PAGE 3 OF 4 0414 IH-2027

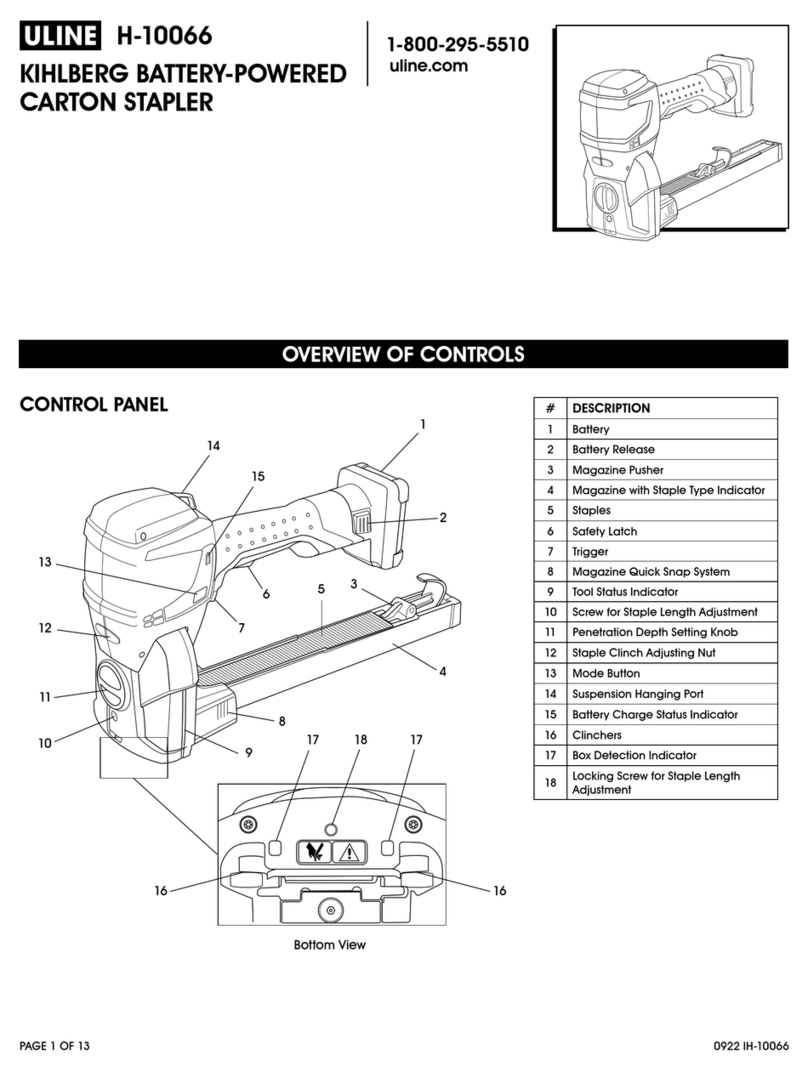

CHECK STAPLE LEG LENGTH

AND ADJUST PLATE POSITION

NOTE: Disconnect the air supply.

NOTE: The H-2027 pneumatic carton stapler

is tested before shipping. Please don't move

adjust plate position.

If you want to operate with different leg length

staples, please change to the suitable clincher

and move the adjust plate to suitable position.

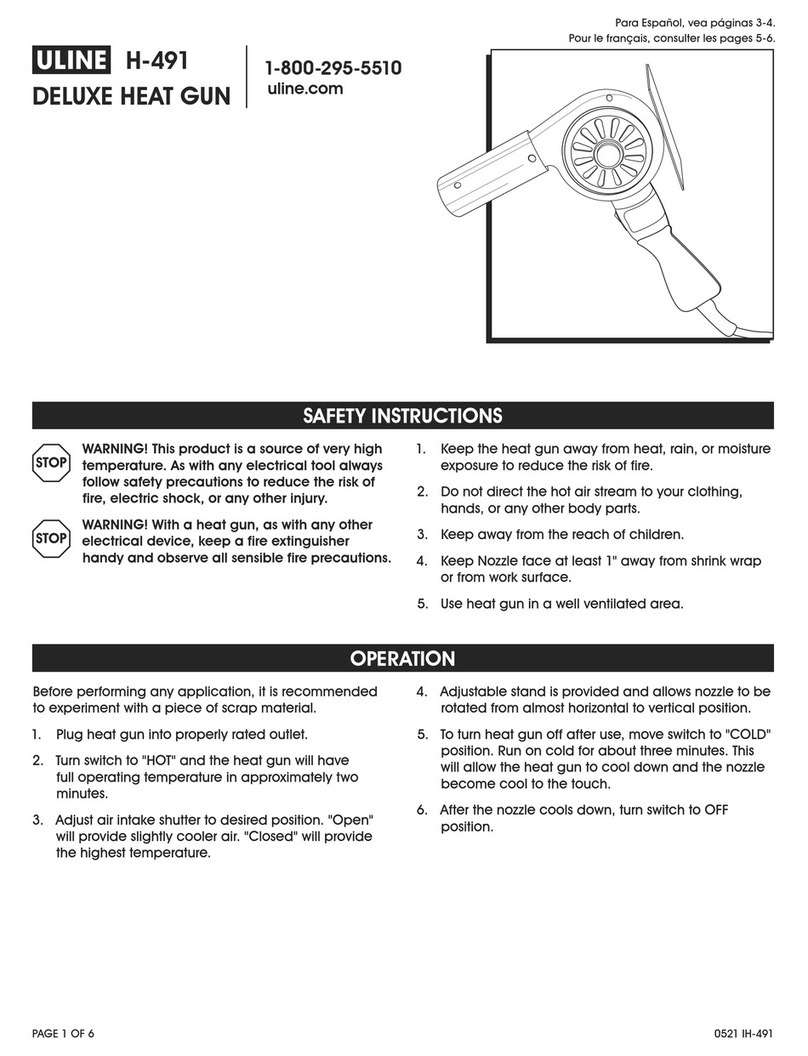

OPERATING THE STAPLER

WARNING! Protect your eyes and ears.

Wear safety glasses with side shields. Wear

hearing protection. Employers and users are

responsible for ensuring the user or anyone

near the stapler wears this safety protection.

WARNING! To prevent accidental injuries, never

place a hand or any other body part in staple

clinching area to adjustment window. Never

point stapler at anyone else. Never engage

in horseplay. Always handle the tool with care.

Never pull trigger unless the stapler is ready for

operation.

WARNING! Check and replace any damaged

or worn components on the stapler.

1. Add a few drops of Unocal RX22 or 3-In-1 oil into the

air inlet.

2. Install a quick connect fitting to the stapler.

3. Regulate the air pressure to obtain 85psi.

4. Insert staples. See Loading the Stapler on page 2.

5. Reconnect the air hose to the stapler.

6. Grasp handle with one hand and position on box in

the desired staple location. Pull trigger, then release.

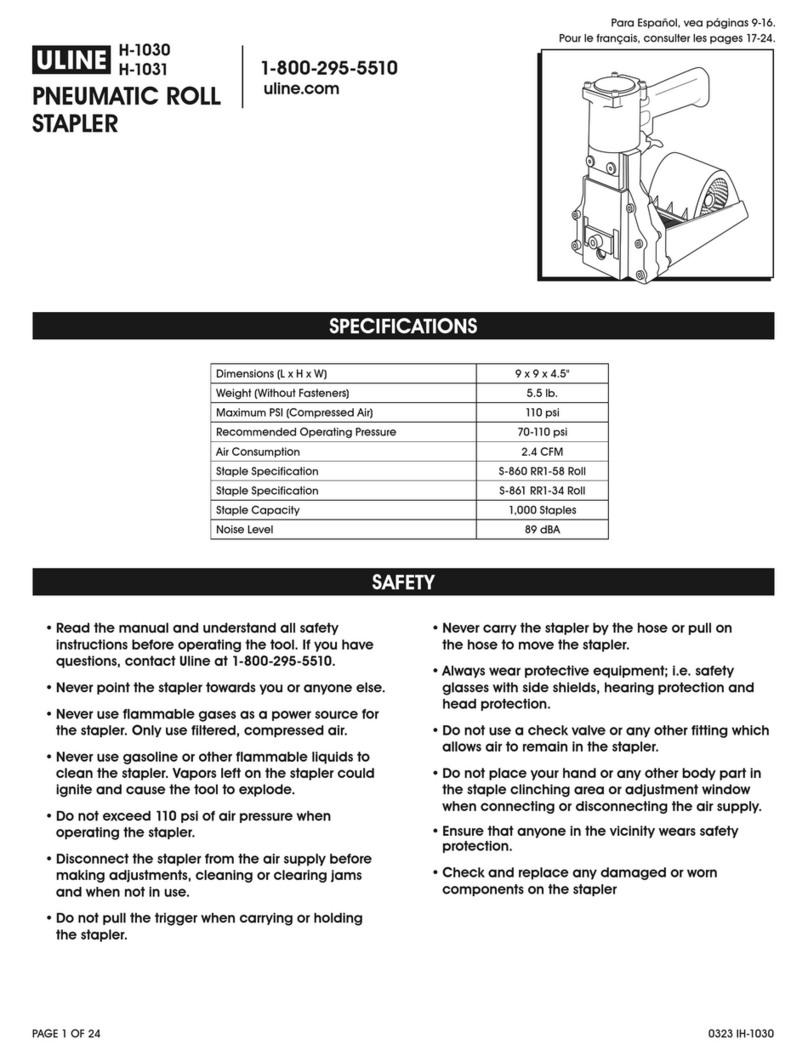

CLEANING THE STAPLER

WARNING! Never use gasoline or other

flammable liquids to clean the stapler. Vapors

could ignite by a spark and cause the stapler

to explode, resulting in death or serious

personal injury.

1. Disconnect the air supply from the stapler.

2. Remove tar buildup with kerosene #2 fuel oil or

diesel fuel. Do not allow solvent to get into the

cylinder or damage may occur.

3. Dry off the stapler completely before use.

CLEARING JAMS

1. Disconnect the air supply from the stapler.

2. Pull pusher back and rotate to locked position.

(See Figure 5)

OPERATION CONTINUED

MAINTENANCE

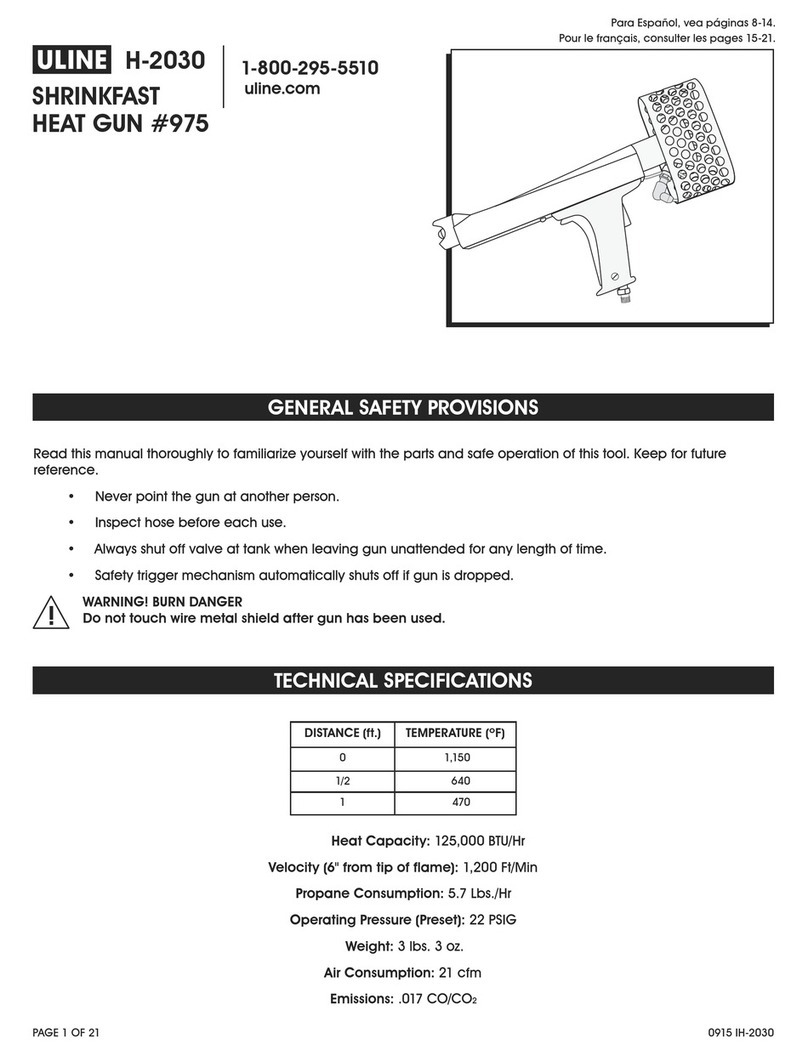

APPEARANCE

STAPLE LEG

LENGTH

ANVIL

SIZE

ADJUSTING PLATE

POSITION

THREADING

DEPTH

25mm 25 615mm

28mm 615mm

32mm 32 518mm

35mm 418mm

38mm 38 624mm

Figure 5