Section 2: Adjusting The Controller For

Stable Control With Different Heaters

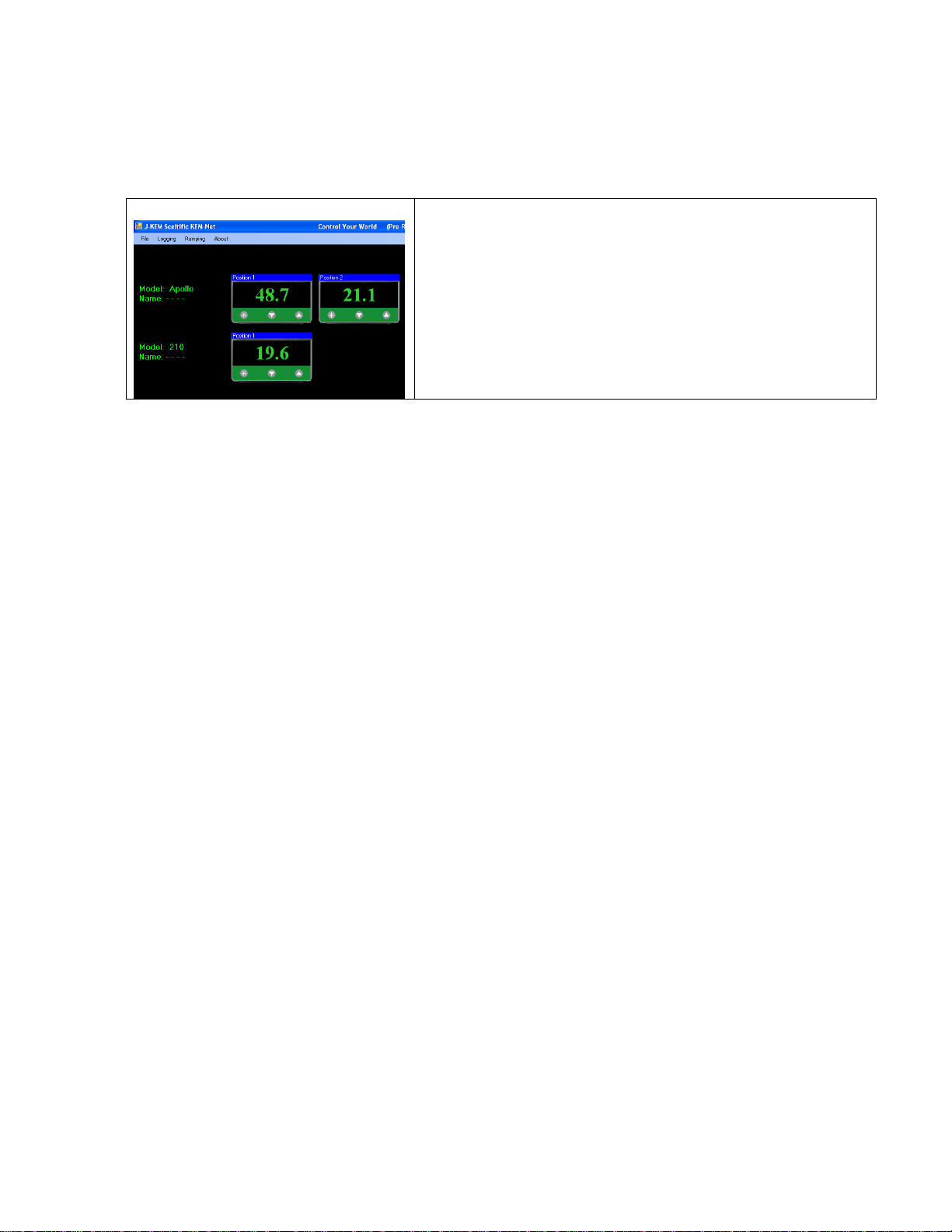

The Gemini controller has 2 completely independent temperature controllers in one cabinet. It's important to

remember that changes made to Channel 1 have no effect on Channel 2 and visa-versa. Each channel must

be tuned and adjusted separately.

2.1 What is Tuning. The controller's most powerful feature is its ability to regulate virtually any heater with

stable temperature control. To achieve stable control, the controller must 1) be set to the correct power level

(see Section 3.6) and, 2) be tuned to the heater being used. Tuning is the process that matches the control

characteristics of the controller to the heating characteristics of the heater. The controller is said to be tuned

to the heater when its memory is programmed with values describing how fast the heater warms up, cools

off, and how efficiently it transfers heat. For example, consider the difference between a heat lamp and a

hot plate. When electricity is applied to a heat lamp it begins to heat instantaneously, and when it's turned

off it stops heating instantaneously. In contrast, a hot plate takes several minutes to begin heating when

electricity is applied and even longer to stop heating when electricity is turned off. Your controller can

regulate both a heat lamp and a hot plate to 0.1oC. But, to do this it must be programmed with the time

constants describing how fast the heater heats and cools when electricity turns ON or OFF. These time

constants are called the tuning parameters.

Every type of heater has its own unique set of tuning parameters. For the controller to heat with

stability, it must have programmed with the tuning parameters for the heater currently being used. Prior to

shipment, tuning parameters were programmed into the controller that maximize heating performance for

laboratory heating mantles since these are the most common heaters used in research. Tuning is regulated

by 5 of the temperature meter’s user programmable functions. The correct value for these 5 functions can

be calculated and loaded manually, or the controller can do it automatically with its autotune feature.

When Should the Controller be Tuned? If the controller is tuned to one type of heater, heating mantles

for example, any size heating mantle can be used without the need to retune. When changing from

heating mantles to a different type of heater, an oven for example, the controller should be tuned with

values describing the oven’s heating characteristics. The effect of tuning is seen below. When the

controller is tuned for heating mantles, using it with any size heating mantle yields stable temperature

control (Plot 1), but poor control results when the same tuning parameters are used with an oven (Plot 2,

Curve 1). However, after tuning the controller to the oven, stable temperature control results (Plot 2,

Curve 2).