17

GB/USBristle Blaster

®

Pneumatic Operating instructions

5. WORKING AREA

1. Keep your working place clean. Cluttered working places and workbenches are risks of injury.

2. Never allow children, unauthorised individuals or individuals without safety glasses and other protective

equipment to enter the working area.

3. Always operate tool in a well ventilated working area.

5.1 Personal safety

1. Wear suitable protective clothing. Never wear loose clothing or jewellery or other items of clothing that could be

trapped by moving parts. Wear gloves and shoes with non-slip soles. Protect long hair with a head band or hair

net to prevent the trapping of hair by moving parts.

2. Always wear safety glasses, face mask, hearing protection, gloves and suitable protective clothing!

3. Make sure that you have a firm grip on the tool when operating it. Always ensure you are standing firmly and

securely.

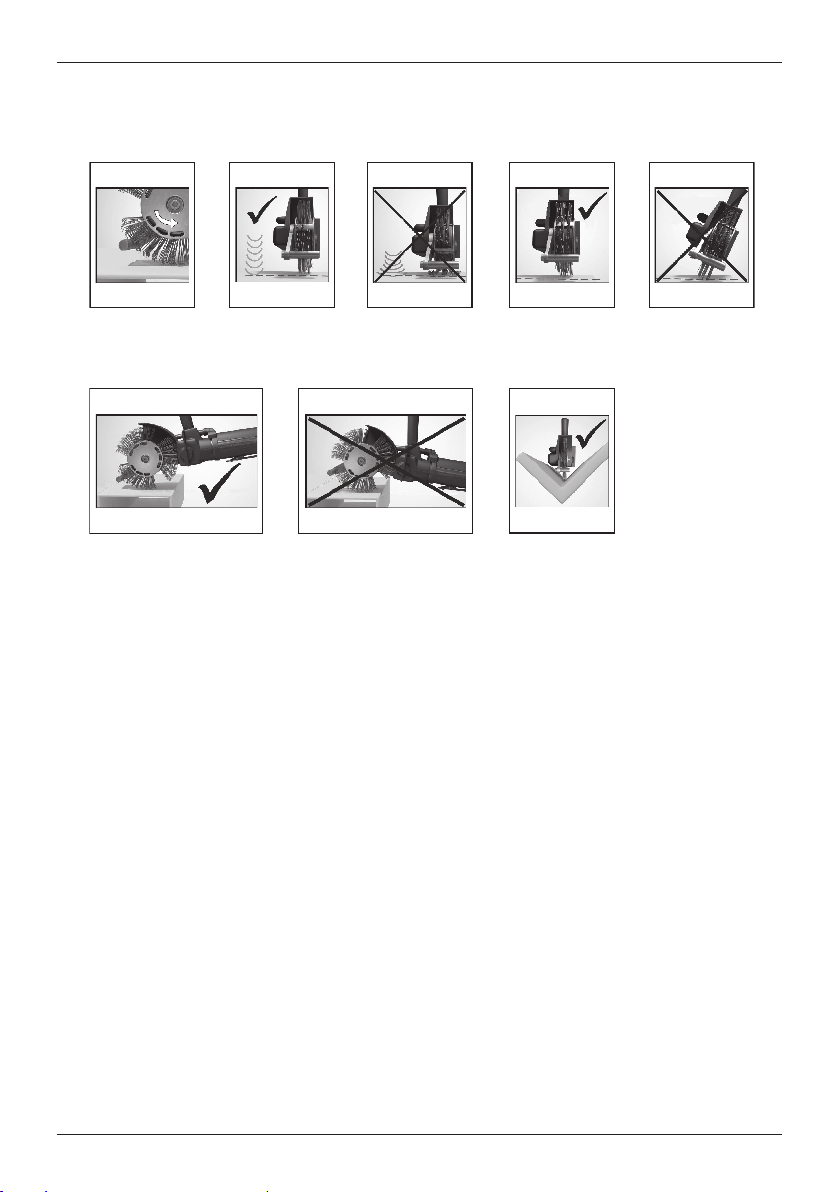

5.2 Tool usage and duty of care

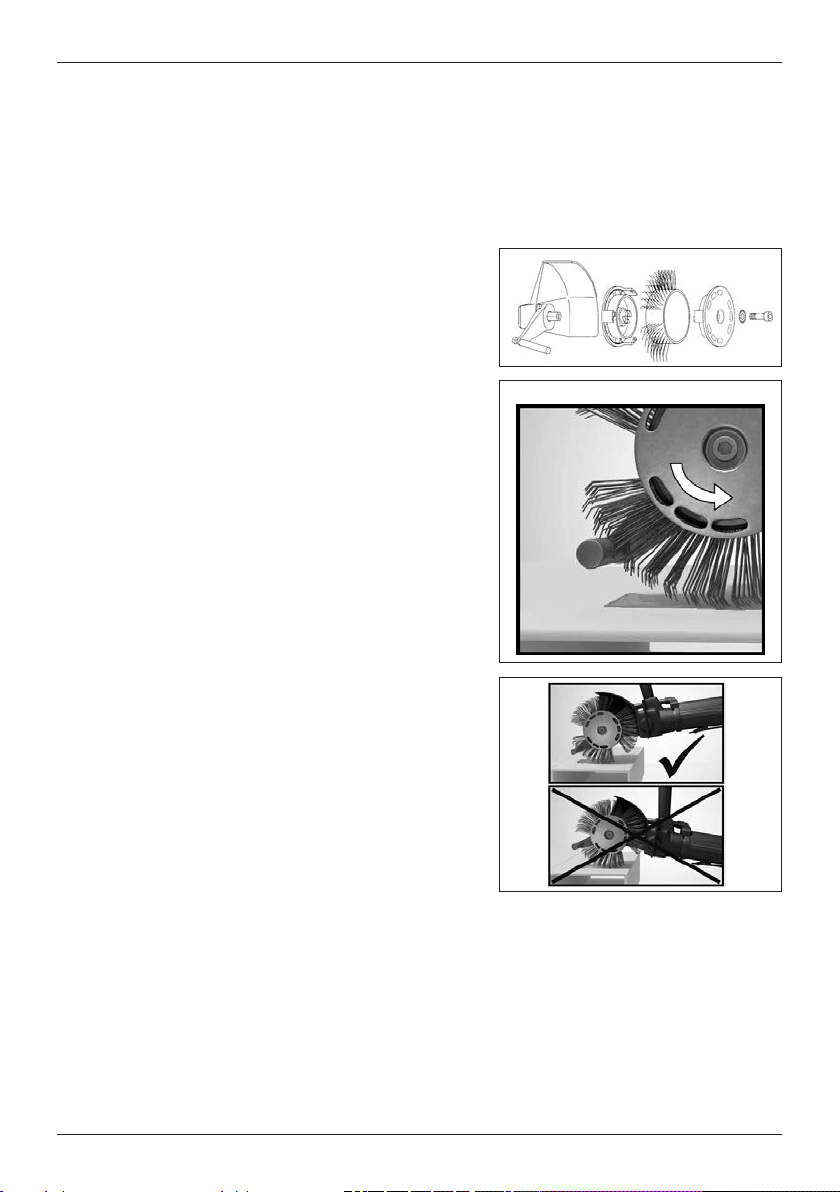

1. After fitting accessories such as the Adaptor System and Bristle Blaster

®

Belt, always remove hex socket

wrench. Always ensure the hex socket wrench is removed prior to switching on the tool.

2. Prevent unintentional starting of the tool. Never carry the connected tool with your hand on the starter lever.

Ensure the starter lever is not actuated on connection to the compressed air pipe.

3. Use care. Handle tool with care. Use your common sense.

4. Never operate this or any other tool when you are tired.

5. Work at a distance to ensure other individuals cannot be injured by objects thrown off. During operation,

nobody should stand in front of or beside the user.

6. Maintain tool carefully. Follow the instructions on lubrication and the replacement of accessories.

(See section 6, Compressed air supply).

7. When not in use, prior to servicing and on the changing accessories, switch off tool and disconnect from the

compressed air supply.

8. Prior to the replacement and inspection of accessories, such as the Adaptor System and Bristle Blaster

®

Belt,

the tool is to be isolated from the compressed air supply. Do not perform any servicing work on the tool as long

as it is connected to the compressed air supply.

9. Bristle Blaster

®

Belt as long as the tool is in operation.

10. Regularly check pneumatic lines and replace if damaged. Keep vertical handle and tool body dry, clean and

free of oil and grease. A soiled housing and/or handle can cause accidents.

Further information on health and safety at work is available from the following web sites:

http://europe.osha.eu.int (Europe) http://www.osha.gov (USA)