4

Contents

FOR THE USER .................................................................................................... 5

Important information....................................................................................... 5

This is how your heat pump works ..................................................................... 6

Technology in and around the heat pump................................................................................................................6

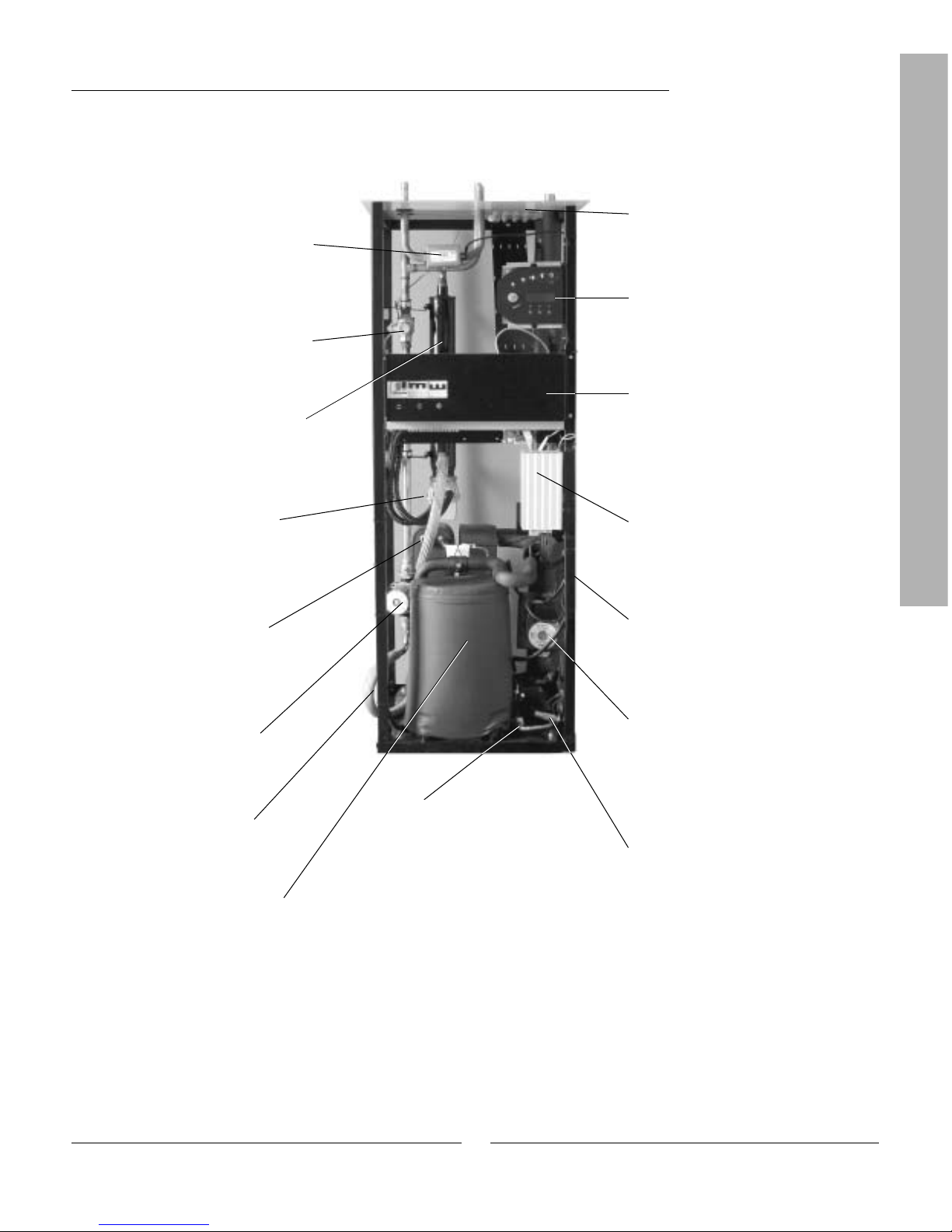

Component parts of the heat pump .................................................................... 8

Control unit Rego 637..................................................................................... 10

The control unit’s two methods to control the heat pump........................................................................................11

The control panel ............................................................................................ 12

Buttons and lamps ................................................................................................................................................12

Menu dial .............................................................................................................................................................13

How to use the control panel .................................................................................................................................13

Basic functions (Customer level 1) ................................................................... 13

Menu outline for Basic functions (Customer level 1).............................................................................................14

Select scrolling information on the menu display...................................................................................................14

Set the heating ......................................................................................................................................................15

Set the desired room temperature ..........................................................................................................................18

Set the heat pump for extra hot water ....................................................................................................................18

Heating and hot water settings ..............................................................................................................................19

Read the temperatures on the heat pump...............................................................................................................19

Extra functions (Customer level 2) ................................................................... 21

Menu outline for Extra functions (Customer level 2).............................................................................................21

Temperature settings ............................................................................................................................................22

Set extra heat curve with mixing valve ..................................................................................................................23

Hot water settings .................................................................................................................................................24

Timer control........................................................................................................................................................24

Reading operating times on the heat pump and additional heat ............................................................................25

Set the time and date ............................................................................................................................................26

Alarms given by the heat pump .............................................................................................................................27

Return to factory settings.......................................................................................................................................27

Maintenance................................................................................................... 28

Opening the front cover .........................................................................................................................................28

Sight glass.............................................................................................................................................................28

Expansion vessel ...................................................................................................................................................29

Particle filter.........................................................................................................................................................29

Checking the protective anode ...............................................................................................................................30

Savings .......................................................................................................... 31

What to do if a fault occurs .............................................................................. 32

Dimmed menu display ..........................................................................................................................................32

Fuses and reset buttons on the heat pump..............................................................................................................33

All alarms.............................................................................................................................................................33

Technical information...................................................................................... 40

The heat pump's factory settings ............................................................................................................................40

Sensor table...........................................................................................................................................................40

Technical information...........................................................................................................................................41

Index ............................................................................................................. 42

Table of Contents