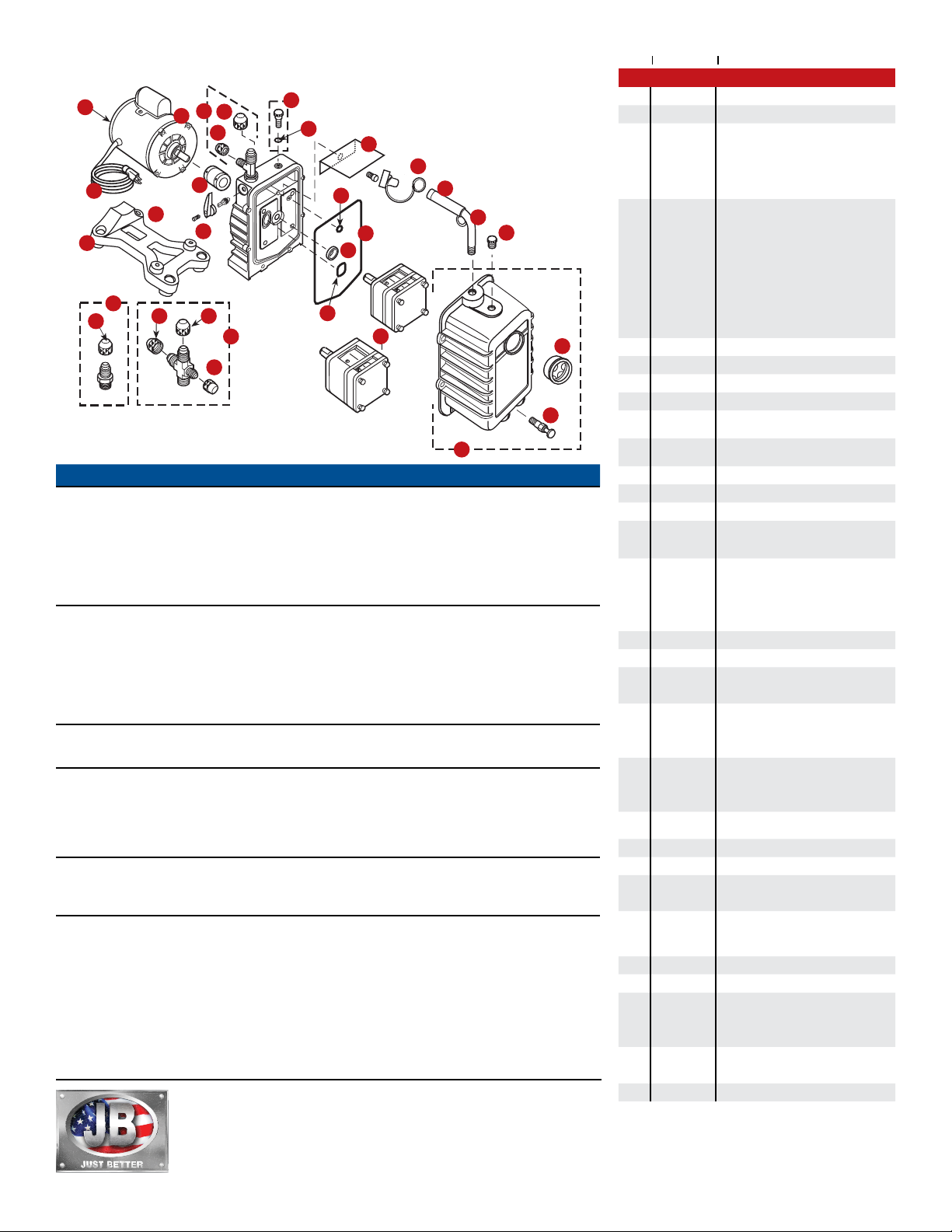

PLATINUM®PUMP REPAIR PARTS

1PR-1 Sight Glass

2PR-2 Drain Valve

3

PR-300

DV-42N through DV-200N Cover Assy.

Includes: Sight Glass, Drain Valve,

Handle, Grip, End Cap and Tethered Plug

PR-301

DV-285N Cover Assy. Includes: Sight

Glass, Drain Valve, Handle, Grip, End

Cap and Tethered Plug

4

PR-302 DV-85N Cartridge w/O-rings and

Cover Seal

PR-303 DV-142N Cartridge w/O-rings and

Cover Seal

PR-304 DV-200N Cartridge w/O-rings and

Cover Seal

PR-305 DV-42N Cartridge w/O-rings and

Cover Seal

PR-314 DV-285N Cartridge w/O-rings and

Cover Seal

5PR-311 Cover Seal

6PR-211 Trap O-ring, Gas Ballast

7PR-3 Shaft Seal

8PR-315 Trap O-ring, Intake

9PR-4 Rubber Foot and Screw Assembly

(1/4” – 20 x 5/8”)

10 PR-76 Intake Cross w/Caps

(38”, 1/2”, 1/4” with 38” MPT Into Pump)

11 NFT5-4 1/4” Cap w/O-ring for Intake

12 NFT5-6 3/8” Cap w/O-ring Cap for Intake

13 PR-32 1/4” Intake w/Cap (U1-4C and NFT5-4)

14 PR-209

Plastic Isolation Valve Handle and

Screw w/Stem and retainer

(Not Interchangeable w/PR-210)

15

PR-208 Flexible Coupler (3 parts)

PR-308 Flexible Section only (From PR-208)

PR-6 Flexible Coupler (3 parts)

PR-77 Flexible Section Only (From PR-6)

16 PR-42 Motor Foot w/Screw

17 PR-59 Rubber Foot for Base (Grommet Style)

19

PR-31 Line Cord (Emerson Motor)

PR-58 Line Cord (Marathon Motor)

20

PR-35 Rocker Switch w/Prongs

(Marathon 1101-0105)

PR-54 Rocker Switch w/Wire Leads

(Emerson)

21

PR-206 1/2 Hp, 115v, 60 Hz Motor w/Line

Cord and Switch

PR-207 1/2 Hp, 115/230v, 50/60 Hz Motor

w/Line Cord And Switch

22 PR-5 Intake Tee w/Caps (3/8”, 1/4” with 3/8”

MPT Into Pump)

23 PR-7 Gas Ballast Valve w/O-ring

24 P90009 O-ring, Gas Ballast Valve

25 PR-40 Splash Guard and Screw

(Excludes 3 CFM Manufactured

Before 1/01. Use PR-39.)

26 PR-75 Cushioned Handle w/Lift Ring 1/2” NPT

And DV-EP-8 As of 2008

PR-205 Cushioned Handle 3/8” NPT

27 PR-22 Oil Fill Plug w/O-ring

28 PR-56 Adapter Nut w/O-Ring

29

PR-62 Pump Base (Includes Feet)

PR-500 Cushion and Cap 3/8” NPT

PR-501 Cushion and Cap 1/2” NPT

31 DV-EP6 Tethered Safety Cap 3/8”

DV-EP8 Tethered Safety Cap 1/2”

32 NFT5-8 1/2” Cap w/O-ring for Intake

REPAIR PARTS

TROUBLESHOOTING

OTC WARRANTY

Platinum®pumps are warranted against defects in materials and workmanship for 2 years. Not changing

oil will void warranty. All JB products are guaranteed when used in accordance with our directions and

recommendations, and we limit this warranty to the repair, replacement, or credit at invoice price (our

option) of products which in our opinion are defective due to defects in workmanship and/or materials. In

no case will we allow charges for labor, expense or consequential damage. Repairs performed on items

out of warranty will be invoiced on a nominal basis. Contact your wholesaler for details. The entire Limited

Warranty and OTC Warranty can be found at www.jbind.com.

Form 10185-308

Printed in the USA

©2016 JB Industries, Inc.

JB INDUSTRIES, INC.

Aurora, IL 60505 USA

Main Warehouse

JB INDUSTRIES, INC.

PO Box 1180 Dept. 85

Aurora, IL 60507-1180 USA

Toll-Free Technical Service #: 800.323.0811

1

2

3

5

6

7

8

22

23

15

14

21

24

10

11

13

25

12

4

20

19

12

11

27

29

30

17

31

26

32

11

DV-42N THROUGH DV-285N

PLATINUM® SERIES

Symptom Possible Cause(s) Corrective Action

Pump won’t start 1. Power cord not plugged in

securely

2. Motor switch not on

3. Pump temp. below 30°F

4. Inconsistent line voltage

1. Plug power cord in securely

2. Turn motor switch to ON

position

3. Warm up pump to 30°F & turn

motor switch on

4. Line voltage must be within

10% of 115 volts

Pump won’t pull deep vacuum 1. Contaminated oil

2. Oil level too low

3. Air leak in system being

evacuated

4. Pump inlet fittings

missing or not tightened

5. Coupler slipping

1. Change oil

2. Add oil

3. Locate & repair leak(s)

4. Clean or replace O-ring

5. Tighten coupler setscrews to

flats of cartridge and motor

Oil drips from point where shaft

enters the pump housing

Damaged shaft seal Replace shaft seal

Pump shuts down and will

not start

Thermal overload may be open Disconnect pump from system.

Wait about 15 minutes for motor

to cool and turn it on again. If it

cycles off again, return pump to

factory for repair.

Pump cycles on and off from a

completely cold start and then

runs smoothly

Oil backed up into cartridge and

was being cleared out. Pump has

not been shutdown properly.

Remove 1/4” cap then turn

pump on

TM

4

REF. NO. PART NO. DESCRIPTION