7

the discharge pressure does not exceed the maximum pressure rating.

Contact IwakiAmerica or your distributor for the pressure rating of your pump if you are using an

external flush, casing drain or monitoring options.

4. Handlingofslurryliquid.

In general, slurries should not be handled. If the density is 5% wt or less and the grain size is 2mil

(50 microns) or less, however, pumping is possible. Prior to pumping such slurry liquid, you should call

IwakiAmerica or your distributor to verify if the operation is feasible.

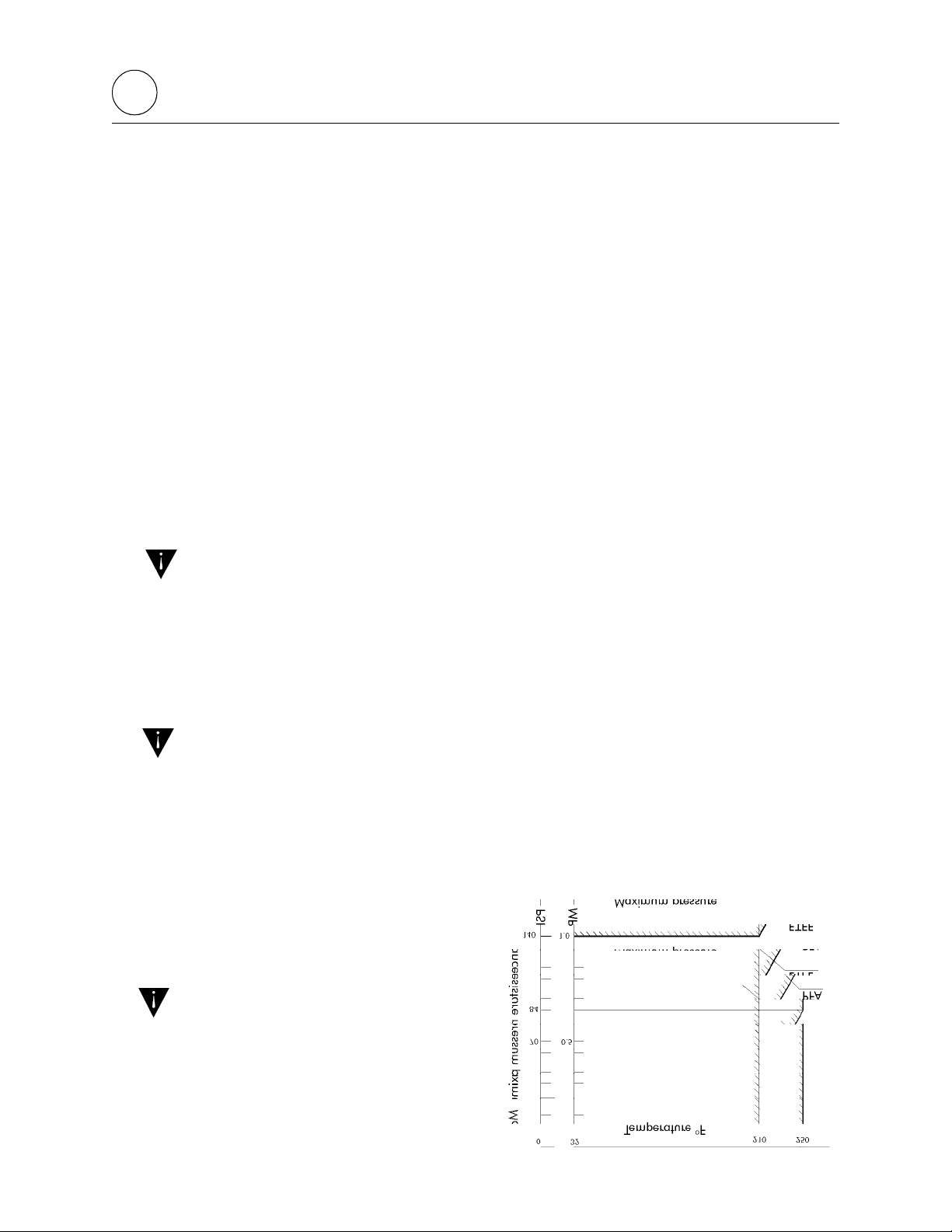

5. Influence of specific gravity on pump performance.

The performance of the pump does not change even for liquids of higher specific gravity. However, a

magnet assembly and motor selected for the specific gravity should be used.

6. Influence of liquid viscosity on pump performance.

When pumping a high viscosity fluid, the discharge head and capacity of the pump may be lower than

in the case of pure water. The required driving power may also vary and should be checked.

7. Intermittentoperation.

Frequent start/stop switching considerably shortens the service life of the pump. Limit the frequency

of switching to six times per hour.

8. Influence of temperature.

The pump itself may not suffer a change in performance due to temperature fluctuation. However, the

liquid may change in terms of viscosity, vapor pressure, and corrosive resistance. Pay special attention

to changes in liquid characteristics as a result of temperature fluctuation.

Installation, Piping and Wiring

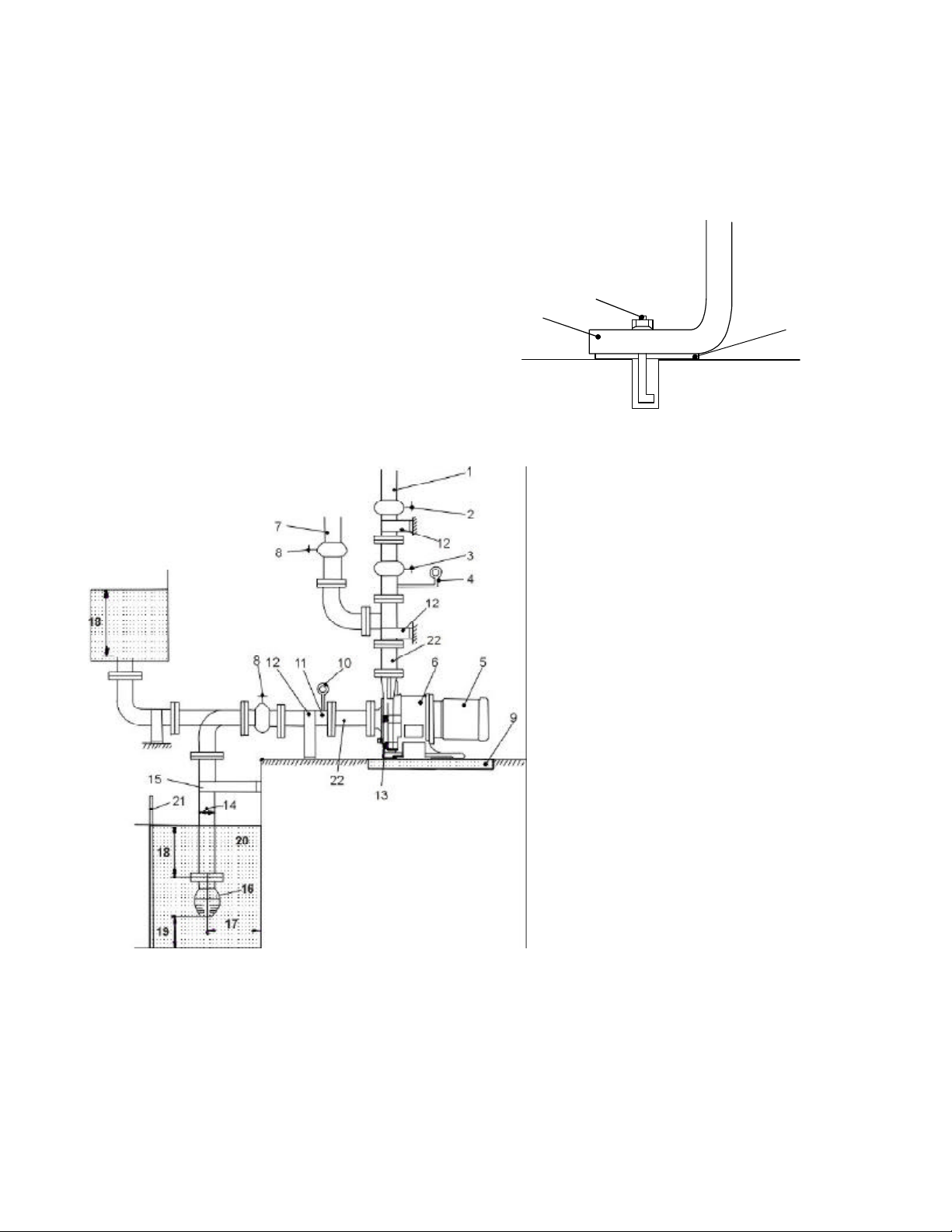

nInstallation position

1Install the pump as close to the suction tank as possible (flooded suction). If the suction port of the

pump is positioned higher than the suction tank (suction lift), be sure to arrange a foot valve in the

priming pipe and suction pipe. The lifting capability depends upon the liquid properties, temperature,

and length of suction piping. For details, consult IwakiAmerica or your distributor.

2. The pump can be installed for use indoors or outdoors. However, there should be sufficient space

around the pump to enable efficient and easy maintenance.

nInstallation

1. The pump anchoring area must be greater than the area of the base. If the anchoring area is not large

enough, the base may be damaged due to the concentration of loads placed on it.

2. Set the pump base on a concrete foundation and fasten the anchor bolts tightly to prevent the pump

fromvibrating during operation.

5