4

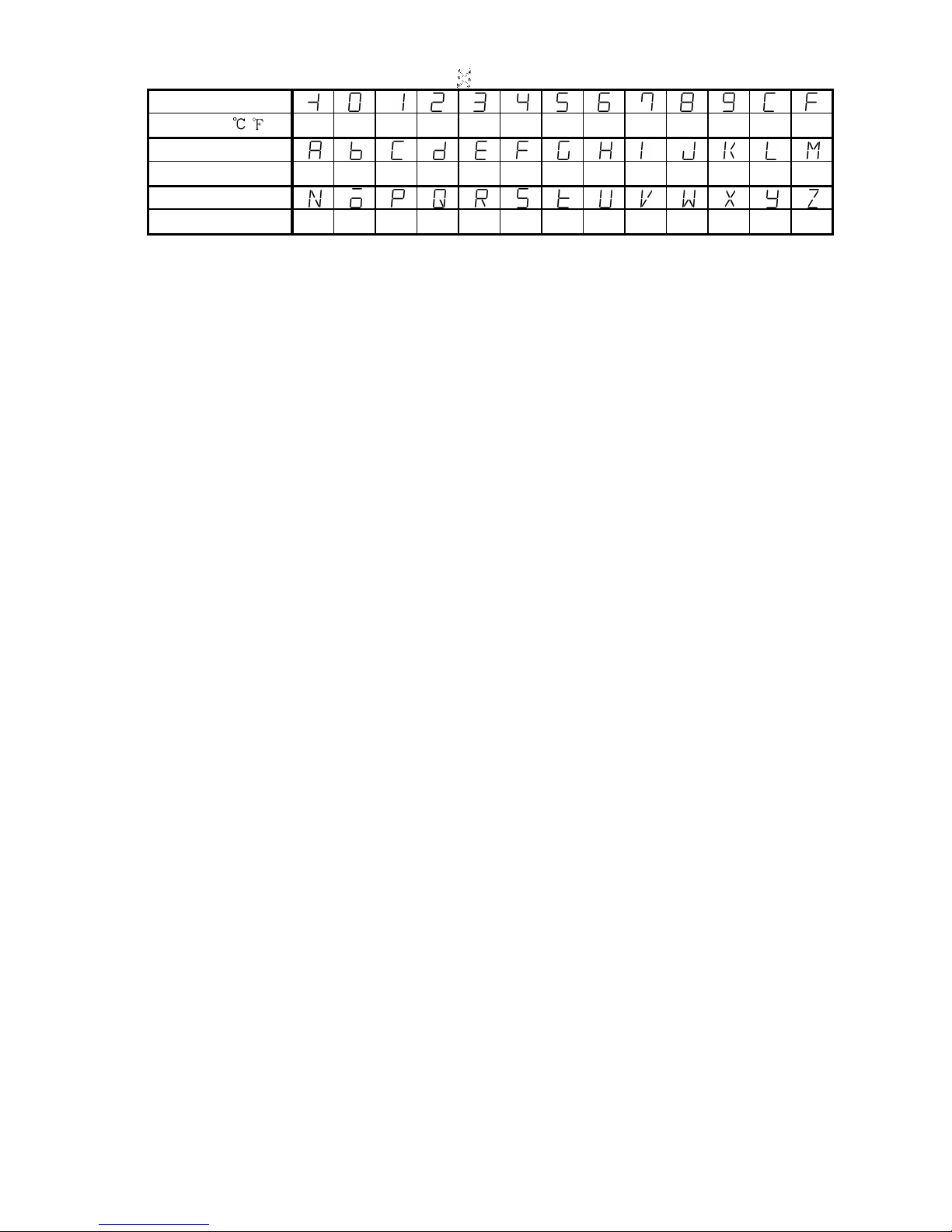

Characters used in this manual [: No character is indicated (unlit).]

Indication

Number, / -1 0 1 2 3 4 5 6 7 8 9 °C °F

Indication

Alphabet A B C D E F G H I J K L M

Indication

Alphabet N O P Q R S T U V W X Y Z

Contents Page

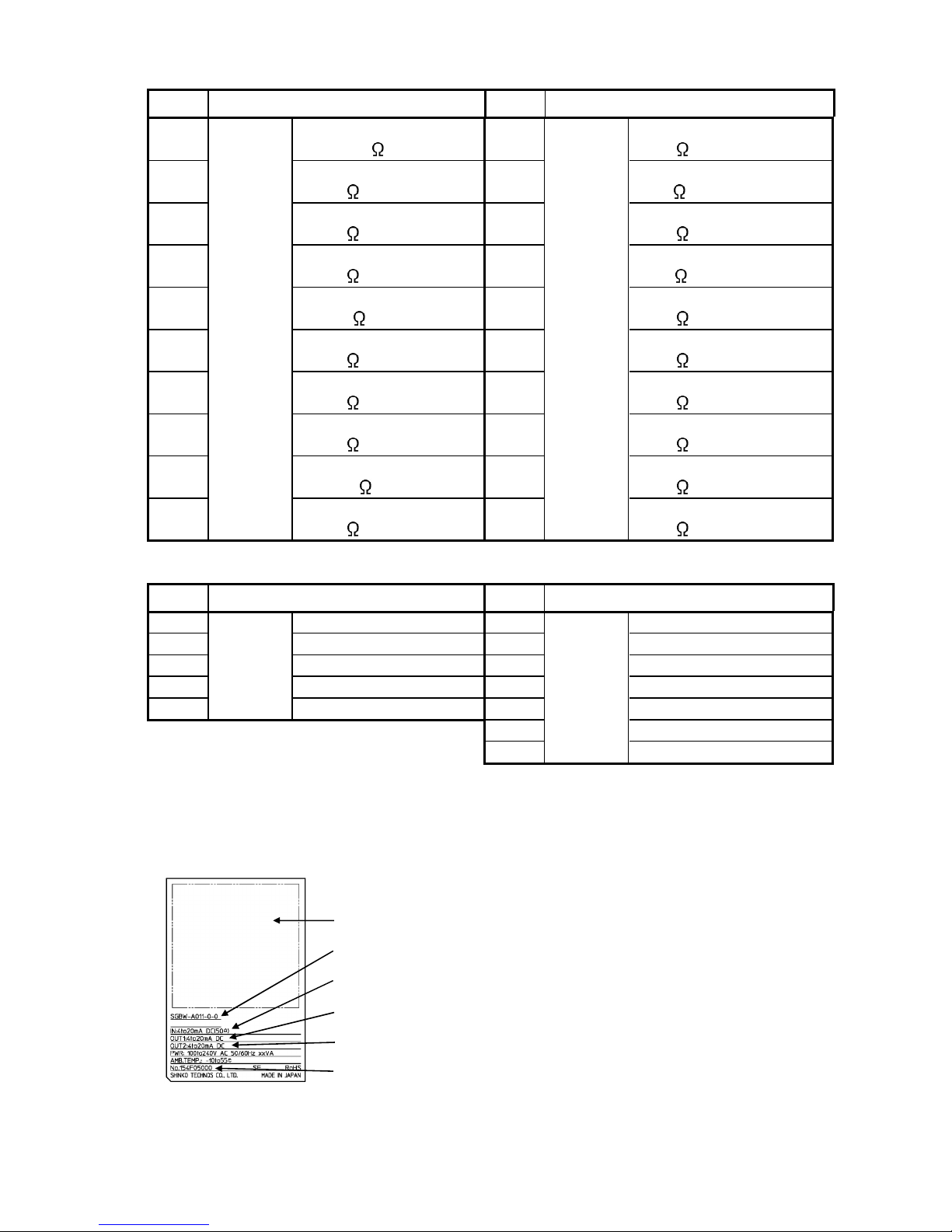

1. Model ....................................................................................................................................5

1.1 Model..........................................................................................................................5

1.2 How to Read the Model Label .................................................................................6

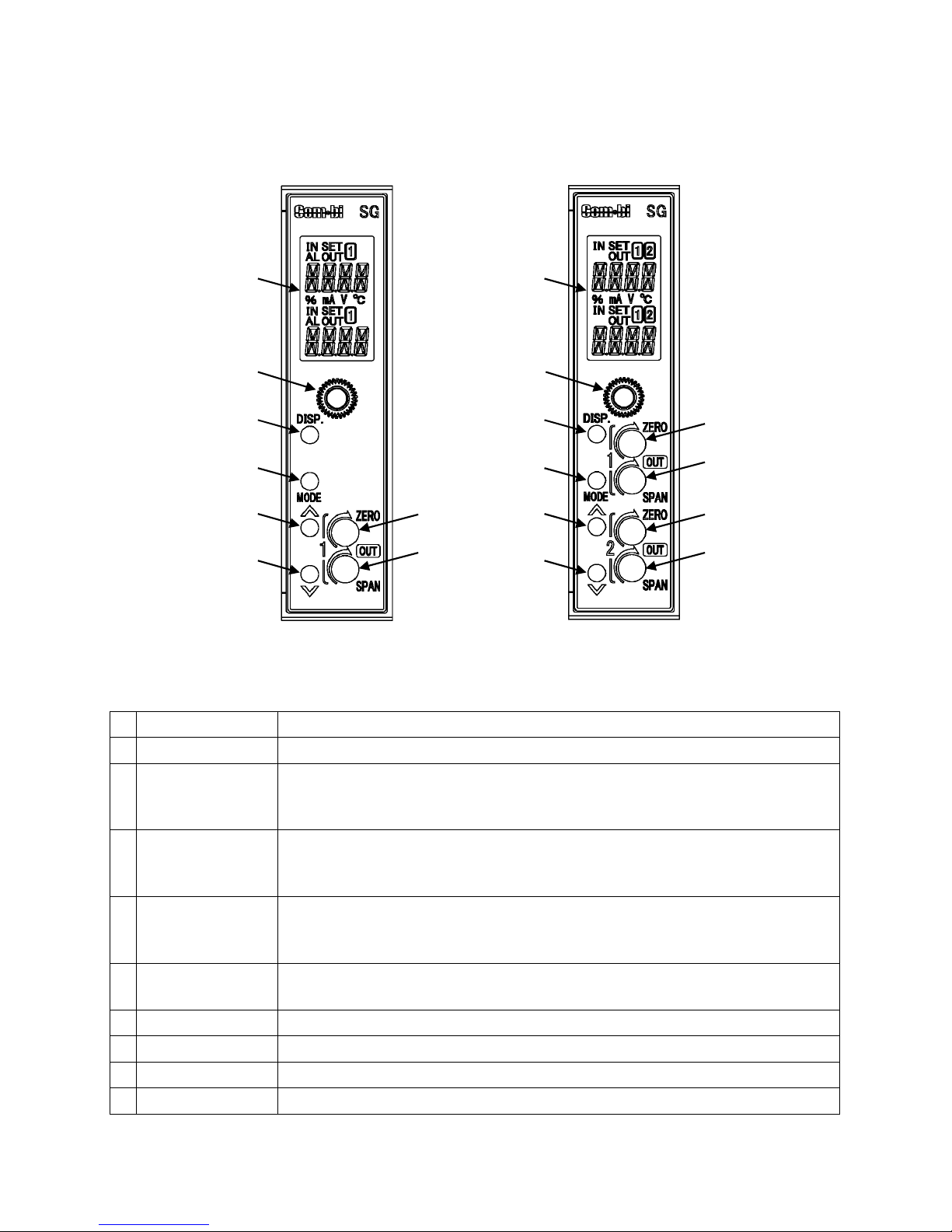

2. Name and Functions...........................................................................................................7

2.1 Front Panel ................................................................................................................7

2.2 Display Section .........................................................................................................8

3. Mounting ..............................................................................................................................9

3.1 External Dimensions (Scale: mm) ..........................................................................9

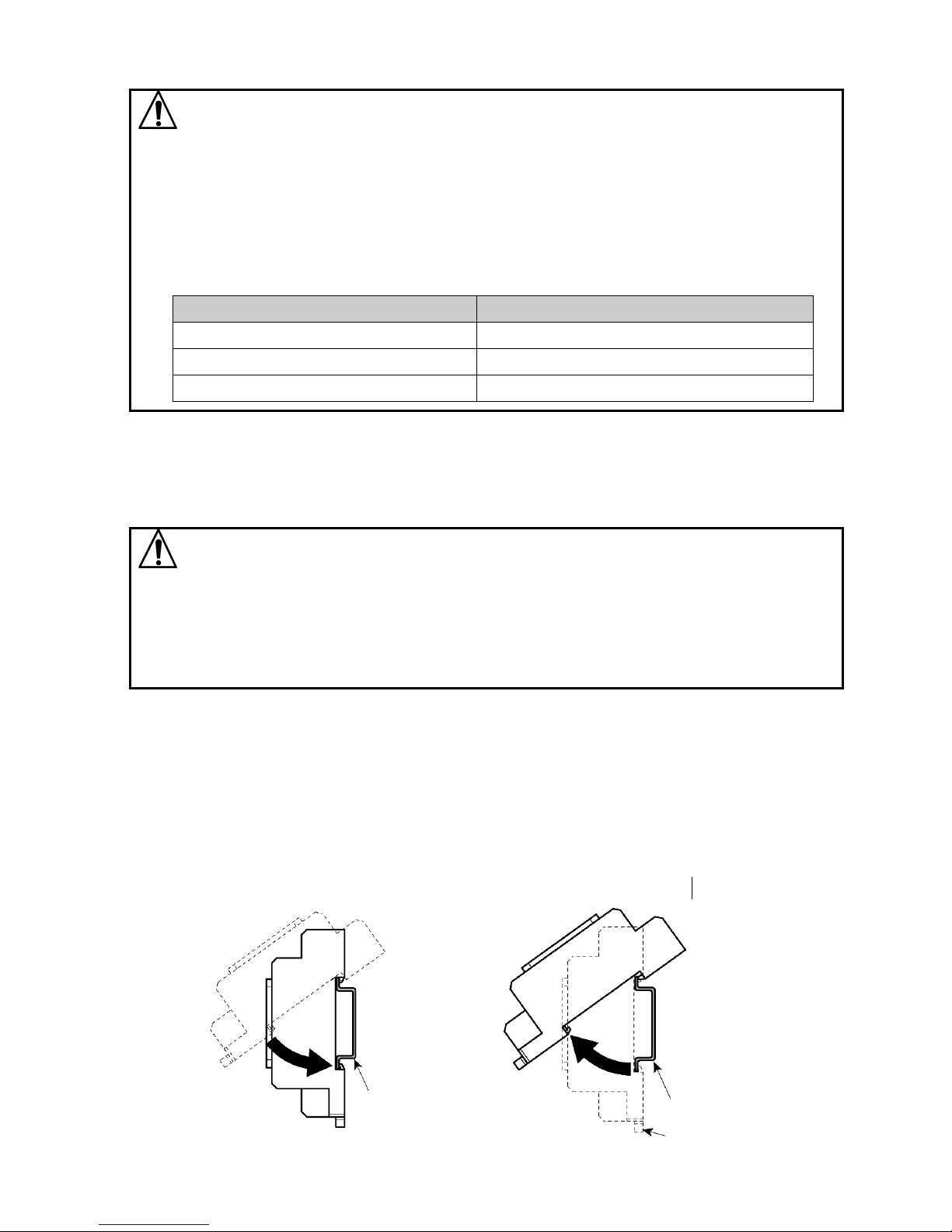

3.2 Mounting to, and Removal from the DIN Rail ......................................................10

4. Wiring .................................................................................................................................11

4.1 Lead Wire Solderless Terminal .............................................................................11

4.2 Circuit Configuration..............................................................................................11

4.3 Terminal Arrangement............................................................................................12

4.4 Wiring.......................................................................................................................13

5. Display Mode .....................................................................................................................14

6. Setting Mode......................................................................................................................16

6.1 Display Transition in Setting Mode.......................................................................16

6.2 Input Setting Mode .................................................................................................18

6.3 Output 1 Setting Mode ...........................................................................................20

6.4 Output 2 Setting Mode ...........................................................................................23

6.5 Instrument Setting Mode .......................................................................................26

6.6 Communication Setting Mode...............................................................................28

6.7 Custom Display Setting Mode...............................................................................30

6.8 Manual Mode ...........................................................................................................30

7. Adjustment.........................................................................................................................31

7.1 Basic Operation of Adjustment.............................................................................31

7.2 Adjustment ..............................................................................................................31

7.2.1 Output 1 Adjustment.......................................................................................31

7.2.2 Output 2 Adjustment.......................................................................................31

8.1 Indication after Power-on.......................................................................................32

8.2 Operation .................................................................................................................32

8.2.1 Input Indication Range....................................................................................32

8.2.2 Indication Range of Output 1 and Output 2..................................................32

8.2.3 Input Disconnection........................................................................................32

8.2.4 Indication Time Setting...................................................................................33

8.2.5 Ratio and Bias Settings ..................................................................................33

9. Specifications ....................................................................................................................37

10. Troubleshooting ..............................................................................................................40

10.1 Indication .................................................................................................................40

10.2 Key Operation .........................................................................................................40

10.3 Operation .................................................................................................................40

11. Character Table................................................................................................................41