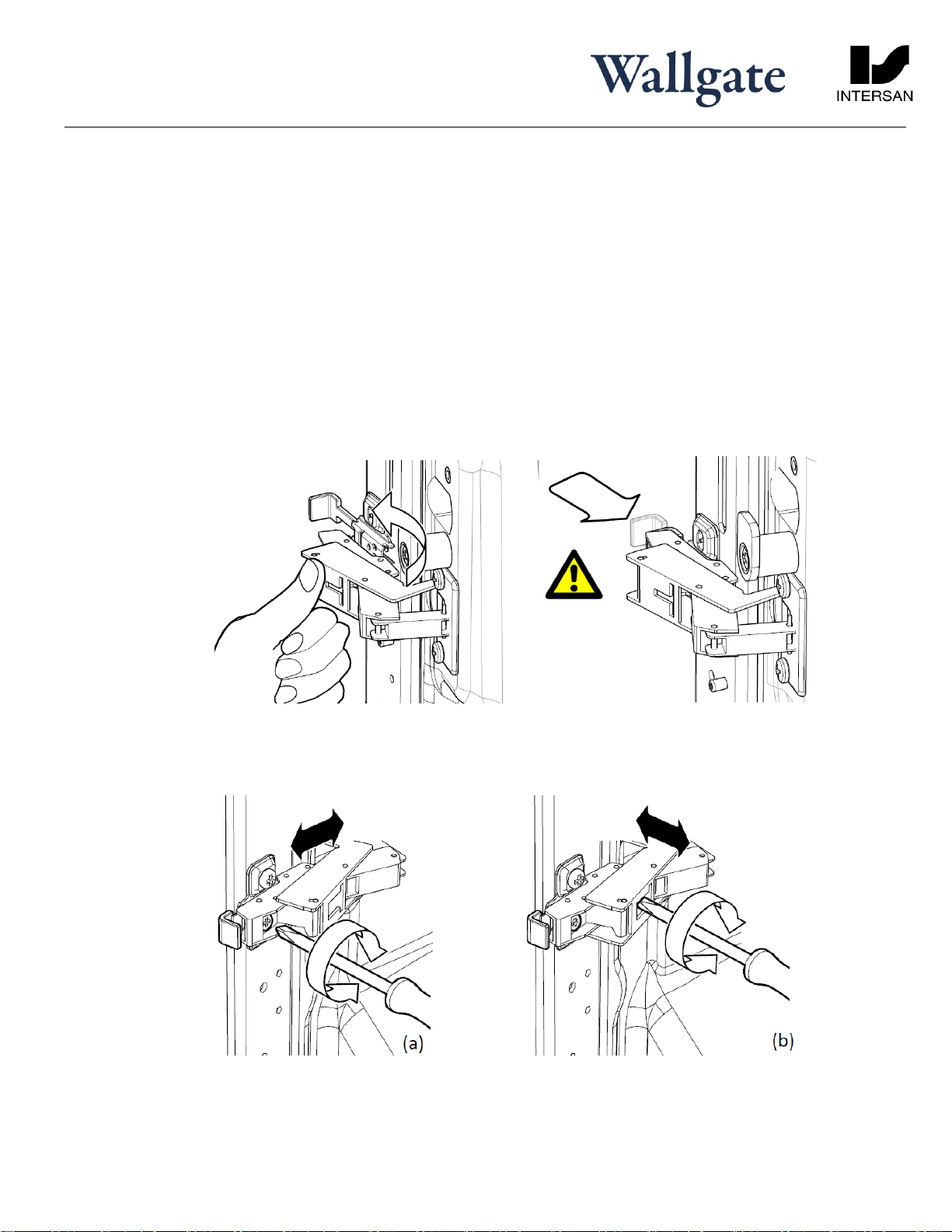

1. Remove the fascia from the packing box.

2. With one person holding the fascia, the second person should extend the hinge components on the right side of the

fascia so they are fully extended. Position the fascia assembly so the two hinges are suspended next to the hinge side

lock plates mounted on the support frame.

Have one person hold the fascia so it is suspended where the hinge halves on the fascia are in alignment with the

halves attached to the mounting frame, hook each of the hinges on the fascia side around the corresponding bar each

hinge on the mounting frame side, and latch each hinge. CONTINUE SUPPORTING THE FASCIA UNTIL YOU HAVE

VERIFIED THAT THE HINGES ARE ATTACHED AND SECURE.

Continue supporting the weight of the fascia, and test the ability of the fascia to swing freely on the hinges. If any

binding or limitation in the range of motion occurs, check each of the two hinges to ensure they are fully attached and

secure (see figure below).

3. Engage the ‘Hinge release lock’ spigot, fitted to each hinge to prevent accidental hinge latch release.

Thrii

Installation

Page 14 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

4. It is necessary to check the fascia alignment with the frame before proceeding further, as the hinges may need

adjustment. Carefully close the fascia ensuring the door opens and closes freely. In the closed position, visually check

the gap between the fascia and the wall along the hinged edge, and adjust the hinges as appropriate to ensure an

even fit using the adjustment screw on the hinges see figure below. Do not over-tighten as this may result in the fascia

damaging the wall finish. Horizontal adjustment of the fascia door can be configured.

5. Once the fit has been checked, close the fascia fully to check the locking bar operation. The locking bar is spring-

loaded and may require a firm push to engage correctly. To re-open insert the key provided into the fascia lock release

at the base of the fascia, ¼ turn anti-clockwise and push the key up to disengage the lock and allow the fascia to open

freely.

6. For installations where front access is not required in addition to the hinge release lock, engage the 2 hinge side locks,

rotating into the slot provided in the frame as shown in figure below and when the lock bar has been fully engaged,

relocate the top screw fixing into the locking position below, as shown in figure below.

Thrii

Installation

Page 15 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

6.5 Engine installation

1. Remove the engine cover, retaining the engine cover fixing.

2. Remove the securing pin out through the side from the base of the engine.

3. Present the engine to the engine mounting plate on the back of the fascia locating the dispensing nozzle into the

aperture provided. Align the engine on the plate and click into place.

4. Replace the securing pin through both mounting plates and engine ensuring it passes fully through this assembly.

Thrii

Installation

Page 16 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

5. Replace the engine cover, ensuring the flexible hose and soap hose attached does not foul upon reassembly, and

secure the cover into place with the fixing provided.

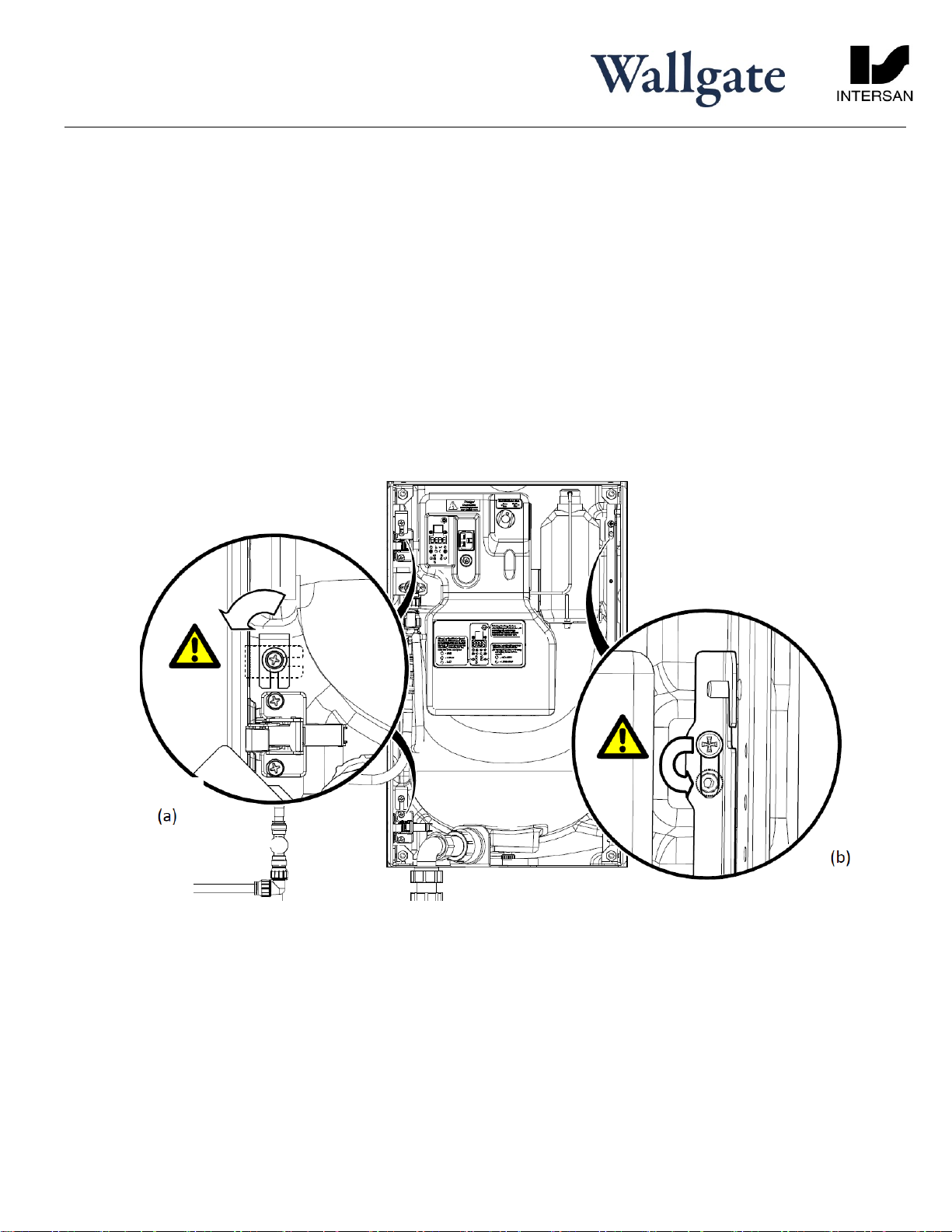

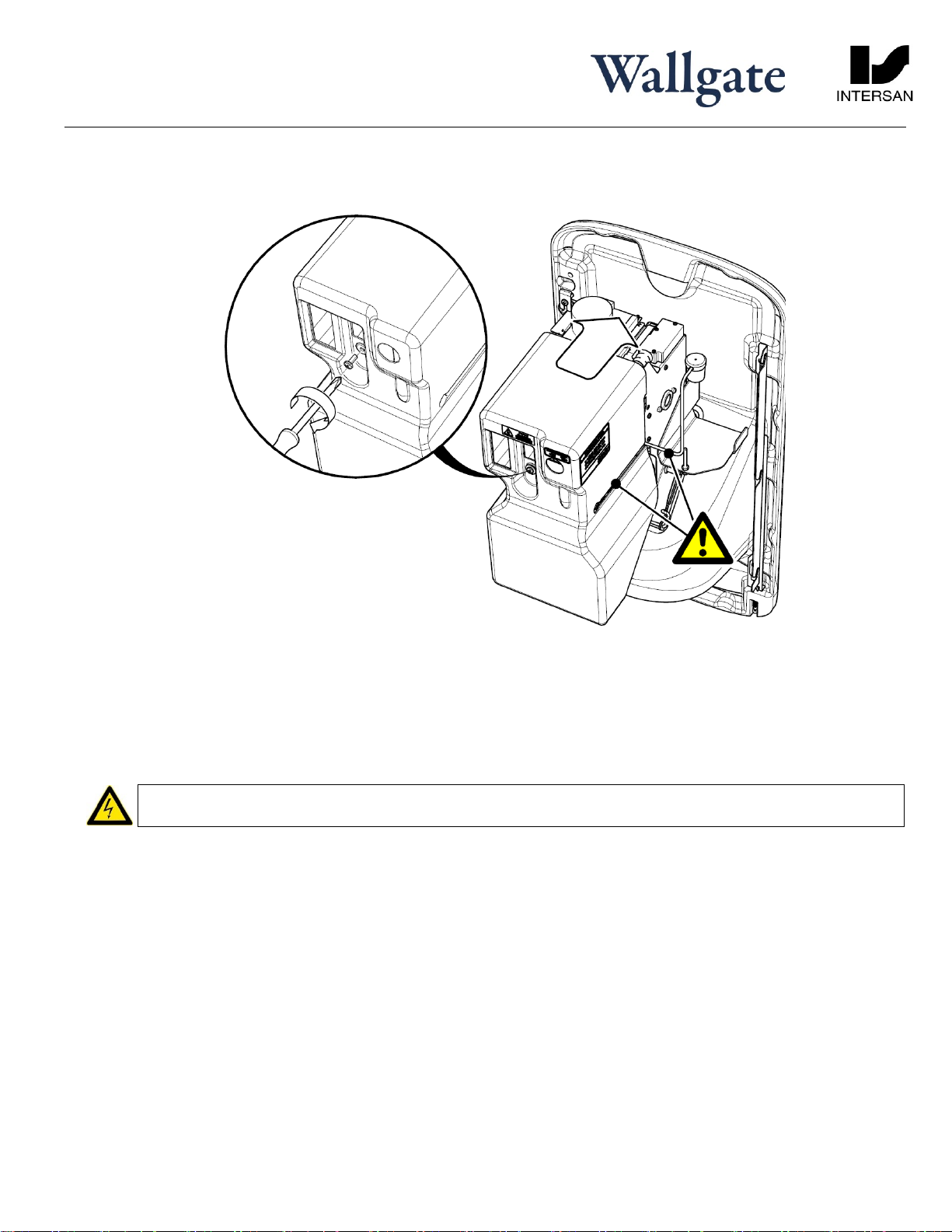

6.6 Electrical and Water Connections

From the rear side of the wall:

6.6.1 Electrical connection from the wall mounted fused spur switch to the Thrii:

All electrical work must be carried out by a qualified electrician and should be installed in accordance with the

current national, regional and local regulations.

GFCI protection is likely required, and should be installed in an appropriate manner per applicable electrical, plumbing

or building codes.

Complete the electrical connection by fitting the plug into the socket on the rear of the engine. Ensure the cable is a

suitable length so that the door can fully open without catching or fouling.

6.6.2 Mains water connection from support frame to the engine:

Using the flexible water hose provided take the loose end of the hose, which is attached to the engine, and attach it to

the water inlet connection mounted on the upper bracket part of the support frame (see figure below). With all

services connected to the Thrii, open and close the fascia assembly to ensure that the wiring and piping feeds move

without snagging or kinking. Ensure the waste spigot from the wash bowl smoothly engages with waste outlet on the

frame bracket.

Thrii

Installation

Page 17 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

6.7 Commissioning for use

To commission the Wallgate Thrii:

1. Ensure the engine cover is securely fitted and the electrical plug is fully pushed in.

2. Fully open the water supply valve to the unit. Check the system for external leaks. If no leaks, open the water valve on

the support frame.

3. Close the fascia, ensuring it closes fully against the wall. Adjust the hinges if required and push the fascia to the closed

position ensuring the locking bar engages fully.

The unit should only be operated with the fascia in the fully closed position and the waste outlet engaged.

Failure to do so may result in leakage.

4. Switch ON the circuit breaker to power up the circuit, which will turn on the Thrii, making the unit ready for use.

½” NPT

Cold water supply

Thrii

Installation

Page 18 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

5. Upon initial power-up the Thrii automatically runs through a 15 second water calibration cycle. This is repeated every

time the mains power supply is interrupted. This will also activate the clock on the LCD.

6. Reopen the fascia using the key provided.

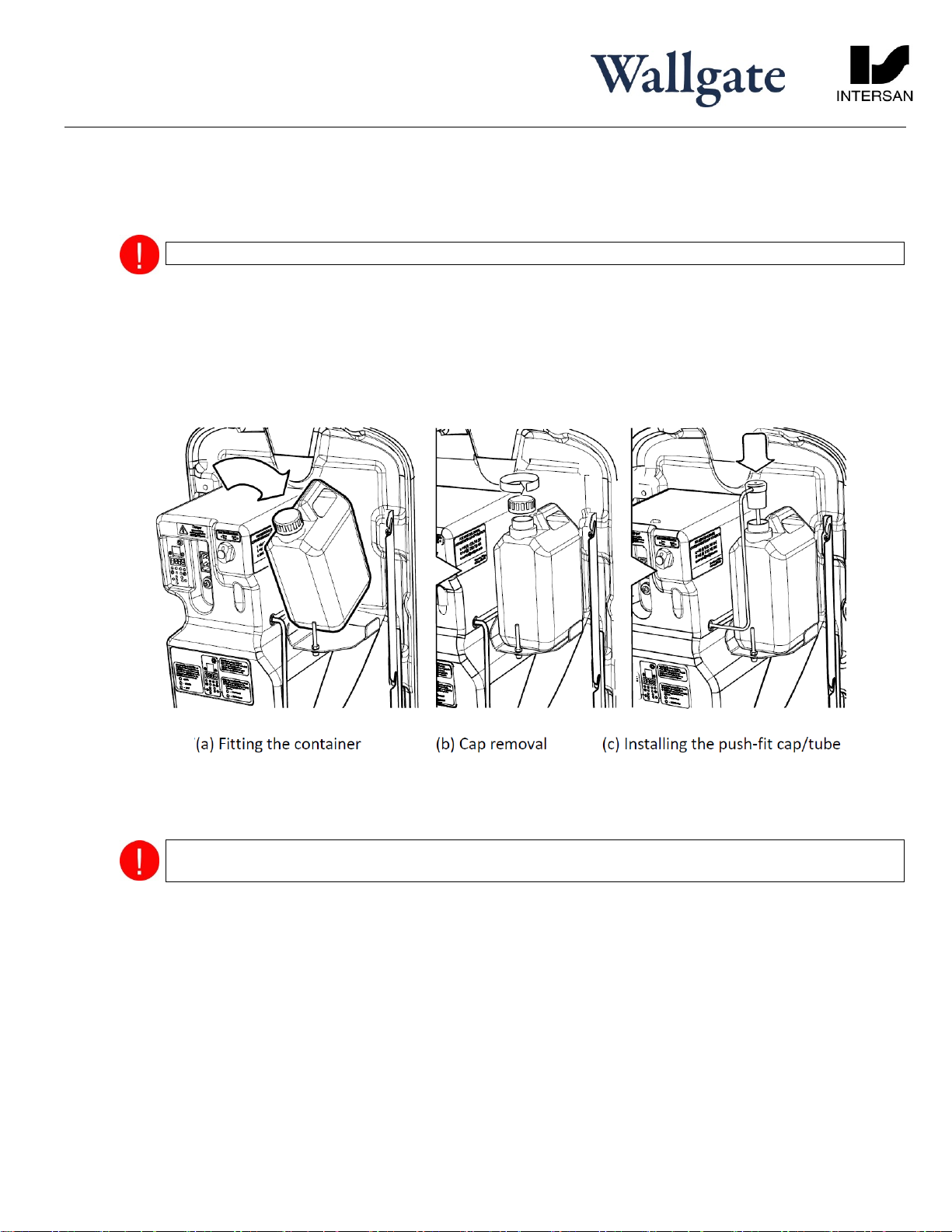

Important! A range of compatible liquid soaps & specifications are available from Intersan.

7. To install the soap container, place the soap container into its stowage position, to the right of the engine unit (figure

a), ensuring the cap is outer most.

8. Unscrew the cap from the soap container (figure b)and replace with the push-fit cap pre-connected to the soap tube

(figure c) pushing fully into place ensuring no leaks.

9. Press the soap prime switch, (located at the rear of the engine unit in the window aperture to the left of the mains

connector, until soap is consistently dispensed into the bowl.

If only rear access is required lock the fascia into the closed position using the front screw fixing and secure

using the fixings provided.

10. When ready for use, a green light will emit from the dispensing unit into the wash bowl. Once hands are placed under

the dispensing unit this light will turn to blue and will activate the wash cycle. The light then changes to red when the

hand dryer is operating.

Check the wash & dry cycles operates correctly as per the list of checks below and repeat the cycle at least five times.

Soap dispenses

Water dispenses & water is warm (Note that water dispenses whilst hand sensor detects the presence of hands in

the bowl, the water will stop when the sensor fails to detect any hands after a period of 2 seconds.

Hand dryer operates (Note that the dryer operates whilst the hand sensor detects the presence of hands in the

bowl, the dryer will stop when the sensor fails to detect any hands after a period of 2 seconds.

Thrii

Installation

Page 19 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

11. If required by the customer, fit the user instruction label to the dispensing unit.

12.Upon completion ensure that a copy of the instruction manual (or leaflet), the instruction label and the fascia lock key

are passed to the customer.

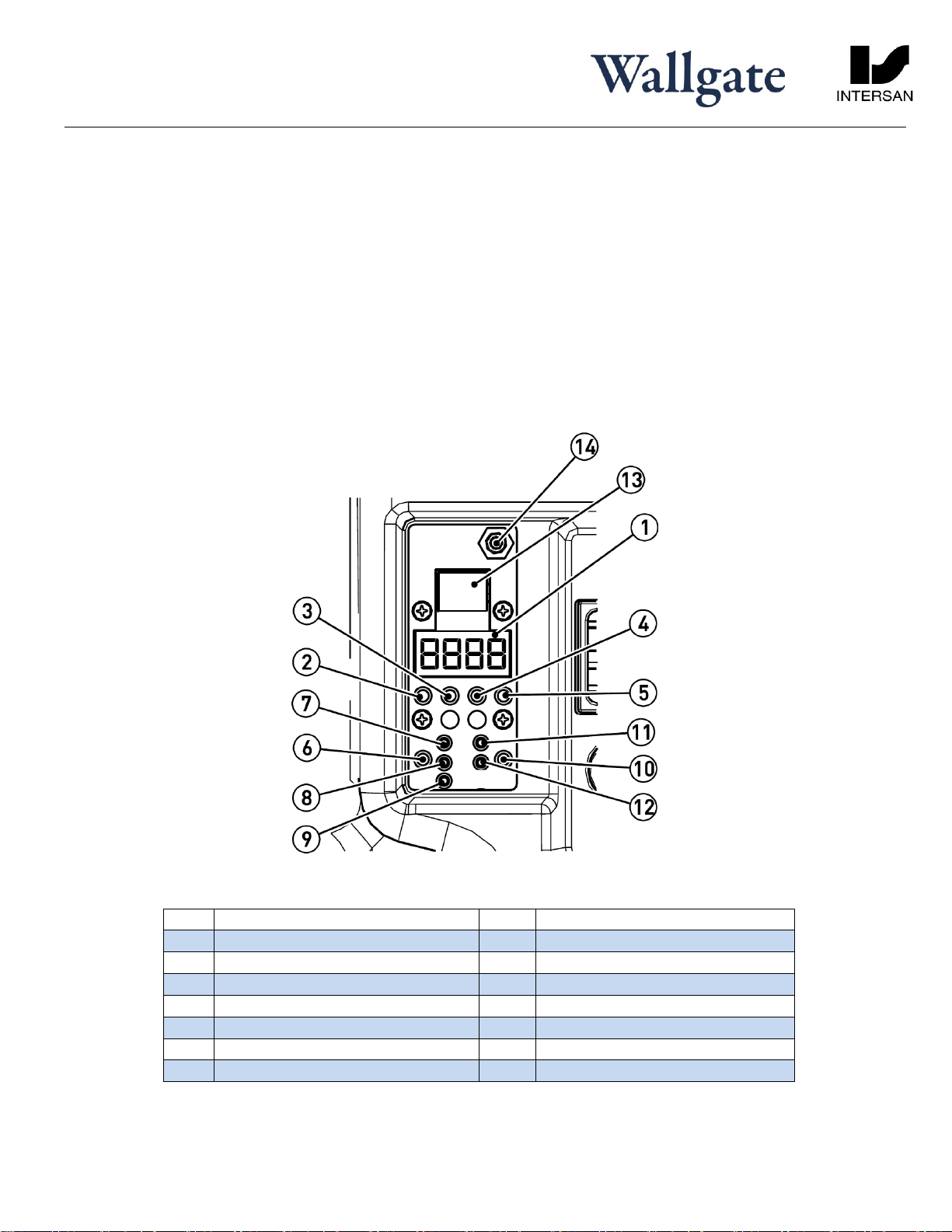

7. Program settings

The Wallgate Thrii operational program is supplied factory set but can be adjusted to suit the end user requirements

Any service or repair work must be done by a qualified engineer. During the warranty period, the service or repair must

only be done by a Wallgate engineer or appointed service agent. Refer to the Wallgate terms and conditions for warranty

information.

Item

Description

Item

Description

1

LCD

8

MED Fan speed LED indicator

2

Menu Select button

9

LOW Fan speed LED indicator

3

UP Button

10

SOAP Select button

4

DOWN Button

11

LIQUID LED indicator

5

ENTER Button

12

FOAM LED indicator

6

FAN SPEED Button

13

Ribbon cable connector

7

HIGH Fan speed LED indicator

14

Soap prime switch

Thrii

Installation

Page 20 of 23

All information including dimensions, changes in design and material are subject

to manufacturer’s change without formal notice and without obligation. Intersan

assumes no responsibility for use of superseded or voided information. Verify all

rough-in information before installation. It is the responsibility of the installer to

conform with local and national codes.

Intersan Manufacturing Company

1748 West Fillmore St., Phoenix, AZ 85007

Phone: 800-999-3101 Fax: 602-254-1776

intersanUS.com

THRII-inst-Rev1

by

7.1 Operation

The hand wash and dry cycle is activated when your hands are placed centrally into the wash bowl below the dispensing

nozzles. An infra-red sensor initiates the cycle when it detects hands in the bowl area. When the cycle starts, a sequence of

soap, warm water and hand dryer air are dispensed. Note that the hand dryer is programmed to cease operation shortly

after hands have been removed from the wash bowl, or when the pre-set dryer cycle time has been reached.

7.1.1 Soap Operation

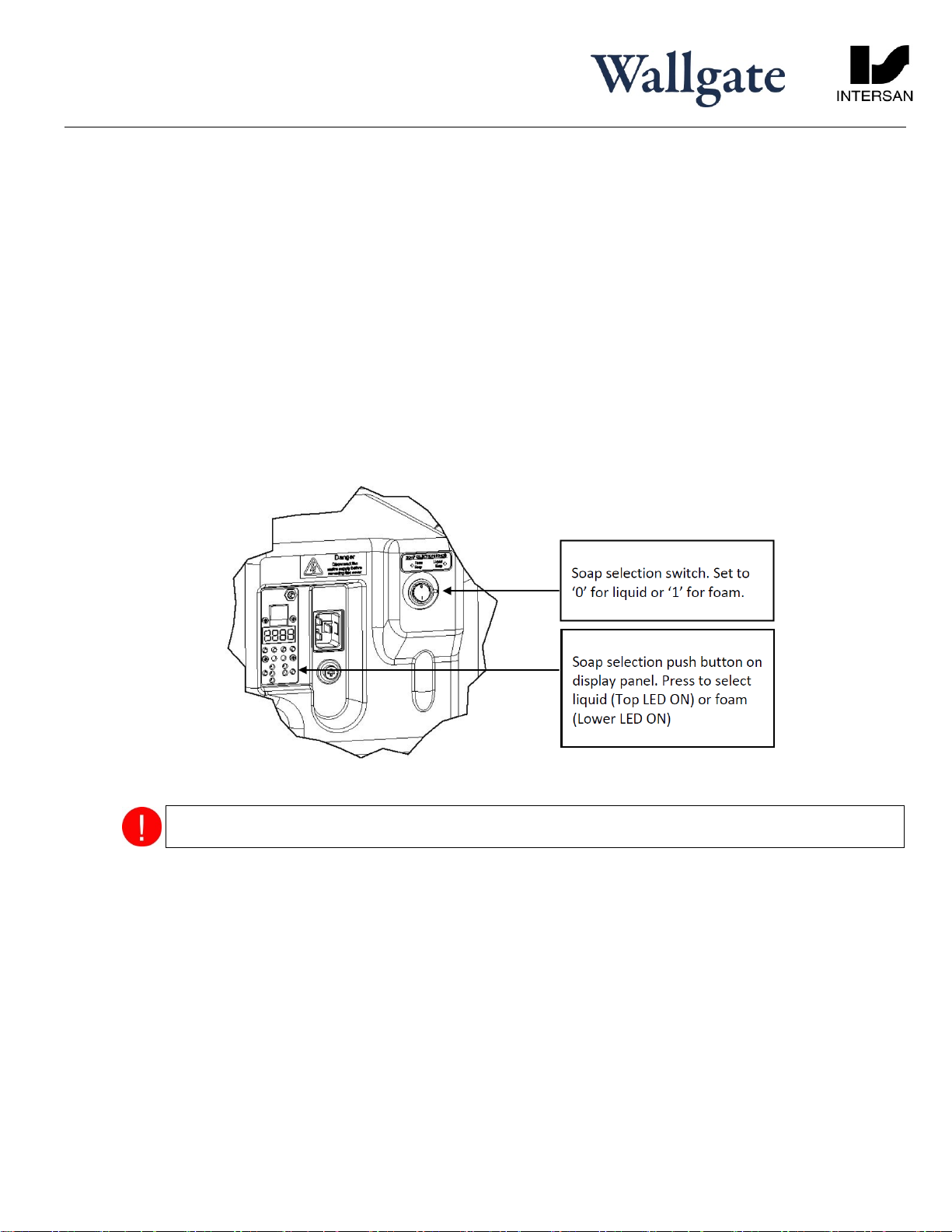

There are 2 settings for soap delivery, LIQUID (default) or FOAM. The controls to set the required soap option are located

on engine unit. To change the settings the unit must be powered up. There are 2 controls that need to be altered:

1. At the window to the left of the mains connector there is a small push button labelled ‘Soap’. Press and hold this

button to select the desired setting this will be confirmed by an illuminated LED.

2. Adjust the soap selection switch to position 1.

Ensure that both button setting and soap selection knob position select the same operation. Failure to do so

may result in an incorrect operation.

Low soap level indicator:

A function on the unit can be enabled, to indicate that the soap container level is low. When this function is set to ON

(Default setting is OFF) and the soap is at a low level the bowl light will pulse once per second. To turn ON this

function refer to section 7.2 for “Advanced Adjustments” and select menu item F146 which is the setting for number

of soap operations before the warning light is activated. Setting this to 20 will activate the warning light after 2000

operations. The setting may require adjustment if the number of operations per full soap container is found to be

fewer or greater than the setting.

To reset the warning light there are two options.

a. Press buttons 2 & 3 on the display together & hold for 5 seconds.

Table of contents

Popular Washer manuals by other brands

Electrolux

Electrolux EWF 12570 X user manual

Koenic

Koenic KWM 71412 A3 user manual

LG

LG F1612SBS owner's manual

Electrolux

Electrolux EW 806 F Installation and instruction manual

GE

GE PTW900BPTRS Owner's Manual & Installation Instructions

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES AMMCO 1475 Safety Instructions, Setup Instructions, Operating Instructions, Maintenance Instructions with Parts

Hotpoint Ariston

Hotpoint Ariston ARSF 109 Instructions for use

Zanussi Electrolux

Zanussi Electrolux ZWA 5120 instruction manual

Hobart

Hobart UCX Installation and operation instruction

Indesit

Indesit SIXL125SEU Service information manual

Rhima

Rhima RF450 Operator's manual

arcelik

arcelik 9100 PMG user manual