Table of Contents

Warning.................................................................................................................................................................iii

Table of Contents...................................................................................................................................................v

Kit Contents ..........................................................................................................................................................vi

Description...........................................................................................................................................................vii

Safety Information................................................................................................................................................xi

Consignes De Securite ........................................................................................................................................xii

Sicherheits Anweisungen..................................................................................................................................xiii

Accessory Products............................................................................................................................................xiv

Introduction....................................................................................................................1

Overview................................................................................................................................................................ 1

Methods..........................................................................................................................3

Getting Started....................................................................................................................................................... 3

Operational Modes................................................................................................................................................ 4

Using PowerEase®500 .......................................................................................................................................... 5

Printing ................................................................................................................................................................. 12

Custom Methods ................................................................................................................................................. 13

Troubleshooting .................................................................................................................................................. 16

Appendix ......................................................................................................................17

Warranty............................................................................................................................................................... 17

Run Conditions for Gels..................................................................................................................................... 18

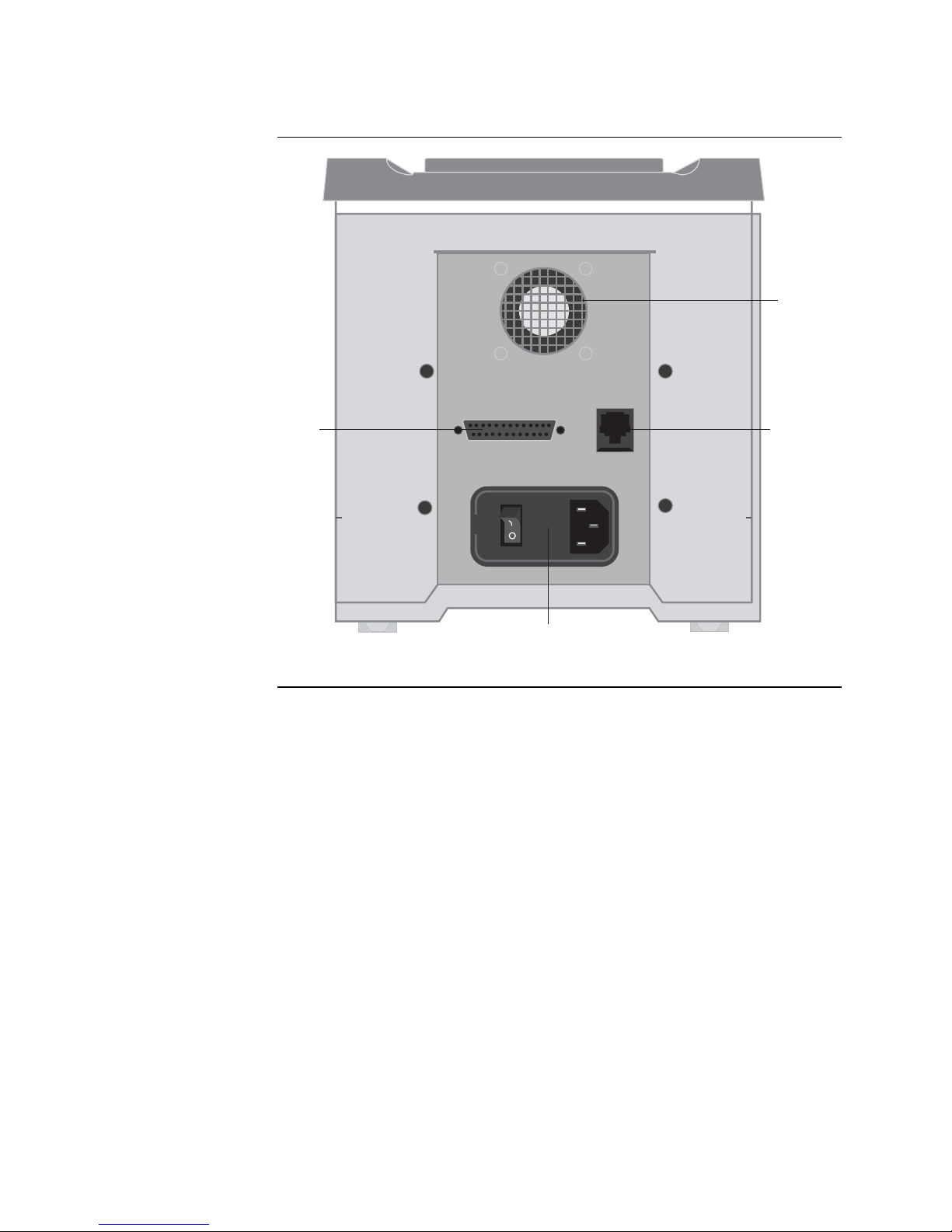

Repair and Maintenance of PowerEase®500................................................................................................... 19

Theory of Operation............................................................................................................................................ 20

Technical Service ................................................................................................................................................. 21

v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com