J&E Hall HBLT-A1 User manual

Section 4

Publication 9-86

Issue 1 : 10/22

Section 9 Publication 9-86

Issue 1 : 10/22 Page 1 of 10

HB Products HBLT-A1 Liquid Level Transmitters

Contents

1. About this Publication.................................................................................................... 2

1.1. Safety Warnings and Symbols.................................................................................................2

1.2. Units of Measurement..............................................................................................................2

1.3. Terminology .............................................................................................................................2

1.4. Additional Copies.....................................................................................................................2

2. Introduction ................................................................................................................... 3

3. Technical Data .............................................................................................................. 3

4. Operation ...................................................................................................................... 5

5. Installation ..................................................................................................................... 5

5.1. General ....................................................................................................................................5

5.2. Wiring.......................................................................................................................................6

6. Commissioning.............................................................................................................. 6

6.1. Selecting the Refrigerant .........................................................................................................7

6.2. Signal Damping........................................................................................................................7

6.3. Calibration................................................................................................................................8

6.3.1. Adjusting the Minimum and Maximum Calibration Points .................................................8

6.3.1.1. Minimum Calibration....................................................................................................8

6.3.1.2. Maximum Calibration...................................................................................................8

6.3.1.3. Minimum Calibration When the Minimum Liquid Level is Different From 4 mA ...........8

6.3.1.4. Maximum Calibration When the Maximum Liquid Level is Different From 20 mA .......9

6.4. Restore Factory Default Settings .............................................................................................9

6.5. LED Indication..........................................................................................................................9

7. Maintenance................................................................................................................ 10

8. Faults and Remedies .................................................................................................. 10

9. Spare Parts ................................................................................................................. 10

10. Safe Disposal, End-of-life (EOL)................................................................................. 10

List of Figures

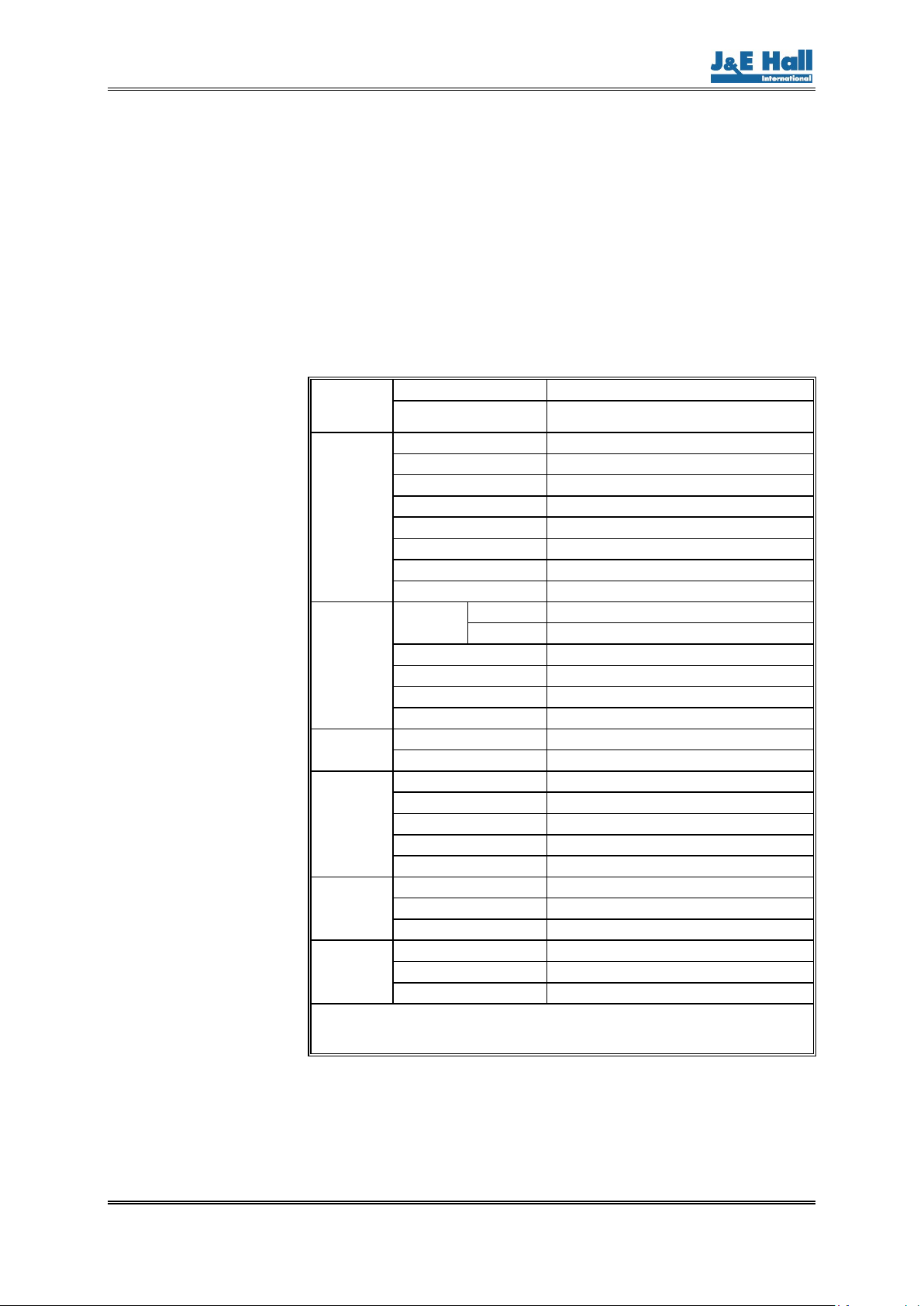

Fig 1 Arrangement, Dimensions and Model Numbers............................................................................4

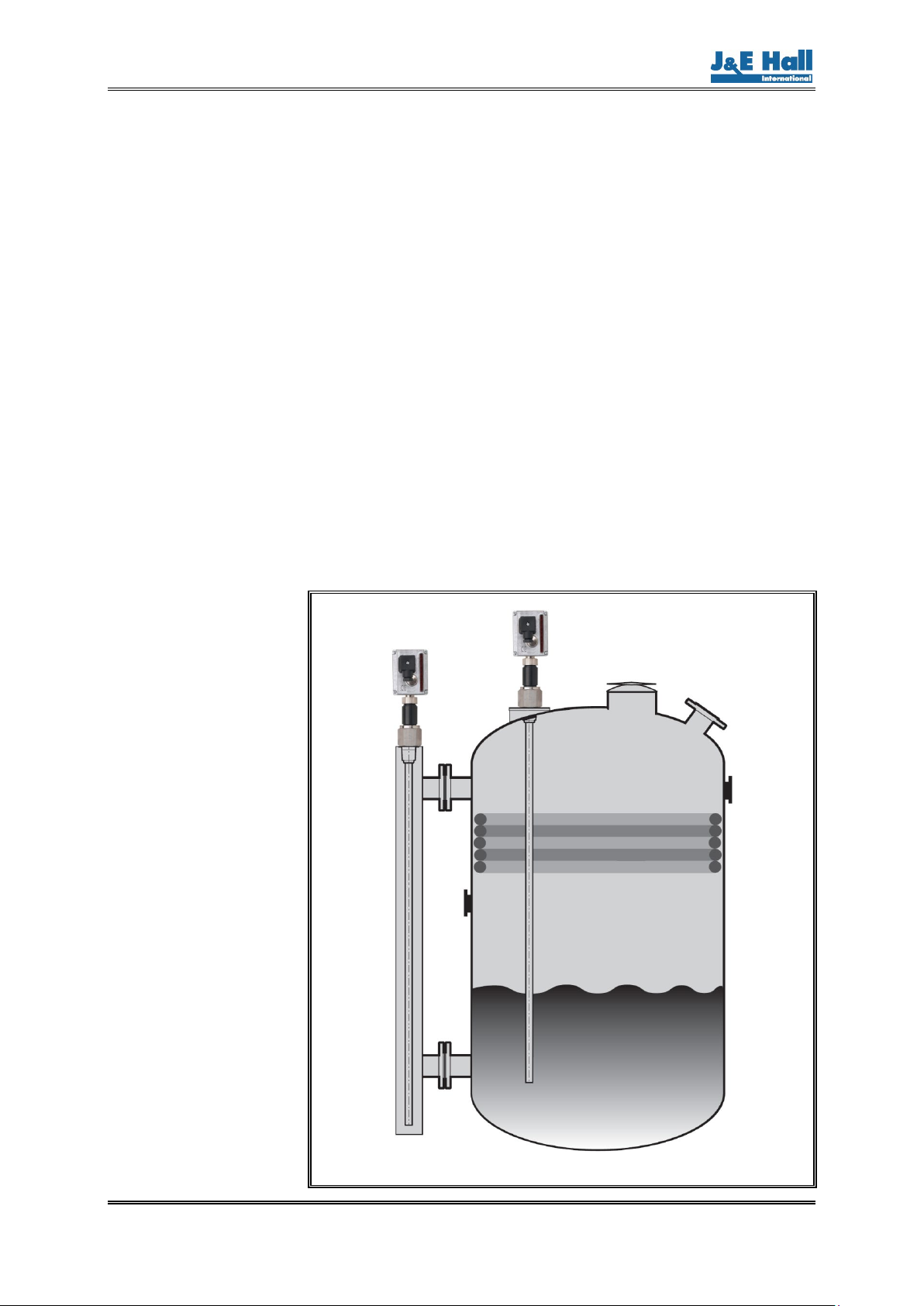

Fig 2 Installation .....................................................................................................................................5

Fig 3 Installation into Standpipe or Vessel..............................................................................................6

Fig 4 Wiring ............................................................................................................................................6

List of Tables

Table 1 Technical Data...........................................................................................................................3

Table 2 Refrigerant Settings...................................................................................................................7

Table 3 Faults and Remedies...............................................................................................................10

J & E Hall International©2022

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying, recording or by any information

storage or retrieval system, without permission in writing from the copyright holder.

The copyright in this publication shall be and remain the sole property of J & E Hall International.

HB Products HBLT-A1 Liquid Level Transmitters

Publication 9-86 Section 9

Page 2 of 10 Issue 1 : 10/22

1. About this Publication

These instructions have been prepared according to the following

standards:

•BS EN ISO 11442: Technical product documentation.

Document management;

•BS EN ISO 12100: Safety of machinery - General principles

for design - Risk assessment and risk reduction;

•BS EN 62023: Structuring of technical information and

documentation;

•BS EN 82079-1: Preparation of instructions for use.

Structuring, content and presentation. General principles

and detailed requirements.

1.1. Safety Warnings and Symbols

The system of safety warnings and symbols is based on:

•BS EN ISO 7010: Graphical symbols. Safety colours and

safety signs. Registered safety signs;

•BS EN 82079-1: Preparation of instructions for use.

Structuring, content and presentation. General principles

and detailed requirements.

DANGER

This indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury if

instructions, including recommended precautions, are

not followed.

WARNING

This indicates a hazard with a medium level of risk,

which if not avoided, will result in death or serious

injury if instructions, including recommended

precautions, are not followed. In addition, there is a

high risk of damage to the component, product or

process.

CAUTION

This indicates a hazard with a low level of risk, which if

not avoided, will result in minor or moderate injury if

instructions, including recommended precautions, are

not followed. In addition, there is a potential risk of

damage to the component, product or process.

NOTE: Draws attention to important additional

information.

1.2. Units of Measurement

Quantities are expressed in SI units or SI derived units; refer to J & E Hall

International Standard JEH-ES-02 Guide to the International System of

Units (SI).

1.3. Terminology

Terminology, abbreviations and acronyms are those currently in use

throughout the refrigeration and air conditioning industry; refer to J & E

Hall International Standard JEH-ES-01 Definition of Terms and Acronyms

Used in the Refrigeration Industry.

1.4. Additional Copies

Obtain additional copies of these instructions from J & E Hall

International; go to www.jehall.com.

HB Products HBLT-A1 Liquid Level Transmitters

Section 9 Publication 9-86

Issue 1 : 10/22 Page 3 of 10

2. Introduction

HBLT-A1 liquid level transmitters are used to measure refrigerant liquid

level for control applications. The transmitter supplies a 4 to 20 mA

signal in proportion to the level of liquid refrigerant. This signal can be

used with a suitable controller to measure and control the level of

refrigerant within a vessel.

The location of the liquid level transmitter and details of the level

controller can be found from the system schematic flow diagram and in

Part A : Specification in Section 1 of the plant instruction manual.

This publication covers HBLT-A1 level transmitters, for other types of HB

level transmitter refer to publication 9-85.

3. Technical Data

General

Type Rigid transmitter

Refrigerants R22, R134a, R404A, R507A,

R717 (ammonia), R718 (water), R744 (CO2)

Electrical

Voltage 24 V ac/dv + 10 % (50/60 Hz)

Power 1.5 W

Maximum load resistance 500 Ω (max)

Connection Plug 4 pins DIN 43650

Cable Wire Size 3 x 0.34 mm2

Analogue output 4 to 20 mA

Indication Red LEDs (bar graph)

Configuration Pushbutton

Environmental

Ambient

Temperatures

Transportation -40.0 to +70.0 °C

Operation -30.0 to +50.0 °C

Media temperature -60.0 to +80.0 °C

Pressure 100 bar (max)

Protection IP65

Vibration IEC 60068-2-6 (4g)

Mechanical

Available lengths 280 to 3000 mm and 6” to 120”

1Connection ¾” NPT or ¾” BSP

Material

Thread Stainless-steel AISI 303

Transmitter rod Stainless-steel AISI 304

Inner electrode PTFE coated

Transmitter housing Cast aluminium

Electronics Nylon 6 (PA)

Approvals

EMC - emission EN 61000-3-2

EMC - immunity EN 61000-4-2

GOST R No 0903044

Factory Default

Settings

Refrigerant R717 (ammonia)

Transmitter rod length 1500 mm (59”)

Signal damping 15 seconds

1Weld and thread adaptors are available, for example, ¾” NPT/1” BSP.

Table 1 Technical Data

HB Products HBLT-A1 Liquid Level Transmitters

Publication 9-86 Section 9

Page 4 of 10 Issue 1 : 10/22

BSP Threads

NPT Threads

Item Description Item Description Item Description

1 Screw - cover 4 Calibration pushbutton 7 Spanner flats

2 DIN plug 5 Cover – transmitter housing 8 Threads (BSP or NPT)

3 Red LEDs (bar graph) 6 Transmitter housing 9 Transmitter rod

Level Transmitter Transmitter

Rod Length L

mm/in

Thread

Level Transmitter Transmitter

Rod Length L

mm/in

Thread

Without LED

Bar Graph

With LED

Bar Graph Without LED

Bar Graph

With LED

Bar Graph

HBLT-A1-2.8 HBLT-A1B-2.8 280 mm

1” BSP

HBLT-A1-15.3U HBLT-A1B-15.3U 15.3 in

¾ NPT

HBLT-A1-5 HBLT-A1B-5 500 mm HBLT-A1-19.2U HBLT-A1B-19.2U 19.2 in

HBLT-A1-8 HBLT-A1B-8 800 mm HBLT-A1-23.1U HBLT-A1B-23.1U 23.1 in

HBLT-A1-10 HBLT-A1B-10 1000 mm HBLT-A1-30U HBLT-A1B-30U 30 in

HBLT-A1-12 HBLT-A1B-12 1200 mm HBLT-A1-35Y HBLT-A1B-35Y 35 in

HBLT-A1-15 HBLT-A1B-15 1500 mm HBLT-A1-45U HBLT-A1B-45U 45 in

HBLT-A1-17 HBLT-A1B-17 1700 mm HBLT-A1-55U HBLT-A1B-55U 55 in

HBLT-A1-22 HBLT-A1B-22 2200 mm HBLT-A1-65U HBLT-A1B-65U 65 in

HBLT-A1-30 HBLT-A1B-30 3000 mm HBLT-A1-85U HBLT-A1B-85U 85 in

HBLT-A1-6U HBLT-A1B-6U 6 in

¾ NPT

HBLT-A1-105U HBLT-A1B-105U 105 in

HBLT-A1-8U HBLT-A1B-8U 8 in HBLT-A1-120U HBLT-A1B-120U 120 in

HBLT-A1-12U HBLT-A1B-12U 12 in

Fig 1 Arrangement, Dimensions and Model Numbers

1

3

5

2

4

6

7

8

9

HB Products HBLT-A1 Liquid Level Transmitters

Section 9 Publication 9-86

Issue 1 : 10/22 Page 5 of 10

4. Operation

Liquid level is detected by change in capacitance. The hollow transmitter

rod acts as one plate of the capacitor, the PTFE coated electrode inside

the rod acts as the other plate.

As the liquid level rises and falls there is a change in the value of

capacitance. The electronics inside the transmitter housing converts this

change to a 4 to 20 mA signal in proportion to the change in liquid level.

It is not necessary to break into the system to replace the transmitter

housing electronics. This item can be separated from the transmitter rod

by hand.

5. Installation

5.1. General

To minimise interference from turbulence installation in a standpipe is

recommended although direct installation into a vessel or tank is

possible; refer to Fig 2.

The level transmitter must be installed:

•In a vertical position;

•With a minimum clearance of 50 mm between the bottom of

the transmitter rod and the bottom of the standpipe, vessel

or tank;

•Allowing adequate space above for transmitter removal.

Install the transmitter as shown in Fig 3.

Fig 2 Installation

HB Products HBLT-A1 Liquid Level Transmitters

Publication 9-86 Section 9

Page 6 of 10 Issue 1 : 10/22

Fig 3 Installation into Standpipe or Vessel

5.2. Wiring

The transmitter supplies a 4 to 20 mA signal in proportion to the level of

liquid refrigerant to a suitable controller (PLC).

Refer to J & E Hall International certified wiring diagrams for electrical

connections specific to this application. Take particular care regarding

the termination of screened cable; refer to the notes on the wiring

diagrams

Fig 4 Wiring

6. Commissioning

WARNING

The pressure and temperature parameters detailed in

Table 1 must NOT be exceeded when pressure testing

the plant.

When the plant is charged with refrigerant for the first time, leave the

isolating stop valves in the open position. If the level column has been

isolated for maintenance while the vessel to which it is fitted is still under

system temperature and pressure, open the stop valve at the top of the

column first of all, then open the valve at the bottom by a small amount to

allow the column to slowly fill with liquid.

During commissioning, check the probe/level column joint for leaks.

Tighten to 80 to

150 Nm

NPT threads: use Loctite 577 thread sealer

BSP threads: use sealing ring provided

HB Products HBLT-A1 Liquid Level Transmitters

Section 9 Publication 9-86

Issue 1 : 10/22 Page 7 of 10

6.1. Selecting the Refrigerant

The liquid level transmitter is supplied factory set for use with R717

(ammonia) refrigerant. If this refrigerant is used there is no need to

change this setting. For other refrigerants, or if the transmitter housing

electronics have been replaced, proceeds as follows:

(a) Arrange to measure the 4 to 20 mA output signal.

(b) Disconnect the power supply by unplugging the DIN plug from the

transmitter housing.

(c) Press the calibration pushbutton and keep it pressed while

restoring the power supply (reinstate the DIN plug). Release the

pushbutton.

NOTE: If the power supply is restored before the

calibration pushbutton is pressed, the signal damping

will be changed; refer to 6.2.

(d) Observe the green LED flashing, at the same time measure the

4 to 20 mA output signal; refer to Table 2.

Green LED Number of Flashes 4 to 20 mA Output Signal 1Refrigerant

1 flash 5 mA R717 (ammonia) (factory setting)

2 flashes 6 mA R22 and R507A

3 flashes 7 mA R404A

4 flashes 8 mA R134a

5 flashes 9 mA R744 (CO2)

1For refrigerants not listed, contact J & E Hall International.

Table 2 Refrigerant Settings

(e) Press and release the pushbutton to step down through the list

until the number of LED flashes and the output signal correspond

to the required refrigerant.

When the output current corresponds to the required

refrigerant, wait 10 seconds until the green LED is constantly

lit (not flashing). This indicates that the required refrigerant

has been selected.

(f) Leave change of refrigerant mode by disconnecting the power

supply to the transmitter (unplug the DIN plug from the transmitter

housing).

(g) Reinstate the power supply.

6.2. Signal Damping

The signal damping setting range is 1 to 120 seconds, factory setting 15

seconds. To change the signal damping proceed as follows:

(a) Disconnect the power supply by unplugging the DIN plug from the

transmitter housing. Restore the power supply (reinstate the DIN

plug).

(b) Press and release the calibration pushbutton. Each press and

release increases the signal damping by 1 second from 1 second

up to a maximum of 120 seconds.

For example, to set signal damping to 37 seconds, press

and release the pushbutton 37 times.

(c) 10 seconds after the last press and release, the damping value is

saved to memory and the green LED will start flashing.

If the damping is set too high, repeat the procedure from

step (a).

HB Products HBLT-A1 Liquid Level Transmitters

Publication 9-86 Section 9

Page 8 of 10 Issue 1 : 10/22

6.3. Calibration

The level transmitter electronics are calibrated for R717 (ammonia)

refrigerant (refer to 6.1) and a transmitter rod length of 1500 mm (59”).

The default factory settings are:

•0 % (transmitter rod completely uncovered) output signal

4 mA;

•100 % (transmitter rod completely covered with liquid) output

signal is 20 mA.

Calibration is not required if the system refrigerant is R717 (ammonia)

and the transmitter rod length corresponds to the actual liquid measuring

range. However, calibration is necessary if:

•The level transmitter is used with a refrigerant other than

R717 (ammonia);

•A transmitter rod length other than 1500 mm (59”) is used in

which case the maximum and minimum calibration points

require adjustment;

•It is required to replace the transmitter housing electronics.

6.3.1. Adjusting the Minimum and Maximum Calibration Points

6.3.1.1. Minimum Calibration

(a) Lower the liquid level in the vessel to the desired minimum level.

(b) Press and hold the calibration pushbutton for approximately 5

seconds until the green LED stops flashing. Release the

pushbutton.

(c) Press and release the pushbutton once within the next 10 seconds.

NOTE: The level switch will return to normal operation if

the pushbutton is not pressed within 10 seconds.

After a few seconds the green LED starts to flash. The

output is now set to 4 mA and the level transmitter is in

normal operation.

6.3.1.2. Maximum Calibration

(a) Raise the liquid level in the vessel to the desired maximum level.

(b) Press and hold the calibration pushbutton for approximately 5

seconds until the green LED stops flashing. Release the

pushbutton.

(c) Within the next 10 seconds press and release the pushbutton twice

with a 1 second delay between each press.

NOTE: The level switch will return to normal operation if

the pushbutton is not pressed twice within 10 seconds.

After a few seconds the green LED starts to flash. The

output is now set to 20 mA and the level transmitter is in

normal operation.

6.3.1.3. Minimum Calibration When the Minimum Liquid Level is Different

From 4 mA

(a) Arrange to measure the 4 to 20 mA output signal.

(b) Lower the liquid level in the vessel to the desired minimum level.

(c) Press and hold the calibration pushbutton for approximately 5

seconds until the green LED stops flashing. Release the

pushbutton.

(d) Within the next 10 seconds, press the pushbutton and keep it

pressed.

NOTE: The level switch will return to normal operation if

the pushbutton is not pressed within 10 seconds.

HB Products HBLT-A1 Liquid Level Transmitters

Section 9 Publication 9-86

Issue 1 : 10/22 Page 9 of 10

(e) Starting at 4 mA, observe the output signal increasing. Release

the pushbutton when the output signal is approximately 0.5 mA

from the desired point.

(f) Repeat steps (c) and (d). Each repeat will increase the output

signal by approximately 0.05 mA.

10 seconds after the last repeat the green LED starts to

flash. The output now corresponds to the last measured

value and the level transmitter is in normal operation.

6.3.1.4. Maximum Calibration When the Maximum Liquid Level is Different

From 20 mA

(a) Arrange to measure the 4 to 20 mA output signal.

(b) Raise the liquid level in the vessel to the desired maximum level.

(c) Press and hold the calibration pushbutton for approximately 5

seconds until the green LED stops flashing. Release the

pushbutton.

(d) Within the next 10 seconds press and release the pushbutton then

after 1 second press again and keep the button pressed.

NOTE: The level switch will return to normal operation if

the pushbutton is not pressed twice within 10 seconds.

(e) Starting at 20 mA, observe the output signal decreasing. Release

the pushbutton when the output signal is approximately 0.5 mA

from the desired point.

(f) Repeat steps (c) and (d). Each repeat will decrease the output

signal by approximately 0.05 mA.

10 seconds after the last repeat the green LED starts to

flash. The output now corresponds to the last measured

value and the level transmitter is in normal operation.

6.4. Restore Factory Default Settings

Press and hold the calibration pushbutton for ≥20 seconds, until the

green LED starts flashing indicating that the factory reset is complete.

Release the pushbutton.

The default setting is for use with R717 (ammonia) refrigerant and a

transmitter rod length of 1500 mm (59”), change if required; refer to 7.1 to

7.4.

6.5. LED Indication

When power is applied to the level transmitter the LED will flash rapidly

as many times as the transmitter has been calibrated during its lifetime.

The 4 to 20 mA output signal is recognised and updated as soon as the

flashing changes from rapid to slow flashing.

Normal Operation

The green LED flashes slowly during normal operation. Generally, the

green LED is lit when the calibration pushbutton is pressed.

Selecting the Refrigerant

Refer to 6.1.

The green LED is unlit until the pushbutton is released at the end of step

(b). The LED then flashes a number of times according to the refrigerant,

then remains lit when the refrigerant has been selected.

Calibration

Refer to 6.3.

While calibration is taking place during step (b) the green LED is unlit.

HB Products HBLT-A1 Liquid Level Transmitters

Publication 9-86 Section 9

Page 10 of 10 Issue 1 : 10/22

7. Maintenance

No routine maintenance is required other than periodically checking that

the level indicated corresponds to the liquid level within the vessel.

If the system uses R717 (ammonia) refrigerant, oil may tend to collect at

the bottom of the level column. The HBLT-A1 is less susceptible to oil

logging than other designs of level transmitter, however, if it is suspected

that oil accumulation might be interfering with the correct operation of the

transmitter, drain off the oil using the apparatus and method illustrated

and described in Pumping Down, Recovering Ammonia Refrigerant

Charge in publication 5-20 in Section 5.

8. Faults and Remedies

Some of the more common fault conditions are given in Table 3.

Fault Probable Cause Remedy

No function, green LED not lit.

No power supply or power supply incorrect, faulty

wiring/plug.

Check power supply is available, supply polarity and

voltage is correct. Check wiring continuity and plug

connections.

Level transmitter electronic defective. Replace electronics.

No 4 to 20 mA output signal, green LED flashes

rapidly.

Faulty wiring/plug Check supply polarity. Check wiring continuity and

plug connections.

4 to 20 mA output signal does not correspond to the

actual liquid level

Wrong refrigerant selected. Select correct refrigerant; refer to 6.1.

Level transmitter not calibrated or incorrect

calibration.

Calibrate level transmitter; refer to 6.3. If calibration

has been carried out incorrectly, restore factory

default settings before recalibrating.

4 to 20 mA output signal is low or erratic Oil accumulation in the standpipe. Drain off the oil; refer to 7. Maintenance.

After supplying power to the level transmitter, there is

a long delay before the 4 to 20 mA output signal is

recognised and updated

Minimum/maximum calibration has been carried

out many times.

When power is applied to the level transmitter the

LED will flash rapidly as many times as the

transmitter has been calibrated during its lifetime.

The 4 to 20 mA output signal is recognised and

updated as soon as the flashing changes from rapid

to slow flashing.

Table 3 Faults and Remedies

9. Spare Parts

Obtain spare parts from the address below:

J & E Hall International Telephone: +44 (0) 1332-253400

Hansard Gate, Fax: +44 (0) 1332-371061

West Meadows, Email: spares@jehall.co.uk

Derby, Website: www.jehall.com

DE21 6JN

England

When ordering always quote the J & E Hall International contract number

and the component serial number (if available).

10. Safe Disposal, End-of-life (EOL)

At the end of the level transmitter's working life, it should not be classed

as domestic waste but be disposed of separately by a registered

recycling company according to local and currently valid legislation.

This manual suits for next models

46

Table of contents

Other J&E Hall Transmitter manuals

Popular Transmitter manuals by other brands

DLO

DLO TuneStik quick start guide

Siemens

Siemens Sitrans LU-180 operating instructions

Sentera Controls

Sentera Controls RSMF-2R Series Mounting and operating instructions

Shinko

Shinko SGB instruction manual

Pfeiffer Vacuum

Pfeiffer Vacuum CPT 100 operating instructions

Duon System

Duon System AUTROL Series Operation manual