RD Series Direct Drive Pump

Table of Contents

1Unpacking and Inspection.................................................................................... 1

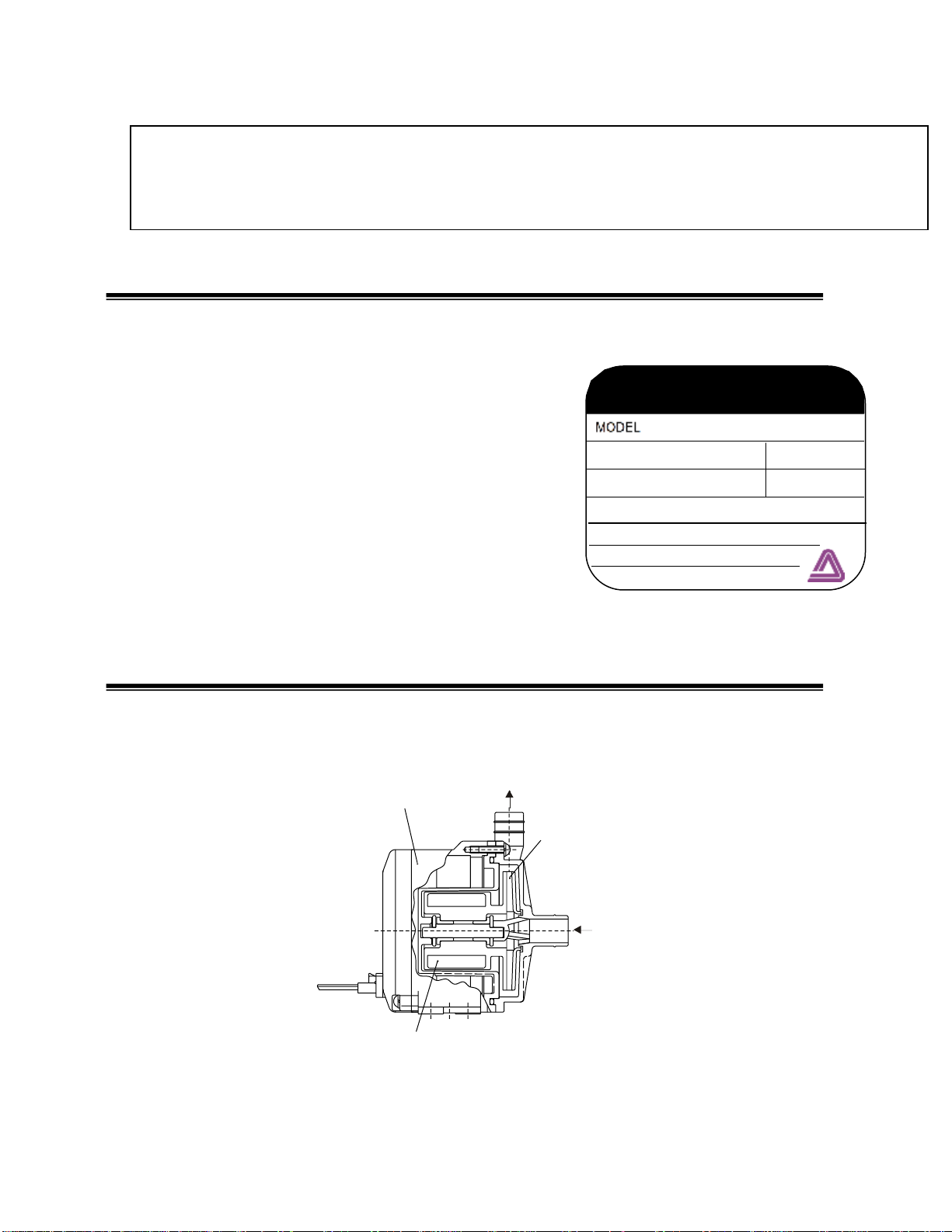

2Operating Principle................................................................................................ 1

3Model Identification Guide.................................................................................... 2

4Specifications ........................................................................................................ 4

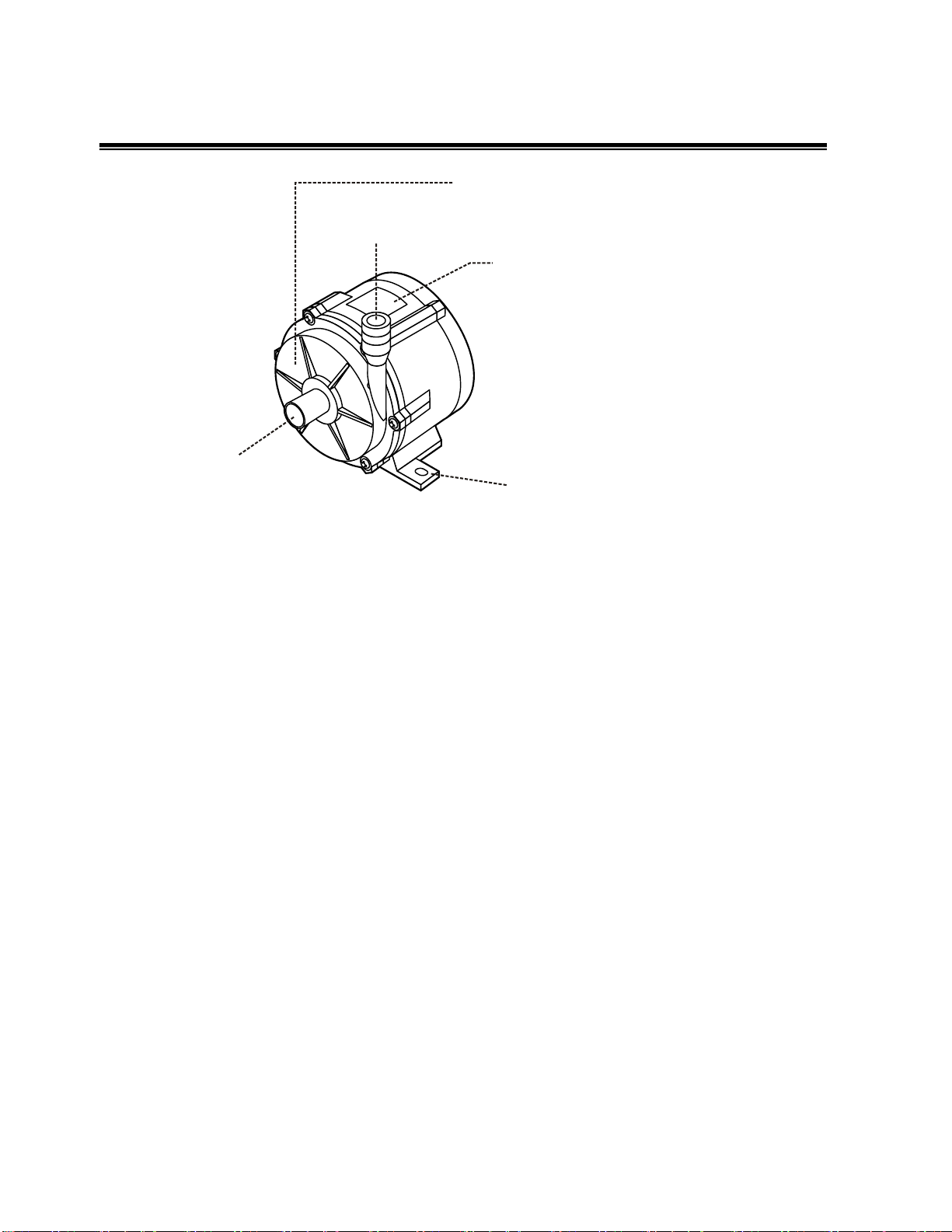

5Main Parts............................................................................................................... 5

6Dimensions ............................................................................................................ 6

7Handling Instructions............................................................................................ 7

8Installation, Piping and Wiring ............................................................................. 8

8.1 Installation ........................................................................................................ 8

8.2 Piping Instructions ............................................................................................ 9

8.3 Wiring ............................................................................................................ 10

9Operation.............................................................................................................. 11

Notes on Operation............................................................................................ 11

Operation ........................................................................................................... 12

Pump Stopping Procedures ............................................................................... 13

How to store pump when it is out of use for a long time..................................... 13

Draining Method................................................................................................. 13

Draining procedure............................................................................................. 14

10 Troubleshooting and Maintenance................................................................. 15

Maintenance....................................................................................................... 15

11 Parts Description ............................................................................................. 16

P/N 180286.G Aug 2012