Intertek Jotul GF 400 DV Sebago User manual

1

137750_Rev_L 11.16.12

Installation and

Operation Instructions

Jøtul GF 400 DV Sebago

Direct Vent Gas Stove

– Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS

•Donottrytolightanyappliance.

•Donottouchanyelectricalswitch;donot

use any phone in your building.

•Immediatelycallyourgassupplierfroma

neighbor’sphone.Followthegassupplier’s

instructions.

•Ifyoucannotreachyourgassupplier,call

the fire department.

– Installation and service must be performed

byaqualifiedinstaller,serviceagencyorthe

gas supplier.

– IntheCommonwealthofMassachusetts,

a carbon monoxide (CO) detector shall be

installed in the same room as the appliance.

WARNING: If the information in these

instructionsisnotfollowedexactly,afire

or explosion may result causing property

damage,personalinjuryorlossoflife.

INSTALLER:Leavethismanualwiththeappliance.

CONSUMER: Retain this manual for future reference.

– QUEFAIRESIVOUSSENTEZUNEODEURDEGAZ:

•Nepastenterd’allumerl’appareil.

•Netouchezàaucuminterrupteur.Ne

pas vous servir des téléphones se trouvant

danslebâtimentoùvoustrouvez.

•Appelezimmédiatementvotre

fournisseurdegazdepuisunvoisin.

Suivezlesinstructionsdufournisseur.

•Sivounepouvezrejoindrele

fournisseurdegaz,appelezleservicedes

incendies.

– L’installatione l’entretien doivent être

assurés par un installateur ou un service

d’entretien qualifié ou par le fournisseur

degaz.

– Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables

dans le voisinage de cet appareil ou de tout

autre appareil.

AVERTISSEMENT:Assurez-vousdebien

suivreles instructions données dans cette

notice pour réduire auninimum le risque

d’incendie ou d’explosion ou pour éviter

toutdommagematériel,touteblessureoula

mort.

ATTENTION : CES INSTRUCTIONS DOIVENT

DEMUERER AVEC LE PROPRIÉTERE D’UNE

MAISON.

Thisappliancemaybeinstalledinanaftermarket,

permanentlylocated,manufacturedhomeormobile

home,wherenotprohibitedbylocalcodes.

Thisapplianceisonlyforusewiththetypesofgas

indicated on the ratingplate. A conversionkit is

suppliedwiththeappliance.

2

137750_Rev_L 11.16.12

We recommend that

our gas products be

installed and serviced by

professionals who are

certified in the U.S. by

the National Fireplace

Institute® (NFI) as NFI

Gas Specialists.

Installation Requirements

fortheCommonwealthof

Massachusetts

THIS PRODUCT MUST BE INSTALLED BY

A LICENSED MASTER OR JOURNEYMAN

PLUMBER OR GASFITTER WHEN

INSTALLED IN THE COMMONWEALTH OF

MASSACHUSETTS.

1. If there is not one already present,

on each floor level where there are

bedroom(s), a carbon monoxide

detector and alarm shall be placed in

the living area outside the bedroom(s).

The carbon monoxide detector shall

comply with NFPA 720 (2005 Edition).

2. A carbon monoxide detector shall:

a) Be located in the room that houses

the appliance or equipment;

b) Be either hard-wired or battery

powered or both; and

c) Shall comply with NFPA 720 (2002

Edition).

3. A Product-approved vent terminal

must be used, and if applicable, a

Product-approved air intake must

be used. Installation shall be in strict

compliance with the manufacturer’s

instructions. A copy of the installation

instructions must remain with

the appliance or equipment at the

completion of the installation.

THIS OWNER’S MANUAL PROVIDES INFORMATION TO

ENSURESAFEINSTALLATIONANDEFFICIENT,DEPENDABLE

OPERATION OF YOUR FIREPLACE INSERT. PLEASE READ

THESE INSTRUCTIONS IN THEIR ENTIRETY AND MAKE THEM

AVAILABLETOANYONEUSINGORSERVICINGTHISGAS

INSERT.

DO NOT ATTEMPT TO ALTER OR MODIFY THE CONSTRUCTION

OF THIS APPLIANCE OR ITS COMPONENTS. ANY

MODIFICATIONORALTERATIONWILLVOIDTHEWARRANTY,

CERTIFICATION AND LISTING OF THIS APPLIANCE.

THISHEATERMUSTBEINSTALLEDANDMAINTAINEDBYA

QUALIFIED SERVICE AGENCY.

Suggested Tools for

Installation and Service

• Externalregulator(forPropaneonly)

• Pipingwhichcomplieswithlocalcode

• Manualshut-offvalve-

T-HandlerequiredinMassachusetts

• Sedimenttrap-ifrequiredbycode

• Teejoint

• Pipewrench

• Pipesealant

• 10mmopenendwrench

• 1/2”,7/16”openendwrench

• Phillipsheadscrewdriver

• Flatheadscrewdriver

• 1/4”nutdriver

• Gloves

• Safetyglasses

• TorxT-20screwdriver

•Tinsnips

61.6%

Jøtul GF 400 DV

3

137750_Rev_L 11.16.12

Table of Contents

Service Tools .............................................2

Specifications ............................................4

General Information................................5

Safety Information ..................................6

Installation Requirements

Location ................................................6

Hearth Protection ...............................6

Clearances ............................................. 7

Mantel&Trim ......................................7

Alcove ....................................................7

Vent Requirements ..................................8

Adding Restriction...............................8

Vertical Termination ...........................9

Co-linear Termination.................... 12

Coaxial Chimney Conversion ......13

Horizontal Termination.................... 14

Vent Terminal Clearances ................15

MobileHomeInstallation ....................16

Fuel Conversion.......................................16

Gas Connection....................................... 18

Gas Pressure ............................................19

HighAltitudeAdjustment ...................19

AirShutterAdjustment ...................... 20

Wall Thermostat.................................... 20

Remote Control...................................... 20

Log Set Installation ................................ 21

System Check ..........................................22

Operation .................................................23

Maintenance ...........................................24

Glass Replacement.............................24

Optional Blower Installation ..............25

Optional Brick Kit Installation ............27

Illustrated Parts Breakdown ................28

Replacement Parts List......................... 29

Warranty Statement ............................ 30

Lighting Instructions ..............................31

Jøtul GF 400 DV Sebago

Direct Vent Gas Heater

Manufactured and Distributed by:

Jøtul AS

Fredrikstad,Norway

Jøtul North America

55 Hutcherson Dr.

Gorham,Maine04038-2634

Test Standards

This appliance complies with

National Safety standards

and is tested and listed by

Intertek Testing Services of

Middleton,Wisconsinto

ANSI Z21.88-2009,

ANSIZ21.88/CSA2.33-2009,

CAN/CGA2.17-M91,andCSA

P.4-01.2

DO NOT ATTEMPT TO ALTER OR MODIFY THE

CONSTRUCTION OF THE APPLIANCE OR ITS COM-

PONENTS. ANY MODIFICATION OR ALTERATION

WILLVOIDTHEWARRANTY,CERTIFICATIONAND

LISTING OF THIS APPLIANCE.

Your stove has a unique serial number stamped on the

rating plate which is hung on the back. Please record

the serial number in the space below. You may also wish

to attach your purchase receipt to this page for future

reference.

MODELNAME:JøtulGF400 DV Sebago Gas Stove

SERIALNUMBER:_______________________________

DATEOFPURCHASE:____________________________

AUTHORIZEDDEALER:__________________________

ADDRESS___________________________________

PHONE:____________________________________

INSTALLER:__________________________________

FUELTYPE:____________________________________

FUELCONVERSION:NO_______YES_____

NOTES:________________________________________

______________________________________________

______________________________________________

4

137750_Rev_L 11.16.12

THIS FIREPLACE IS SHIPPED FROM THE FACTORY

FOR USE WITH NATURAL GAS ONLY. IF USE

WITHPROPANEISDESIRED,THEAPPLIANCE

MUSTFIRSTBECONVERTEDUSINGTHE

FUELCONVERSIONKITPROVIDED,#155351.

CONVERSIONSHOULDBEMADEBEFORETHE

APPLIANCEISINSTALLED.SEEPG.16.

Jøtul GF 400

Input Rates

Natural Gas

32,000BTU/hr.maximuminput

18,000BTU/hr.minimuminput

Propane

32,000BTU/hr.maximuminput

16,000BTU/hr.minimuminput

Inlet Pressure: MIN MAX

NaturalGas: 5.0WC(1.24kPa)7.0WC(1.74kPa)

Propane: 12.0WC(2.99kPa)14.9WC(3.71kPa)

Manifold Pressure: MIN MAX

Natural Gas: 1.2 WC (.30 kPa) 3.8 WC (.95 kPa)

Propane: 2.9WC(.722kPa)11.0WC(2.74kPa)

PiezoIgnitor/StandingPilot

261/2”

673mm

13”

330 mm

DV Sebago

Specifications

Top Exit

29”

737 mm

191/2”

495mm

121/4”

311 mm

7”

178 mm

C

L

281/2”

724mm

261/2”

673mm

10”

254mm Gas Inlet

*Forheightwith6”Legs,subtract21/4”

Rear Exit

251/2”*

647mm

281/2”*

724mm

195/8”

500 mm

C

L

5

137750_Rev_L 11.16.12

HardwareBagContents

• FuelConversionKit-LP.................................... 155351

• EmberBag,4oz. ............................................... 129123

• RockWool,1oz,..................................................157259

General Information

THISHEATERMUSTBEINSTALLEDANDMAINTAINED

BY A QUALIFIED SERVICE AGENCY.

The installation and repair of this appliance must be

done by a qualified service person. Failure to properly

install and maintain this heater could result in an

unsafe or hazardous installation, which may result in

afire,explosion,propertydamage,personalinjuryor

loss of life.

This appliance should be inspected before use and

atleastannually.Morefrequentcleaningmaybe

required due to excessive lint from carpeting, bedding

material, etc. It is imperative that control compart-

ments, burners, and circulating air passageways of

the appliance be kept clean.

THISAPPLIANCEMUSTNOTBECONNECTEDTOA

CHIMNEYORFLUESERVINGANYOTHERAPPLIANCE.

The installation must conform to local codes. Your lo-

calJøtuldealercanassistyouindeterminingwhatis

required in your area for a safe and legal installation.

Some areas require a permit to install a gas burning

appliance. Always consult your local building inspec-

tor,orauthorityhavingjurisdiction,todetermine

what regulations apply in your area.

CODECOMPLIANCE:Yourlocalofficialshavefinal

authority in determining if a proposed installation is

acceptable. Any requirement that is requested by the

localauthorityhavingjurisdiction,thatisnotspecifi-

cally addressed in this manual, defaults to local code.

In the absence of local codes, the installation require-

ments must comply with the current National codes.

In the U.S., these requirements are established in the

NationalFuelCode,ANSIZ223.1.(NFPA54).InCanada,

thecodeshavebeenestablishedinCAN/CGAB149

Fuel Installation Code.

Installer l’appareil selon les codes ou reglements

locaux, ou, en l’absence de tels reglements, selon les

Codesd’installationCAN/CGA-B149.

DO NOT OPERATE THIS STOVE IF ANY PART HAS BEEN

UNDER WATER. Call a qualified service technician to

inspect the heater and to replace any part of the con-

trol system and any gas control which may have been

under water.

Ne pas se servir de cet appareil s’il a ete’ plonge dans

l’eau, completement ou en partie. Appeler un tech-

nicien qualifie pour inspecter l’appareil et remplacer

toute partie du syste’me de controle et toute com-

mande qui ont ete plonges dans l’eau.

Glass Panel

Do not operate this appliance with the glass

front removed, cracked, or broken. Replacement

of the glass should be done by a licensed or

qualified service person. Only remove glass for

routine service. Always handle glass carefully.

Unpacking your stove

1. Remove the Top Plate of the stove by simply lifting it

straight off of the stove body.

2. To open the firebox, disengage the two Glass Frame

Latches located on top of the firebox. Pull each handle

forward to clear the latch from the notch in the frame.

3. Familiarize yourself with the installation requirements

specified in this manual,before beginning the installation.

Glass Frame

Latch

6

137750_Rev_L 11.16.12

Location

In selecting a location for the stove, consider the

following points:

1) Heat distribution

2) Vent termination requirements

3) Gas supply line routing

4)Trafficareas,furniture,draperies,etc.

TheGF400DVSebagomaybelocatedonornear

conventional construction materials, however, proper

clearance to combustibles must be maintained in order

to provide adequate air circulation around the appliance.

Also, it is important to provide adequate access around

the stove for servicing and proper operation.

The clearance and hearth specifications listed in this

manual are the minimum requirements for combustible

material. A combustible material is anything that can

burn (i.e. sheet rock, wall paper, wood, fabrics etc.). These

surfaces are not limited to those that are visible and also

include materials that may be located behind non-com-

bustibles.

If you are not sure of the combustible nature of a

material, consult your local fire officials. Remember,“Fire

Resistant”materialsareconsideredcombustible:theyare

difficulttoignite,butwillburn.Also,“fire-rated”sheet

rock is considered combustible.

Hearth Requirements

This appliance CANNOT be installed directly on carpeting,

vinyl, linoleum or Pergo®.

If this appliance will be installed on any combus-

tible material OTHER THAN WOOD, a floor pad must be

installed that is either metal, wood, ceramic, stone, or a

listed hearth pad. This floor protection must extend the

full width and depth of the appliance. It is not necessary

to remove carpeting, vinyl or linoleum from underneath

the floor protection. See fig. 1.

Figure 1. Minimum Hearth Protection.

14”

(356mm)

27”

(686mm)

Safety Information

Due to the high operating temperatures this appliance

shouldbelocatedoutoftrafficandawayfrom

furniture,draperies,etc.Maintainproperclearanceto

combustible mantels and fireplace trim.

Childrenandadultsshouldbealertedtothehazards

ofhighsurfacetemperaturesandshouldstayawayto

avoid burns or clothing ignition.

Enfants et adultes doivent être avertis des dangers des

températuresdesurfaceélevéesetdevraientresterà

l’écart pour éviter les brûlures ou l’inflammation des

vêtements.

Youngchildrenshouldbesupervisedwhiletheyare

inthesameroomastheappliance.Toddlers,young

children and others may be susceptible to accidental

contactburns.Aphysicalbarrier,suchasachild

guard,isrecommendedtobeusedifthereareat-risk

individuals in the house. To restrict access to a fireplace

orstove,installanadjustablesafetygatetokeep

toddlers,youngchildrenandotherat-riskindividuals

outoftheroomandawayfromhotsurfaces.

Lesjeunesenfantsdoiventêtresurveilléspendant

qu’ils sont dans la même pièce que l’appareil. Les

tout-petits,lesjeunesenfantsetd’autrespeuventêtre

sensibles aux brûlures par contact accidentel. Une bar-

rièrephysique,commeungardedel’enfant,estrecom-

mandépourêtreutilisésiilyadespersonnesàrisque

danslamaison.Pourrestreindrel’accèsàunecheminée

ouunpoêle,installerunebarrièredesécuritéréglable

pourgarderlestout-petits,lesjeunesenfantsetautres

personnesàrisqueàsesortirdelasalleetàl’écartdes

surfaces chaudes.

Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the

appliance.

Tout écran ou grille de protection pour l’entretien d’un

appareil doit être remplacé avant de faire fonctionner

l’appareil.

Clothing or other flammable materials should not be

placed on or near the fireplace.

Surveillerlesenfants.Garderlesvêtements,les

meubles,l’essenceouautresliquidesàvapeur

inflammables lin de l’appareil.

Neverallowanyonetousethefireplaceiftheyare

unfamiliarwithitsoperation.

NEVER store or use gasoline or any other flammable

vapors or liquids in the vicinity of this appliance.

Neverburnanysolidmaterials(wood,cardboard,paper,

coal,etc.)inthisappliance.Usewithnaturalgasor

propane fuel ONLY.

Do not slam or strike the glass panel.

ThisapplianceisNOTforusewithaftermarketglassdoors.

Cet appareil ne sert pas avec des portes en verre de

marché des accessoires.

Wear gloves and safety glasses while installing or

performing maintenance procedures on this appliance.

7

137750_Rev_L 11.16.12

Stove and Vent Clearance

Requirements

Minimum Clearances from the Stove

to Combustibles: Seefigs.2-4.

Rear: 2”(51mm)

Ceiling: 321/4”(819mm)

Corner: 2”(51mm)

Sides: 3”(76mm)

Figure 4a. Mantel and Trim Clearance specifications. Back of

bottom plate is flush with the fireplace face. Subtract 2 1/4” with

Short Legs.

Figure 2.

Parallel

Installation

Clearances.

Figure 3.

Corner Clearances.

2”

51 mm

2”

51 mm

3”

(76mm)

2”

(51 mm)

To Rear Wall

3”

(76mm)

Alcove Installation

MaximumAlcoveDepth:24”(61cm)

MinimumAlcoveWidth: 313/4”(80.6cm)

)MinimumCeilingHeight:61”(155cm)

WithShortLegs(6”): 59”(150cm)

Alcove dimensions result from test configurations,

not stove clearance specifications.

Minimum Clearances from the Vent Pipe to

Combustibles:

HorizontalRun:

Offthetopofthepipe 2”(51mm)

Offthesidesandbottom1”(25mm)

Vertical Run:

Allsides 1”(25mm)

Figure 4b

Stove is installed with the top plate flush with the fireplace face.

Figure 4c. Stove is installed recessed half-way into fireplace.

Top plate extends 6.5” forward of the fireplace face.

12.5

10.25

8

5.75

Max. Mantel Depth

Min. Mantel

Depth

Max. Trim

Depth = 1

3.5

61.75

156.8 cm

63.25

160.7 cm

64.75

164.5 cm

66.25

168.3 cm

67.75

172.1 cm

6.5

58.75

149.2 cm 29

74.7 cm

12.5

10.25

8

5.75

Max. Mantel Depth

Min. Mantel

Depth

Max. Trim

Depth = 1

3.5

28.5

72.3 cm

53.75

136.5 cm

55.25

140.3 cm

56.75

141.1 cm

58.25

148 cm

52.25

132.7 cm

48.25

122.5 cm

8

137750_Rev_L 11.16.12

Vent Restriction

This appliance is equipped with Restrictor Plates which

enable you to regulate the flow of incoming combustion

air and exhaust gas. The plates prevent overly strong draft

that can cause poor combustion and weak flame picture.

Followtheguidelinesbelow,andonthefollowingpages,

to determine the correct restrictor plate setting for your

particular installation configuration.

Intake Air Restrictor

This plate is located at the rear of the firebox behind the

burner plate. It is set in a CLOSED position at the factory

and should be left there for most vent configurations.

It should be opened only for snorkel terminations and

some short run horizontal terminations as specified on

thefollowingpages.ToadjusttheAirRestrictortothe

OPEN position, locate and loosen the wing nut under the

burnerandpushitbackasfarasitwillgo.SeeFig.6.

Exhaust Restrictor

TheExhaustRestrictorisanadjustableshutterlocatedat

thetopofthefirebox.Itisadjustedbymovingapivotpin

into one of four positions. It is set in the FULLY OPEN posi-

tion at the factory. See Fig. 7.

Use the chart in Table 1 to determine the correct

position for your installation and follow the instructions

belowtoadjustitifnecessary.

Additional restriction may be needed depending the

overall vent height. Use Simpson Dura-Vent Restrictor

Disk #929.

AdjustingExhaustRestrictorPlate:

1. Remove the Top Plate.

2. Locate the pivot pin at the left side of the firebox top.

Loosen the wing nut on the pivot pin and push the

pin to the left to disengage it from the current setting

position.Movethepintowardtherearandthenright

to engage it in the appropriate position indicated on

the firebox. See fig. 7.

3. Tighten the lock nut and replace the Top Plate.

Venting Requirements

This appliance may be installed with a vertical or horizon-

tal termination and must conform to the configuration

requirements described below.

This appliance is approved for use with vent systems

from the following manufacturers:

•SimpsonDura-VentGS

•Metal-FabSure-SealDV

•AmeriventCorporation

•SecurityVentLtd.

•SelkirkMetalbestos

•InternationalChimneyCorp.(ExcelDirect)

•BernardDelsinMfg.(ProForm)

Usepartsofonemanufactureronly-DONOTMIX

VENTCOMPONENTSFROMDIFFERENTMANUFACTURERS

INTHESAMESYSTEM.

Installation of any components not manufactured or

approvedbyJøtulorfailuretomeetallclearancerequire-

ments will void all warranties and could result in property

damage,bodilyinjury,orseriousfire.

The approved vent configurations described in this

manual are derived from extensive testing under con-

trolled laboratory conditions. Gas appliance performance

can be negatively affected by variables present in the

installation environment, i.e: atmospheric pressure, strong

prevailingwinds,adjacentstructuresandtrees,snow

accumulation, etc. These conditions should be taken into

consideration by the installer and stove owner when plan-

ning the vent system design.

IMPORTANT

• JOINT SEALING REQUIREMENT: APPLYA1/8”BEADOF

HIGH-

TEMPERATURE(750°F)SEALANTTOTHEMALESEC-

TION OF THE INNER VENT PIPE. THE

CEMENTSHOULDFORMASEAL

BETWEEN THE INNER AND OUTER

PIPES.

• NEVERMODIFYANYVENTING

COMPONENT,ORUSEANYDAM-

AGED VENTING PRODUCT.

• THEGASAPPLIANCEAND

VENTSYSTEMMUSTBE

VENTED DIRECTLY TO THE

OUTSIDE OF THE BUILDING

AND NEVER ATTACHED TO

ACHIMNEYSERVINGASOLIDFUELORGASBURNING

APPLIANCE.EACHDIRECTVENTGASAPPLIANCEMUST

HAVEITSOWNSEPARATEVENTSYSTEM.

COMMONVENTSYSTEMSAREPROHIBITED.

• IFVENTINGSYSTEMISDISASSEMBLEDFORANYREA-

SON, REINSTALL PER THE INSTRUCTIONS PROVIDED FOR

THE INITIAL INSTALLATION.

Fig. 5.

9

137750_Rev_L 11.16.12

Vertical Vent Termination

This appliance can be vertically vented through a ceiling

or to a roof termination with the following guidelines:

The termination should fall within the shaded areas

of the grids depicted in the Vent Window diagrams on

the pages 10-11.

MaximumVerticalrunshouldnotexceed35ft.(10.66

m).

MinimumVerticalrunmustbeatleast8ft.(2.43m).

Max.ColinearHorizontalrunis2ft.(61cm).

Vent Terminus Clearance: In no case shall any dis-

chargeopeningonthecapbelessthan18in.(610mm)

horizontally from the roof surface.

Steep roofs, nearby trees, and predominantly windy

conditionscancontributetopoordraftand/orpro-

mote down-draft occurances. Increasing the height of

the vent may alleviate these conditions.

Use Wall Straps to support an offset pipe run at three

feet intervals to avoid excessive stress on the offsets.

Elbows:Four45°,ortwo90°elbowsmaybeused.Do

notincludethe45°elbowattachedtothestove.When-

everpossibleuse45°elbowsinsteadof90°elbowsas

they are less restrictive to exhaust gas and intake air

flow.

A firestop is required at every floor. The opening

shouldbeframedto10"X10"insidedimension.

Any venting that is exposed above the first floor,

regardless of attic space or living space, must be en-

closed. Always maintain the required 1" clearance from

all sides of the vertical vent system.

Figure 7. Adjusting the Exhaust Restrictor plate - Top Plate

removed. Viewed from front of stove.

Figure 6. Adjusting the Air Inlet Restrictor plate - View is

from the right side of the stove.

Figure 8. Vertical vent termination height above roof.

Push the

Pivot Pin into

the slot

FRONT

LEG BACK

LEG

Default

Factory

Setting is

“D”

Front of Stove

Horizontal Overhang

Vertical Wall

Termination

Cap

18.

min.

Lowest Discharge

Opening

18 min.

18.

min.

10

137750_Rev_L 11.16.12

Figure 9. Coaxial Vent Termination Window / NG Figure 10 . Colinear Termination / NG

• ALL VENTING MUST TERMINATE (END) WITHIN ONE OF

THE SHADED AREAS.

• SETSTOVEEXHAUSTRESTRICTORTOTHEPOSITIONTHAT

CORRESPONDS TO THE VENT TERMINATION AREA IN THE

DIAGRAMABOVE.

• ALWAYSMAINTAINTHEPROPERCLEARANCESTOCOM-

BUSTIBLES.

The circled letter designations in the vent diagram correspond

to the Exhaust Restrictor Setting on the stove. First, determine

which vent termination zone is appropriate for your installation

andfueltype,thenadjusttherestrictortothecorresponding

position as shown in Figure 7, page 9.

VentTerminationZones-NaturalGas Vertical

Termination for

COLINEAR VENT

HorizontalandVertical

Terminations for COAXIAL VENT

• VENTING MUST TERMI-

NATE (END) WITHIN THE

SHADED AREA.

• AdjusttheExhaustRe-

strictortopositionBfor

any NG colinear termi-

nation.

11

137750_Rev_L 11.16.12

Figure 11. Coaxial Vent Termination Window / LP Figure 12 . Colinear Termination / LP

VentTerminationZones-Propane

• VENTING MUST TER-

MINATE (END) WITHIN

THE SHADED AREA.

• AdjusttheExhaust

Restrictor to position

Cfor a straight vertical

colinear termination.

• AdjusttheExhaust

Restrictor to position

Dfor a vertical colinear

termination with maxi-

mum 2 ft. offset.

• VENTING MUST TERMINATE (END) WITHIN ONE OF THE DESIGNAT-

ED AREAS. ZONE “A” IS FOR VERTICAL TEMINATIONS ONLY.

• SETSTOVEEXHAUSTRESTRICTORTOTHEPOSITIONTHATCOR-

RESPONDS TO THE VENT TERMINATION AREA IN THE DIAGRAM

ABOVE.

• OPENAIRINLETRESTRICTORFORTERMINATIONS5FTANDUNDER.

SEEFIG.6,PAGE9.

• ALWAYSMAINTAINTHEPROPERCLEARANCESTOCOMBUSTIBLES.

The circled letter designations in the vent diagram correspond

to the Exhaust Restrictor Setting on the stove. First, determine

which vent termination zone is appropriate for your installation

andfueltype,thenadjustthestoverestrictorplatetothecor-

responding position as shown in Figure 7, page 9.

Vertical

Termination for

COLINEAR VENT

HorizontalandVertical

Terminations for COAXIAL VENT

12

137750_Rev_L 11.16.12

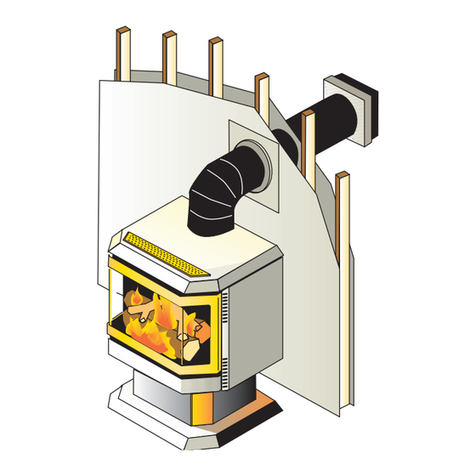

Co-linearVentInstallation

This appliance may be vented through a masonry or Class

A prefabricated chimney using a Co-linear Flexible Vent

system approved for use with a solid-fuel burning fire-

place. When installed in the manner described below, this

system can improve the performance of the appliance in

cold climate situations, as well as simplify the vent instal-

lation. See fig. 13.

These installation requirements must be followed:

1. Use the guidelines for Co-linear Vent Termination ap-

propriate for your gas type on pages 10 - 11.

1. Prior to the installation the chimney flue must be thor-

oughly cleaned and inspected by a qualified chimney

service person.

2. In a masonry chimney, a fireclay liner must be present

the entire length of the chimney.

3. PrefabricatedchimneysmustbeUL103orULCS-629

listedandhaveaminimumINSIDEdiameterof6

inches, (150 mm).

4. Noappliancecanbeinstalledintoachimneyflueserv-

ing any other appliance of any kind.

5. THEAIRINTAKEFLEXPIPEMUSTEXTEND6FEETBE-

YONDTHEDAMPERAREAOFTHEFIREPLACE.

6. Iftheintakeflexductdoesnotextendthefulllength

of the chimney and connect to both the unit and the

terminationcap,AMETALBLOCKOFFPLATEMUST

BE CONSTRUCTED AND INSTALLED ABOVE THE UNIT

PRIORTOTHEENDOFTHEINTAKEFLEXANDMUST

COMPLETELYSEALTHECHIMNEYFLUEFROMTHE

ROOM.

Consultwiththelocalcodeauthorityhavingjurisdic-

tion before proceeding with this type of installation.

Refer to the vent manufacturer’s instructions for

specific installation requirements.

WARNING: FAILURE TO POSITION THE PARTS AND

STOVE IN ACCORDANCE WITH THESE DIAGRAMS OR

FAILURE TO USE ONLY PARTS SPECIFICALLY APPROVED

FOR USE WITH THIS APPLIANCE MAY RESULT IN PROPERTY

DAMAGEORPERSONALINJURY.BESURETOMAINTAIN

THEPROPERCLEARANCESTOCOMBUSTIBLESASDEFINED

IN THIS MANUAL AND IN THE INSTRUCTIONS PROVIDED

WITH EACH VENT COMPONENT.

Figure 13. Co-linear Adaptor installed through a masonry

chimney. Components shown may differ somewhat from

manufacturer to manufacturer.

Figure 14. Simpson Dura-Vent #923GCL Co-linear Adaptor

is shown - other manufacturer’s components may differ.

Subtract 2 1/4” for Short Legs.

Max.offset

24”

(609mm)

The Air

Intake Flex

pipe must

extend

beyond the

damper.

The chimney

must be sealed

off from the

room by a steel

plate at the

damper area.

High Wind Cap

Exhaust Gas

Intake Air

Max.Co-linear

Height - 35 ft.

(10.66m)

Min.Co-linear

Height - 10 ft.

(3.05 m)

Dual3”Flex

Liners

251/2”

to center

of flue collar

29”

to top of

Co-linear

Adapter

13

137750_Rev_L 11.16.12

Masonry or Prefabricated Chimney

Conversion

This appliance is approved for use with listed chimney

conversion kits from any of the manufacturers listed on

page 8. These kits are for use in a masonry chimney or a

prefabricated solid fuel listed chimney. See fig. 15.

These installation requirements must be followed:

1. Use the guidelines for Coaxial Vent Termination ap-

propriateforyourgastypeonpages11-12.

2. In masonry chimney, a fireclay liner or listed steel liner,

must be present the entire length of the chimney.

3. Chimneyheightshouldnotexceed35ft.(10.66m).

4. Thelinermusthaveaninsidedimensionof6”roundor

greater.

5. PrefabricatedchimneysmustbeUL103orULCS-629

listedandhaveaminimumINSIDEdiameterof6inch-

es, (150 mm). Prefabricated chimneys must be listed for

the specific Chimney Conversion Kit you choose.

Figure 15. Vent System through a masonry chimney using

a chimney conversion kit. May also be used in listed

prefabricated chimneys. Drawing is for illustrative purposes

only - DO NOT VENT TWO APPLIANCES INTO A SINGLE

CHIMNEY.

Vertical Termi-

nation Cap

Cap Adaptor-

included in

#934Kit

Support/Wall

Thimble Cover

Exhaust

Gas

Intake Air

Use standard

vent pipe

from stove

to thimble

from the same

manufacturer

4”FlexPipe

not included

in kit

IMPORTANT NOTICE

THE USE OF AN EXISTING CHIMNEY AS AN AIR

INTAKE IS NOT COVERED UNDER THE ANSI

Z21.88-1999-CSA2.33-M99TESTMETHODSAND

RESULTING ITS/WHI PRODUCT CERTIFICATION.

THE CODE AUTHORITY HAVING JURISDICTION

MUSTBECONSULTEDPRIORTOPROCEEDING

WITH THIS INSTALLATION METHOD.

14

137750_Rev_L 11.16.12

HorizontalTermination

Any horizontal termination must fall within the shaded

portion of the vent window graph illustrated in figs. 9

or 11. For Snorkel Terminations, see below.

Any horizontal termination except a snorkel termina-

tion, must include:

1) Minimumriseof2ft.

2) Minimumhorizontalrunof12in.whenvertical

runislessthan8ft.

3) Maximumriseof35ft.

4) Maximumhorizontalrunof27ft.

5) Nomorethanfour45°ortwo90°Elbows

Follow all termination clearance guidelines as specified

in fig. 19.

The horizontal termination cap must maintain a 3"

clearancetoanyoverheadcombustibleprojections

21/2"orless.Itmustalsomaintain12"clearancefrom

projectionsexceeding21/2".Seefig.20.

WallCut-outOpening:Aminimum10"X10"(250mmx

250 mm) square hole is required for proper pipe clear-

ances through a combustible wall. Usealistedwall

thimbleforthewallpenetration.

DO NOT FILL AIR SPACE WITH ANY TYPE OF INSULA-

TION.

Anyhorizontalrunofventmusthavea1/4"riseforev-

ery foot of run toward the termination cap. NEVER AL-

LOWTHEVENTINGTORUNDOWNWARDFROMSTOVE

TOTERMINATION;DOWNWARD VENT RUNS TRAP HEAT

ANDCAUSEHIGHTEMPERATURESTODEVELOPWITHIN

THE VENT THAT COULD START A FIRE.

Install a Vinyl Siding Standoff between the vent termi-

nation and an exterior wall covered by vinyl siding ma-

terial to prevent potential heat damage to the siding.

Do not recess the termination cap into a wall or siding.

Figure 16.

• Minimum vent for horizontal termination.

• 14” Maximum horizontal run directly off rear of stove

with 14” Snorkel termination.

Figure 17. Maximum Horizontal and Vertical Run with 36”

Snorkel Termination.

Max.

6ft.

183 cm

36in.

Snorkel

(915 mm)

Figure 18. Corner Installation with 14” Snorkel Termination.

Snorkel Terminations

THEAIRINLETRESTRICTORMUSTBESETFULLYOPEN

FOR ANY SNORKEL TERMINATION.SeeFig.6,pg.9.

Witha14”Snorkel:

The horizontal run made directly off the rear of the

stoveintoa14”snorkelcapshouldincludenomore

thanasingle12”straightsectionasshowninfig.17.

One45°Elbowmaybeusedforacornerinstallationas

shown in fig. 18.

Witha36”Snorkel:

The maximum horizontal run may be no more than

6ft.(182cm.)

12 in.

Straight Pipe

Max.14”

355 mm

Wall Thimble

and Trim Collar

45°Elbow

See Note F

Fig. 20

14”

355 mm

Max.

12 in.

(305 mm)

12”

Vent

Pipe or

less

57”

(1448mm)

24in.

Snorkel

(305 mm)

251/2in.

Snorkel

(648mm)

15

137750_Rev_L 11.16.12

Figure 19. Vent Terminal Clearances per National Fuel Gas Code.

Figure 20. Termination Clearance to overhangs

A = Clearance above grade, veranda, porch , deck, or balcony

: 12 inches (30 cm) minimum.

B = Clearance to window or door that may be opened:

**Min.9inches,U.S./*12inches(30cm)CAN.

We recommend 12in. minimum to prevent condensation

on the window.

C = Clearance to permanently closed window:

**Min.9inches,U.S./*12inches(30cm)CAN

We recommend 12 in. minimum to prevent condensation

on the window.

D = Vertical clearance to ventilated soffit located above the

terminalwithinahorizontaldistanceof2feet(60cm)

from the centerline of the terminal: 18 inches

(46cm)minimum.

E=Clearancetounventilatedsoffit:12inches(46cm)

minimum.

F=Clearancetooutsidecorner:**Min.9inches,U.S./*12

inches (30 cm) CAN.We strongly recommend 12 inches,

particularly where windy conditions pevail.

G=Clearancetoinsidecorner:**Min.6inches,U.S./*12

inches (30 cm) CAN.We strongly recommend 12 inches,

particularly where windy conditions pevail.

H=*Nottobeinstalledwithin15feet(4.5m)aboveame-

ter/regulatorassemblywithin3feet(90cm)horizontally

from the center-line of the regulator.

I = Clearance to service regulator vent outlet:

3 feet (91 cm) minimum.

J=Clearancetononmechanicalairsupplyinlettobuilding

or the combustion air inlet to any other appliance:

12 inches (30 cm) minimum.

K = Clearance to a mechanical air supply inlet:

**Min.3feet(91cm)aboveifwithin10feethorizontally,

U.S./*6feet(1.83m)minimum/CAN

L = 1Clearance above paved sidewalk or a paved driveway

located on public property: 7 feet (2.1 m) min.

* InaccordancewithCSAB149InstallationCodes.

**InaccordancewiththecurrentANSIZ223.1/NFPA54,National

Fuel Gas Code. Note: Local Codes and Regulations may require

different clearances.

***InaccordancewiththecurrentNFPA58LiquifiedPetroleum

Gas Code

1A vent shall not terminate directly above a sidewalk or driveway

which is located between two single family dwellings and serves

both dwellings.

2Only permitted if veranda, porch, deck, or balcony, is fully open

on a minimum of two sides beneath the floor.*

M=Clearanceunderveranda,porch,deck,orbalcony:

12inches(30cm)minimum.2

N = Clearance to propane tank relief valve and filler connection***:

5feet(1.52m)minimumtotanksnotfilledonsite

10feet(3.05m)minimumtotanksfilledonsitefrombulktruck

HorizontalTerminationClearance

16

137750_Rev_L 11.16.12

Tools required:

• 1/2”openendedwrenchordeep-wellsocket,TorxT20

orslottedscrewdriver,4mmallenwrench.

Conversion Kit Contents:

• 1,regulatortowerlabeledforpropane

• 3,regulatortowerscrews

• 1,burnerorifice(#33forNG,1.65mmforLPG)

• 1,pilotorifice(#51forNG,#30forLPG)

• LabelA-tobecompletedandappliedto

the back of the stove

• LabelB-applytothestove’sRatingPlate

• Smallvalvelabel-applytovalvebody

Conversion instructions are also shipped in the stove

with the conversion kit.

Mobile Home Installation

This appliance can be installed for use in a mobile home

in the U.S. and Canada provided:

1. The stove is secured to the floor of the mobile home.

UseJøtulFloorBracketKit#750304.

2. Provision must be made to secure an electrical ground

between the stove and the mobile home chassis.

3. ThestoveisinstalledinaccordancewithTitle24CFR,

Part3280-ManufacturedHomeConstructionand

Safety Standard, in the U.S. In Canada, comply with CSA

Z240.4,GasEquippedRecreationalVehiclesandMobile

Housing.

4. Alwayscontactyourlocalofficialsaboutinstallation

restrictions and requirements in your area.

THISAPPLIANCEMAYBEINSTALLEDINANAFTERMAR-

KETPERMANENTLYLOCATED,MANUFACTURED(MOBILE)

HOME,WHERENOTPROHIBITEDBYLOCALCODES.THIS

APPLIANCE IS ONLY FOR USE WITH THE TYPE OF GAS THAT

IS INDICATED ON THE STOVE’S RATING PLATE. A GAS

CONVERSIONKITISPROVIDEDWITHTHEGF400SEBAGO

DIRECT VENT GAS STOVE.

CET APPAREIL PEUT ETRE INSTALLE DANS UN MAISON

PREFABRIQUEE(MOBILE)DEJAINSTALLEEADEMEURESI

LES REGLEMENTS LOCAUX LE PERMETTENT. CET APPAR-

EIL DOIT ETRE UTILISE UNIQUEMENT AVEC LES TYPES DE

GAS INDIQUES SUR LA PLAQUE SIGNALETIQUE. NE PAS

L’UTILISER AVEC D’AUTRES GAS SAUF SI UN KITDE CON-

VERSION CERTIFIE EST INSTALLE.

Fuel Conversion

This appliance is shipped from the factory equipped to

burn NATURAL GAS only. If PROPANE gas is to be used as

fuel, the appliance must first be converted for use with

propane. Use Propane Conversion Kit 155351, supplied with

the appliance.

Order and install NG Conversion Kit 155352 to change

back to use with natural gas.

WARNING:

THECONVERSIONKITISTOBEINSTALLEDBYAN

AUTHORIZED JØTUL SERVICE TECHNICIAN IN AC-

CORDANCE WITH THE MANUFACTURER’S INSTRUC-

TION AND ALL CODES AND REQUIREMENTS OF THE

AUTHORITY HAVING JURISDICTION. FAILURE TO

FOLLOW THESE INSTRUCTIONS COULD RESULT IN

SERIOUS INJURY OR PROPERTY DAMAGE. THE QUAL-

IFIED AGENCY PERFORMING THIS WORK ASSUMES

RESPONSIBILITYFORTHISCONVERSION.

IN CANADA:

THECONVERSIONSHALLBECARRIEDOUTINAC-

CORDANCE WITH THE REQUIREMENTS OF THE PRO-

VINCIAL AUTHORITIES HAVING JURISDICTION AND

IN ACCORDANCE WITH THE REQUIREMENTS OF THE

CAN1-B149.1AND.2INSTALLATIONCODE.

17

137750_Rev_L 11.16.12

Fuel Conversion Procedure

Refertofig.47,IllustratedPartsBreakdown,toidentifypart

numbers below.

1. Turn off gas supply to stove.

2. RemovethestoveTopPlate(41).

3. Disengage the two Glass Frame Latches at the top of

the firebox. See illustration on page 5. Carefully lift the

glass panel up and out of the stove.

4. Ifinstalled,removetheEmbersandLogSetusingcare

not to damage the fragile log parts.

5. Lift out the Burner Skirt (33). Tilt the skirt at an angle

to clear the firebox sides and front.

6. ReachunderthestoveandremovetheAirShutter

wingnut from its stud. As you face the right side, it is

the one closest to you. See fig. 21.

7. Lift out the Burner Plate: NOTE: There are no screws

securing the Burner to the floor of the firebox. Pull the

Air Shutter forward and lift the burner together with

shutter up and out of the stove as a unit. See fig. 22.

8. ChangetheMainBurnerOrifice.Seefig.23.Usinga

1/2”openendedwrenchordeep-wellsocketremove

the burner orifice from its brass elbow housing and

replace with the appropriate orifice supplied in the kit.

#33 for NG

1.65mmforLP

9. Replace the Air Shutter with its gasket and push it all

the way back to allow replacement of the Burner Plate.

10. Replace the Burner Plate. Engage the Air Inlet Tube

with the Air Shutter and burner orifice. Properly

seated, the burner plate will be engaged at its front

corners with the two support brackets located at the

front of the firebox.

•Replacethewingnutlooselyontheairshutterstem

underthestove.Airshutteradjustmentwillbedone

last.

11. CHANGE THE PILOT ORIFICE: From within the firebox,

remove the Pilot Head by pulling it straight up from

the pilot base. See fig. 25.

Usingthe4mmallenwrenchthatisincludedwiththe

conversion kit, unscrew the pilot orifice (counterclock-

wise). Replace with the appropriate orifice:

# 51 for natural gas

#30 for propane gas

12. Tighten orifice into the base of the pilot assembly.

To prevent bypass leaks, be sure the orifice is secured

tightly and flush with the base. Replace pilot head by

pushing it down onto the pilot base.

13. Replace the Variable Regulator. Using a Torx T-20 screw-

driver, remove the three screws from the front of the

valveregulator.Seefig.26.

Figure 21. Locate and remove the Air Shutter wingnut

from under the right side of the stove.

Figure 22. Remove the Air Shutter and Burner as a unit.

BurnerPlate

Air Shutter

Figure 23. Change the Burner Orifice.

Burner

Orifice

BrassElbow

Figure 24. Air Shutter Setting

Air Shutter

Opening

Dimension

Air

Shutter

Wingnut

BurnerPlate

Air Inlet

Tube

FRONT

LEG

BACK

LEG

18

137750_Rev_L 11.16.12

Gas Supply Connection

Connectthegassupplylinetothestove,before

installingtheoptionalBlower.

Iftheblowerwillbeinstalled,usea45°elbowoffthe

controlvalvetocreateclearancerequiredfortheblower

installation.

The gas supply line connection is made to the left side of

thevalve.Thegassupplylineshouldbe3/8”nptwitha

1/2”diametersupply,ortheappropriatesizetoprovide

sufficient gas pressure to the valve regardless of the input

setting.

The use of Flexible Gas Appliance Connectors is ac-

ceptable in many areas in the U.S. However, Canadian

methods vary depending on local code.

ALLINSTALLATIONSMUSTCOMPLYWITHLOCALCODE

ORINTHEABSENCEOFLOCALCODE,MUSTCOMPLYWITH

THEMOSTRECENTEDITIONOFTHENATIONALFUELGAS

CODEANSIZ223.1/NFPA54ORCAN-B149.

All codes require a gas shut-off valve (gas cock) and

union, to be installed in the supply line, and in the same

room as the appliance. This allows for the disconnection

of the stove for servicing and maintenance. See fig. 27.

Figure 27. Supply valve coupling.

Pilot Head

Orifice Retainer

Clip

PilotBase

Figure 25. Pilot orifice removal and replacement.

14.RemovetheRegulatorTower,Gasket,whiteplastic

disk, and Spring.

15. Install the new regulator: Be sure the new gasket is

properly positioned and tighten screws securely.

16. Installtheidentificationlabelstothestovesothat

they can be seen by any person that may be servicing

the stove.

Label A: apply to back of stove.

Label B: apply to stove’s rating plate.

Small valve Label: apply to valve.

17. Reassemble the stove, apply gas to the system and

check for leaks using a soapy water solution.

18.AdjusttheAirShutter:

CAUTION!USEWORKGLOVES.SURFACESMAYBEHOT!

Youwillneedtoadjusttheshuttertotheposition

that supplies the correct amount of air mixture to

achieve the best flame picture with your particular in-

stallation. Start with the shutter stem at the midway

position in the slot in the bottom of the stove. See fig.

21. Pushing the stem back will restrict air, while push-

ing it forward will open the shutter. Too much air will

produce a lighter flame, while too little will promote

long,darkflamesandmaypromotesooting.Make

adjustmentsinsmallincrements.Withsomeexperi-

mentation, you will find the shutter position that

works best for your installation.

NEVERUSEANOPENFLAMETOCHECKFORGASLEAKS.

Correct gas pressure is essential for efficient and

safe operation of this appliance. Correct gas pres-

sure must be established at the time of installation.

For more details, see the Gas Pressure section of this

manual (page 19).

ALWAYS REFER TO THE LIGHTING INSTRUCTIONS ON THE

INSIDEBACKCOVEROFTHISMANUALWHENLIGHT-

ING YOUR STOVE.

Figure 26. Regulator assembly.

Apply small

label here

Remove black

gasket

Regulator

Tower

19

137750_Rev_L 11.16.12

Gas Pressure

Correct gas pressure is essential for efficient and safe

operationoftheGF400DVSebagogasstove.Itisim-

portant that the correct pressure is established at the

time of the installation. Proper gas pressure provides

a consistent flow of gas to the appliance and is instru-

mental in checking for gas leaks.

Pressure Test: Attach a manometer to the appro-

priate test point on the valve. See fig. 28.The gauge

connections are located on the front of the valve under

theOn/Off/Pilot-knob.Gaugeconnectionsareidenti-

fied by:

E - for Inlet or Supply Pressure (the amount of gas

coming to the valve.)

A-forManifoldPressure(theamountofgasthat

is coming out of the valve to the burner.)

ALWAYS TEST PRESSURES WITH VALVE CONTROL

KNOB SET ON HIGH.

HighAltitudeAdjustment

Installationslocatedataltitudesfrom2000-4500ft.

(610m-1370m)DONOTrequireadjustmentforaltitude.

DO NOT DERATE THIS APPLIANCE FOR ALTITUDE.

Figure 28. Pressure test points.

EA

Leak test:

1. Mixa50-50solutionofwateranddish

soap.

2. Light appliance- see lighting instructions

on the inside back cover of this manual or

on the stove’s rating plate.

3. Brushorsprayalljointsandconnections

with the soapy water solution.

4. Ifbubblesappearatanyconnectionor

seam or a gas odor is detected, imme-

diately turn gas control knob to the OFF

position.

5. Tightenorreconnecttheleakingjoint

and retest for any gas leaks.

AT-HANDLEGASCOCKISREQUIREDIN

MASSACHUSETTSTOCOMPLYWITHCODE248CMR.

Securealljointstightlyusingappropriatetoolsand

sealing compounds. For propane units be sure to use com-

pounds that are propane resistant. Turn on gas supply and

test for gas leaks using a soapy water solution. Never use

an open flame to check for leaks.

INLET GAS PRESSURES

(inches water column)

MIN MAX

NATURAL GAS 5.0 7.0

PROPANE 12.0 14.9

The appliance and its appliance main gas

valve must be disconnected from the gas supply

piping system during any pressure testing on that

systemattestpressuresinexcessof1/2psig(3.5

kPa).

The appliance must be isolated from the gas

supply line by closing its individual manual gas

shut-off valve (gas cock) during any pressure test-

ing of the gas supply piping system that is equal

toorexceedspressuresof1/2psig(3.5kPa).

MANIFOLDPRESSURES

(inches water column)

MIN MAX

NATURAL GAS 1.2 3.8

PROPANE 2.9 11.0

20

137750_Rev_L 11.16.12

Optional Wall Thermostat or

Remote Control

Use only a 750 millivolt DC two-wire circuit thermostat

with this appliance. The thermostat should be placed

in the same room as the heater, typically 5 feet off the

floor. Avoid drafty areas or any area that may affect the

accuracy of the thermostat.

The thermostat should be connected to this appli-

anceusingaminimumof16gaugewirewithamaxi-

mumlengthof25feetofwire.

Connect the two thermostat wire leads to the two

lower terminals on the terminal block located directly

above the ignitor button. Do not overtighten the con-

nections. IT IS NOT NECESSARY TO DISCONNECT ANY

OTHER WIRES. See Fig. 30.

Forthermostaticoperation,theOn/Off/T-Statswitch

on the back of the stove must be in the T-stat position,

and the pilot light must be running, as it is the power

source for the thermostat.

At the thermostat, the two wires should be connect-

ed to the two connection screws on the thermostat base

plate per the manufacturer’s instructions.

Remote Control

When using a remote, the remote receiver should be

wired to the terminal block the same way the thermo-

stat would be. See the instructions above.

Follow the operating instructions included with the

Remote Control unit.

CAUTION:

LABELALLWIRESPRIORTODISCONNECTIONWHENSERVICING

THE CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER OR

DANGEROUS OPERATION. ALWAYS VERIFY PROPER OPERATION

AFTER SERVICING THE APPLIANCE.

Figure 30. Accessory wiring diagram.

Flame Appearance / Air Shutter

Adjustment

This appliance is shipped from the factory equipped to

burn natural gas with the air shutter set half-open.

Be aware, however, that this initial setting may not provide

the optimal flame picture in your particular installation.

No single setting will be appropriate for all vent configu-

rations, fuel types, or installation environments.The air

shuttersettingcanalsobeadjustedtoachievethede-

sired flame appearance. Flame appearance is a matter of

individualpreference,however,mostpeopleenjoyawarm

yellowish flame.

Toomuchair- the appliance will generate a flame that

isblueandtransparent,oran“anemic”flame.

Too little air - the appliance may generate very long

yellow flames resulting in soot. Sooting produces black

deposits on the logs, on the inside walls of the appliance,

and potentially, on the exterior termination cap. Sooting is

caused by incomplete combustion and lack of combustion

air entering the air shutter opening.

Toadjusttheairshutter:CAUTION!USEWORKGLOVES.

SURFACESMAYBEHOT!

1. Reach under the right side of the stove and loosen the

wingnut located closest to you. See fig. 29. Slide the

wingnut stem forward to open the air shutter and

increase air. Slide the shutter stem back to decrease the

air supply.

2. Tighten the wingnut to secure the shutter at the de-

sired setting.

3. Operate the burner for 30 minutes on the HIGH setting,

observing the flame continuously. If the flame appears

weak,slow,orsooty,adjusttheairshuttertoamore

open position as described above until the flame is as

desired.Makeadjustmentsinsmallincrementsand

allow the burner to settle in before making further

adjustment

WARNING: AIR SHUTTER ADJUSTMENTS SHOULD ONLY

BEPERFORMEDBYAQUALIFIEDPROFESSIONALSERVICE

TECHNICIAN.

Figure 29.

Loosen the wingnut to adjust the air shutter stem.

FRONT

LEG

BACK

LEG

Table of contents

Other Intertek Stove manuals

Popular Stove manuals by other brands

Regency

Regency FG38NG2-BRA Owners & installation manual

Cleveland Ironworks

Cleveland Ironworks Single F500300 Operating instructions and owner's manual

Sportsman

Sportsman SSBGS instruction manual

United States Stove

United States Stove 5710-XH Owner’s Instruction and Operation Manual

Jetboil

Jetboil Genesis instructions

Palazzetti

Palazzetti ECOFIRE ANNA U.S. PRO2 DESCRIPTION / CLEANING / TECHNICAL DATA