7

JB

INDUSTRIES

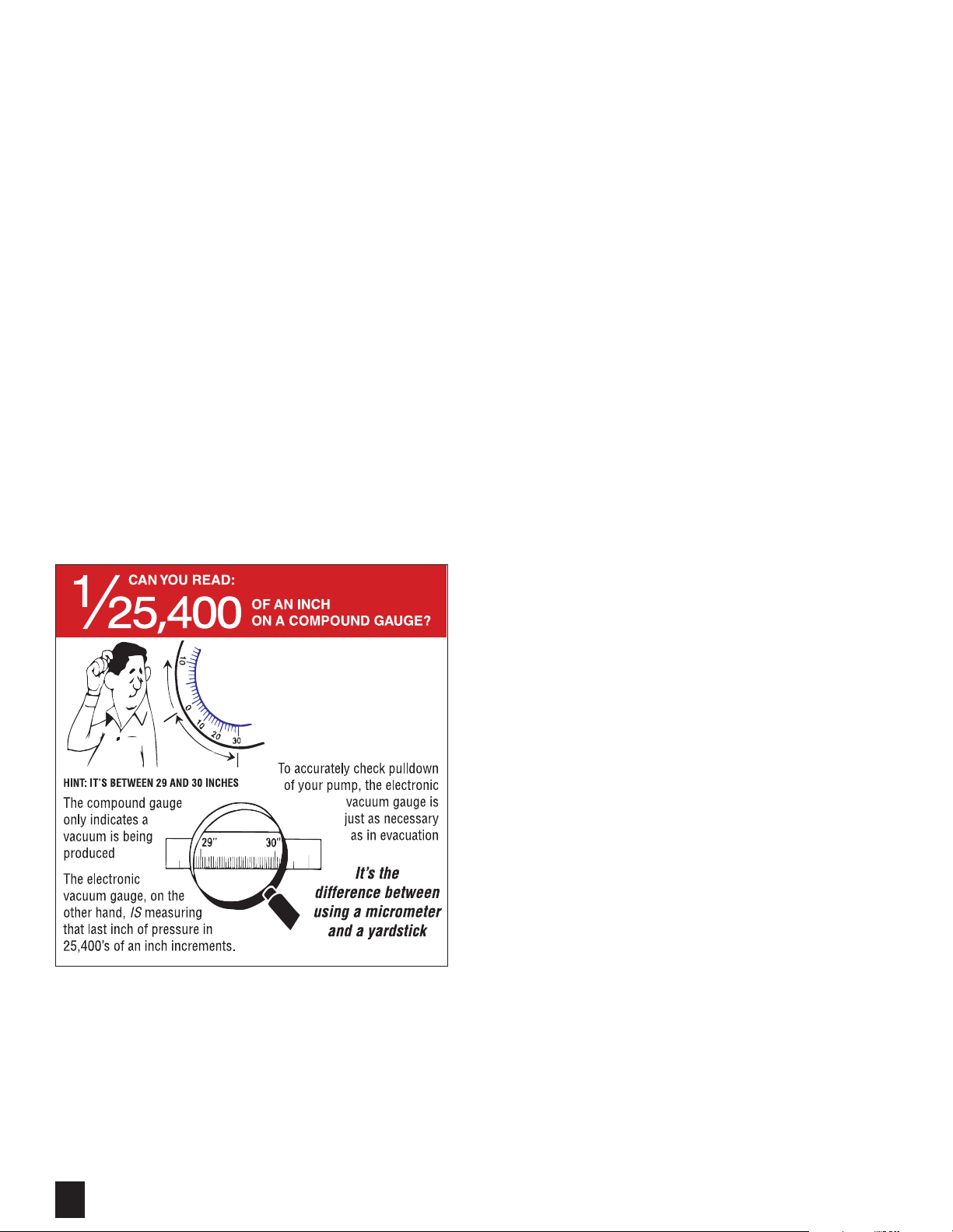

• PLATINUM OPERATING MANUAL • 800.323.0811 • [email protected] • JBIND.COMIf you are used to using a compound gauge when testing for a leak or holding a

vacuum, using a digital gauge will be a little tricky the first time you use it. JB

digital vacuum gauges will display microns jumping up and down in measure.

You might think that the gauge is erratic or that there is a leak in the system. The

reason for the changing microns is due to a whole other area of understanding the

environment inside a system being vacuumed. We will discuss this event in the

next section on Digital Micron Gauges.

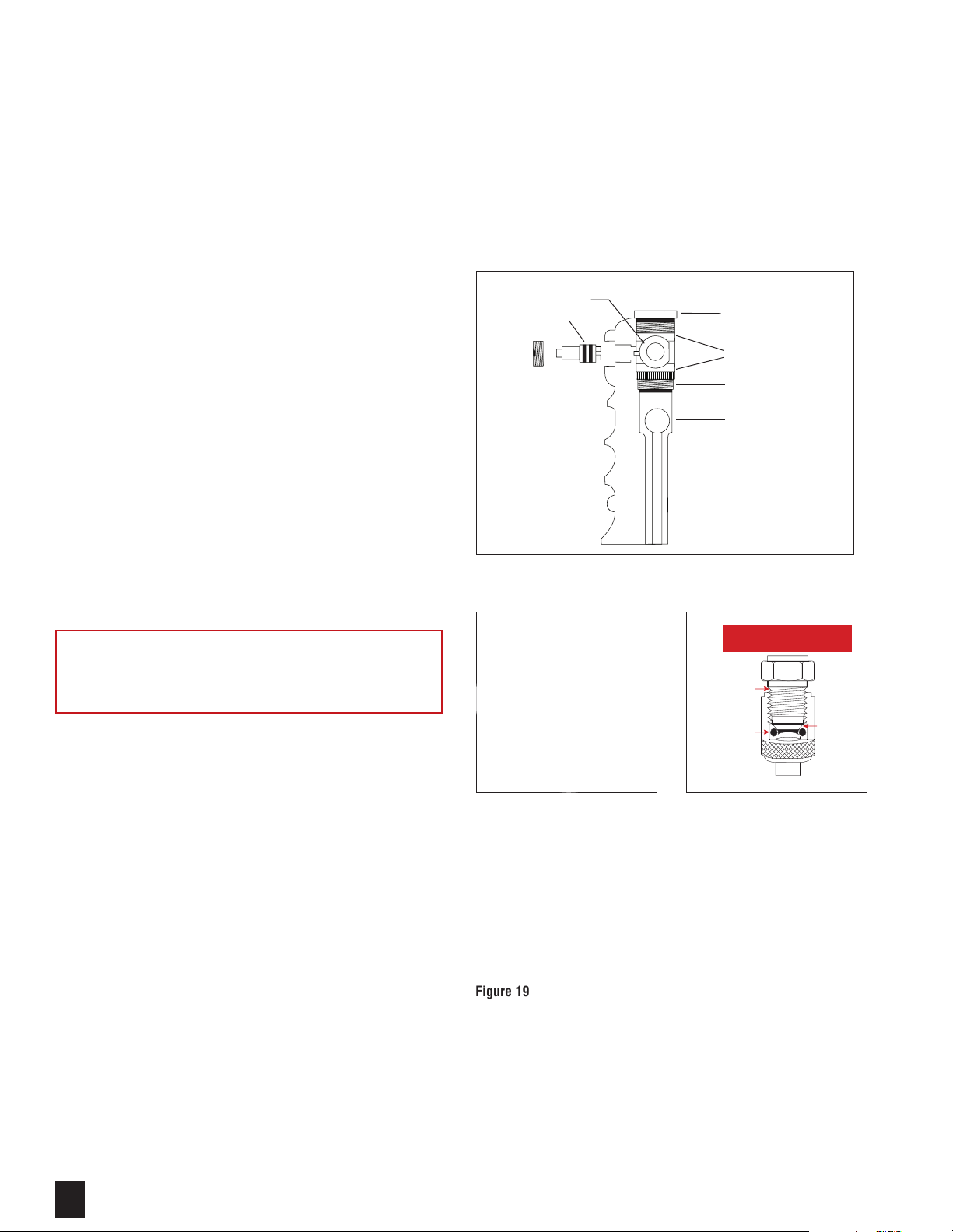

To help show the difference of a digital and analog displays in microns, and a

compound gauge display in inches of mercury (inHg) as it relates to their displays

of vacuum, we need to hook them up. Take a compound gauge and a digital micron

gauge, and an empty refrigerant tank. This hook-up is illustrated on the next page

(Figure 20). This allows you to demonstrate the four components in holding a

vacuum: the connections, the volume, the depth of vacuum, and the length of time

that volume is in deep vacuum.

Link both gauges together by solid brass adapters and o-ring couplers and couple

to the tank. The tank is connected by an o-ring coupler to one of the intake ports

of the pump by way of braided metal hose with o-ring connections. Then, with

the isolation valve in the open position, we can begin to vacuum this hook-up

and watch the readings on the various gauges move into deep vacuum. Within

seconds, the compound gauge’s needle should be nearing 27-29" while the digital

and analog gauge readings are still heading into deeper microns.

After the digital gauge reaches 500-600 microns, close the isolation valve. You

will see the digital reading start a pretty rapid rise in micron readings. Notice that

the compound gauge’s needle has not moved.

NOTE: If the compound gauge’s needle does move toward zero on the scale, you

have an air leak in your connections. Open the isolation valve again and this time

let the hook-up vacuum for 5 minutes. Then close the isolation valve again and

watch. Open the isolation valve for about a minute, then move the valve to the

pause position for about 5 seconds, then close the valve completely. This removes

that trapped air around the isolation valve. You will still see a rise in pressure, but

not as rapid. The readings will start to stabilize the longer this hook-up is allowed

to vacuum down and use the pause position of the isolation valve the slower and

lower the rise in pressure.

If you increase the volume of the cylinder and follow the same procedure, you will

notice a slower and lower rise. If you watch your compound gauge, you will notice

there is no movement.

DIGITAL MICRON GAUGES

Inaccurate Readings

NOTE: For the JB digital vacuum gauges we have a stated accuracy that references

AVERAGE accuracy. Thus, between 250 and 6000 microns the unit is +/-10%

AVERAGE accuracy and between 50 to 250 microns it is +/-15% AVERAGE

accuracy. This does not mean our gauge has a large accuracy discrepancy.

The term AVERAGE is an important part of this accuracy description. The number of

increments displayed on the JB digital micron gauge between 50 and 250 microns

are 97. Between 250 microns and 6000 microns, there are 232 increments. If you

take a comparison reading between the JB digital vacuum gauges and the MKS

Baratron master gauge at each of the increments displayed on the digital micron

gauge the average accuracy would be +/-10% in one range and +/-15% the average

in the other range. Also, the number of increments decrease from the lower micron

readings to the higher micron readings.

For example, from 250 to 300 microns there are 16 increments, from 650-

700 microns there are only 7 increments, between 1000 and 1050 there are 4

increments, and between 4000 and 4500 there are 4 increments. So at 650 to

700 microns the gauge has the ability to show 650-658-667-675-680-685-690-

695. But at the micron range of 4000 to 4500, the gauge only displays 4125-

4250-4375. This is important because when the system has an actual micron

level of 4260, the digital micron gauge will show a reading of 4375 because the

threshold for the lower value that the gauge displays, 4250, has not been reached.

Once that threshold has been reached, the gauge will display that lower value of

4250. Because the readings in these higher micron ranges only need to show the

movement through them , the difference between 4375 and 4250 is of no concern

in reaching the ultimate vacuum desired. This is why the JB digital vacuum gauges

are designed with the most increments in range that are going to be the most critical

in determining if the system is ready for charging.

If you understand the size of a micron, then small differences in ranges is nothing

to be concerned about. For instance:

MICRON RANGE MICRON DIFFERENCE

60-100 10-20

200-350 30-40

500-700 50-60

900-1500 80-100

2500-4000 200-300

When a JB digital vacuum gauge comes in for repair, it is compared to a secured

system set up with a N.I.S.T. traceable master gauge. Usually starting around

(1) 60-100 microns, then (2)200-350 microns, then (3)500-700 microns, then

(4) 900-1000 microns. These ranges of vacuum are the most common that people

work with to determine deep vacuum.

Figure 20