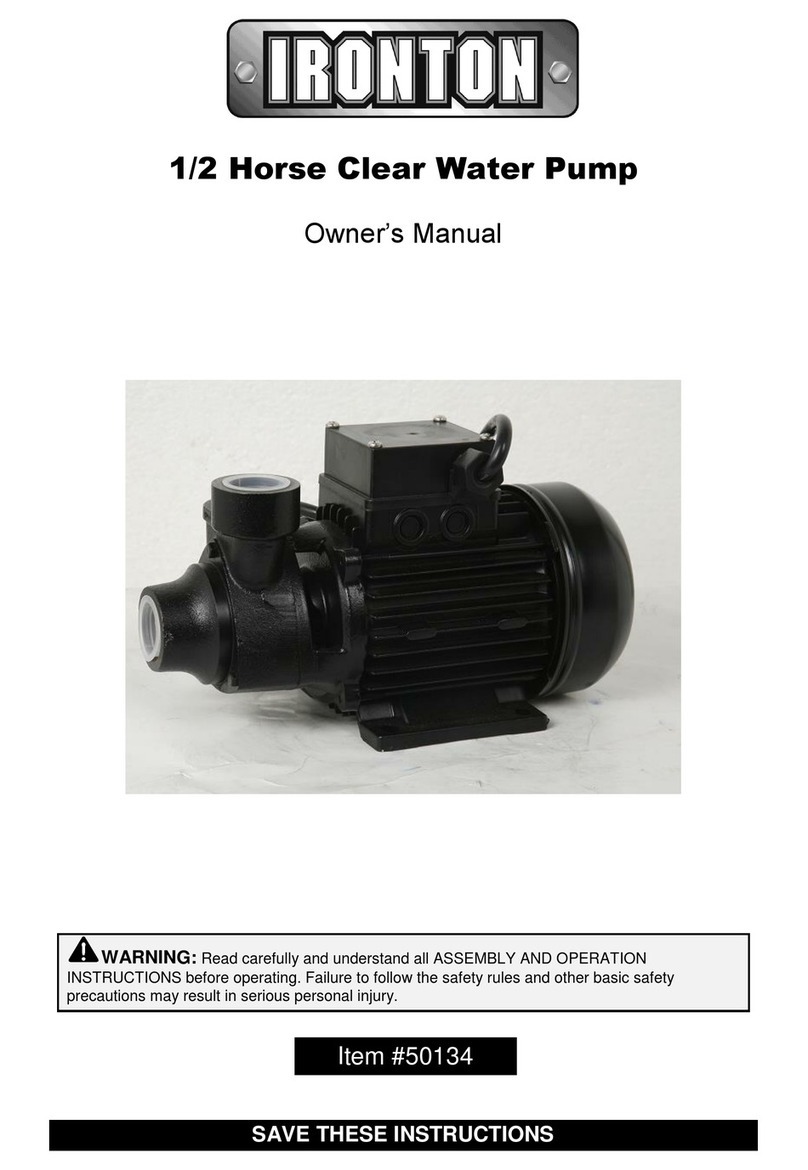

Step One: Prepare for Installation

•This Ironton pump is self-priming.

•The pump is for indoor use only and should be mounted on a solid surface in a location that

is dry and provides adequate ventilation.

•Prior to installation, ensure properly sized wiring, proper electrical protection, and

adequately sized plumbing lines and connections.

Step Two: Mounting

•The pump may be mounted in any horizontal position. If mounting the pump vertically, the

pump head should be in the down position so that in the unlikely event of a leak, fluid will

not enter the motor.

•Secure the rubber feet with #10 fasteners. DO NOT compress the feet, doing so will reduce

their ability to isolate vibration/noise. (Note: fasteners are not included.)

•Mount pump within 6 feet of the tank for best pump performance and longer pump life.

Step Three: Plumbing

•See table below for port size and recommended hose sizes.

oRemove shipping plugs from pump ports.

NOTE: Ironton does not recommend the use of rigid pipe to plumb the inlet/outlet ports.

•Tubing/hose should be flexible, compatible with potable water, and rated for the pump’s

maximum pressure. At least 18" [450mm] length is suggested to minimize stress on the

fitting/ports and reduce noise. Allow for the shortest possible tubing/hose route and avoid

sharp bends that may kink over time.

•The tubing/hose should be anchored where it meets rigid pipe/hard plumbing to reduce

vibration.

•Installation of a potable water approved 50-mesh strainer is recommended to prevent

foreign debris from entering the system. Failures due to foreign debris are not covered

under the warranty.

NOTE: Restrictions on the inlet may cause a loss in performance. Additionally, inlet pressure must

not exceed 30 psi [2.1 bar].

•If a check valve is installed in the plumbing, it must have a cracking pressure of no more

than 2 psi [.14 bar].

Step Four: Connect Pump to 12 Vdc Power Supply