Page 4 of 4 GT_8-IOM Rev. 0 7/19 Printed in USA

THIS INFORMATION IS SUBJECT TO THE CONTROLS OF THE EXPORT ADMINISTRATION REGULATIONS (EAR). THIS INFORMATION SHALL NOT BE PROVIDED TO

NON-US PERSONS OR TRANSFERRED BY ANY MEANS TO ANY LOCATION OUTSIDE THE UNITED STATES CONTRARY TO THE REQUIREMENTS OF THE EAR.

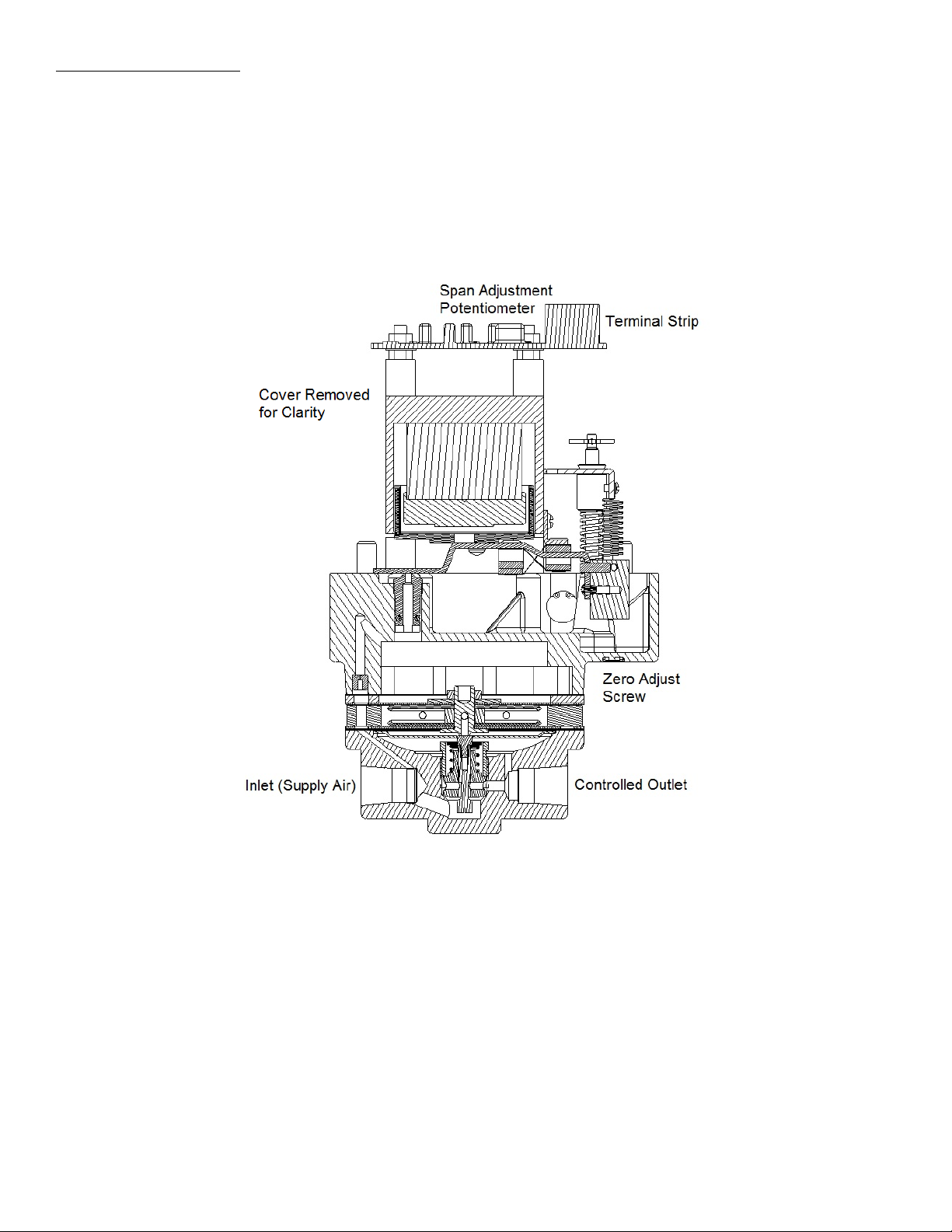

CALIBRATION AND ADJUSTMENTS

For adjustment and/or calibration verification, use the following

calibration procedure:

1. Connect the required air supply pressure (25 psig for the

GT18 and GT28, 35 psig for all others) to the inlet of the

transducer, and a pressure gauge to the outlet.

2. Connect the electrical input and set the input signal to the

0% value (e.g. 4 mA for a direct acting 4-20 mA unit).

3. Observe the output pressure. Adjust if necessary by

turning the external zero adjust screw located under the

cap near the output pressure connection.

4. Increase the electrical input signal to the 100% value (e.g.

20 mA for a direct acting 4-20 mA unit).

5. Observe the output pressure. If adjustment is necessary,

remove the cover cap and adjust the range potentiometer

on the circuit board to obtain the required output.

6. The zero and range adjustments are interactive. After

adjusting the range potentiometer it will be necessary to

recheck the zero. Repeat steps 2 through 5 until both

endpoints are at the required values.

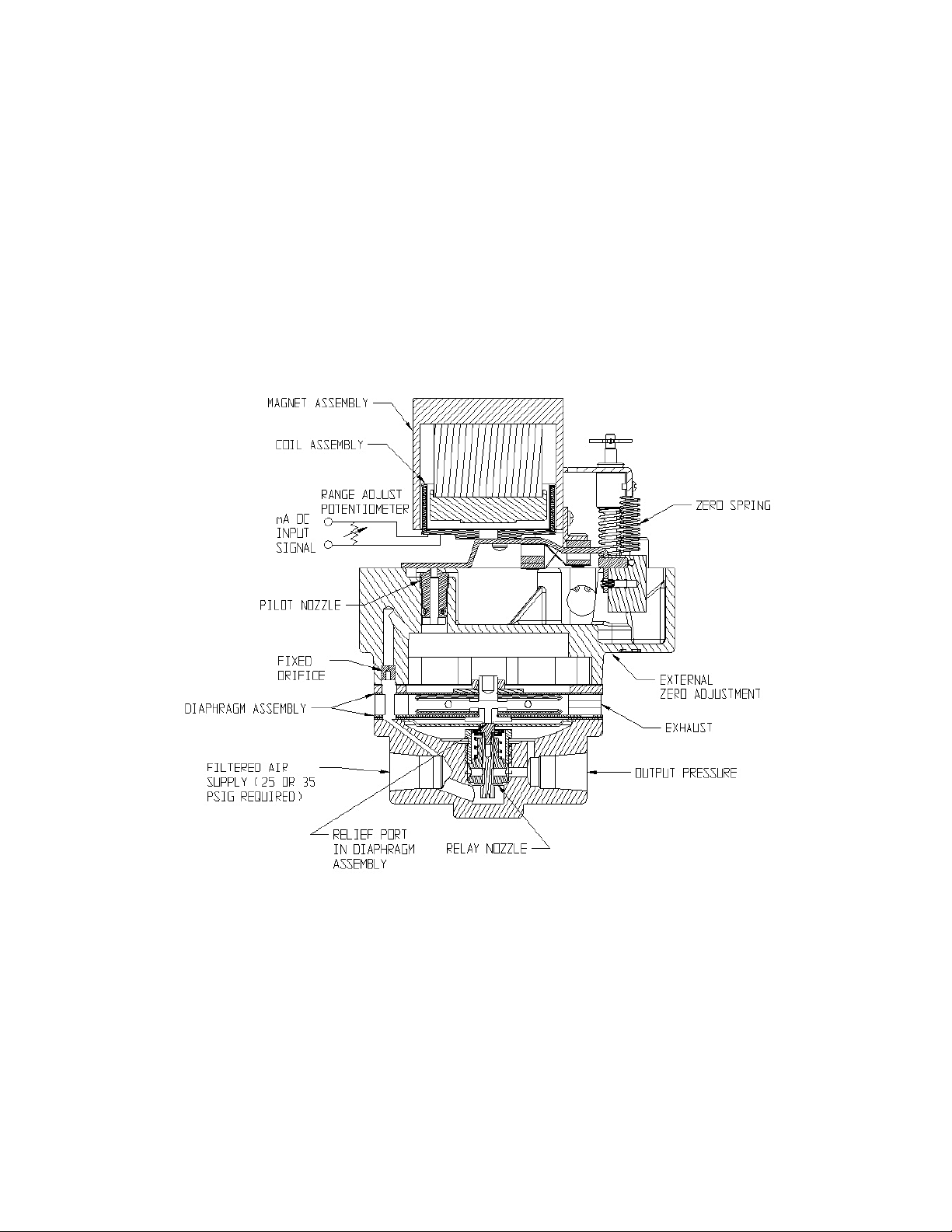

MAINTENANCE

Under normal conditions, no maintenance should be required. If

disassembly is necessary, refer to PNEUMATIC

TROUBLESHOOTING section of this document. It is important

that clean, dry air be supplied to the unit at all times. An ITT

Conoflow FR95 series Airpak (filter regulator) or equivalent

filtered air supply can be used to supply this I/P transducer

For pressure relay equipped models (GT28, GT48, or GT68)

periodically inspect the diaphragm assembly to see if the

diaphragm assembly shows signs of wear. To inspect, remove

the six (6) machine screws from the relay. While the relay is

disassembled from the I/P transducer, check freedom of

movement of the relay valve, and remove any foreign matter

which may have accumulated. When reassembling the relay, be

sure to properly orient the relay body to align the feed hole from

the inlet port to the fixed orifice in the housing cap. Tighten the

six (6) machine screws to 24 in-lb.

For replacement components, contact the factory with the full

model number and serial number of the product that parts are

required for.

TROUBLESHOOTING

PNEUMATIC

1. Check supply pressure. It should be constant 25 psig

(172 kPa) for the GT18 or GT 28 models, or a constant 35

psig (241 kPa) for all other models.

2. Make sure that tubing connections are tight.

3. Check zero and span calibration as previously outlined.

4. Check to see if housing body screen or flame arrestor (XP

version) is obstructed.

5. If disassembly is necessary, it must be done in a clean

work area. Should foreign debris become lodged between

the coil assembly and the magnet assembly, a malfunction

may occur. Removal of the magnet assembly will destroy

the calibration of the nozzle and balance beam

relationship.

6. If resonance (humming) is experienced, check outlet

piping to be sure it meets the minimum requirements

specified under INSTALLATION.

ELECTRICAL

1. Check to see that the input signal leads are connected to

proper terminals (see ELECTRICAL CONNECTION

section).

2. Make sure there are no loose wires at terminal or solder

connections.

3. Some field calibrators may not be able to supply sufficient

current to this transducer. Verify the input DC mA signal

using a digital ammeter.

4. Check input impedance by connecting an ohm meter to

terminals 1 and 2. In making any resistance tests, the

input signal wires from the controller (mA source) must be

disconnected. Nominal total input impedance of the 4-20

mA unit is 145 ohms. Nominal total input impedance of

the 10-50 mA unit is 60 ohms. Do not change the setting

of the range adjust potentiometer on the printed circuit

board when performing input impedance test.

5. A measure of resistance between any terminal of the

transducer and the external case should indicate an

“open” circuit. If resistance is indicated, coil windings or

the leads to the voice coil may be touching the case.

Further checks must then be made.

6. Remove housing from the transducer and disconnect the

coil lead plug from the circuit board. Check the

impedance of the coil. Nominal impedance is

approximately 150 ohms.

EXPLOSIONPROOF MODEL INFORMATION

FM Approvals lists the explosionproof model as

XP / I / 1 / BCD / T6 Ta = 60°C

DIP / II / 1 / EFG / T6 Ta = 60°C