Page 6

GENERAL SAFETY REGULATIONS

The regulations below must be carefully followed in order to avoid harm to the operator and damage to the machine.

WARNING:

•Carefully read the warnings in this booklet. Keep it in a safe place for future consultation.

•The packaging elements (plastic bags, clips, etc.) are potential sources of danger and must not therefore be left within the reach of children,

incompetent persons, etc.

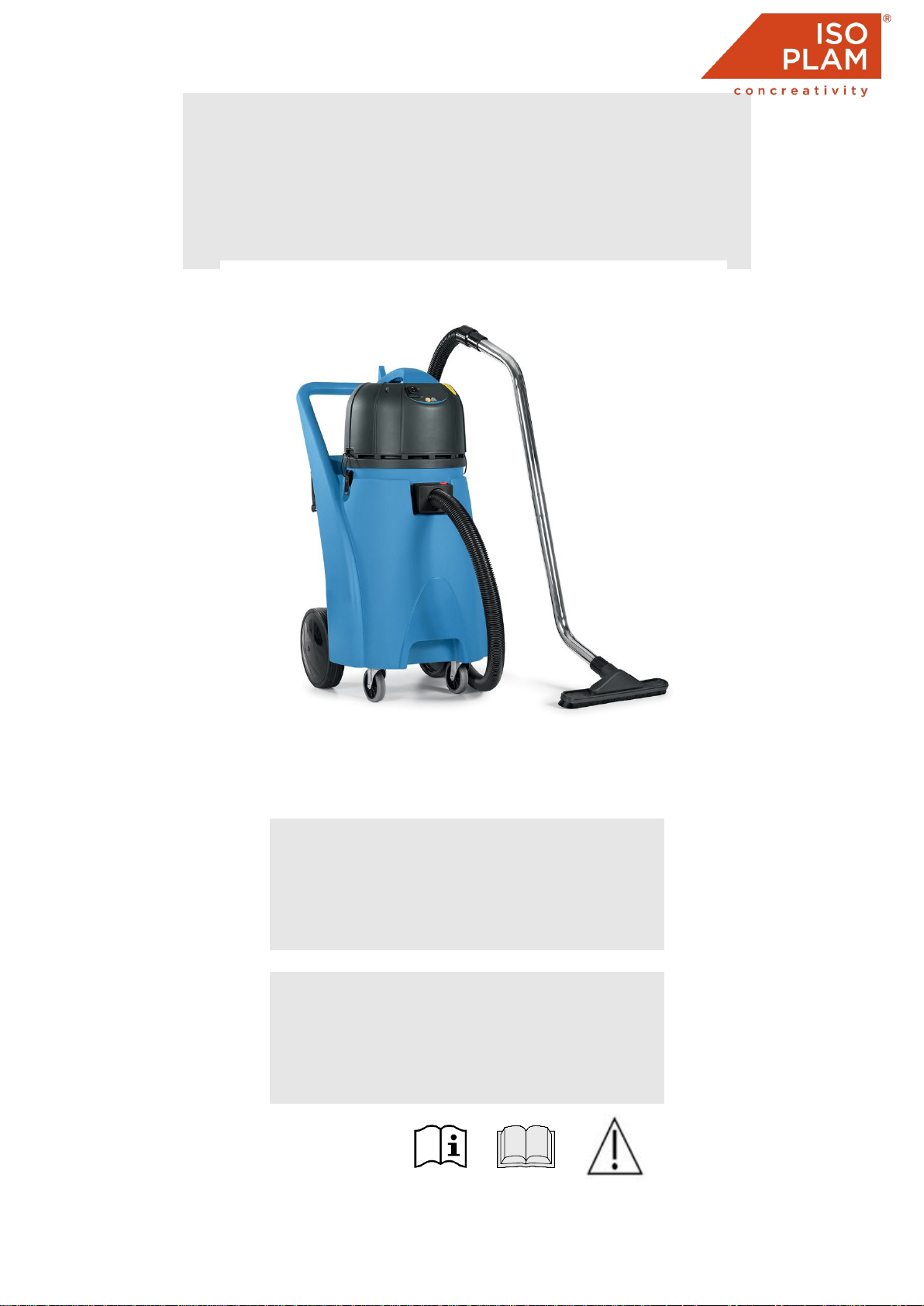

•This machine must only be used for the purpose for which it was built, i.e. the cleaning of inert surfaces and the vacuum removal of solid, non-

flammable and non-explosive substances. Any other use must be considered incorrect and hence dangerous.

•Make sure the working machine does not come too close to delicate organs like the ears, mouth, eyes, etc.

•This machine must not be used by people (including children) with reduced physical, sensorial or mental capabilities, or with no knowledge

or experience, unless supervised and instructed by people responsible for their safety.

•Children must be supervised to ensure they do not play with the device.

•Read the labels on the machine carefully. Do not cover them for any reason, and replace them immediately if they become damaged.

•The machine must only be used by authorised, trained personnel.

•Do not use the machine on surfaces with an inclination greater than the one shown on the serial number plate.

•The machine is not suitable for cleaning rough or uneven floors. Do not use the machine on slopes.

•It is important to make sure the power supply cable or extension cable is not damaged by the wheels of moving vehicles, by crushing, tearing, etc.

Protect the cable from heat, oil and sharp edges. Check the power cable regularly for damage, such as the formation of cracks or signs of ageing. If you

notice any damage, the cable must be replaced before using the machine. If you notice any damage to the power cable, contact an authorised technical

assistance centre immediately.

•In the event of danger, quickly remove the plug from the electricity socket.

•For all maintenance interventions, switch off the machine from the main switch and disconnect the power cable plug from the mains socket.

•While the machine is operating, pay attention to other people and especially to children.

•Only use the accessories supplied with the machine, or those specified in the instruction manual. The use of other accessories could compromise the

safety of the machine.

•When it is not being used, the machine must not remain plugged into the electricity supply. Before carrying out any maintenance on the machine:

disconnect the plug from the mains; do not immerse the machine in water; do not use solvents. The manufacturer cannot be held liable for any harm to

people or animals, or damage to property, resulting from any type of use considered improper and unreasonable or anyway not complying with the

above indications. When disposing of the machine, respect the regulations in force in the country of use. Do not use the vacuum cleaner with the power

supply cable wound up on the cover.

•Before connecting the machine to the power supply, make sure the electric data shown on the label correspond to those of the mains supply. The

machine must only be powered with a voltage of the level shown on the serial number plate.

•Make sure the working machine does not come too close to delicate organs like the ears, mouth, eyes, etc.

ATTENTION:

•The machine is not suitable for use by children and persons with reduced physical, mental and sensory capabilities, or people who lack experience and

knowledge.

•The machine must not be used or stored outdoors, in damp conditions or directly exposed to rain.

•The storage temperature must be between -25°C and +55°C; do not store outdoors in damp conditions.

•Conditions of use: room temperature between 0°°C and 40°°C, with relative humidity between 30 and 95%.

•The power supply cable outlet must have an earth connection in compliance with the regulatory standards.

•Do not use the machine as a means of transport for people or objects.

•The machine does not cause harmful vibrations.

•Never vacuum gases, liquids, explosive/inflammable powders, or undiluted acids and solvents! This list includes gasoline, paint thinners and

combustible oil (which, when mixed with the vacuum air, may form explosive vapours or mixtures), as well as acetone, undiluted acids and solvents,

and aluminium/magnesium powders. These substances may also corrode the materials that the device is made from.

•If the device is used in dangerous areas (e.g. petrol stations), the relative safety standards must be respected. It is forbidden to use the device in

environments with a potentially explosive atmosphere.

•Do not place any liquid containers on the machine.

•In the event of a fire, use a powder extinguisher. Do not use water.

•Do not knock against shelving or scaffolding, where there is a danger of falling objects. The operator must always be equipped with the appropriate

safety devices (gloves, shoes, helmet, goggles, etc.).

•If the machine does not work properly, check this is not caused by failure to carry out routine maintenance. Otherwise, ask for intervention of the

authorised technical assistance centre.

•If you need to replace any components, request the ORIGINAL spare parts from an Authorised dealer and/or Retailer.

•Restore all electrical connections after any maintenance interventions.

•Before using the machine, check that all the hatches and covers are positioned as shown in this Use and Maintenance Manual.Do not remove the

guards that can only be removed with the aid of tools, except for maintenance work (see the relevant paragraphs).

•Do not wash the machine with direct water jets or pressurised water, nor with corrosive substances.

•Have the machine checked by an authorised technical assistance centre every year.

•When disposing of consumable materials, observe the laws and regulations in force.When your machine has reached the end of its long working life,

dispose of the materials it contains in an appropriate manner, bearing in mind that it was constructed using 100% recyclable materials.

ISOPISOPLAM S.R.L.

Via E. Mattei, 4 – Z. I. Maser (TV) – Italy

Tel. (+39) 0423 925023 - www.isoplam.it

Company certified UNI EN ISO 9001:2015