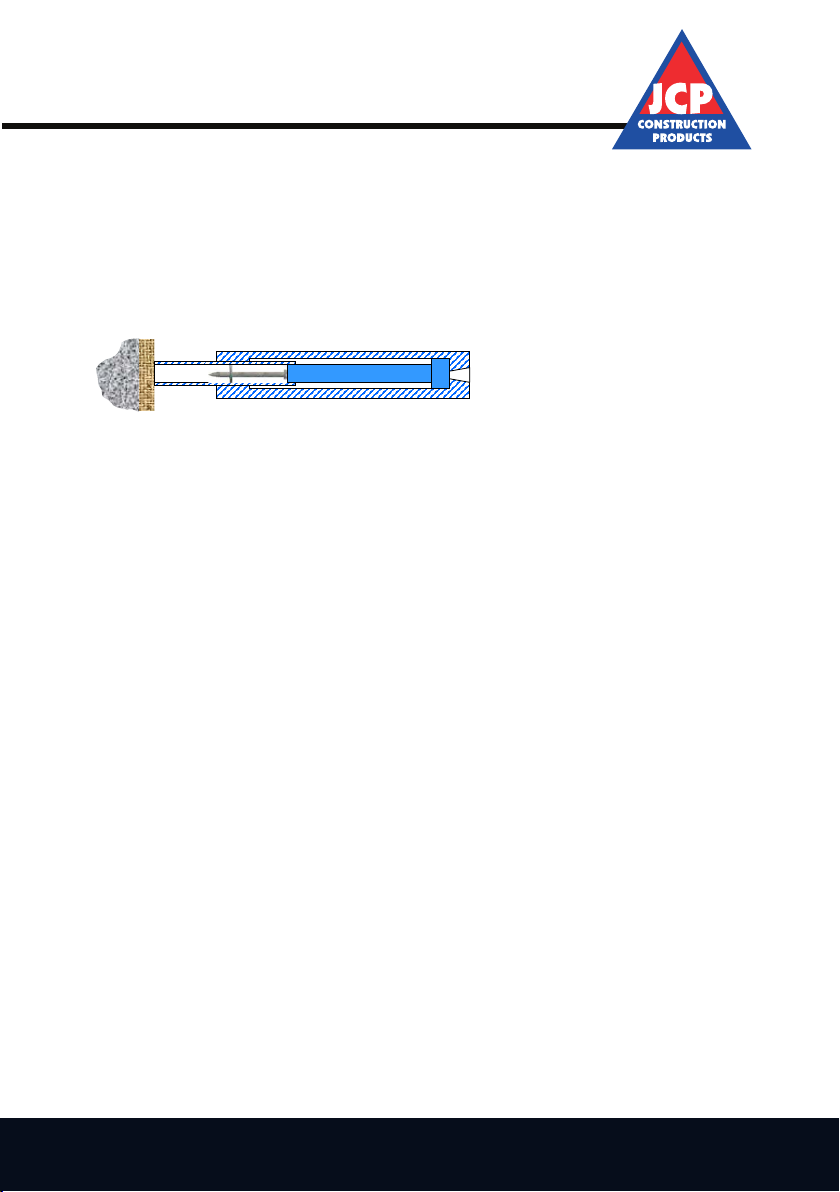

STEEL: When xing steel of a suitable type and strength the base material must be at least 4mm thick to ensure a

positive x. The length of the fastener must be the thickness of the xture (t) plus 12mm.

CONCRETE: For xing into concrete the fastener should be the thickness of the xture (t) plus 25mm.

BRICKWORK: Fixings can be made to solid brickwork but due to the variable nature of bricks extra care must be

taken. A penetration depth of between 25 & 32mm is usually required. If in doubt contact your supplier or JCP

Construction Products.

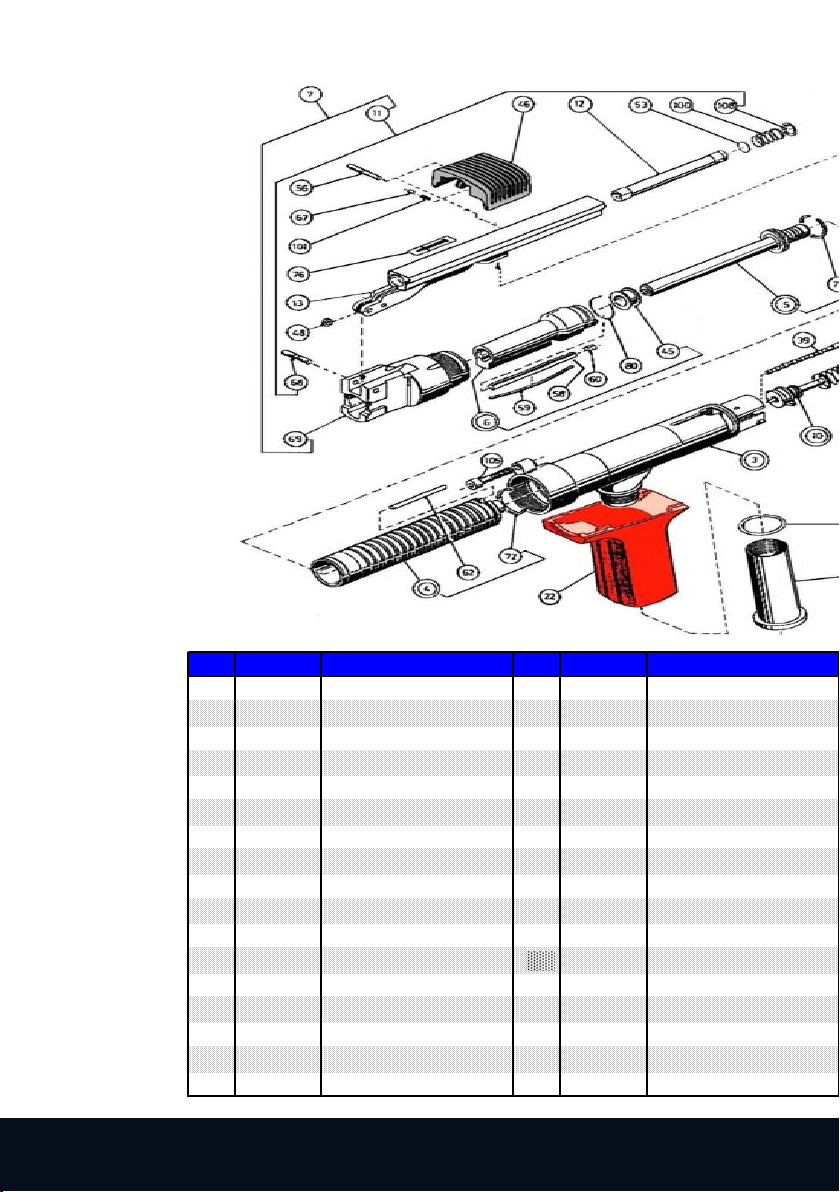

EDGE AND SPACING DISTANCES

FASTENER SELECTION

Steel Before use

Make sure you have been properly trained in the use of the tool

least 4mm thick to ensure a positive fix. The length of the fastener must be the Ensure the tool is in safe condition

thickness of the fixture (t) plus 12mm. Check the tool is not loaded

Ensure the area is safe and warn other trades working nearby

Carry out a suitability test of the base material

During use

Always wear suitable eye, ear and head protection as well as suitable

footwear, plus any other safety or protective equipment as may

designated for the site or application

Concrete Adopt a well balanced stance

For fixing into concrete the fastener should be the thickness of the fixture (t) Always point the tool away from yourself and bystanders.

plus 25mm Never place your hand over the front of the tool

Hold the tool perpendicular to the work surface

Never fix close to an edge, another fixing or where a fixing has failed.

(See page 8 for edge and spacing distances)

Maximum repetition rate 12 fixings/minute

Noise level (EN15895-1)

A-weighted sound level, LWA, in decibels 88

Uncertainty, KWA, in decibels 3

A-weighted sound level at work station, LpA, in decibels 75

Uncertainty, KpA, in decibels 3

Brickwork Vibration level Does not exceed 2.5m/s2

Fixings can be made to solid brickwork but due to the variable nature of bricks

extra care must be taken. A penetration depth of between 25 & 32 mm is usually Misfire Procedure

required. If in doubt contact your supplier or JCP Construction Products In the event of a misfire do not remove the tool from the work surface

at least 30 seconds. Re-apply the tool and try again. In event of

another misfire and after waiting a further 30 seconds remove

the cartridge strip from the tool and remove the fastener.

Spacing Edge Thickness Mark the tool with a DO NOT USE label and place the tool in a secure

Distance box

Steel 20 25 4-7mm Contact your supplier to have the tool inspected.

15 20 >7mm

Concrete 100 75 80

A fixing to brickwork should be at least 3 courses down from the top of a wall and Remove the cartridge strip from the tool

1 full brick in from an edge. Only 1 fixing per brick should be made and do not Inspect the tool for damage

fix into mortar joints Clean and lubricate tool

Return the tool to its box and secure in a safe place.

Store the tool in a dry environment

EDGE & SPACING DISTANCES

8

When fixing to steel of a suitable type and strength the base material must be at

FASTENER SELECTION

5

USING THE TOOL

min 4 mm

12 mm

t

Steel Before use

Make sure you have been properly trained in the use of the tool

least 4mm thick to ensure a positive fix. The length of the fastener must be the Ensure the tool is in safe condition

thickness of the fixture (t) plus 12mm. Check the tool is not loaded

Ensure the area is safe and warn other trades working nearby

Carry out a suitability test of the base material

During use

Always wear suitable eye, ear and head protection as well as suitable

footwear, plus any other safety or protective equipment as may

designated for the site or application

Concrete Adopt a well balanced stance

For fixing into concrete the fastener should be the thickness of the fixture (t) Always point the tool away from yourself and bystanders.

plus 25mm Never place your hand over the front of the tool

Hold the tool perpendicular to the work surface

Never fix close to an edge, another fixing or where a fixing has failed.

(See page 8 for edge and spacing distances)

Maximum repetition rate 12 fixings/minute

Noise level (EN15895-1)

A-weighted sound level, LWA, in decibels 88

Uncertainty, KWA, in decibels 3

A-weighted sound level at work station, LpA, in decibels 75

Uncertainty, KpA, in decibels 3

Brickwork Vibration level Does not exceed 2.5m/s2

Fixings can be made to solid brickwork but due to the variable nature of bricks

extra care must be taken. A penetration depth of between 25 & 32 mm is usually Misfire Procedure

required. If in doubt contact your supplier or JCP Construction Products In the event of a misfire do not remove the tool from the work surface

at least 30 seconds. Re-apply the tool and try again. In event of

another misfire and after waiting a further 30 seconds remove

the cartridge strip from the tool and remove the fastener.

Spacing Edge Thickness Mark the tool with a DO NOT USE label and place the tool in a secure

Distance box

Steel 20 25 4-7mm Contact your supplier to have the tool inspected.

15 20 >7mm

Concrete 100 75 80

A fixing to brickwork should be at least 3 courses down from the top of a wall and Remove the cartridge strip from the tool

1 full brick in from an edge. Only 1 fixing per brick should be made and do not Inspect the tool for damage

fix into mortar joints Clean and lubricate tool

Return the tool to its box and secure in a safe place.

Store the tool in a dry environment

EDGE & SPACING DISTANCES

8

When fixing to steel of a suitable type and strength the base material must be at

FASTENER SELECTION

5

USING THE TOOL

min 4 mm

12 mm

t

25

t

Spacing Edge Thickness

Distance

Steel 20 25 4-7mm

15 20 >7mm

Concrete 100 75 80

A xing to brickwork should be at least 3 courses down from the top of a wall and 1 full brick in from an edge.

Only 1 xing per brick should be made and do not x into mortar joints.

10