Janfire NH Burner Service Installation Manual 4.16.09 - Technical specifications are subject to change without prior

notice. 6(38)

3 Operational Description

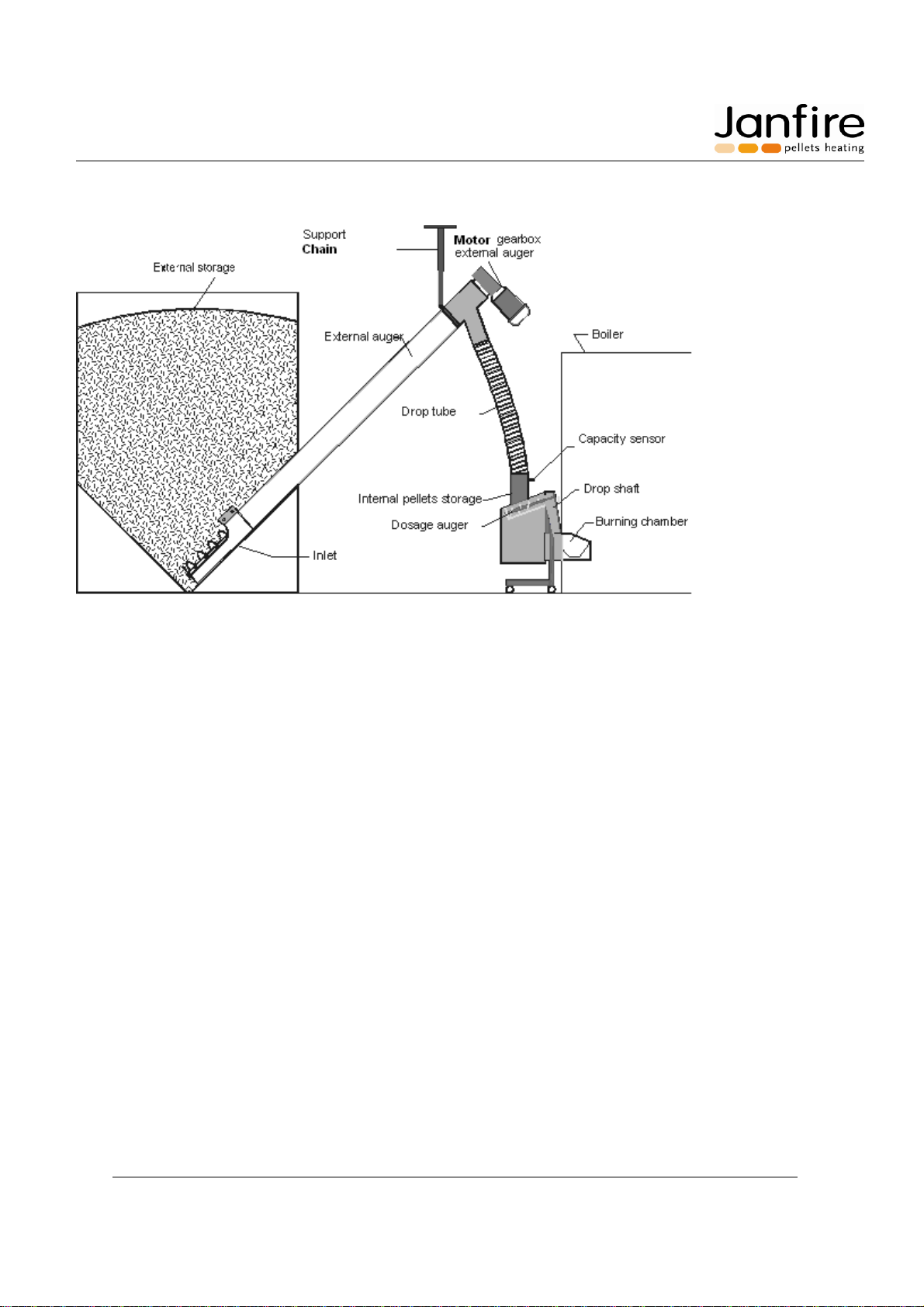

An external auger feeds pellets from an external storage bin to a receptacle located in the top of the burner

(internal hopper). An internal dosage auger then feeds the pellets to a drop shaft where they fall freely into the

combustion chamber or burning bowl/cup; this eliminates the possibility of reverse combustion.

A variable speed fan supplies the burner with primary and secondary air. On its way to the burning cup the air

cools heat-exposed parts of the burner. The correct amount of air is then fed to the burning cup for primary and

secondary combustion. The ignition coil preheats the air for automatic ignition. Burner up sensor (flame guard)

detects pellet ignition. If ignition does not take place, then the process repeats itself automatically and a new

ignition attempt is made. If ignition still does not take place after a pre-set number of trials, then the burner shuts

itself down.

If the draft is insufficient then the hot flue gases will rise into the drop shaft. The temperature sensor in the drop

shaft will detect this rise in temperature at 158oF (70oC). The burner will compensate by reducing the burner

output, thus eliminating the risk for reverse combustion. During this operation, the control lamp changes color to

yellow to indicate that the system is running in back-up level and the wording ”low chimney draft” will appear on

the display screen.

If the drop shaft temperature rises to the highest allowed level 203oF (95oC) then the burner will shut down

based on this temperature reading from the drop shaft temperature sensor. The control lamp will turn red and the

wording “Overheated” will appear on the display screen.

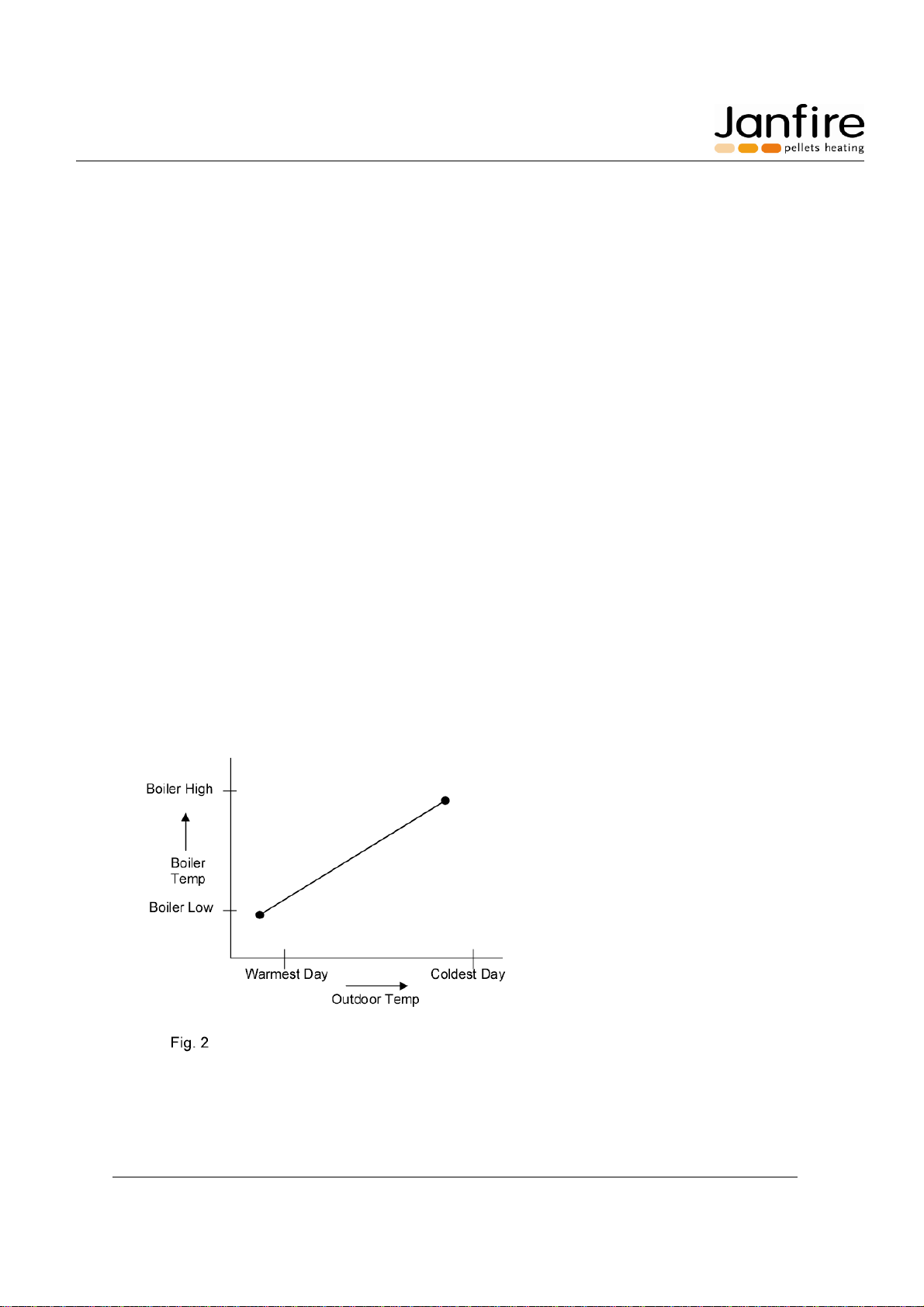

The burner input is controlled by a PID regulator using the boiler water temperature as input. Temperature is

measured with a PT-100 sensor placed in the boiler sensing well. The burner input is modulated automatically

between adjustable limits. The Min and Max input levels can be set from 10,000 to 78,000 Btu/hr (3 - 23 kW). If

no PT-100 sensor is connected to the burner, the burner input is controlled by pre-programmed ouput levels,

which are regulated with help of a thermostat. Except for the standby level of about 2,000 Btu/hr (600 W), the

burner input can be set between 10,000 to 78,000 Btu/hr (3 – 23 kW) in increments of 3,000 Btu/hr (1 kW).

These burner input levels are based on a pellet weight density of 5.77 lbs/gal (= 42.17 lbs/ft3 or 675 g/litre) and

an energy content of 7,420 Btu/lbs (4.8 kWh/kg). To adjust for variations in the burner input and combustion

levels when using pellets with another weight or energy content the levels can be changed here. The different

levels can be fine tuned to produce the best overall combustion result.

High quality pellets produce high efficiency and output. High quality pellets are solid wood pellets ¼” – 3/8” (6-

10 mm) in diameter with little sawdust. Moisture levels should be no higher than 10%, ash content no higher

than 1% weight, and energy content expressed as European Net Heat Value (ENHV) should be about 7,290 –

7,750 Btu/lbs** (4.7 - 5.0 kWh/kg). Always verify the energy density and weight density values for the pellets

upon delivery.

**Note: Contact your pellet supplier regarding the dry matter energy value, or European Net Heat Value

(ENHV), which is discounted for pellet moisture content as the Janfire NH burner requires this specific value. US

PFI (Pellet Fuel Institute) pellet standards at this point do NOT record this value and the PFI energy content

value can NOT be used directly.

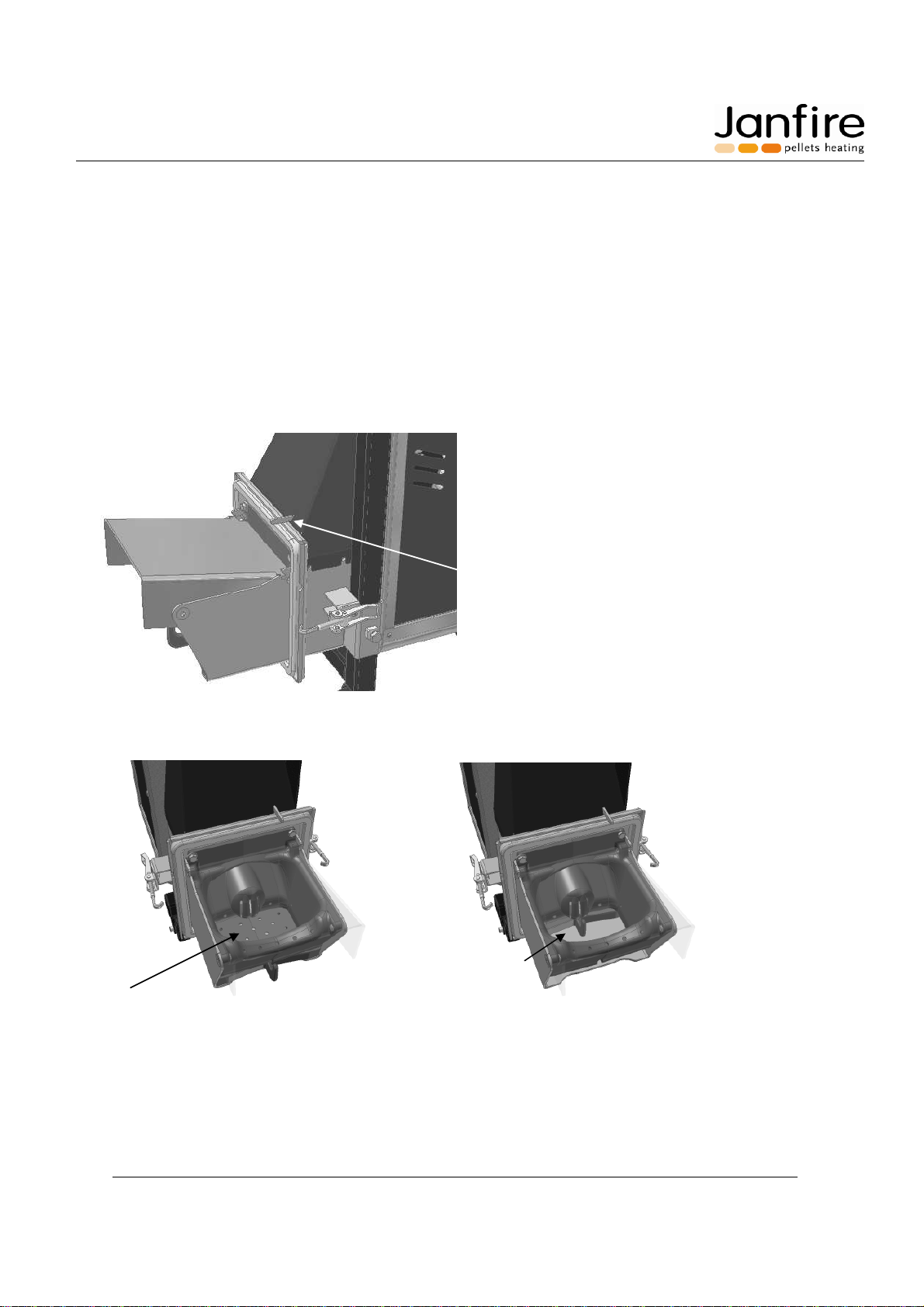

A patented moving base of the burning chamber scrapes away slag and waste material, feeding it into the boiler

firebox. The burner automatically cleans itself according to a signal from the boiler thermostat or based on pre-

programmed intervals (pellets consumption – 40lbs.).

PID regulator – function description

The PID regulator is commonly used to control processes in an efficient way. Here the PID regulates the burner

power level to reach the desired water temperature in the boiler. If the needed power is less than the minimum

power of the burner the temperature will increase to the upper temperature setting and the burner will go to

maintenance fire position.