Jackson 636 User manual

JACKSON TOOL • P. O. BOX 5701 • GREENVILLE, SC 29606

877-522-8995 or 864-721-4235 • FAX 864-721-4236 • www.jacksontoolinc.com

Model 636 Jumbo Jack Pipe Stand

This manual is free of charge. All personnel who operate this Pipe

Stand should have a copy of this manual and read and understand

its contents. To request a copy, call or write to the address below.

Read and understand this material before operating

or servicing the Jumbo Jack. Failure to understand

how to safely operate and service this Pipe Stand may

result in property damage, serious injury or death.

Assembly, Operating, Safety and Parts Manual

08/2016

1

2

3

5

6

7

8

9

4

8" CASTERS

QUICK

LOCK

BRAKE

ADJUSTING

HANDLE

HEAD

STEEL

ROLLERS

1

2

3

4

5

6

HEAD

SHOULDER BOLT

ROLLER

SPACER

SET SCREW

BRONZE WASHER

ITEM QTY DESCRIPTIONPART NUMBER

1

2

3

4

5

6

1 636-856BASE WELDMENT

1 636-855TOP WELDMENT

5

CASTER

1

1 636-5WASHER

5

SET SCREW-5/16-18 X 1/4" LONG

74NUT-HEX, 3/8-16 (NYLON INSERT)

84SCREW-SHOULDER 1/2" X 2-1/4" LONG

94ROLLER 536-752

SPACER 636-846

636-4

2508-8

636-3

636-2

ITEM QTY DESCRIPTIONPART NUMBER

1

2

3

4

5

6

1

1

1

1

1

1

HANDLE NUT

HOLDDOWN WELDMENT

ACME SCREW

LINK-WRENCH CHAIN

LINK-QUICK

CHAIN - 10 ft

636-858

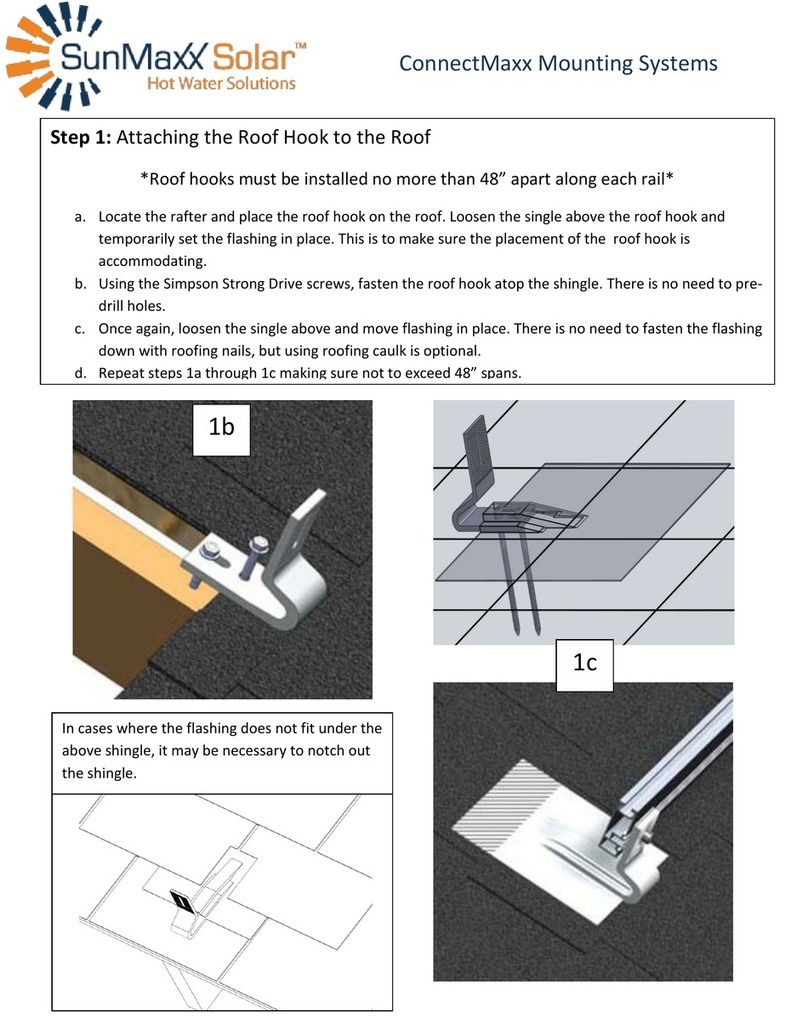

FRONT PICTURE FEATURES

EXPLODED VIEW EXPLODED VIEW

ASSEMBLY INSTRUCTIONS

2

TABLE OF CONTENTS

Safety Alerts .............................................. 2

Safety Information ......................................... 3

Features.................................................. 3

Specifications and Operating Instructions ..................... 4

Assembly Instructions ...................................... 5

Exploded View and Parts List – 636 ........................... 6

Exploded View and Parts List – 636NC ........................ 7

Hold Down Device Operating Instructions ................... 8, 9

Hold Down Device Exploded View and Parts List .............. 10

SAFETY ALERTS

Safety Alert

Symbol

THIS SAFETY SYMBOL is used to call your attention to instructions

that concern your personal safety. It means: ATTENTION! BE

AWARE! THIS IS AN IMPORTANT SAFETY INSTRUCTION!

Read, understand and follow these safety instructions. Failure to

follow these safety instructions may result in injury or death.

DANGER

WARNING

CAUTION

Immediate hazards which, if not avoided, WILL result in serious personal

injury or death.

Hazards or unsafe practices which, if not avoided, COULD result in serious

personal injury or death.

Hazards or unsafe practices which, if not avoided, COULD result in minor

personal injury or property damage.

RETAIN SAFETY INFORMATION

3

ALWAYS place the Pipe Stand on a smooth, level, firm surface that will

support the weight of the load. NEVER use on dirt or gravel surface. Be sure

all casters of the Pipe Stand make contact with the floor.

ALWAYS be sure the pipe is properly placed onto the Pipe Stand.

Improperly loaded pipe can cause tipping of the Pipe Stand, falling pipe

and serious injury.

ALWAYS inspect the Pipe Stand before each use. Never use if any part of the

Pipe Stand is bent, deformed or broken.

ALWAYS use a minimum of 2 Pipe Stands to support the pipe.

ALWAYS use a hold down device for each Pipe Stand when transporting pipe.

NEVER exceed the maximum rated capacity of the Pipe Stand.

NEVER alter the Pipe Stand. Only use the Pipe Stand for its designed purpose.

ALWAYS unlock and align casters before loading pipe on the Pipe Stands.

ALWAYS adjust the V-head height prior to loading the pipe onto the Pipe

Stands.

NEVER drop pipe onto

the Pipe Stand.

NEVER load more than

one pipe on the Pipe

Stands.

NEVER allow anyone

under the pipe while it is

supported by the Pipe

Stand.

NEVER use a hammer to

reposition the casters.

Damage can occur,

possibly causing serious

injury or death.

Hold down device is to be

used only to secure pipe

to Pipe Stands. DO NOT

use for any other purpose.

ALWAYS wear gloves

and other safety

equipment for your

specific job when using

the Pipe Stand.

IMPORTANT SAFETY INFORMATION

Follow ALL safety information provided by the manufacturer.

WARNING

DANGER

CAUTION

This manual should be read and understood by all personnel who operate or service this Pipe

Stand. Failure to understand how to safely operate and service this Pipe Stand could result in

injury or death. This unit should only be operated or serviced by qualified personnel.

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

FEATURES

8" CASTERS

QUICK LOCK

BRAKE

ADJUSTING

HANDLE

LARGE

V-HEAD

WIDE STEEL

ROLLERS

CHAIN RETAINER

BRACKET

(1 EACH SIDE)

WARNING

DANGER

CAUTION

4

1. Inspect the Pipe Stand before each use. Never use if any part of a Pipe Stand is bent,

deformed or broken. Never modify or use a Pipe Stand that has been modified.

2. Place the Pipe Stand on a smooth, level, firm surface that will support the weight of

the load. Be sure all casters of the Pipe Stand are making contact with the floor.

3. Always support the pipe with a minimum of two (2) Pipe Stands. Pipe size, weight and

length are some of the factors to consider when supporting pipe with the Pipe Stands.

4. Using the adjusting handle, adjust the V-heads of the Pipe Stands so they are the

same height. ALWAYS adjust the V-head height prior to loading the pipe onto the Pipe

Stands. Be sure all the casters are unlocked and pointing in the same direction before

loading the pipe onto the Pipe Stands.

5. Place the pipe onto the Pipe Stands. Never drop the pipe onto the Pipe Stands. Never

exceed the maximum rated capacity of the Pipe Stands. Never allow anyone under the

pipe while it is supported by the pipe stands.

6. Each caster on the Pipe Stand has a locking brake. To engage the brake, push down

on the brake lever. To unlock the brake, lift up on the brake lever.

NOTE: The V-head rollers have an oilite bearing and do not need regular lubrication.

OPERATING INSTRUCTIONS

SPECIFICATIONS

Model No. 636 636NC (No Casters)

Pipe Size Capacity 4" to 36" 4" to 36"

Max. Weight Capacity 2500 lbs. per Pipe Stand 2500 lbs. per Pipe Stand

Overall Dimensions W 35" H 361⁄4" W 35" H 28"

Weight 130 lbs. 90 lbs.

TO UNLOCK TO LOCK

ITEM QTY DESCRIPTIONPART NUMBER

1

2

3

4

5

6

1 636-856BASE WELDMENT

1 636-855TOP WELDMENT

5CASTER

1

1 636-5WASHER

5 SET SCREW-5/16-18 X 1/4" LONG

74NUT-HEX, 3/8-16 (NYLON INSERT)

84SCREW-SHOULDER 1/2" X 2-1/4" LONG

94ROLLER 536-752

SPACER 636-846

636-4

2508-8

636-3

636-2

ITEM QTY DESCRIPTION PART NUMBER

1

2

3

4

5

1

1

1

1

1

HANDLE NUT

HOLDDOWN WELDMENT

ACME SCREW

LINK-WRENCH CHAIN

CHAIN - 10 ft

636-858

EXPLODED VIEW

EXPLODED VIEW

ASSEMBLY INSTRUCTIONS

FEATURES

FRONT PAGE

CASTERS

1

2

3

4

5

SET SCREW

1

2

3

4

5

6

7

8

V-HEAD

ADJUSTING

HANDLE

QUICK

LOCK

BRAKE

STEEL

ROLLERS

8" CASTERS

4

8

ASSEMBLY INSTRUCTIONS — 636 JUMBO JACK

5

1. Fully insert five casters into base as shown and secure each with set screw provided.

2. Insert V-head into center tube of base.

3. Using adjusting handle, raise or lower V-head.

STEEL ROLLER

ADJUSTING

HANDLE

BASE

V-HEAD

SET SCREWS (5)

ONE PER CASTER

CASTERS (5)

6

EXPLODED VIEW — 636 JUMBO JACK

PARTS LIST — 636

ITEM# PART# QTY DESCRIPTION

1 .........636-861 .......... 1.............Base

2 .........636-855 .......... 1.............V-Head

3 ...........636-2 ............ 5.............Caster

4 .........636-846 .......... 8.............Spacer

5 ...........636-3 ............ 5.............Set Screw – 5⁄16"-18 X 1⁄4" Long

6 ...........302-2 ............ 4.............Nut – Hex, 3⁄8-16 (Nylon Insert – Thin)

7 ...........636-4 ............ 4.............Screw – Shoulder 1⁄2" X 2" Long

8 .........636-895 .......... 4.............Roller

8

4

2

7

6

1

5

3

ASSEMBLY INSTRUCTIONS — 636NC

7

1. Fully insert five foot assemblies into the base

as shown and secure each with set screw provided.

2. Insert V-head into center tube of base.

3. Using adjusting handle, raise or lower V-head.

V-HEAD

STEEL ROLLER

ADJUSTING

HANDLE

BASE

SET SCREWS (5)

ONE PER FOOT ASSEMBLY

FOOT ASSEMBLY

ALWAYS fully insert the

foot assemblies into the

base and secure with

the set screws. The foot

assemblies are NOT

designed to level the

Jumbo Jack.

CAUTION

8

EXPLODED VIEW – 636NC

PARTS LIST — 636NC

ITEM# PART# QTY DESCRIPTION

1 ....................302-2 .................. 4......... Nut – Hex, 3⁄8-16 (Nylon Insert – Thin)

2 ....................636-3 ................... 5......... Screw – Socket Set (5⁄16"-18 X 1⁄4") Cup Pt

3 ....................636-4 ................... 4......... Screw – Shoulder, (1⁄12" X 2")

4 ..................636-846 ................. 8......... Spacer

5 ..................636-855 ................. 1......... V-Head

6 ..................636-861 ................. 1......... Base

7 ..................636-895 ................. 4......... Roller

8 ..................636-902 ................. 5......... Foot Assembly

2

6

8

7

4

1

3

5

1. Insert the loose end of the chain through one of the chain retainer brackets located on

the V-head (See photo 1) until the hold down bracket is located at the top of the pipe

(See photo 2).

NOTE: There is a chain retainer bracket located on both sides of the V-head.

Either one may be used.

2. In order that you have the

maximum amount of adjustment

travel, adjust the handle/nut so

that the nut is flush with the end

of the acme screw. (See photo 3.)

3. Pull the loose end of the chain

around the pipe until snug and

place the end of a chain link into

the hook on the hold down

bracket (See photo 4).

9

HOLD DOWN DEVICE OPERATING INSTRUCTIONS

DANGER

WARNING

CAUTION

Hold down device is only to secure pipe to the Jumbo Jack Pipe Stand.

DO NOT use for any other purpose.

Photo 1 Photo 2

Photo 3

Photo 4

10

HOLD DOWN DEVICE OPERATING INSTRUCTIONS

4. As you tighten the chain with the handle/nut,

check to ensure that a link of the chain

engages the chain retainer slot (See photo 5).

NOTE: If the chain does not tighten before

you run out of adjustment, loosen the

handle/nut and place the next link of

the chain into the hook on the hold

down bracket. Be sure the hold down

bracket and chain are in line with the

chain retainer to ensure the chain

remains tight. (See photos below).

ALWAYS use a hold down device with each pipe stand when transporting pipe.

5. Before transporting, align the casters as follows:

A. Unlock ALL caster brakes (See page 4).

B. Rotate the pipe stand base in a circular

motion to align casters.

NEVER use a hammer to

reposition the casters. Damage

could occur causing serious

injury or death.

6. Ready for transport. (See photo to right).

ALWAYS push or pull the load

from the end. DO NOT stand to

the side of the load while

transporting.

WARNING

DANGER

CAUTION

WARNING

DANGER

CAUTION

Right Wrong

Photo 5

ITEM# PART# QTY DESCRIPTION

1 ...................636-7 ..................1................ Handle/Nut

2 .................636-858 ................1................ Holddown Bracket

3 .................636-899 ................1................ Acme Screw/Chain

Assembly

HOLD DOWN DEVICE #636-851

EXPLODED VIEW AND PARTS LIST

11

1

2

3

This manual suits for next models

1

Other Jackson Rack & Stand manuals

Popular Rack & Stand manuals by other brands

HAGOR

HAGOR WH Turn M installation manual

PEERLESS

PEERLESS PARAMOUNT PF640 Installation and assembly

Konig & Meyer

Konig & Meyer Double 17620 instruction manual

AA Products

AA Products KS-02 instruction manual

SmartRoom

SmartRoom ZigBee SR-IES-01 quick guide

Premier Mounts

Premier Mounts LMVSP installation guide