Page 3 of 35

Table of Contents

Intended Use..........................................................................................................................................4

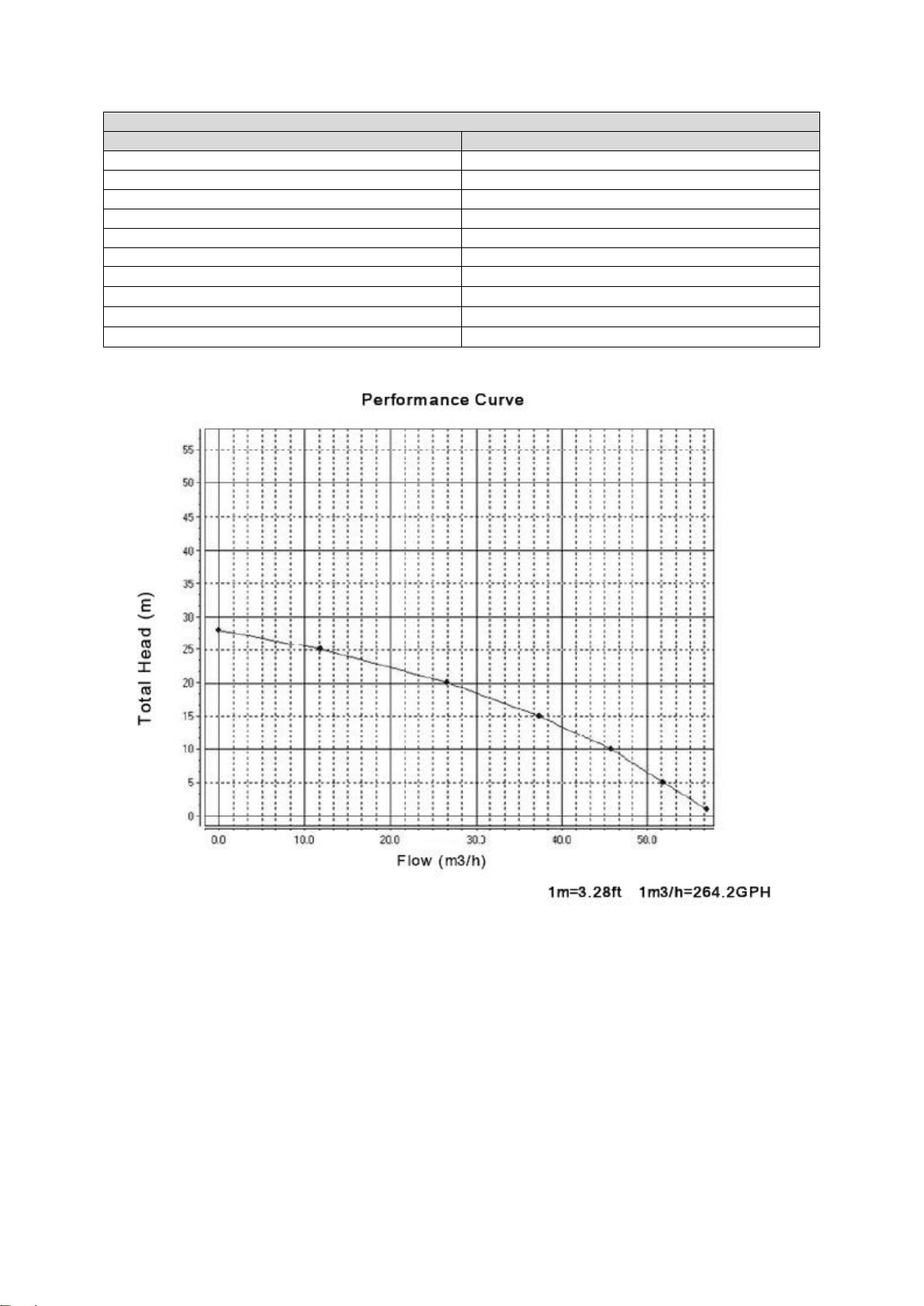

Technical Specifications......................................................................................................................4

Important Safety Information...............................................................................................................6

Specific Operation Warnings...............................................................................................................8

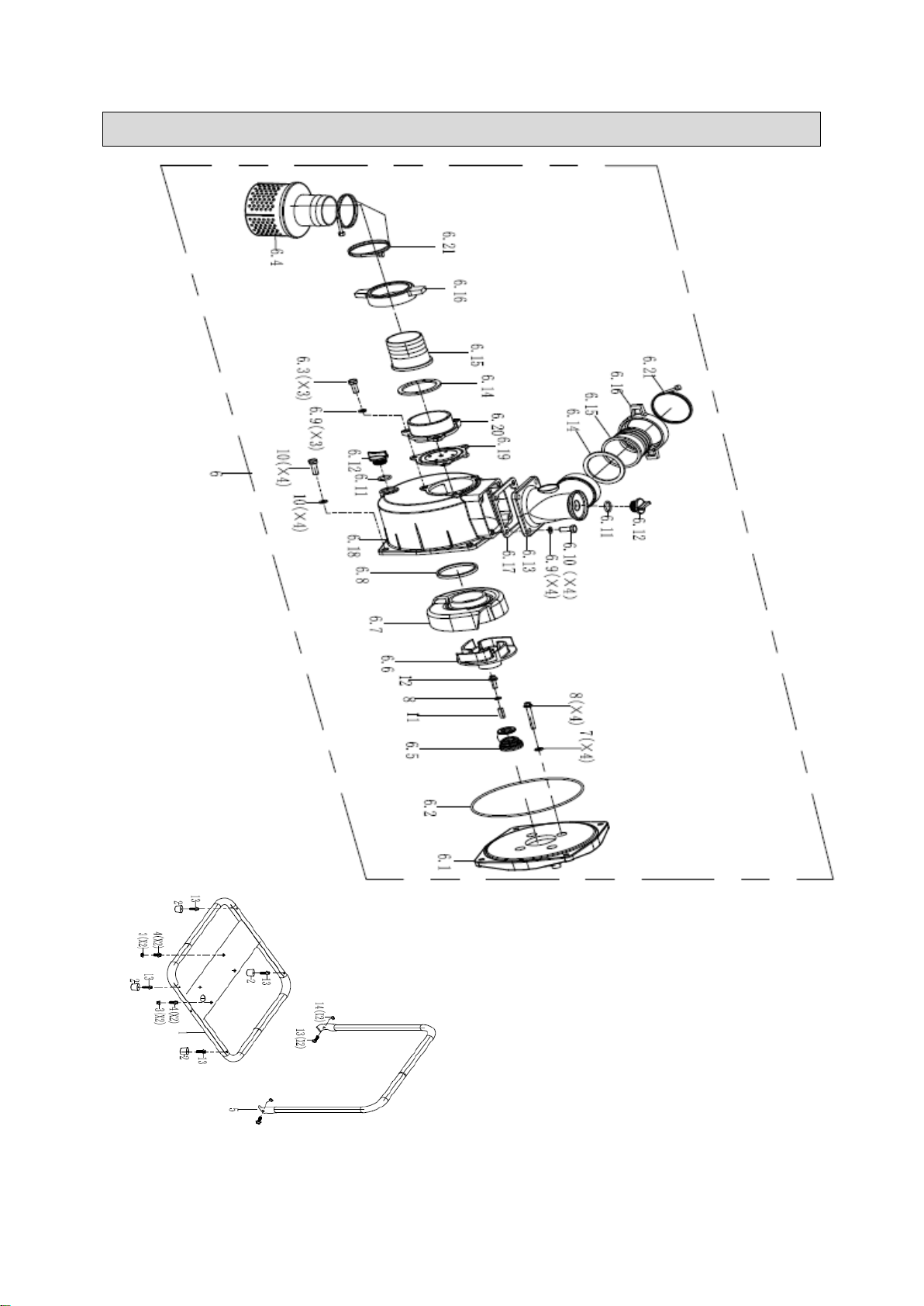

2" Pump Exploded View......................................................................................................................9

2’’ Pump Main Parts of Water Pump .................................................................................................10

3’’ Pump Main Parts of Water Pump .................................................................................................10

3″Pump Exploded View ....................................................................................................................11

Exploded View of Engine ...................................................................................................................12

Main Parts of Engine...........................................................................................................................13

Exploded View of Engine Kit..............................................................................................................14

Assembly Instructions........................................................................................................................15

Before Each Use..................................................................................................................................16

Operating Instructions........................................................................................................................19

Maintenance ........................................................................................................................................26

Storage.................................................................................................................................................30

Troubleshooting..................................................................................................................................31

Parts Diagram......................................................................................................................................32

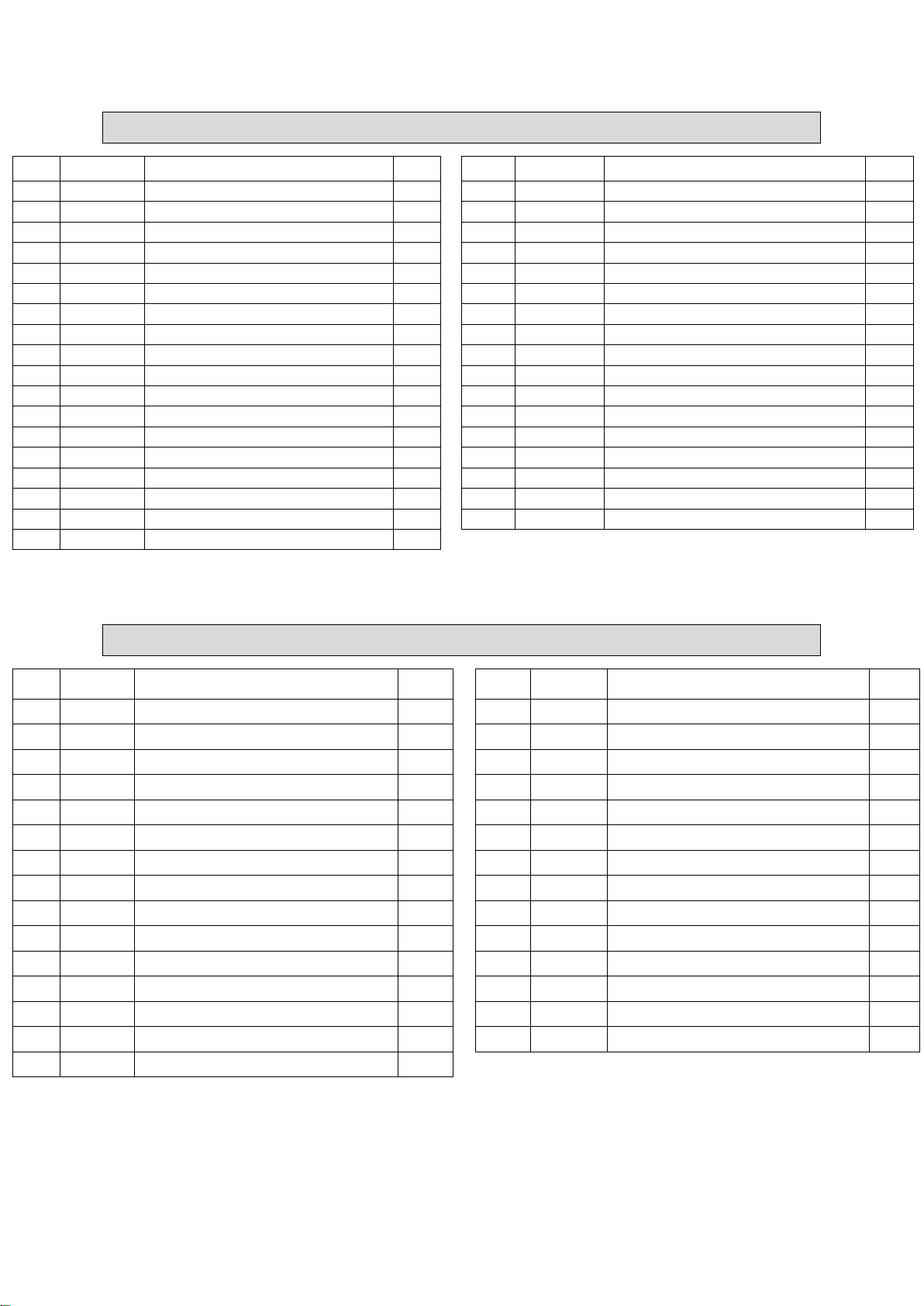

Parts List..............................................................................................................................................33

Replacement Parts..............................................................................................................................33

Limited Warranty.................................................................................................................................34