Jefferson JEFIW772 User manual

User Manual

v.1.1

JEFIW772

AIR IMPACT

WRENCH

2

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

Contents

1. Specications 3

2. Safety Guidelines 3

3. Connectivity 6

4. Operation Guide 7

5. Maintenance 7

6. Exploded Parts Diagram & Parts List 8

Limited Warranty Statement 9

EC Declaration of Conformity 11

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without guarantee. Since the conditions of use are beyond

their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance

with this data or suggestions infringes any patent. Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification.

All images are for illustration purposes only.

3

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

1. Specifications

• Drive: 3/4"

• Torque Range (Forward): 135-956 ft. -lbs. (200-1300 Nm)

• Max Torque (Reverse): 956 ft. -lbs. (1300 Nm)

• Blows / Min: 1300

• Free Speed: 5000 rpm

• Standard Bolt Capacity: M21mm

• Average Air Consumption: 7.76cfm / 220 l/min.

• Air Inlet: 1/4"

• Minimum Hose: 1/2"

• Noise: LpA: 92 dB(A) KpA: 3 dB(A) LwA: 103 dB(A) KwA: 3 dB(A)

• Vibration / Uncertainty: 5.47 m/s² / K= 1.5 m/s²

• Net Weight: 10.17 lbs / 4.6kg

• Overall Length: 220mm

2. Safety Guidelines

General Safety

• Please read and understand the safety instructions before installing, operating, repairing, maintaining,changing accessories on, or working

with this equipment. Failure to do so can result in serious bodily injury. You will need this manual for the safety warnings and precautions,

assembly, operating, inspection, maintenance and cleaning procedures, parts list and assembly diagram. Keep this manual and invoice/proof of

purchase in a safe and dry place for future reference.

•Only qualified and trained operators should install, adjust or use this equipment

•Do not modify or adjust this equipment. Modifications can reduce the effectiveness of safety measures and increase the risks to the operator.

•Do not discard the safety instructions; store them in a safe place and present to the operator before use.

•Do not use this equipment if it has been damaged or displays any faults.

•Ensure that all safety and specification labels are clear and legible to the operator.

• Keep young children pets and animals away from the work area. This equipment should only be used by trained and competent individuals

who have read the user manual and fully understand how to operate the air impact wrench.

• Do not operate the tool where there are ammable liquids or gases. Pneumatic tools create sparks which may ignite ammable substances.

• Stay alert and use common sense - do not operate the tool when you are tired or under the inuence of alcohol, drugs or medication.

• Do not overreach when using the equipment - keep proper footing and balance at all times.

• Never use oxygen, CO combustible gases or any type of bottled gas as a source of power for this tool.

• Do not connect the air supply hose with your nger on the trigger.

• Do not exceed the maximum pressure for the tool (see specications or refer to your nearest Jefferson Dealer for advice if you are unsure).

• Keep the air supply hose away from heat, oil and sharp edges.

• Do not t the tool to any stand or clamping device that may damage it.

• Check all hoses for leaks or worn condition before use, and ensure that all connections are secure.

• Do not use the tool for any purpose than that described in this manual.

• Do not carry out any alterations or modications to the tool. Ensure all maintenance and repairs are carried out by an approved Jefferson

Tools repair center using Jefferson approved parts

• Always disconnect from the air supply when performing any maintenance, when the tool is not in use or left unattended

Remove adjusting keys or wrenches before turning on the tool. A wrench or a key that is left attached to a rotating part of the tool may

result in personal injury.

4

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

Personal Protection Equipment (PPE)

•Misuse or technical failure in this equipment, accessories or the workpiece itself can result in high-velocity projectiles: The operator and

any other people in the working area must wear the appropriate Personal Protection Equipment (PPE) at all times. In particular, impact-resistant

eye protection should be worn during use of this equipment.

The grade of protection required should be assessed for each use as part of the overall risk assessment for the job.

• Ensure that the workpiece is securely fixed at all times.

• Never wear loose clothing or jewellery or long hair when operating this equipment.

Entanglement hazards can result in choking, scalping and/or lacerations if loose clothing, personal jewellery, neckwear, hair or gloves are not kept

away from the equipment and accessories.

•Gloves can become entangled with the rotating drive, causing severed or broken fingers.

•Rotating drive sockets and drive extensions can easily entangle rubber-coated or metal-reinforced gloves.

•Do not wear loose-fitting gloves or gloves with cut or frayed fingers.

•Never hold the drive, socket or drive extension.

• Keep hands away from rotating drives.

•The use of the tool can expose the operator's hands to hazards including crushing, impacts, cuts, abrasions and heat.

•Wear suitable gloves to protect hands.

• Wear warm clothing when working in cold conditions and keep your hands warm and dry.

Operator Safety

•Ensure that operators and maintenance personnel are physically capable of handling the bulk, weight and power of the tool.

• Hold the tool correctly; be ready to counteract normal or sudden movements and have both hands

available at all times.

• Maintain a balanced body position and secure footing.

•It is recommended to use a suspension arm whenever possible.

• Reaction bars are recommended for angle nutrunners.

•It is recommended to use a means to absorb the reaction torque above 4 Nm for straight tools, above 10 Nm for pistol-grip tools.

•Release the start-and-stop device in the case of an interruption of the energy supply.

• Use only lubricants recommended by Jefferson authorized sales or service representatives.

•Do not use in confined spaces and beware of crushing hands between tool and workpiece, especially when unscrewing.

•Be aware that the Tool and/or accessories may briefly continue their motion after the trigger is released.

•Keep others a safe distance from your work area, or ensure they use appropriate Personal Protective

Equipment (PPE).

•The operator should stop using the equipment and rest if they experience discomfort in the hands, arms, shoulders, neck, or other

parts of the body.

•The operator should adopt a comfortable posture whilst maintaining secure footing and avoiding awkward or off-balanced postures when using

this equipment.

•The operator should change posture during extended tasks, which can help avoid discomfort and fatigue.

•If the operator experiences symptoms such as persistent or recurring discomfort, pain, throbbing, aching, tingling, numbness, burning

sensations or stiffness, these warning signs should not be ignored. The operator should tell the employer and consult a qualified health

professional.

Working with Accessories

•Disconnect the equipment from the energy supply before changing the inserted tool or accessory.

•Never touch sockets or accessories during impacting, as this increases the risk of cuts, burns or vibration injuries.

•Use only rated sockets, accessories and consumables that are recommended by Jefferson authorized sales or service representatives.

•Ensure that all equipment and accessories have been checked and confirmed to be in safe working condition. Sockets and other accessories

that are not suitably rated for use with this equipment or that are in poor

condition can shatter under pressure and become dangerous projectiles. Contact your nearest Jefferson

authorized sales or service representatives for advise on rated sockets and accessories for this equipment.

Safe Working Environment

• Slips, trips and falls are major causes of workplace injury.

• Be aware of slippery surfaces caused by the use of the tool and also of trip hazards caused by the air line or hydraulic hose.

• Proceed with care in unfamiliar surroundings. Hidden hazards, such as electricity or other utility lines, can exist.

• This equipment is not intended for use in potentially explosive atmospheres and is not insulated against coming into contact with electric power.

• Make sure there are no electrical cables, gas pipes, etc., that can cause a hazard if damaged during operation

• Ensure that the working environment is kept ventilated, clean and illuminated at all times

5

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

Dust & Fumes

•Dust and fumes generated when using air power tools can cause ill health (for example, cancer, birth defects, asthma and/or dermatitis); risk

assessment and implementation of appropriate controls for these hazards are essential.

• Risk assessment should include dust created by the use of the tool and the potential for disturbing existing dust.

•Direct the exhaust so as to minimize disturbance of dust in a dust-filled environment.

•Ensure that any dust or fumes created during operation are controlled at the point of emission

• All integral features or accessories for the collection, extraction or suppression of airborne dust or fumes should be correctly used and

maintained in accordance with the manufacturer's instructions.

•Use respiratory protection in accordance with employer's instructions and as required by occupational health and safety regulations.

Noise & Vibration Levels

• This tool may cause Hand Arm Vibration Syndrome if its use is not managed adequately.

• This tool is subject to the vibration testing section of the Machinery Directive 2006/42/EC.

• This tool is to be operated in accordance with these instructions.

•Unprotected exposure to high noise levels can cause permanent, disabling, hearing loss and other problems, such as tinnitus (ringing, buzzing,

whistling or humming in the ears).

•Risk assessment and implementation of appropriate controls for these hazards are essential.

•Appropriate controls to reduce the risk may include actions such as damping materials to prevent workpieces from “ringing”.

•Use hearing protection in accordance with employer's instructions and as required by occupational health and safety regulations.

•Operate and maintain this equipment as recommended in the instruction handbook, to prevent any unnecessary increase in noise levels.

•Select, maintain and replace any consumable parts as recommended in the instruction handbook, to prevent an unnecessary increase in noise.

•For recommended interface dimensions for spindles and drive adapters to help reduce vibrations, please contact a Jefferson authorized sales or

service representative.

•Exposure to vibration can cause disabling damage to the nerves and blood supply of the hands and arms.

•Keep the hands away from the sockets during operation.

•If you experience numbness, tingling, pain or whitening of the skin in your ngers or hands, stop using the assembly power tool for threaded

fasteners, tell your employer and consult a physician.

•Sleeve ttings should be used where practicable.

•Support the weight of the tool in a stand, tensioner or balancer, if possible.

•Hold the tool with a light but safe grip, taking account of the required hand reaction forces, because the risk from vibration is generally greater

when the grip is too strong.

Note: A health and safety assessment by the user (or employer) will need to be carried out to determine the suitable duration of use for this

equipment. Stated Vibration Emission values are type-test values and are intended to be typical. Whilst in use, the actual value will vary and can

depend on many factors which need to be taken into consideration during the assessment (factors include; the operator, the task and the working

environment, the work at hand).

Ensure that the length of leader hoses is sufficient to allow unrestricted use, as this also helps to reduce vibration.

The state of maintenance of the tool itself is also an important factor, a poorly maintained tool will also increase the risk of Hand Arm Vibration

Syndrome.

Guidance relating to the management of hand arm vibration can be found on the HSC website www.hse.gov.uk - Hand-Arm Vibration at Work.

Air Pressure Safety

•Air under pressure can cause severe injury.

•Always shut off air supply, drain hose of air pressure and disconnect tool from air supply when not in use, before changing accessories or when

making repairs.

•Never direct air at yourself or anyone else. • Whipping hoses can cause severe injury.

•Always check for damaged or loose hoses and fittings.

•Ensure that cold air is directed away from the hands during operation.

•Do not use quick-disconnect couplings. Use hardened steel (or material with comparable shock resistance) threaded hose fittings.

•Whenever universal twist couplings (claw couplings) are used ensure that lock pins are installed and whipcheck

safety cables used to safeguard against possible hose-to-tool and hose-to-hose connection failure.

• Do not exceed the maximum air pressure stated on the tool.

• Never carry an air tool by the hose.

• Ensure that this equipment is properly maintained at all times.

• Check the speed and make a simple check of the vibration level after each service.

6

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

3. Connectivity

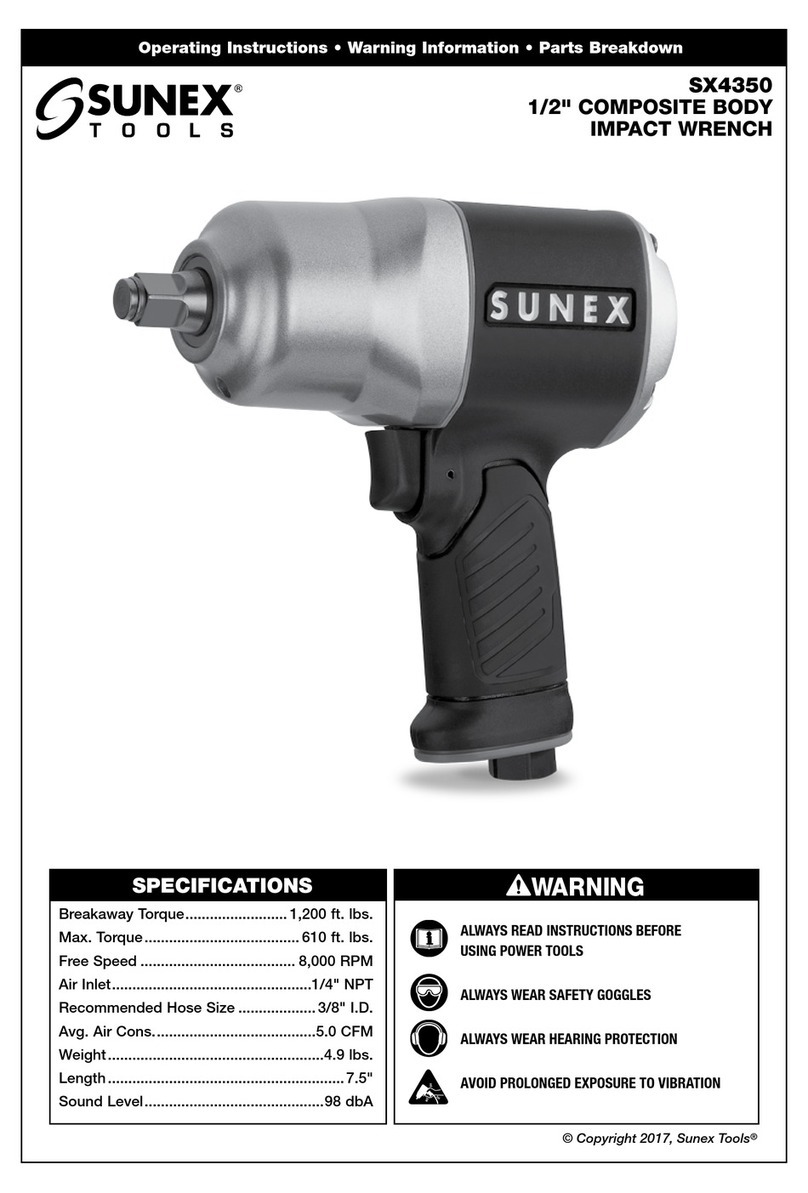

Air Supply & Pressure

• Always use a clean and dry air supply to operate the tool at 90 PSIG-6.2 bar.

• To ensure operating safety, performance and prevent damage to the tool do not operate exceed the maximum working air pressure.

Air Line

• Use a fitting air hose for connection between the compressor & tools.

• Ensure that the compressed air is cooled and its water content filtered and lubricated as required as shown in Fig 1 below.

• Excessive moisture levels can be compressed in the pipe and can permeate into tools & equipment resulting in mechanical failures and pos-

sible injury.

Air Hose

• Ensure all hoses and fittings are clean and free of dust and debris before connecting any tools and equipment.

• Dust and debris can cause rust and malfunction in the tools and can result in dangerous operation.

Fig 1. Connectivity Example

7

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

4. Operation

• Use clamps or other practical ways to secure and support the workpiece to a stable platform. Holding the work by hand is unstable and may

lead to loss of control. Only work on a workpiece that is properly secured.

• Do not force or modify the tool. Use the correct tool for your application.

• Check for misalignment or binding of moving parts, breakages of parts, damaged air hose (not included), and any other condition that may

affect the tool's operation. If damage is detected ensure that you have the tool repaired before use.

• Ensure you read, understand and apply safety instructions before use.

• Only use impact sockets which are specically designed for use with an impact wrench (contact your nearest Jefferson dealer for advice on

the best sockets to use.

• Place the socket fully over the working nut and depress the trigger to operate the wrench.

• Do not use any additional force upon the wrench in order to remove a nut.

• Do not allow the wrench to free-run for an extended period of time as this will reduce bearing life.

• To operate, check connections are correct and safe, pull the trigger on the handle.

• To operate with a forward rotation move the lever on the rear of the wrench to the "F" position.

• To operate with a reverse motion move the lever to the "R" position.

• This equipment is designed as a “plug-and-run” type device.

• The tool will stop operation/rotation in a few seconds after relieving the trigger control.

5. Maintenance

Lubrication

Before connecting the air hose, apply 4 to 5 drops of air line oil, or equivalent, at the air inlet. Repeat this process after every 3 to 4 hours of use

and as necessary. Do not lubricate tools with ammable or volatile liquids such as petrol, diesel or jet fuel.

Fittings

Check ttings and accessories daily and ensure all parts are fastened securely and in good working condition .

Cleaning

Ensure handle is kept clean and free from oil, dust and dirt to ensure that the equipment can be gripped securely.

Ensure that the handle is cleaned before and during use using a clean, dry cloth.

Storage

Ensure that the tool is stored in clean, dry environment. If the tool is not in use for a period of time, any residual moisture inside of the wrench

could result in rusting. Before storing after use, the wrench should be oiled at the air inlet with air line oil and allowed to operate for a short period

before storing.

Repairs

Ensure that all repairs are carried out by Jefferson authorised engineers or at your nearest authorised Jefferson Repair Centre.

8

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

6. Parts List & Diagram

# Description Qty # Description Qty

1Hammer Case Assembly 121 Rear Bearing 1

2Screw 822 Housing 1

3Spring Washer 823 Trigger 1

4Hammer Case Gasket 124 Elastic Cylindrical Pin 1

5Bushing 125 Throttle Valve Seat 1

6Retainer Ring 126 Valve Stem 1

7O-Ring 127 Spring 1

8Anvil 128 Exhaust Board 1

9Hammer Pin 229 Filter 1

10 Hammer 230 Air Inlet 1

11 Hammer Frame 131 Reverse Valve Bushing 1

12 Rear Washer 132 Reverse Valve 1

13 Front Bearing 133 O- Ring 1

14 Front End Plate 134 Knob 1

15 Elastic Cylindrical Pin 235 Elastic Cylindrical Pin 1

16 Cylinder 136 Steel Ball 1

17 Rotor 137 Spring 1

18 Rotor Blade 638 Back Cover Gasket 1

19 139 Back Cover 1

20 1

9

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

Limited Warranty Statement

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be

free of defects in workmanship or material. Jefferson shall, upon suitable notication, correct any defects, by repair

or replacement, of any parts or components of this product that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal op-

erations, improper care, unauthorised service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty

periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is

unavailable from the end user, then the date of purchase will be deemed to be 3 months after the initial sale to the

distributor.

1 Year

Jefferson 3/4" Air Impact Wrench - JEFIW772

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of

90 days cover or the remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form.

Online warranty registration is recommended as it eliminates the need to provide proof of purchase should a warranty

claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair

or replacement at an authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will

arrange collection and transportation of any equipment returned under warranty.

Upon inspection of the equipment, if no defect can be found or the equipment is not covered under the terms of the

Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred.

These costs will be agreed with the customer before the machine is returned.

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers.

Jefferson's liability under this warranty will not exceed the cost of correcting the defect of the Jefferson

products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute

equipment etc.) caused by the defect or the time involved to correct the defect. This written warranty is the only

express warranty provided by Jefferson with respect to its products.

10

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine

inspection of cables for possible wear and to correct any issues prior to cable failure.

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their

nearest authorised Jefferson dealer where final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete

the form online and submit it to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your

nearest authorised Jefferson repair centre. On receipt of this form Jefferson will arrange to collect the equipment

from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection.

Please ensure that you include a copy of your proof of purchase. Please note that Jefferson cannot assume any

responsibility for any damage incurred to equipment during transit. Any claims against a third party courier will be

dealt with under the terms & conditions of their road haulage association directives.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the

equipment is defective and in need of repair and any repairs needed are covered by the warranty policy. In order to

qualify for warranty cover all equipment presented must have been used, serviced and maintained as instructed in

the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the

customer (normally within 7 working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour time at £30 per

hour plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identified as the cause

of the problem, a minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be

despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working

days upon receipt of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not

immediately available Jefferson will contact you with a revised date for completion of the repair.

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry

11

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

EC Declaration of Conformity

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following equipment

conforms to the requirements of the following Directives:

2006/42/EC (as amended) Machinery Directive

EN ISO 11148-6:2012 Hand-held Non-Electric power tools

Equipment Category: Air Impact Wrench

Product Name/Model: 3/4" Air Impact Wrench / JEFIW772

Notified Body: INTERTEK TESTING & CERTIFICATION LTD

Intertek House, Cleeve Road

Leatherhead, Surrey KT22 7SB

Country : United Kingdom

Noise: LpA: 92 dB(A) KpA: 3 dB(A)

LwA: 103 dB(A) KwA: 3 dB(A)

Vibration / Uncertainty 5.47 m/s² / K= 1.5 m/s²

EU Member State, United Kingdom

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 28 February 2018

This technical document is held by: Jimmy Hemphill

Technical file holder's address as shown below

Name and address of manufacturer or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park, Chester, United Kingdom, CH4 9QR

www.jeffersontools.com

12

USER MANUAL

JEFIW772

3/4" AIR IMPACT WRENCH

Jefferson Tools, Herons Way, Chester Business Park, Chester, United Kingdom, CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please

read all the safety precautions and operating

instructions outlined in this manual to reduce

the risk of fire, electric shock and

personal injury.

www.jeffersontools.com

Table of contents

Other Jefferson Impact Driver manuals

Popular Impact Driver manuals by other brands

Chicago Pneumatic

Chicago Pneumatic CP7762 Operator's manual

Hitachi

Hitachi WH 14DMR Technical data and service manual

Makita

Makita 6905B instruction manual

Central Pneumatic

Central Pneumatic 37730 Assembly and operating instructions

master mechanic

master mechanic 147616 owner's manual

Central Pneumatic

Central Pneumatic 92037 Owner's manual and safety instructions