5

SUGGESTED INSTALLATION

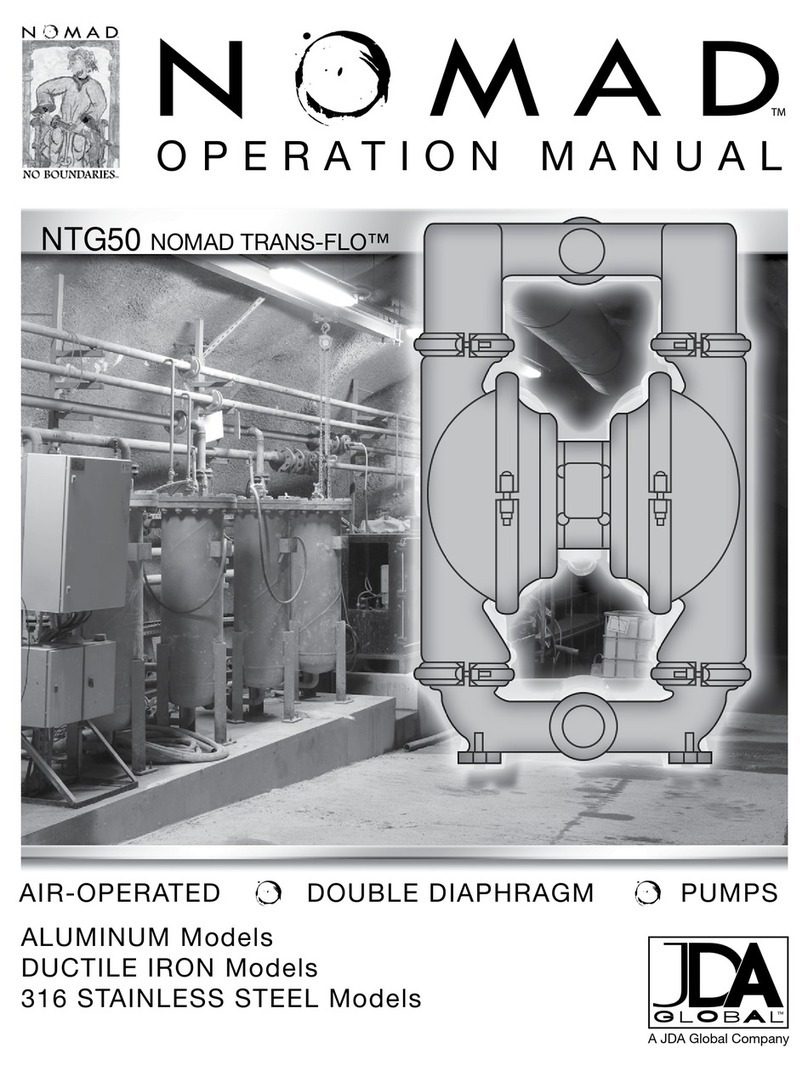

NTG80 NOMAD TRANS-FLO™

The suction pipe size should be at least 76mm (3")

diameter or larger if highly viscous material is being

pumped. The suction hose must be non-collapsible,

reinforced type as the NTG80 is capable of pulling

a high vacuum. Discharge piping should be at least

76 mm (3"); larger diameter can be used to reduce

friction losses. It is critical that all ttings and con-

nections are airtight or a reduction or loss of pump

suction capability will result.

Every pump location should have an air line large

enough to supply the volume of air necessary to

achieve the desired pumping rate.

Unnecessary elbows, bends and ttings should be

avoided. Pipe sizes should be selected so as to keep

friction losses within practical limits. All piping should

be supported independently of the pump.

Expansion joints can be installed to aid in absorbing

the forces created by the natural reciprocating action

of the pump. Flexible connections between the pump

and rigid piping will also assist in minimizing pump

vibration. A surge suppressor should be installed to

protect the pump, piping and gauges from surges and

water hammer.

When pumps are installed in applications involving

ooded suction or suction head pressures, a gate

valve should be installed in the suction line to permit

closing of the line for pump service.

The NTG80 can be used in submersible applica-

tions only when both wetted and no-wetted portions

are compatible with the material being pumped. If

the pump is to be used in a submersible application,

a hose should be attached to the pump’s air exhaust

and the exhaust air piped above the liquid level.

PERFORMANCE

NTG80 METAL

PTFE-FITTED

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation

parameter will fall in the center of the pump performance curve.

Height ................................. 810 mm (31.9")

Width .................................. 432 mm (17.0")

Depth.................................. 279 mm (11.0")

Est. Ship Weight . Aluminum 53 kg (116 lbs)

Stainless Steel..................... 85 kg (187 lbs)

Ductile .................................. 91kg (200lbs)

Air Inlet ................................... 19 mm (3/4")

Inlet............................................ 76 mm (3")

Outlet......................................... 76 mm (3")

Suction Lift ........................ 3.49 m Dry (13')

8.53 m Wet (28')

Displacement/Stroke......... 3.6 l (0.95 gal.) 1

Max. Flow Rate..............704 Ipm (186 gpm)

Max. Size Solids..................... 10 mm (3/8")

1Displacement per stroke was calculated at

4.8 bar (70 psig) air inlet pressure against a 2

bar (30 psig)head pressure.

Example: To pump 378 lpm (100 gpm)

against a discharge pressure head of 2.1

bar (30 psig) requires 4.1 bar (60 psig) and

136 Nm3/h (80 scfm) air consumption.

(See dot on chart.)

Caution: Do not exceed 8.6 bar (125 psig) air

supply pressure.