Jefferson Professional Tools & Equipment JEFWASPET075HP User manual

JEFWASPET075HP

7.5HP Petrol Pressure Washer

1

www.jeffersontools.com

User Manual

v.1.2

7.5HP Petrol Pressure Washer

JEFWASPET075HP

JEFWASPET075HP

7.5HP Petrol Pressure Washer

2

www.jeffersontools.com

JEFWASPET075HP

7.5HP Petrol Pressure Washer

3

www.jeffersontools.com

Contents:

Important: This manual is an essential part of this Jefferson product and should be kept safe with the product for future reference.

This manual outlines the purpose for which the product has been designed and contains important information to ensure its

correct and safe use. It is essential that you read and understand the information in this manual before operating this equipment.

General Safety

Parts Indentication

Specications

Unpacking & Assembly

Connections

Pressure Washer Nozzles

Starting the Washer

Using the Spray Gun

Washing Cleaning

Pressure Adjustment

Using Chemicals & Cleaning Solvents

Shutdown Procedure

Maintenance

Storage

Troubleshooting

Parts Lists & Diagrams

Limited Warranty Statement

Declaration of Conformity

4

5

6

6

7

8

9

10

10

11

11

12

13

15

16

18

26

29

JEFWASPET075HP

7.5HP Petrol Pressure Washer

4

www.jeffersontools.com

General Safety

1.

This equipment should only be operated by qualified

and responsible individuals who have read and

understood the information and guidelines described

in this document. In particular, the following safety

instructions should be followed to reduce the risk of

injury to the operator and members of the public.

1. Ensure that all the necessary safety precautions

are observed for the handling of fuel.

2. Familiarise yourself with this equipment and its

operation before use - read this user manual

carefully before use. Save for future reference.

3. This appliance is for outdoor use only. Ensure that

all bystanders are kept at a safe distance and that ani-

mals and children are kept from the work area. Ensure

that the exhaust emissions are kept away from

air intakes.

4. Never use this equipment if any part or accessory

is damaged or malfunctioning.

5. This appliance has been designed for use with

detergents specified by the manufacturer (for example

neutral shampoo based on biodegradeable anionic

surface active detergents). Please consult the

manufacturer for advise before using other

detergents or chemicals in order to prevent damage

to the equipment and the environment.

6. Do not direct the nozzle towards mechanical parts

containing lubricant grease. High pressure jet can be

harmful and dangerous always ensure a safe working

distance when spraying objects and assess and fix

the appropriate nozzle for the job at hand.

Never point the high pressure hose directly

at people animals, live electrical parts or the

appliance itself.

7. Do not step or stand on the high pressure hose

and ensure that the hose is clean, free from debris,

obstructions and kinks before use. Always unwind the

hose fully before use.

8. Check and ensure that the nozzle has been fitted

correctly before use as the high pressure can result in

the nozzle being "fired" from the lance with

considerable force if not fitted correctly.

9. Beware of kick-back force and the sudden torque

on the spray gun assembly when operating the trig-

ger.

10. Ensure that you have evaluated the pressure

required for the job at hand and selected the

appropriate nozzle before use. High pressure jets can

remove paint and other specialised surface

treatments (including alloy wheel lacquer). High

pressure jets may also breakdown and remove the

grouting between paving slabs and can even damage

tarmac.

11. Always shut the equipment off completely when

not in use and if left unattended.

12. Keep the hose clear from the engine exhaust as

this can be extremely hot before and after use and

can burn and damage the hose.

13. Never refuel the engine when it is running, and

allow the engine to cool sufficiently before refuelling.

Dry up any fuel spillage before restarting the

equipment. Only use fresh clean high-quality fuel.

Always restart the equipment away from the refuelling

area. Fill tank to within 10mm of neck to allow space

for fuel expansion.

14. Do not operate this equipment in an explosive

atmosphere, near combustible materials.

15. Only operate outdoors in well-ventilated areas.

16. Never run the engine without oil - always check

for oil and refill where necessary before use.

17. Only Jefferson approved engineers should carry

out repairs and maintenance on this equipment.

Only use Jefferson-approved replacement parts to

repair this equipment. Never modify the equipment

in anyway. Ensure that the equipment is kept in good

working order and cleaned and serviced regularly.

Regularly check external nuts and fixings to ensure

that they have not loosened from vibration during use.

18. After use: remove the spark plug ignition lead

from the back of the spark plug and position the lead

to prevent avoid accidental reconnection. Store in a

clean dry environment. Store all fuel in a suitable con-

tainer designed for petrochemical applications - away

from heat and out of direct sunlight.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

5

www.jeffersontools.com

General Safety Parts Identication

2.

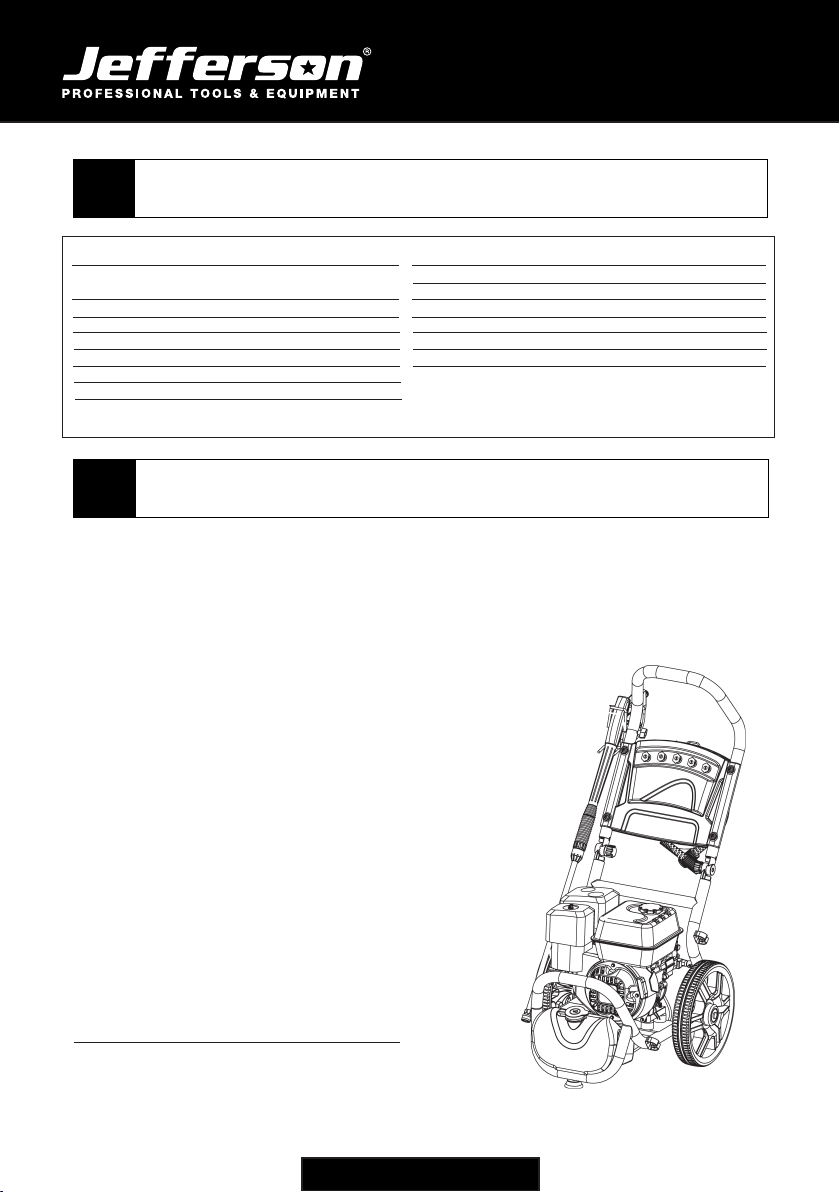

Important: After unpacking, inspect the equipment carefully and ensure that the product is in perfect condition without any

defects or no damaged or worn parts. Please dispose of all the packaging materials appropriately, recycling all materials where

facilities are available.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

6

www.jeffersontools.com

Unpacking & Assembly

4.

Specications

3.

Rated Flow:

Working Speed:

Guaranteed Noise Level:

Fuel Tank:

Hose Length:

Wheel Diameter:

Dimensions:

Net Weight:

9.6L/Min

3350 - 3550rpm

99dB Lwa

3.6L

10M x ø 7.2mm

12"

590mm x 540mm x 595mm

34kg

Model Number:

Engine:

Starting System:

Displacement:

Bore & Stroke:

Compression Ratio:

Pump:

Maximum Pressure:

Rated Pressure:

JEFWASPET075HP

7.5HP Single Cylinder, 4 Stroke

OHV Petrol

Recoil

223cc

70 x 54mm

8.5:1

Direct Drive Triplex Pump

3200psi / 220bar / 22.6Mpa

2700psi / 158bar / 18.6Mpa

Frame assembly:

1. Carefully tip the washer forward and place on its front side and

proceed to assemble the parts with the tools provided.

2. Insert the axle into the corresponding holes on the lower frame.

3. Attach the wheels to the shadt using the bushings, washers

and cotter pins provided. Insert the cotter pins into the holes in

the axle and bend back the cotter pins using a pair of pliers (not

provided)

4. Attach the rubber feet to the lower frame using the nuts and

bolts provided (tighten all mounting hardware)

5. Reposition the washer so that it stands normally on the wheels

and rubber feet.

6. Pull the handle lock pin and raise the handle to the upright

position. Release and snap the locking pin into the corresponding

hole in the frame.

7. Assemble the top and bottom spray gun holders to the frame

using the nuts and bolts provided. Again tighten all mounting

hardware.

Unpacking & inspection:

After opening the carton, unpack the washer and related parts and accessories. Inspect the equipment for any

damage that may have occurred during transit, contact your nearest Jefferson Dealer is any damage or defects

are discovered. Check that all nuts and bolts are secure before putting the washer into operation.

Warning: Do not use this equipment is damaged or defective in any way.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

7

www.jeffersontools.com

Unpacking & Assembly

Specications

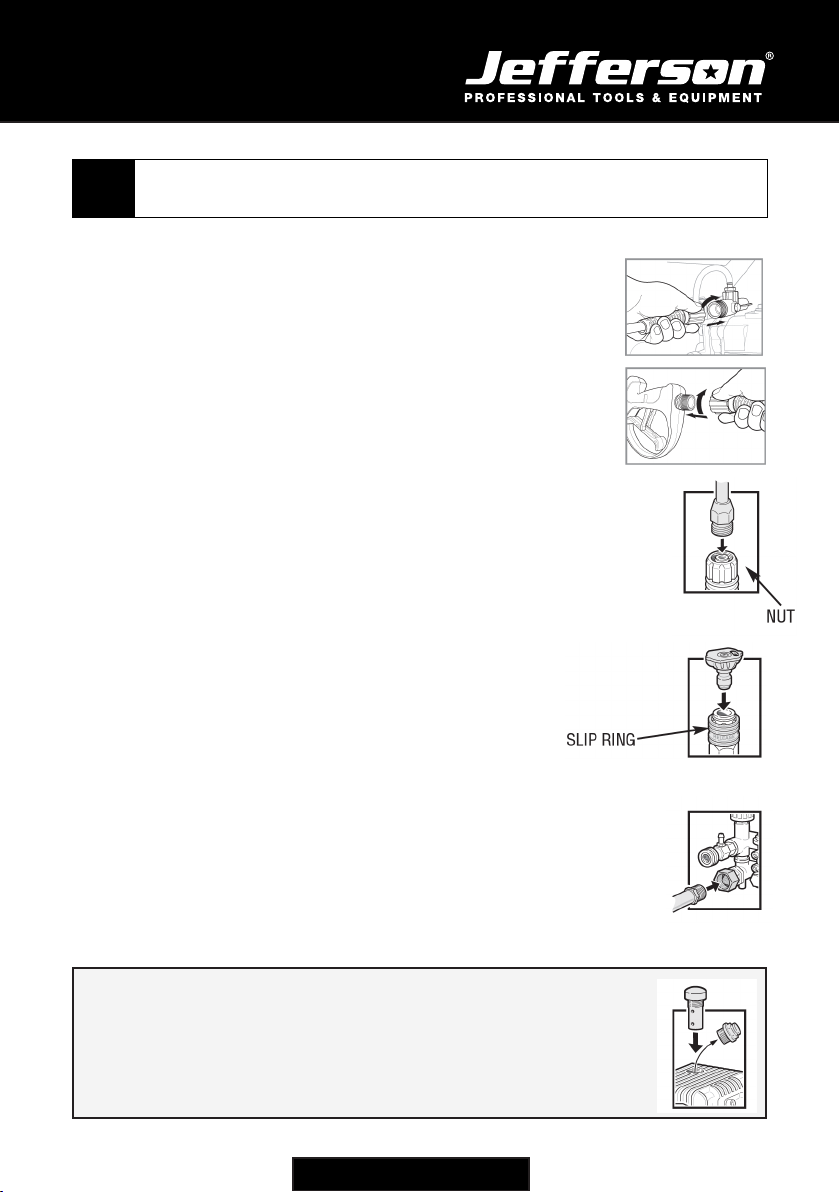

Connecting the pressure hose to the pump

1. Pull back the high pressure outlet fitting collar. Insert the connector into

the quick release fitting and release the collar to close the fitting.

Carefully tug on the fitting to ensure it is secured.

Connecting the hose to the spray gun

1. Pull back the slip ring on the female quick connect fitting and

connect with the male outlet on the spray gun.

2. Release the slip ring on the female quick disconnect and twist. Listen

for a "click" to ensure that the coupling is secure.

Connecting the Lance to the Spray Gun

1. Remove the protective plastic cap on the lance connection.

2. Thread the lance connection onto the spray gun as shown

3. Tighten the nut to secure

Connecting the Nozzle / Removing the Nozzle

1. Insert the nozzle into the quick- connect fitting on the lance and press

to snap in the nozzle.

2. To remove pull back the slip ring to eject the nozzle. See page 8 for

more information about nozzle selection for various applications.

Connecting the pressure pump to the water supply

1. Connect the garden hose to the water supply and turn the water supply

on to run water through the hose and remove any debris prior to

connecting to the pressure washer, then turn off the supply.

2. Check the filter inside the pressure washer inlet is clean and

undamaged. Thread the garden hose fitting into the water hose inlet. Hand

tighten to make a secure connection.

3. Turn on the water supply and check that there are no leaks. Ensure that

there is a minimum of 20psi and a flow rate of 5GPM.

Connections

5.

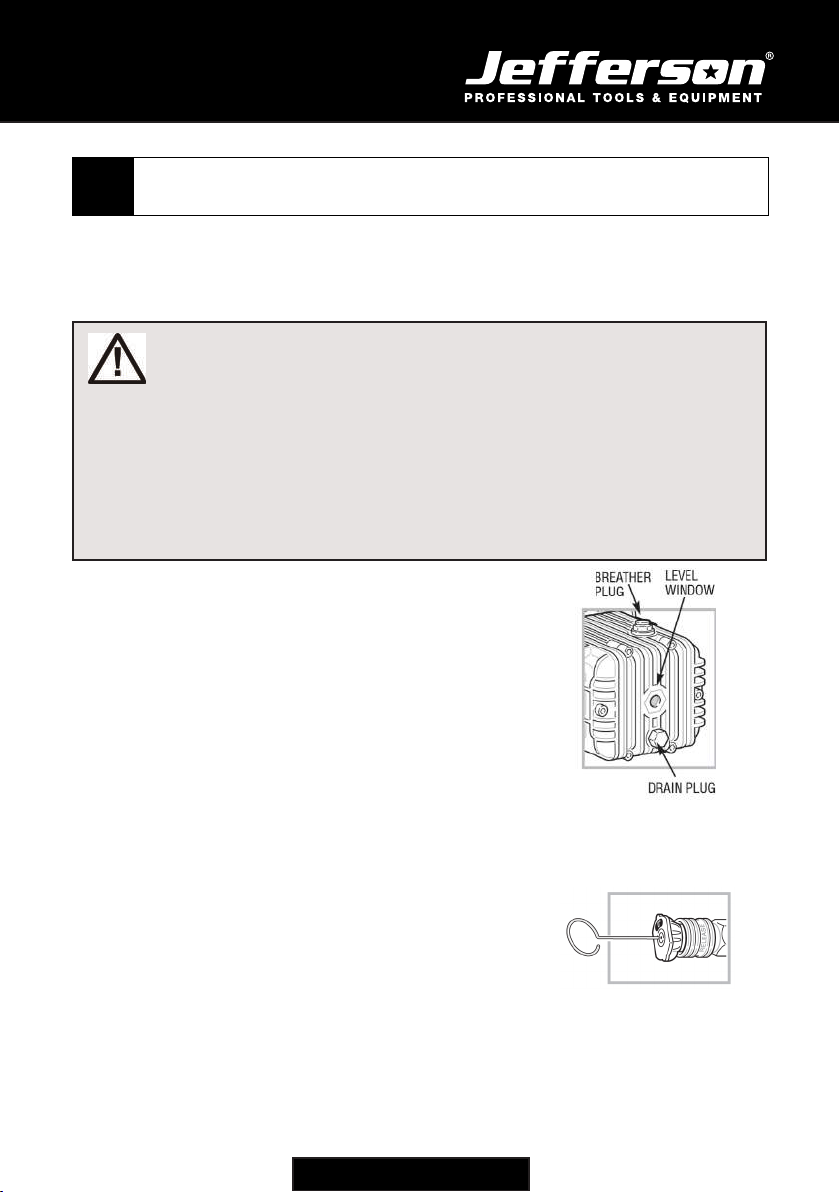

Preparing the pump for first use

This equipment is shipped with a special oil plug to prevent oil leak-

age from the pump during shipping.

You will need to replace the shipping plug with the breather plug pro-

vided before use. Hand tighten the breather plug to avoid damaging

the threads.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

8

www.jeffersontools.com

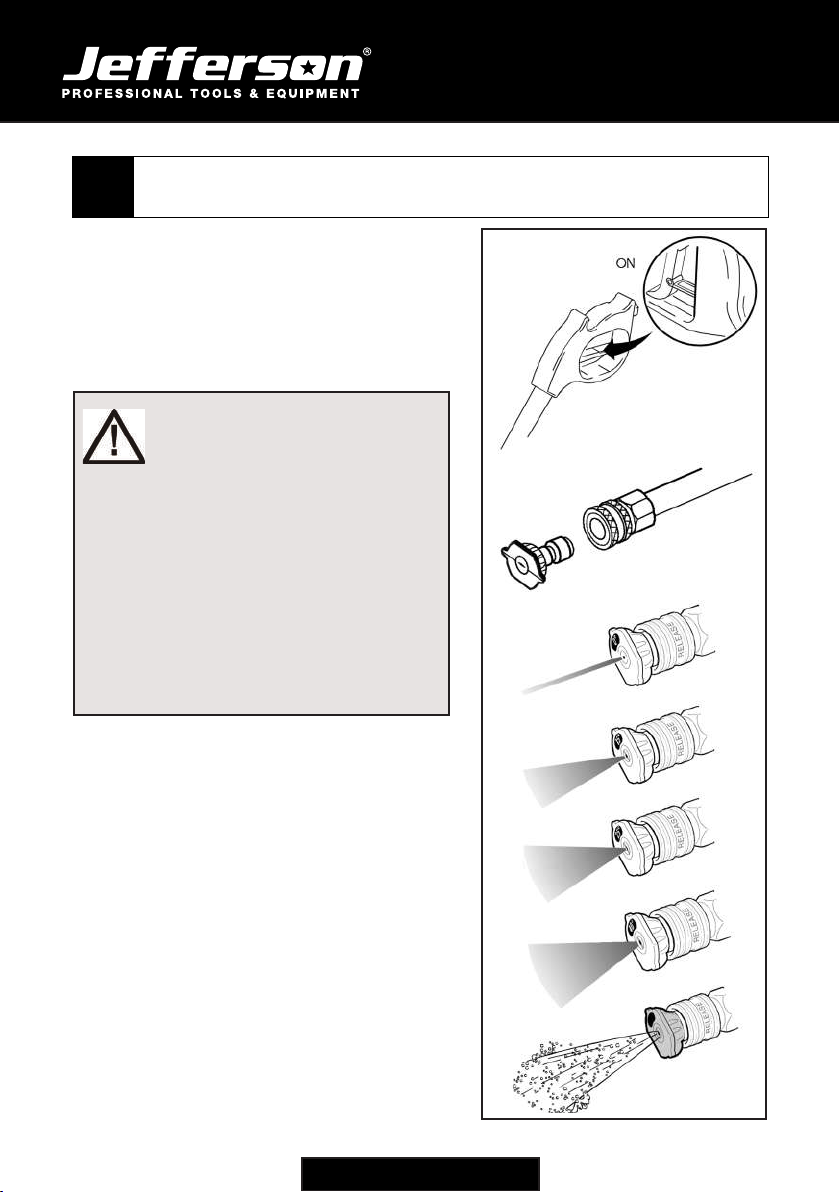

This equipment comes complete with ve different

colour-coded spray nozzles. Each nozzle delivers a

specic spraying pattern for a particular cleaning

application. The size of the nozzle determines the size

of the spray jet and the pressure delivered from the nozzle.

The 0˚, 15˚, 25˚, 40˚ nozzles are high pressure nozzles,

the 84˚ chemical nozzle is for use in low pressure

applications.

Changing Nozzles:

1. Pull back the collar on the end of the lance and insert the

nozzle into the female quick release socket.

2. Release the collar and twist the nozzle to make sure

that it is secure in the quick release socket. Ensure that the

nozzle is secure before squeezing the gun trigger when the

engine is running.

Basic Nozzle Types and Applications:

•Cutting Nozzle (0˚):

High pressure cleaning (stone, metal etc.)

•Chisel Nozzle (15˚):

Mid pressure cleaning (stone, metal, wood etc.)

•Flushing Nozzle (25˚):

Low - Mid pressure cleaning (metal, plastics, wood etc.)

•Wide Wash Nozzle (40˚):

Low pressure, everyday use (wood plastics etc.)

•Detergent Nozzle (84˚):

Delicate materials

WARNING

This equipment operates at fluid pressures

and velocities high enough to penetrate

human flesh. Leaks caused by loose

fittings or worn or damaged hoses can

result in injection injuries. Do not direct the

spray jet towards people or animals as the

jet is very powerful and serious injury can

occur. Wear the appropriate safety

equipment when operating this equipment.

Do not attempt to change the

nozzles when the equipment is

running. Always shut down the

engine completely before changing

the nozzles. 0˚

15˚

40˚

84˚

25˚

Pressure Washer Nozzles

6.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

9

www.jeffersontools.com

Starting the Washer

7.

1. Ensure that the equipment is operating in a well ventilated outdoor area. Check fuel level and top-up if

necessary.

2. Check the engine oil level. On first use there will be a small amount of oil left from factory testing but this

will always require topping up.

This equipment is shipped with a low-oil sensor that will prevent startup if insufficient oil is

available for operation. The low oil sensor will also shut down the engine when level is too low to protect the

engine.

3. Check that the filter is clean and in place at the water inlet (cone side facing out).

4. Connect the water supply to the pump inlet. (Note: the water source must provide a minimum of 19L / Min

at 20PSI for this equipment to operate.

5. Connect the high pressure water hose to the pump outlet. Turn on the water supply.

6. Make sure that the Throttle lever is set to the "Fast" position. Slide the fuel lever to the "On" position and

allow the fuel to flow to the engine. Slide the choke lever to the "Start" position. Turn the Engine ON/OFF

switch to the ON position. Pull the starter cord to start the engine. Slide the choke lever to RUN position.

7. Stand on a stable surface, gripping the gun with both hands, and press the trigger to begin spraying -

expect the gun to kickback when triggered. Adjust the spray nozzle as required for the task.

8. Release the trigger to stop water flow and enter bypass mode pior to spraying.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

10

www.jeffersontools.com

Using the Spray Gun

8.

WARNING

Do not leave the pressure washer in bypass mode for more than 2 minutes at a

time. Water temperature inside the pressure washer pump will rise to

dangerous level and can result in damage to internal components within the

pump. Failure to follow this warning can result in personal injury and damage to

the equipment and will void the warranty.

Do not run the pump without a connection to the water supply. Any damage caused by such

use will void the warranty.

Always wear the appropriate safety equipment when using this equipment.

The high pressure water jet produced can cut through skin and underlying tissues resulting in

serious injury. Never point the jet at people or animals. Beware of kickback when

spray gun trigger is pressed.

1. To engage the Trigger Lock, pull the lock up until it clicks into the slot.

2. To disengage the Trigger Lock push the lock down and into its original

position.

To operate the trigger:

Squeeze the trigger to start the water flow through the nozzle.

Release the trigger to stop the water flow.

Washing / Cleaning

9.

1. Grip the spray gun with both hands.

2. Point the nozzle in a safe direction and

squeeze the spray gun trigger to allow the pump

to purge air and impurities in the system and

then redirect the nozzle to the working surface.

3. When finished release the trigger gun

to stop the water flow.

Important: For most effective cleaning keep

the spray nozzle approximately 8 to 24 inches

away from the cleaning surface. When cleaning

tyres do not bring the nozzle within 6 inches

of the surface to avoid damage and potential

injury.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

11

www.jeffersontools.com

Using the Spray Gun

Washing / Cleaning

Pressure Adjustment

10.

1. Vary the Cleaning Distance.

One method of adjust the pressure on the cleaning surface is to vary the distance between the nozzle and the

object you are cleaning.

2. Change the pressure nozzle.

Completely shut down the pressure washer and stop

the petrol engine. Change the spray nozzle as required

for the cleaning application.

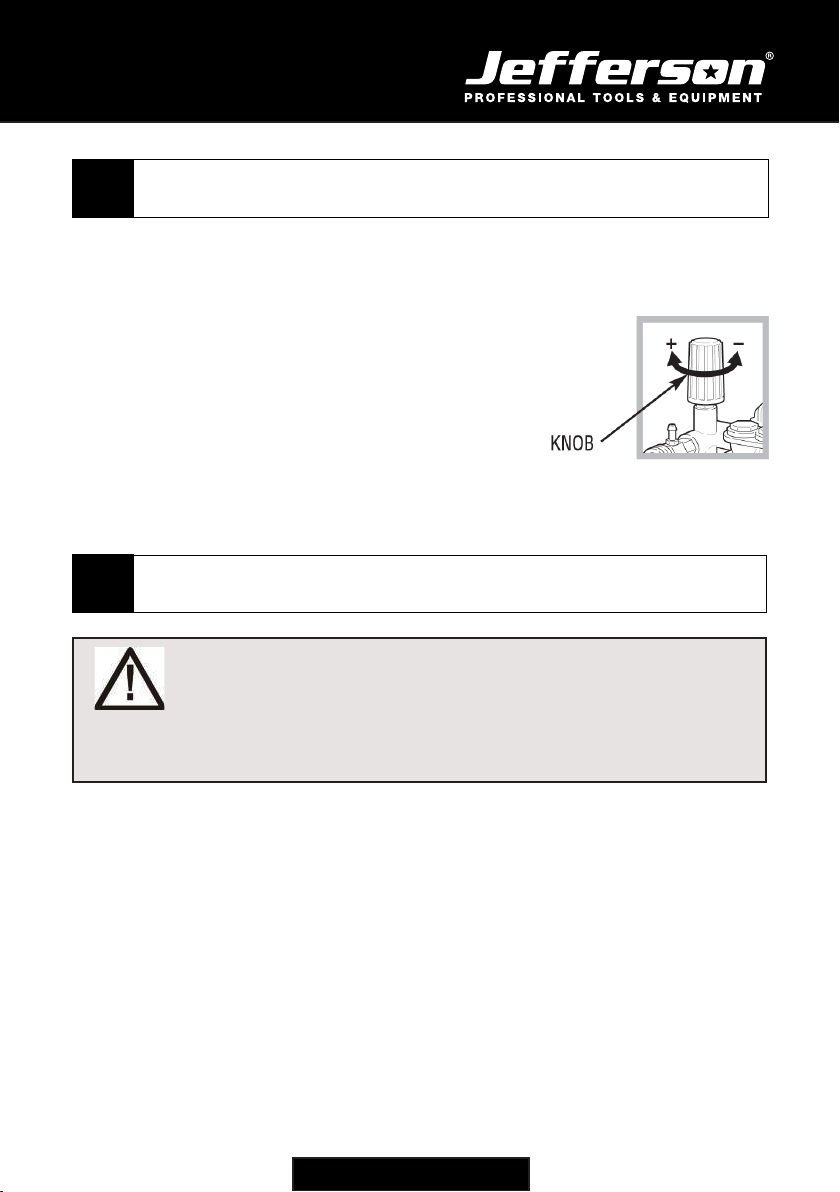

3. Adjust the pump pressure regulator.

The pump pressure regulator allows pressure adjustment at the pump.

Turn the pressure regulator knob on the pressure pump counterclockwise / clockwise to increase and decrease.

To Apply detergent

1. With pressure washer turned off, Prepare the detergent solution as recommended by the manufacturer.

2. Remove the detergent tank cap (located in front of the pressure washer).

3. Fill the tank with the prepared detergent solution using a funnel if necessary. Replace the detergent tank cap.

4. Lock the trigger and attach the Black Detergent Nozzle to the wand.

5. Start the pressure washer. Unlock the trigger and squeeze the spray gun trigger and apply detergent to the

cleaning surface using long, even & overlapping strokes.

6. Allow the detergent to "soak in" for 3-5 minutes before washing and rinsing. Reapply as required to prevent

the surface from drying. Do not allow the detergent to dry on the surface (this will result in streaking).

WARNING

Use only soaps and chemicals designed for petrol washers - if in doubt contact your

nearest Jefferson Tools retailer for advise. Do not use bleach to spray with this equipment.

Applying chemicals or cleaning solvents is a low pressure operation. Chemicals, soaps

and cleaning solvents will not siphon when a high pressure nozzle is used. Always use the

black detergent nozzle for chemical and solvent cleaning .

Using Chemicals and Cleaning Solvents

11.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

12

www.jeffersontools.com

1. If you have used any chemicals rinse system thoroughly as outlined on pg.11 to prevent damage to the

pump.

Never turn the water supply off when the engine is running.

2. To stop the engine set the engine switch on the side of the engine to the OFF position.

3. Turn the water supply off and disconnect the garden hose from the pressure washer.

4. Pull the trigger on the spray gun to relieve any water pressure in the hose or the gun.

Allow the engine to cool before folding down the frame in preparation for storage.

To Rinse

1. Shut down the pressure washer. Replace the detergent nozzle with a suitable cleaning nozzle. Squeeze

the trigger and wait for the detergent to clear.

2. Keep the spray gun a safe distance from the area you plan to spray.

3. Start at the top of the cleaning area working down with consistent overlapping strokes.

Flush the system

1. Turn off the engine and ll the detergent tank with clean water.

2. Remove the nozzle and turn the washer back on.

3. Point the wand in a safe direction and squeeze the trigger to ush clean water through the detergent tank

and pressure washer system until it is thoroughly clean.

WARNING

Leaving chemicals and cleaning solutions in the pressure pump could result in damage to the

pump components. Any damage caused by soap or detergent residue will not be

covered under warranty.

Shut Down Procedure

12.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

13

www.jeffersontools.com

Maintenance

13.

To ensure efficient operation and longer life of your pressure washer a routine maintenance schedule should

be prepared and followed. If the equipment is used in unusual conditions such as high-temperature or dusty

conditions more frequent maintenance checks will be required.

Engine:

Check the engine regularly, replace oil, clean spark plugs and maintain

parts as required.

Pump Oil:

Change the pump oil regularly. Change the pump oil after the first 50 hours

of work and successively every 100 hours. In either case ensure that the oil

is changed at least once a year. Oil Type: SAE 15W-40

Spray Gun:

If the nozzle becomes clogged with dirt and debris excessive pressure can build up. If the nozzle becomes

partially clogged or restricted the pump pressure will fluctuate and can become harmful and dangerous.

Clean the nozzle immediately and follow these instructions:

1. Shut-off the engine and turn off / disconnect the water supply.

2. Pull the trigger on the gun to relieve any water pressure

3. Disconnect the lance from the gun

4. Remove the nozzle from the lance - remove any obstructions

with the nozzle cleaning tool provided and back flush with clean water

5. Direct the water supply into the spray wand end to back flush loosened

particles for 30 seconds.

6. Reassemble the nozzle onto the lance

7. Reconnect the lance to the gun and turn on the water supply

8. Start the washer pump and place the lance into the high pressure setting to test.

WARNING

Before performing any maintenance be aware that the equipment should be completely

shutdown, depressurised and allowed to cool down. This will ensure that no injuries can be

sustained by moving parts, water pressure or hot surfaces.

Engine contains flammable fuel do not smoke near or work near naked flames

while maintaining this equipment.

Please note: All repairs should be carried out by Jefferson approved

engineers. All replacement parts should be supplied or recommended by

Jefferson. Any unapproved repairs or modifications will invalidate the warranty.

Shut Down Procedure

JEFWASPET075HP

7.5HP Petrol Pressure Washer

14

www.jeffersontools.com

Cleaning The Water Filter:

The water filter should be checked regularly and cleaned if necessary:

1. Remove the filter by grasping the end and removing it from the water

inlet on the pump

2. Clean the filter by flushing it with water on both sides

3. Re-insert the filter in the water inlet on the pump

Cleaning the Fuel Tank Filter:

The fuel tank filter should be removed and cleaned after every 150 hours of running or every 3 months using an

environmentally-friendly water-based de-greasing agent. Refit when clean.

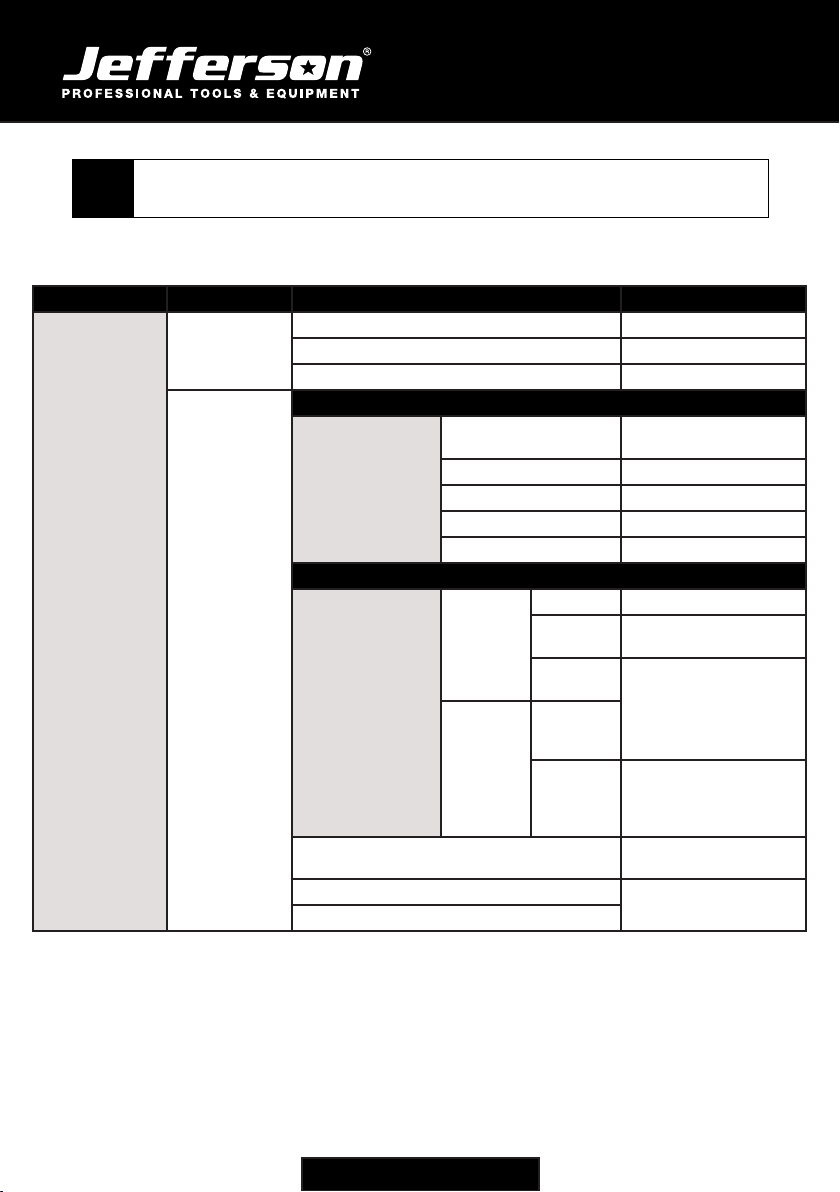

Frequency

Item Task Description Each Use 1st Month

(20Hrs)

Each

Season

(50Hrs)

Every

6 Months

(100Hrs)

Every

Year

(300Hrs)

Engine Oil Oil Level Check •

Replace • •

Reduction gear

oil

Oil Level Check •

Replace • •

Air Cleaner

Check •

Clean •x•x*

Replace •**

Deposit Cup Clean •

Spark Plug Clean, adjust •

Replace •

Spark Eliminator Clean •

Idling Check, Adjust •∆

Valve Clearance Check, Adjust •∆

Fuel Tank &

Filter

Clean •∆

Fuel Supply Line Check Check with your Jefferson dealer for advice

if any problems are detected

Key:

* = Only for inside ventilating double core carburettors

** = Only for paper core cleaners

x = Repeat task more often than scheduled if equipment is used in dusty working environments

∆ =Maintenance to be carried out by Jefferson approved technician

JEFWASPET075HP

7.5HP Petrol Pressure Washer

15

www.jeffersontools.com

Storage

14.

After General / Regular Use

1. Drain all water from the high pressure hose, coil it and hang on the cradle on the petrol washer frame. If

chemicals where used ensure the pump and chemical hose are thoroughly cleaned out

2. Drain all the water from the gun and lance by holding the gun in a vertical position with the nozzle end

pointing down and squeeze the trigger. Store in the gun/hose holder

Preparation for Winter and Long-term Storage

Note: It is recommended that you follow these steps tp protect the internal seals of the pump when storing the

equipment for more than 30 days and or when, freezing temperatures are expected.

1. Obtain a funnel, 200ml of anitfreeze and approximately 1M of garden hose with a male hose connector

attached to one end

2. Disconnect the spark plug wire

3. Connect the hose to water inlet on the pump

4. Pour the antifreeze into the hose via the funnel

5. Pull the engine starter cord slowly several times until antifreeze comes out of the high pressure water hose

connection on the pump

6. Remove the short hose from the water inlet on the pump

7. Reconnect the spark plug wire

Service After Storage

Before reusing the equipment after storage, you should carry out the following to keep the equipment in good

condition.

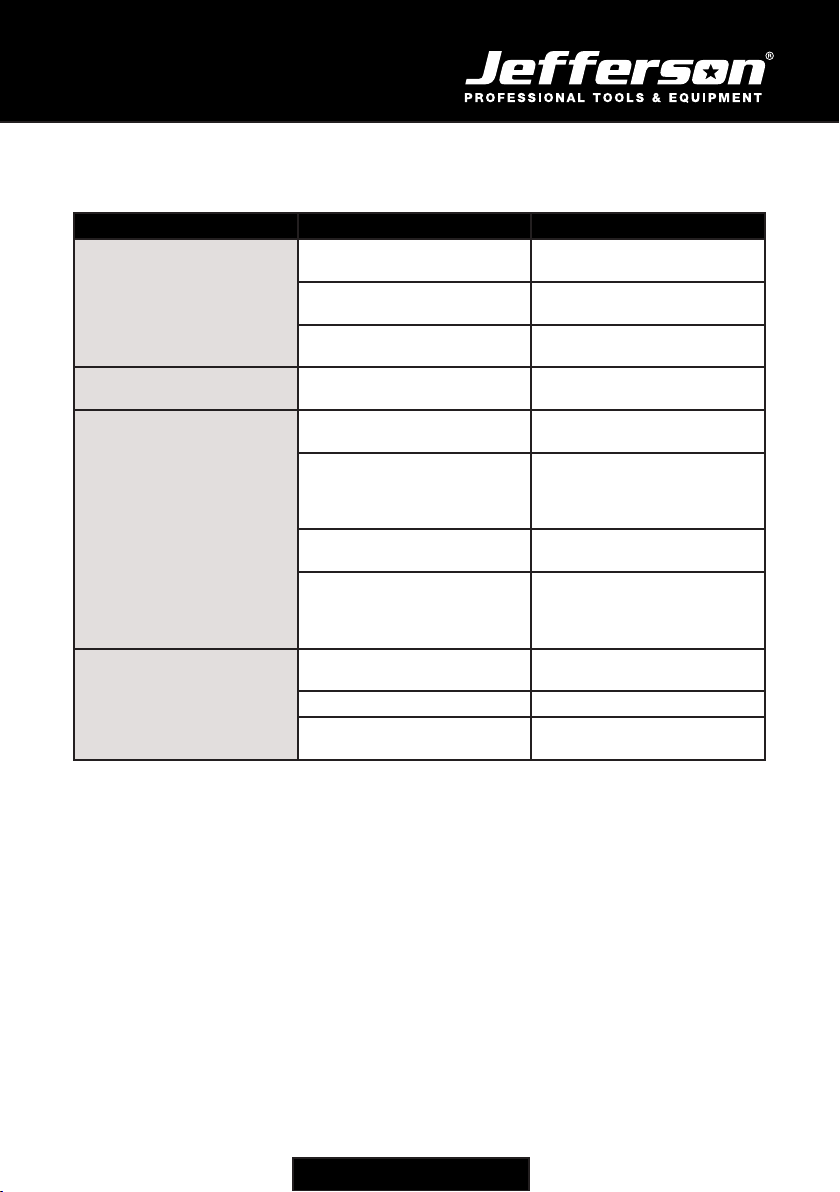

Storage Time Service Task

Within one month No service required

One - two months Drain out the existing fuel out of the fuel tank and fresh fuel

Two months - one year Drain out the existing fuel out of the fuel tank and fresh fuel

Drain the fuel out of the carburettor*

Empty the deposit cup**

Over a year Drain out the original fuel of the fuel and refuel

Drain the fuel out of the carburettor*

Empty the deposit cup**

Start the engine and allow to run for a few minutes

Key:

* = Unscrew the drain plug and drain out the fuel in the carburettor

** = Turn engine switch to the off position, disconnect the deposit cup and empty contents safely

Note: Do not dump oil vessels or discarded engine oil onto the ground. Take all discarded engine oil in a closed

container to your nearest recycling station.

JEFWASPET075HP

7.5HP Petrol Pressure Washer

16

www.jeffersontools.com

Troubleshooting Guide

15.

Fault Probable Cause Repair

Engine fails

to start

Low engine

output

Engine runs

erratically

Insufficient

compression

Loose spark plug Tighten the spark plug

Loose cylinder head bolt Tighten the head bolt

Damaged gasket Replace the gasket

Sufficient

compression

Fuel System Problems

No fuel supplied

to the combustion

chamber

Starter cord Pull the start cord

sharply

Debris in the fuel tank Clean the tank out

Blocked fuel line Clean the fuel line*

Insufcient fuel in the tank Refuel

Fuel tap is closed Open the tap

Electric System Problems

Combustion

chamber supplied

with fuel

Poor spark

from the

plug

Dirty plug Clean / dry the plug

Damaged

spark plug

Replace the spark plug

Faulty

magneto

Contact your nearest

Jefferson dealer for

advice

Good spark

Carburetor

incorrectly

adjusted

Insufcient

pull speed

on recoil

cord

Pull the recoil starter

rope sharply

Wrong grade of fuel being used Check the quality of

the fuel

Overloading Assess the working

conditions

Overheating

Engine Troubleshooting:

JEFWASPET075HP

7.5HP Petrol Pressure Washer

17

www.jeffersontools.com

Troubleshooting Guide Pump Troubleshooting:

Fault Probable Cause Solution

Fluctuating pressure

levels

Pump is drawing in air Check connections

and tighten if required to seal

Faulty or dirty valves Contact your nearest Jefferson

dealer for advice

Blocked nozzle jet Remove debris from the nozzle

using the cleaning tool

Water leaking from the pump Seals are worn out Contact your nearest Jefferson

dealer for advice

Pump will not reach the

required pressure

The pump is sucking air from

connections or the hose

Check all connections and

tighten if required

The suction delivery valves are

clogged

Clean the valves

Arrange to have the equipment

serviced at your nearest Jef-

ferson repair centre

The unload valve is stuck Loosen and re-tighten the

regulating screw

Nozzle is dirty, worn out or there is

a problem with the lance

Clean the nozzle

Check the connections on the

lance

Replace parts if required

Pump is running but no

water

Kinked inlet or pressure hose

Damaged hose

Check, clean, straighten

Replace the hose

Blocked inlet filter Remove and clean the filter

Blocked jet Remove the blockage using the

nozzle cleaning kit

JEFWASPET075HP

7.5HP Petrol Pressure Washer

18

www.jeffersontools.com

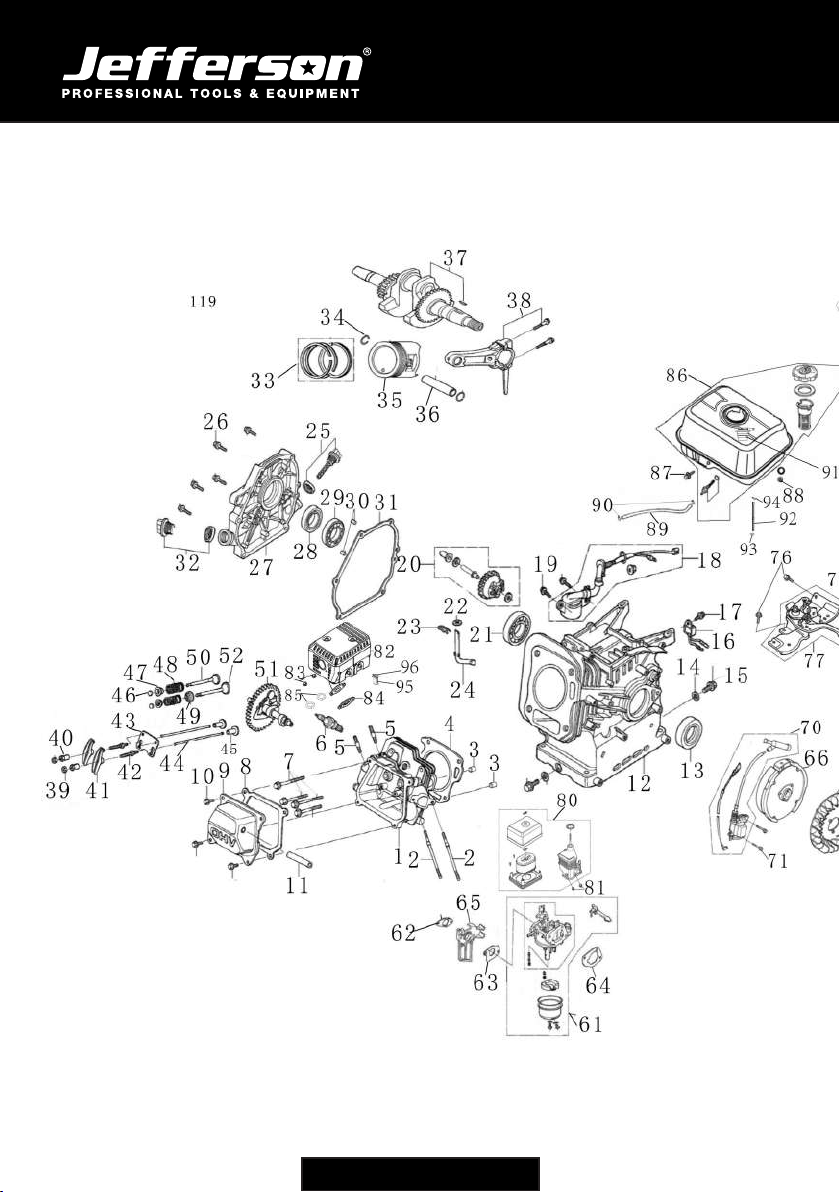

Parts Lists & Diagrams

16.

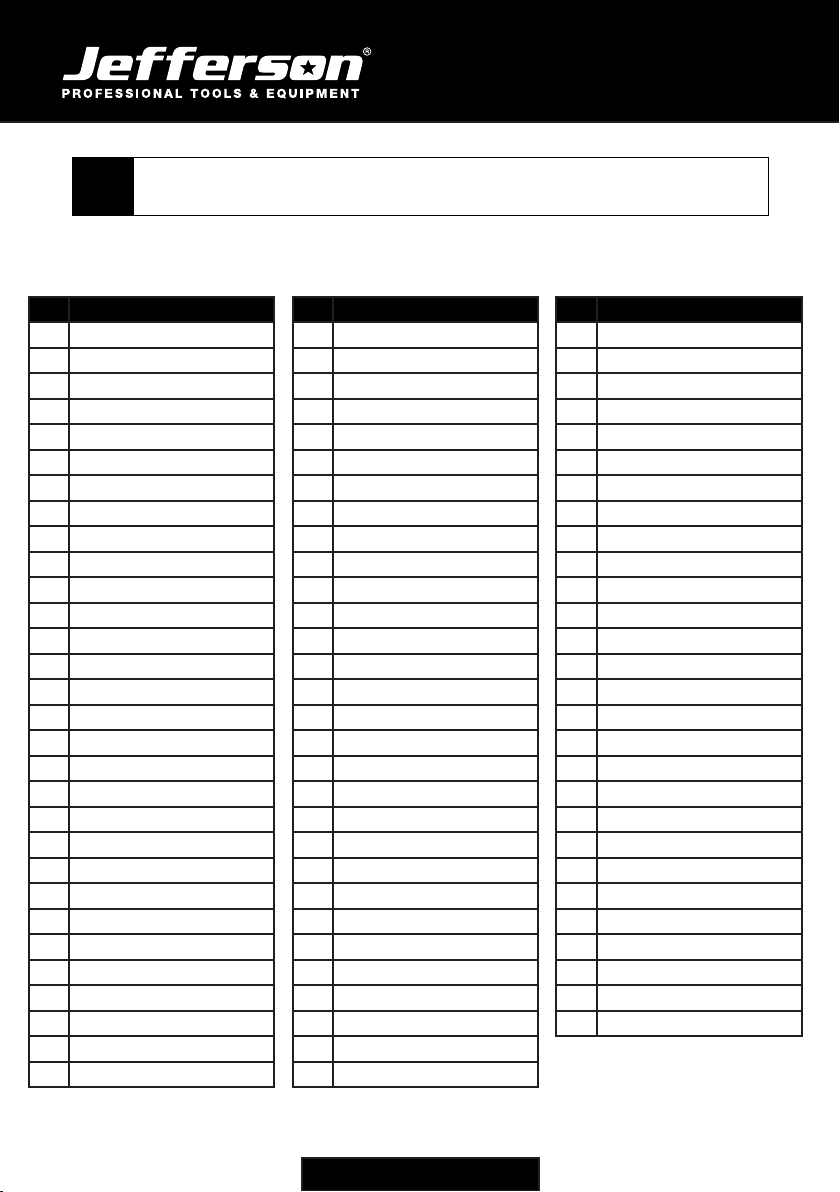

Pump Parts List

No. Description

1Inner Hexagonal Bolt

2Oil Draining Bolt

3O' Ring

4Rear Cap

5O' Ring

6Rear Oil Level

7Oil Level Indicator

8Circlip

9O' Ring

10 Fuel Filter Cap

11 O' Ring

12 Crank Chamber

13 O' Ring

14 3/8" Plug

15 Inner Hexagonal Bolt

16 Pressure Plate

17 Side Oil Cap

18 O' Ring

19 Internal Circlip

20 Internal Circlip

21 Bearing

22 Crank

23 Needle Bearing

24 Circlip

25 Crank Oil Seal

26 Flange

27 Bolt Assembly

28 Bolt Assembly

29 Bolt Assembly

30 Connecting Rod

No. Description

31 Plunger Pin

32 Plunger Rod

33 Plunger Oil Seal

34 Carriage

35 Rear Guard Sleeve

36 Auxillary Water Seal

37 O Seal Ring

38 Supporting Ring

39 Flat Gasket

40 Main Water Seal

41 Supporting Gasket

42 Voltage Regulating Handwheel

43 Voltage Regulating Tube

44 Check Nut

45 Voltage Regulating Spring

46 Spring Retainer

47 Voltage Regulating Valve Stem

48 O' Ring

49 Adjustable Valve Stem

50 O' Ring

51 Seal Assembly

52 O' Ring

53 Seal Guiding Gasket

54 Cone Valve

55 O' Ring

56 Valve Seat

57 Valve Body

58 O' Ring

59 Inlet Connector

60 Inlet Pipe

No. Description

61 O' Ring

62 Check Valve Body

63 O' Ring

64 Return Connector

65 Connector Inlet Pipe

66 O' Ring

67 O' Ring

68 Outlet Valve

69 Outlet Valve Spring

70 O' Ring

71 Base

72 O' Ring

73 Cylinder Block

74 O' Ring

75 Valve

76 O' Ring

77 Valve Nut

78 Bolt Assembly

79 Bolt Assembly

80 O' Ring

81 1/2" Plug

82 O' Ring

83 3/8" Plug

84 Outlet

85 Connector

86 Inlet Connector

87 Outlet Valve

88 Filter

JEFWASPET075HP

7.5HP Petrol Pressure Washer

19

www.jeffersontools.com

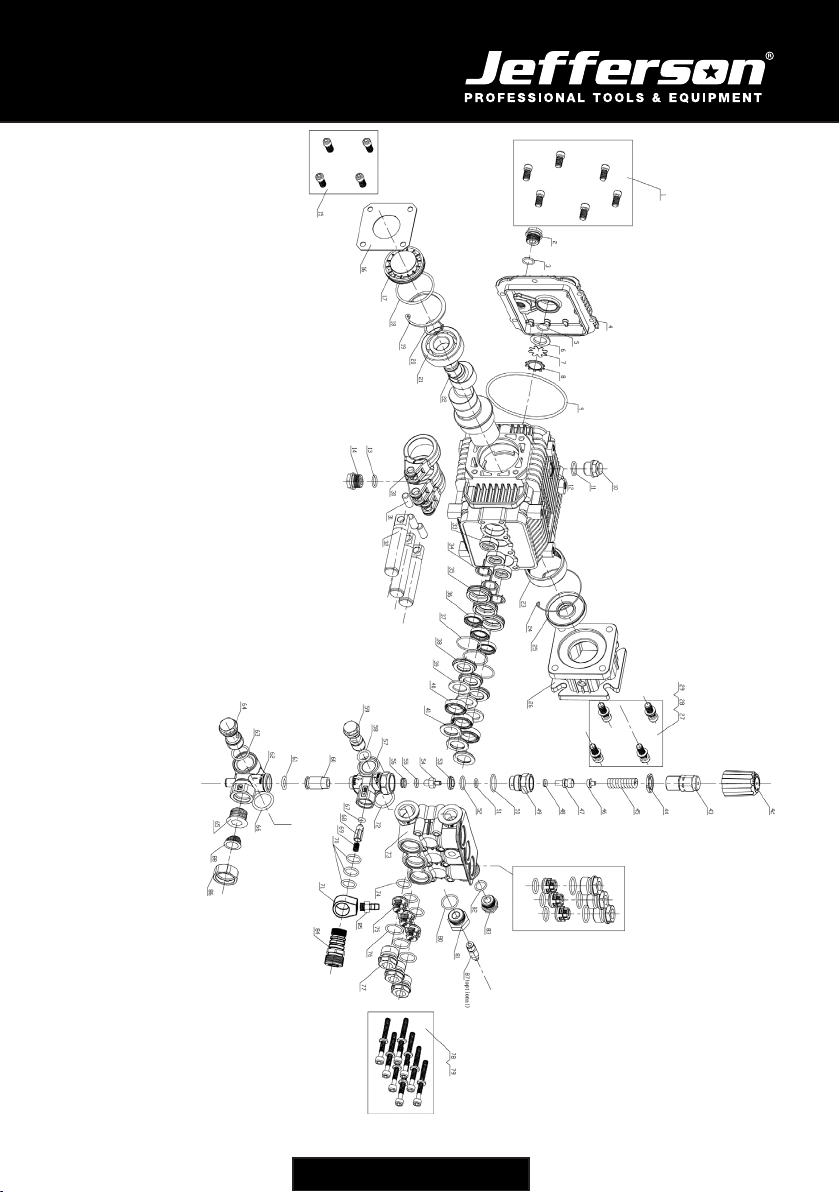

Parts Lists & Diagrams

No. Description

61 O' Ring

62 Check Valve Body

63 O' Ring

64 Return Connector

65 Connector Inlet Pipe

66 O' Ring

67 O' Ring

68 Outlet Valve

69 Outlet Valve Spring

70 O' Ring

71 Base

72 O' Ring

73 Cylinder Block

74 O' Ring

75 Valve

76 O' Ring

77 Valve Nut

78 Bolt Assembly

79 Bolt Assembly

80 O' Ring

81 1/2" Plug

82 O' Ring

83 3/8" Plug

84 Outlet

85 Connector

86 Inlet Connector

87 Outlet Valve

88 Filter

Pump Parts Diagram

JEFWASPET075HP

7.5HP Petrol Pressure Washer

20

www.jeffersontools.com

Table of contents

Other Jefferson Professional Tools & Equipment Pressure Washer manuals