Interscan Corporation ACCUSAFE F901B User manual

Interscan Corporation.

Instruction Manual

ACCUSAFESensorModule

Accusafe Sensor Module User Manual 1 06/21/2021

Table of Contents

Section 1 - Introduction...................................................................................................................................... 2

1.1 Important Safeguards .............................................................................................................................. 2

1.2 Accusafe F901B Sensor Specifications..................................................................................................... 3

1.2.1 Sensor MODULE Configuration......................................................................................................... 3

Section 2 - Installation ........................................................................................................................................ 4

2.1 Enclosure Wall Mounting......................................................................................................................... 4

2.2 Wiring and Pneumatic Connections ........................................................................................................ 4

2.1.1 Power and MODBUS connections .................................................................................................... 4

2.1.2 Pneumatic connections..................................................................................................................... 5

Section 3 - Operation.......................................................................................................................................... 7

3.1 Pump & Sensor Operation....................................................................................................................... 7

3.2 MODBUS Operation................................................................................................................................. 7

3.2.1 RTU RS485 Configuration.................................................................................................................. 8

3.2.2 F-901B MODBUS Specifications........................................................................................................ 9

3.2.3 Input Registers.................................................................................................................................. 9

3.2.4 Holding Registers ............................................................................................................................ 10

3.2.5 Coils................................................................................................................................................. 10

Section 4 - Calibration....................................................................................................................................... 12

4.1 Zero Calibration ..................................................................................................................................... 12

4.1.1 Zero Calibration Procedure............................................................................................................. 13

4.2 Span Calibration..................................................................................................................................... 15

4.2.1 Gas Calibration Procedure......................................................................................................... 15

4.2.2 Digital Calibration Procedure.......................................................................................................... 18

Section 5 - Maintenance of the F-901B............................................................................................................ 20

5.1 Replacing the Gas Sensor....................................................................................................................... 20

5.2 Particulate Filter Maintenance .............................................................................................................. 21

Section 6 –Sensor Module Tester App............................................................................................................. 22

Section 7 - Warranty......................................................................................................................................... 25

Accusafe Sensor Module User Manual 2 06/21/2021

Section 1 - Introduction

To reduce the risk of fire, electrical shock, injury to persons or permanent damage to this device,

these safety precautions should always be followed:

•Use the included 12VDC power supply or specified power connector to operate this device.

Inappropriate voltage supply or power connector could cause irreparable damage to this

device.

•Make sure power plug and Modbus cable are plugged in and secured before powering up the

device. The power connector will not make connection to GND if not fully plugged into the

socket. Also make sure the locking ring is securely tightened.

•If sampling via tubing, make sure that the tubes are securely attached to the device before

operating. Use the provided particulate filter to prevent dust and particulates from entering the

device. See section 2.1.2, pg. 5.

•Do not operate the device with an obstructed flow path. Obstruction during air sampling will

damage the internal micropump. See section 5.2, pg. 21.

•Do not expose this device to any liquids.

•Sensors must not be exposed to temperature, humidity and pressure that are outside the

operating range. See section 1.2, pg. 3.

1.1 IMPORTANT SAFEGUARDS

Accusafe Sensor Module User Manual 3 06/21/2021

Measurements

Target Gas, RH, Temperature, Barometric

Pressure

Air Sampling Rate

60-160 mL/min (Pump speed 50% - 100%)

Measuring Rate

Continuous

Communication

Modbus via RTU/RS485 & TCP/IP

Sampling Port

Inlet/outlet with Luer lock fittings

Operating environment

0°C - 50°C, 15-90% relative humidity non-

condensing

Power Input

12VDC regulated

Avg. Power Consumption

2.5W

Dimensions

8 in x 4.7 in x 2.2 in (includes mounting flanges)

Weight

0.98kg

Enclosure

Powder-coated aluminum

Gas Sensor

Type

3 electrode electrochemical

Nominal Range

See section 1.2.1 below

Accuracy

± 2% of reading ± least significant digit

Lower Detection Limit

2 ppm

Response Time (T90)

< 3 minutes (varies by gas type)

Temperature Range

-20 °C to 50 °C (varies by gas type)

Pressure Range

atmospheric ± 10 %

Relative Humidity Range

15 % to 90 % R.H. non-condensing

Long Term Output Drift

< 2 - 5 % per month in continuous exposure

(varies by gas type).

Lifetime

2 –3 years (varies by gas type)

1.2.1 SENSOR MODULE CONFIGURATION

This section details the specific gas and range parameters for your ACCUSAFE instrument.

GAS –

SENSOR RANGE –

1.2 ACCUSAFE F901B SENSOR SPECIFICATIONS

Accusafe Sensor Module User Manual 4 06/21/2021

Section 2 - Installation

The sensor module is wall mountable using M5 or #10 screws. Install the module in the immediate

area from which you want to draw sample. Consideration should be givento the whether thetarget

gas is heavier or lighter than air in choosing the height of the installation location. Allow for 18”

total horizontal space to accommodate pneumatic and cabling connections to the sides of

the enclosure.

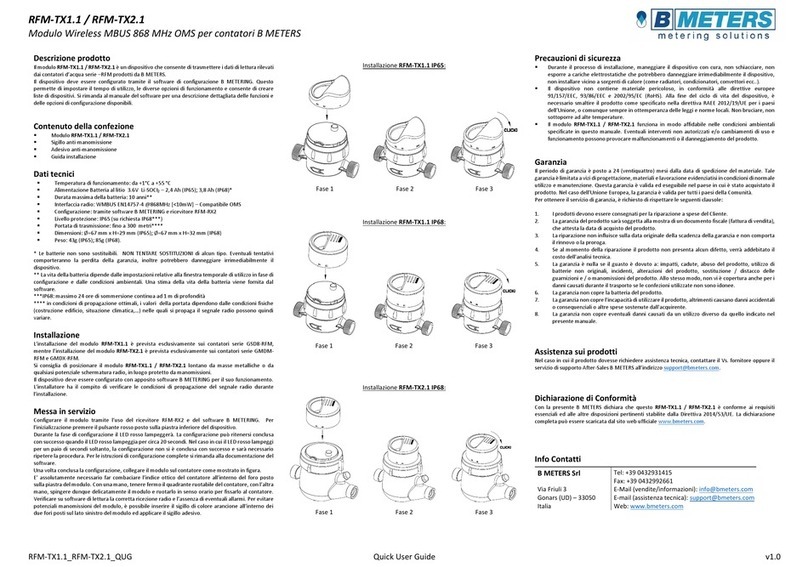

2.1.1 POWER AND MODBUS CONNECTIONS

Connect the 12V power adapter to the sensor module by inserting the plug into the 12V power

receptacle and tightening the lock ring snugly.

For TCP/IP communications applications, connect a standard CAT5 communications cable to the

MODBUS communications port. This cable will connect to the “ETHERNET” port on the

ACCUSAFE controller module for non-web browser single sensor applications or to an Ethernet

switch or hub for single or multi-sensor applications that utilize the web browser application.

For RTU (RS485) communications applications, connect a standard CAT5 communications cable

to the MODBUS communications port. This cable will connect to the “RS485” port on the

ACCUSAFE controller module for single sensor applications or to the next sensor in the daisy

chain for multi-sensor applications**.

**NOTE: Multi-sensor applications using RS485 connections will require a splitter device be used

at each node in the chain using a multi-drop (daisy chain) topology.

2.1 ENCLOSURE WALL MOUNTING

2.2WIRING AND PNEUMATIC CONNECTIONS

12V Power Receptacle

LED

ModBus Communication Port

Gas Inlet

Gas Outlet

Mounting Holes*

7

.

*accepts M5 or #10 screw

4

7

.

3.14 in

7

.

4

0

”

7.40 in

Accusafe Sensor Module User Manual 5 06/21/2021

NOTE: Waterproof cap for CAT5 cabling shown below (not provided with sensor) can be acquired

as needed at this link: https://www.installerparts.com/16279-patch-cable-waterproof-cap.html

2.1.2 PNEUMATIC CONNECTIONS

A particulate filter (pictured on the right) is provided for

connection to the inlet of the sensor module. This filter

protects the sensor and internal components from dust

and particulates that may be present in the sample.

To connect this filter, slip the end of the filter fitting into

the opening of the inlet fitting and rotate the filter in a

clockwise direction. Tighten snugly but do not over

tighten.

Connect exhaust tubing (1/8” I.D.) as needed by

inserting the provided barbed adapter fitting

connected to tubing into the OUTLET fitting as shown

on the right. Turn the fitting in a clockwise direction

until snugly tightened. Do not over tighten.

RJ45 Male Plug*

Waterproof Cap

ROTATE

Accusafe Sensor Module User Manual 6 06/21/2021

IMPORTANT:

•MAKE SURE POWER CABLE AND MODBUS CABLE ARE SECURED BEFORE POWERING

UP DEVICE.

•MAKE SURE THERE IS NO FLOW OBSTRUCTION AT INLET/OUTLET BEFORE POWERING

UP DEVICE.

•PARTICULATE FILTER SHOULD BE CHECKED PERIODICALLY AND REPLACED AS

NEEDED ACCORDING TO SECTION 5 OF THIS MANUAL.

Accusafe Sensor Module User Manual 7 06/21/2021

Section 3 - Operation

The ACCUSAFE F901B Sensor Module is designed for continuous operation when paired with

the ACCUSAFE Controller Module (see dedicated controller manual for operation of the

controller).

As soon as the F901B Sensor Module is powered up and the firmware is fully booted, the pump

will run continuously, drawing sample air past the sensor. The sensor’s output signal is

communicated via MODBUS to the controller which then displays this signal in graphical and

numeric forms.

The pump’s speed can be controlled at the controller if more or less flow rate is desired (factory

set nominal pumpspeed is 50%). This functionality is described in greater detail in the ACCUSAFE

Controller Module manual.

The F901B supports the standard Modbus protocol in both RTU and TCP/IP modes. The 3

available operation modes are detailed below. (see MODBUS MODE in table 3-4, pg. 10 for

Modbus mode register addressing information). AUTO MODE is the recommended mode and is

factory set prior to shipment:

•AUTO Mode (factory preset mode) - In this mode, if the sensor detects a connection to an

active Ethernet device, it will initialize Modbus TCP/IP protocol via the default static IP address

192.168.1.XX port 502 (The suffix of this address will be indicated on a label next to theEthernet

port. Address is configurable via Modbus commands where necessary. See SLAVE ADDR in

Table 3-4, pg. 10). If not connected to an Ethernet connection, it will initialize in RTU mode.

•Fixed TCP/IP mode - Upon powering up, the F901B always initializes the Modbus TCP/IP

protocol via the default static IP address 192.168.1.XX port 502 (The suffix of this address will

be indicated on a label next to the Ethernet port. Address is configurable via Modbus commands

where necessary. See SLAVE ADDR in Table 3-4, pg. 10).

•Fixed RTU mode - Upon powering up, the F901B always initializes the Modbus RTU protocol

via the default static IP address 192.168.1.XX port 502 (The suffix of this address will be

indicated on a label next to the Ethernet port. Address is configurable via Modbus commands

where necessary. See SLAVE ADDR in Table 3-4, pg. 10).

NOTE: The F901B sensor’s internal communications cabling is configured to operate in TCP/IP

mode. If operating in RTU mode is desired, the internal communications cabling will need to be

swapped. Contact the INTERSCAN SERVICE DEPT. for more information on making this

change.

3.1 PUMP & SENSOR OPERATION

3.2 MODBUS OPERATION

Accusafe Sensor Module User Manual 8 06/21/2021

3.2.1 RTU RS485 CONFIGURATION

RS485 cabling configuration is shown in the diagrams and table 3-1 below.

Pin

Name

Type

Description

1

3.3V

Reference potential

3.3V Reference Voltage

2

GND

Reference potential

Local device ground

3

UART_TX

Digital Output

Firmware update interface

4

B (D-)

Bus In/Out

Driver output and receiver input

5

A (D+)

Bus In/Out

Driver output and receiver input

6

UART_RX

Digital Input

Firmware update interface

7

BOOT

Digital Input

Firmware update interface

8

RESET

Digital Input

Microcontroller reset input (Active-Low)

Firmware update interface

TABLE 3-1

IMPORTANT: use pin 4,5 (B/A) and GND for Modbus RS485 communication. Pin 3,6,7,8 are

reserved for firmware updating and are 3.3V tolerant.

Absolute Maximum Rating

Voltage range at A or B ………………………………………………. -8V to 12V

Voltage range at pin 3,6,7,8 ……………………………………….. -0.3V to 4V

Electrostatic discharge at A and B ………………………………. ±8kV

RS485 Modbus Parameters

Parameter

Value

Default

address

50

Baud Rate

19200

Data bits

8

Parity

Even

Stop bits

1

TABLE 3-2

Bottom

View

Accusafe Sensor Module User Manual 9 06/21/2021

3.2.2 F-901B MODBUS SPECIFICATIONS

•Operates as a slave, half-duplex mode

•Modbus functions supported:

o0x01 - Read Coils

o0x03 - Read Holding Registers

o0x04 - Read Input Registers

o0x05 - Write Single Coil

o0x06 - Write Single Register

o0x0F - Write Multiple Coils

o0x10 - Write Multiple Registers

•Exception messages supported

•Default address:

oRTU: 50

oTCP/IP: 192.168.1.50

3.2.3 INPUT REGISTERS

Mode: Read-only, size: 16 bits

Name

Address

Description

SENSOR OUTPUT

0

Gas measurement x 10, ppm

TEMPERATURE

3

Temperature measurement x 10, C (Note: 16bit

signed number)

RELATIVE HUMIDITY

4

Relative Humidity measurement x 10, %

BAROMETER

5

Barometric pressure measurement x 10, mbar

VAPOR PRESSURE

6

Vapor pressure of water measurement x 10, mbar

ERROR STATUS

9

0 = OK.

1 = C2H4 offset error, Sensor over-exposed or

KMnO4 filter needs to be replaced.

SENSOR_RAW_VALUE

10

C2H4 raw measurement, count

DEV_TYPE

100

Default device type ID: 9011

FIRMWARE

101

Firmware version

TABLE 3-3

NOTE:

•Above addresses are offsets. The function address for input register is [30001 + offset]

•Temperature and Humidity are measured at the sensor’s inlet and may not represent room

condition or remote/localized spots. External temperature probe provided in F901B v2 sensor.

Accusafe Sensor Module User Manual 10 06/21/2021

3.2.4 HOLDING REGISTERS

Mode: Read/Write, size: 16 bits (unsigned)

Name

Address

Default

Description

PUMP_POWER

0

50

Internal pump power 0-100%

SENSOR_SPAN

1

NONE

Sensor span calibration parameter. Calibration formula:

SENS_SPAN=SENS_CUR*SENS_SPAN_CUR/SENS_CAL

Note: SENS_CAL: expected calibration concentration

SENS_SPAN_CUR: Current span value

SENS_CUR: Current SENSOR measurement

SENSOR_ZERO

2

NONE

SENSOR zero calibration parameter

SLAVE_ADDR

30

50

Device Modbus RTU slave address. Update this

register to change the slave address. Valid slave

addresses: 0-99

MODBUS_MODE

31

0

0: TCP/IP (LED blinks 2 times at boot)

1: RTU (LED blinks 3 times at boot)

2: Auto Config Mode. (Factory Default) During boot up,

if the internal TCP/IP cable is plugged in and the device

is connected to active ethernet hub/router or the F901C

Controller, the device will select TCP/IP mode.

Otherwise, RTU mode is selected.

IP_ADDR0

32

192

Device local IP address

IP_ADDR1

33

168

Device local IP address

IP_ADDR2

34

1

Device local IP address

IP_ADDR3

35

50

Device local IP address

TABLE 3-4

NOTE:

•Above register addresses are offsets. The function addressfor holding register is [40001 + offset]

•Values written to the above holding registers remain after Power-off/Reset

IMPORTANT:

•Changing the pump power to different value than the factory default may affect measurement

accuracy. In such case, a complete sensor re-calibration is recommended.

•Backup calibration parameters before overwriting their values (performing a calibration) or

update device firmware(all parameters will be erased). All F-901B comes with factory calibration

using standard certified gases.

3.2.5 COILS

Mode: Read/Write, size: 1 bit

Name

Address

Default

Description

CONF

7

False

Confirmation of zero action

RESET

9

False

True: (software) reset

False: no action

Note:

•Above addresses are offsets. The function address for coil is [00001 + offset]

Accusafe Sensor Module User Manual 11 06/21/2021

IMPORTANT:backup calibration parameters before performing a calibration. A calibration will

overwrite the factory calibration parameter in the Holding register.

Accusafe Sensor Module User Manual 12 06/21/2021

Section 4 - Calibration

All units are shipped factory‐calibrated. Over time all sensors require recalibration to compensate

for natural sensor sensitivity loss. The performance of a sensor or the whole instrument should be

checked occasionally with calibration gas. When there is significant accuracy error in response,

calibration may be indicated.

NOTE: Because environmental conditions may differ between factory calibration and installation,

it is a good idea to challenge the sensor with a known concentration of gas upon installation to

confirm the calibration integrity following shipping. Re-calibration may be indicated if reading error

is significant.

Calibration frequency depends on a number of factors including application, environmental

conditions, local regulations and accuracy requirements. Calibrating every quarter is a good

starting point. If significant scaling adjustment is required during calibration using this interval,

more frequent calibration is indicated.

There are several options for calibration:

•You can ship your F-901B sensor module back to Interscan Corp. for calibration.

•You can order pre-calibrated sensors from Interscan for replacement of the existing sensor and

perform Digital Calibration after installation (See section 4.2.2, pg.18)

•You can calibrate the sensors yourself (Gas Calibration –See section 4.2.1, pg. 15).

NOTE 1: If performing calibration yourself, replace the sensor when its sensitivity (span) is

below 50 % of its initial value. Initial SPAN value can be determined from the “Sens Span” value

on the SENS DATA Panel in the Control Panels Menu of the Controller. See section 3.1.2, Figure

3-4 of the Controller Module User Manual for details on accessing this parameter.

NOTE 3: Calibration procedures will entail making numeric entries

on the pop-up screen shown to the right. The current value is shown

at the top of the window. Always clear this value first by touching the

C button (red arrow shown on right) before entering a new value.

Use the BACKSPACE button (green arrow shown on right) to erase

individual digits and use the ENTER button (yellow arrow shown on

right) to save the entered value.

Zero calibration should be performed periodically to compensate for natural temperature drift in

the gas sensor. Zeroing should also be performed upon initial start-up and prior to every SPAN

calibration. In applications where temperature swings are significant, daily zeroing may be

indicated.

4.1 ZERO CALIBRATION

Accusafe Sensor Module User Manual 13 06/21/2021

In most cases clean ambient air can be used for

zeroing as long as it is known to be free of any

interference gases. Some interferences can be

eliminated with the use of the provided charcoal

scrubber filter shown to the right. This filter attaches

to the inlet filter as shown.

O2can also be used as a zero gas where clean

ambient air is not available and charcoal scrubbing

is not effective. DO NOT USE NITROGEN AS A

ZERO GAS FOR THE ACCUSAFE SYSTEM.

If using a pressurized gas bottle and pressure-controlled regulator for O2zeroing, follow the setup

below to properly apply the gas at the sensor’s INLET fitting (limit pressure to 4 PSI or lower).

If using an On-demand type regulator, the T junction fitting can be omitted.

4.1.1 ZERO CALIBRATION PROCEDURE

1) Open the CALIBRATION screen on the Controller Module by touching the CALIBRATION

icon on the main toolbar as shown below.

2) Select the ZERO radio button as shown by the arrow below.

Excess Gas

INLET

T JUNCTION

PRESSURE REGULATOR

Accusafe Sensor Module User Manual 14 06/21/2021

3) Enter the correct Sensor Slave Address by touching the entry field (circled in the image

above) and entering the address number on the pop-up entry screen.

-For TCP/IP applications, the slave address will be 192.168.1.XX (substitute the Sensor

module’s modbus address for “XX”).

-For RTU applications, the slave address will only be the 2 digit modbus address. Be sure

to check that the address is correct before continuing.

4) Enter the Calibration Duration time in minutes by touching the entry field circled below and

entering the number on the pop-up entry screen. Typically 2-3 minutes is adequate for most

applications.

5) Tick or untick the Pump On During Calibration checkbox (red arrow above) for your

application. PUMP ON will be the correct selection in most applications. Consult with the

INTERSCAN Service Dept. for guidance if unsure.

6) Connect the zero air sample source to the inlet of the F901B sensor as shown on the previous

page.

7) Touch the “NEXT STEP” button to advance.

8) Wait while the Zero calibration timer elapses as indicated by the green timeline bar. Press

“ABORT” to cancel the calibration if desired.

Accusafe Sensor Module User Manual 15 06/21/2021

9) When the calibration timer has elapsed, a “Calibration Completed” window will be displayed

as shown below. Press “OK” to accept then press “EXIT” to return to the main SENSOR

CALIBRATION screen.

10)If finished with calibration, select the desired screen from the main toolbar.

SPAN Calibration compensates for sensitivity loss in the gas sensor. The instrument can be

calibrated in one of two ways:

Gas Calibration - A known concentration of gas is introduced and the sensor is allowed to

respond over the calibration sampling period. The calibration scaling is automatically updated at

the end of this sampling period.

The sources of gas standards include commercially available gas mixtures diluted with air in

cylinders or permeation devices. NOTE: Gas blends in a balance of nitrogen should not be

used with the Accusafe sensors.

Digital Calibration –A pre-calibrated sensor is provided by Interscan to replace the old sensor.

The new sensor is accompanied by a calibration certificate that includes a sensitivity value to be

entered during the Digital calibration procedure.

4.2.1 GAS CALIBRATION PROCEDURE

1) Open the CALIBRATION screen on the Controller Module by touching the CALIBRATION

icon on the main toolbar as shown below.

2) Select the Gas Calibration radio button as shown by the arrow below.

4.2 SPAN CALIBRATION

Accusafe Sensor Module User Manual 16 06/21/2021

3) Enter the correct Sensor Slave Address by touching the entry field (circled in the image

below) and entering the address number on the pop-up entry screen.

-For TCP/IP applications, the slave address will be 192.168.1.XX (substitute the Sensor

module’s modbus address for “XX”).

-For RTU applications, the slave address will only be the 2 digit modbus address. Be sure

to check that the address is correct before continuing.

4) Enter the Calibration Duration time in minutes by touching the entry field circled below in

red and entering the number on the pop-up entry screen. Typically 5 minutes is adequate for

most applications.

5) Enter the Calibration Concentration [PPM] value by touching the entry field circled above

in green and entering the number on the pop-up entry screen. This is the value of the CAL

GAS concentration being used for calibration.

NOTE: If the cal gas being used is measured in PPB units, be sure to convert its value

to PPM for this entry –i.e. if the Cal Gas is specified as 500 PPB, the entry would be

0.5 PPM.

Accusafe Sensor Module User Manual 17 06/21/2021

6) Leave the Calibration in Trigger Mode box indicated by the red arrow above UNTICKED.

This option will not apply to most Accusafe applications.

7) Touch the “Next Step” button to advance the cal routine.

8) Connect the CAL GAS supply to the inlet of the sensor module as indicated on the screen

shown below. Touch the “NEXT STEP” button when ready. Touching the “RESET” button will

cancel the calibration.

NOTE: When using CAL GAS from a pressurized source, be sure to include an “on demand”

regulator at the source OR a tee fitting between the source and inlet as shown below. (limit

pressure to 4 PSI or lower).

9) Wait while the Span calibration timer elapses as indicated by the green timeline bar. During

this time, the gas sensor will respond to the Cal Gas as indicated by the green “Sensor

Measurement” value. The screen also displays the Calibration Concentration, the previous

span value, and the new updated span value (shown after cal is completed). Press “ABORT”

to cancel the calibration if desired.

Excess Gas

INLET

T JUNCTION

PRESSURE REGULATOR

Accusafe Sensor Module User Manual 18 06/21/2021

10)Once the calibration timer elapses and the verification process is complete, a new window

will display “Calibration Completed”. Click OK to accept the calibration and EXIT to return

to the main sensor calibration screen.

4.2.2 DIGITAL CALIBRATION PROCEDURE

1) Replace the existing sensor with the pre-calibrated sensor provided by Interscan Corp. (See

section 5-1, pg. 20 for directions on replacing the sensor). With power applied to the sensor

module, allow 24 hours for the new sensor to stabilize before calibrating.

2) Perform a ZERO calibration according to section 4.1.1, pg. 13.

3) Open the CALIBRATION screen on the Controller Module by touching the CALIBRATION icon

on the main toolbar as shown below.

4) Select the Digital Calibration radio button as shown below (red arrow)

Accusafe Sensor Module User Manual 19 06/21/2021

5) Enter the correct Sensor Slave Address by touching the entry field (circled in red in the image

above) and entering the address number on the pop-up entry screen.

-For TCP/IP applications, the slave address will be 192.168.1.XX (substitute the Sensor

module’s modbus address for “XX”).

-For RTU applications, the slave address will only be the 2 digit modbus address. Be sure

to check that the address is correct before continuing.

6) Enter the Sensor Sensitivity (nA/PPM) value as indicated on the calibration certificate that

accompanied the sensor. Touch the field shown above circled in green and enter this value

on the pop-up entry screen. Be sure this value is correct before proceeding. Touch the NEXT

STEP button when satisfied with your entry.

7) The confirmation screenshown below will now bedisplayed indicating that the sensitivity value

was set. Touch the OK button to confirm then touch the EXIT button to complete the

calibration.

Table of contents

Other Interscan Corporation Control Unit manuals