Jefferson JEFDMM300V User manual

JEFDMM300V

300V DIGITAL MULTIMETER

USER GUIDE

v.1.1

www.jeffersontools.com

Important: Please read all information carefully

before use and keep these instructions in a safe

place for future reference.

EQUIPMENT OVERVIEW

This is a compact CAT III 300V rated multimeter for measuring DC and

AC voltage, DC current, resistance, continuity, diode and batteries. A

short summary of the features of this equipement is listed below:

• CAT III 300V Digital Mulitmeter

• 3.5 Digit LCD Display (Maximum reading 1999)

• Data Hold Function & Overload Protection

• Low Battery Indication

• Negative Polarity Indication

• Continuity and Diode Testing

• Battery Testing: 1.5V / 9V / 12V

• Resistance Measurements: Up to 2000KΩ

• Manufactured & tested to IEC 61010

SPECIFICATIONS

DC Voltage Range: 200m ~ 300V

DC Current Range: 2000μ ~ 10A

AC Voltage: 200 ~ 300V

Input Impedance: 1MΩ

Resistance: 200 ~ 2000kΩ

Continuity: less than 30Ω

Diode Testing: 2.8V (approx)

Test Current: 1mA

Battery Testing 1.5V / 9V / 12V

Overload Protection:

Both Fuses: ø5x20mm

F1: Fuse, 250mA / 300V, Fast action

F2: Fuse, 10A / 300V, Fast action

Power Supply: 1x 9V Battery

Dimensions: 138 x 74 x 32mm

Weight: 160g (including battery)

ELECTRICAL SYMBOLS

This equipment should only be used by fully trained, qualied and

responsible personel. The following list of common electrical symbols

is provided for reference:

Alternating Current (AC)

Direct Current (DC)

Both Alternating and Direct Current AC/DC

Earth (ground) Terminal

Fuse

Double or reinforced insulation protection

Caution: Risk of electric shock

SAFETY

• Always check this equipment before use. In particluar ensure that

you check the case and insulation surrounding the connectors. Inspect

the test leads for damaged insulation or exposed wiring. Replace the

test leads if any defects are identified .Do not use the equipment if any

damage or defect is found.

• Do not operate the meter in environments where explosive gas, vapor

or dust is present.

• You can test that the meter is functioning correctly by measuring a

known voltage before use.

• Never exceed the rated voltage, as marked on the meter, between

terminals or between any terminal and earth ground.

• When using the probes, ensure you keep your fingers behind the

finger guards.

• Connect the common test lead before connecting the live test lead.

When disconnecting test leads always disconnect the live test lead

first.

• Remove the test leads from the meter before opening a battery cover

or case.

• Do not operate the meter with a battery cover that is removed or

loose.

• Avoid touching conductors with hands or skin.

• Never use the equipment in wet conditions or when hands or skin are

wet.

• Do not use the equipment if any part of it or the test leads are wet.

• Please note that where an input terminal is connected to dangerous

live potential, the potential can occur at all other terminals.

This equipment is suitable for use for CAT III rated measurements

only and should not be used on equipement that requires CAT IV.

Check compatibility before use.

• Disconnect circuit power and discharge all capacitors before testing

resistance, diode, continuity or temperature (where applicable).

• Always use the proper terminals, function and ranges specified for

your equipment. Contact Jefferson Tools for advise if you are unsure

about any aspect of the functionality of this equipment.

• When measuring current always turn off the circuit power before

connecting the meter. Remember to place the meter in series with the

circuit.

• Always take precautions when working with voltages exceeding 30V

AC RMS, 42V Peak or 60V DC.

• Always disconnect the test leads before rotating the range switch to

change functions.

Important: Always replace the battery as soon as the

low battery indicator appears on the display. Never

use the equipment on low battery.

JEFDMM300V

300V DIGITAL MULTIMETER

USER GUIDE

v.1.1

EQUIPMENT IDENTIFICATION

The table below describes the features numbered in the diagram shown to

the right:

1 LCD Display 3.5 Digits (Maximum reading 1999)

2 H Button: - Used to Enter / Exit “Data Hold” function

3 Function / Range Switch: - Used to select the required Function /

Range and turn the meter ON and OFF

4 10A Terminal: Plug in connector for the red test lead for current

measurements between 200mA - 10A

5 VΩmA Terminal: For all other measurements except current ≥

200mA

6 COM Terminal: Plug-in connector for the black test lead

MEASURING DC VOLTAGE

1. Connect the black test lead to the COM terminal and the red lead to the

VΩmA terminal.

2. Set the Function / Range switch to the desired range position. If the

magnitude of the voltage is not known before hand you can set the range

to the highest range rst and then reduce it range by range until a suitable

resolution is obtained.

3. Connect the test leads across the source or circuit to be tested.

4. Check the DC Voltage reading on the display. The polarity of the red test

lead connection will also be indicated.

Note: To avoid electric shock, personal injury or damage to the equipment

do not apply any voltage higher than the rated capacity of 300V between

the terminals

MEASURING AC VOLTAGE

1. Connect the black test lead to the COM terminal and the red lead to the

VΩmA terminal.

2. Set the Function / Range switch to the desired range position. If the

magnitude of the voltage is not known before hand you can set the range

to the highest range rst and then reduce it range by range until a suitable

resolution is obtained.

3. Connect the test leads across the source or circuit to be tested.

4. Check the AC Voltage reading on the display. The polarity of the red test

lead connection will also be indicated.

Note: To avoid electric shock, personal injury or damage to the equipment

do not apply any voltage higher than the rated capacity of 300V between

the terminals.

BATTERY TESTING

1. Connect the black test lead to the COM terminal and the red lead to the

VΩmA terminal.

2. Set the Function / Range switch to the corresponding BATT range

position.

3. Connect the red test lead to the positive terminal on the battery and the

black test lead to the negative battery terminal.

4. Check the working voltage of the battery on the display.

DC Voltage

AC Voltage

Battery Testing

JEFDMM300V

300V DIGITAL MULTIMETER

USER GUIDE

v.1.1

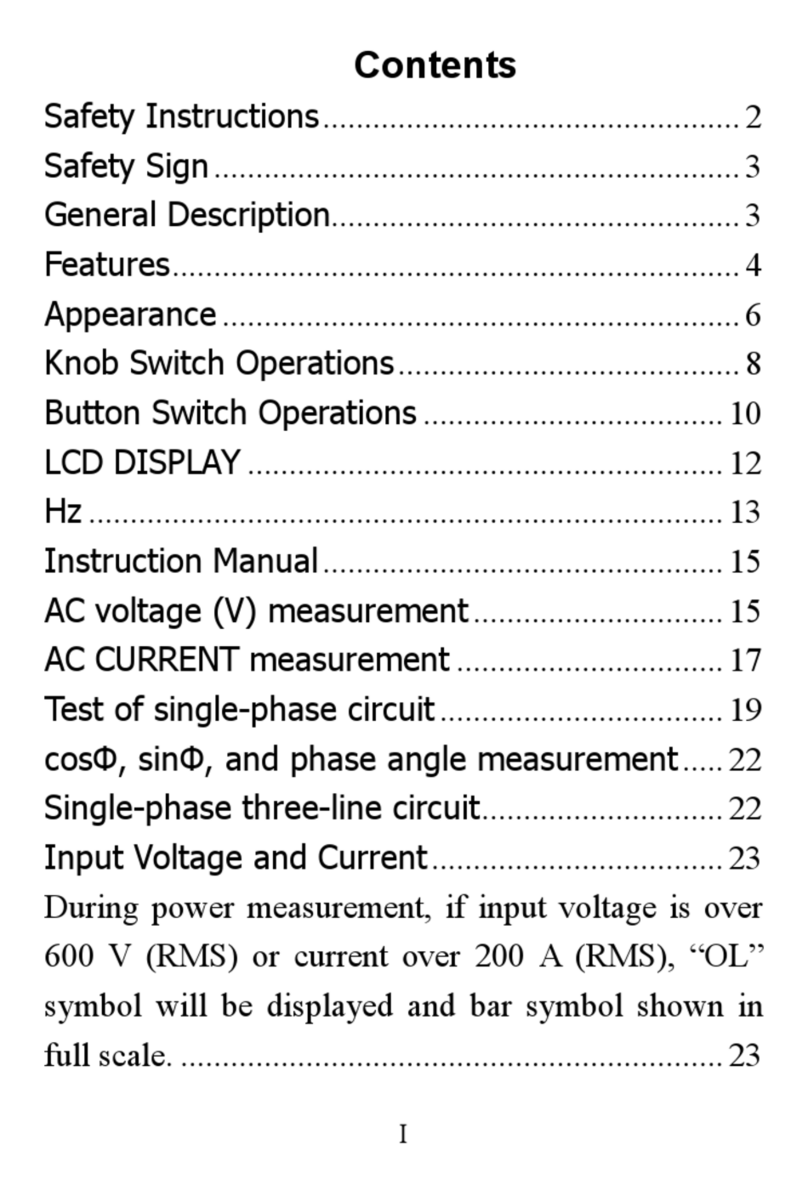

MEASURING DC CURRENT

1a. For current measurements less than 200mA:

Connect the black test lead to the COM terminal and the red lead to the

VΩmA terminal.

1b. For current measurements between 200mA and 10A:

Connect the black test lead to the COM terminal and the red lead to the

10A terminal.

2. Set the Function / Range switch to the desired range position. If the

magnitude of the current is not known before hand you can set the range

to the highest range rst and then reduce it range by range until a suitable

resolution is obtained.

3. Turn off the power to the circuit you need to measure then discharge all

capacitors of the circuit.

4. Break the circuit path to be measured and connect the test leads in

series with the circuit.

5. Check the DC Current reading on the display. The polarity of the red test

lead connection will also be indicated.

MEASURING RESISTANCE

Before measuring in-circuit resistance, disconnect all power to the circuit

to be tested and discharge all capacitors thoroughly.

1. Connect the black test lead to the COM terminal and the red lead to the

VΩmA terminal.

2. Set the Function / Range switch to the desired Ωrange position.

3. Connect the test leads across the equipment to be tested.

4. Check the resistance reading on the display.

Note: For measurements > 1000kΩ, the meter may take a few seconds

to stabilize the reading. This is normal for high resistance measurements.

When the input is not connected, i.e at open circuit, “1” will be displayed

as an over-range indication.

CONTINUITY TESTING

Before measuring the continuity, disconnect all power to the circuit to be

tested and discharge all capacitors thoroughly.

1. Connect the black test lead to the COM terminal and the red lead to the

VΩmA terminal.

2. Set the Function / Range switch to the setting.

3. Connect the test leads across the circuit to be measured.

4. If the resistance is lower than about 30Ω, the built in buzzer will sound.

DIODE TESTING

1. Connect the black test lead to the COM terminal and the red lead to the

VΩmA terminal. Note the polarity of the red test lead is positive “+”

2. Set the Function / Range switch to the setting.

3. Connect the red test lead to the anode of the diode to be tested and the

black test lead to the cathode of the diode.

4. The display will show the approximate forward voltage drop of the

diode. If the connection is reversed, then only the reading “1” will be

shown on the display.

Max Open Circuit Voltage: Approx 2.8V

DC Current

Resistance

Continuity & Diode Testing

LIMITED WARRANTY STATEMENT

Jefferson Professional Tools & Equipment ®, or hereafter "Jefferson" warrants its customers

that its products will be free of defects in workmanship or material. Jefferson shall, upon

suitable notification, correct any defects, by repair or replacement, of any parts or components

of this product that are determined by Jefferson to be faulty or defective. This warranty is void

if the equipment has been subjected to improper installation, storage, alteration, abnormal

operations, improper care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the

stated warranty periods below. All warranty periods start from the date of purchase from an

authorised Jefferson dealer. If proof of purchase is unavailable from the end user, then the date

of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

• JEFDMM300V - 300V DIGITAL MULTIMETER

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be

subject to a minimum of 90 days cover or the remaining duration of the warranty period from

the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the

following address: www.jeffersontools.com/warranty and completing the online form. Online

warranty registration is recommended as it eliminates the need to provide proof of purchase

should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will

be corrected by repair or replacement at an authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for

collection. Jefferson will arrange collection and transportation of any equipment returned under

warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not

covered under the terms of the Jefferson warranty, the customer will be liable for any labour

and return transportation costs incurred. These costs will be agreed with the customer before

the machine is returned.

NOTE: * Jefferson reserve the right to void any warranty for damages identified as being

caused through misuse *

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians

or engineers. Jefferson's liability under this warranty will not exceed the cost of correcting the

defect of the Jefferson products. Jefferson will not be liable for incidental or consequential

damages (such as loss of business or hire of substitute equipment etc.) caused by the defect

or the time involved to correct the defect. This written warranty is the only express warranty

provided by Jefferson with respect to its products. Any warranties of merchantability are

limited to the duration of this limited warranty for the equipment involved.

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment:

(Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where final

determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form.

You can complete the form online and submit it to us directly or download the form to print out

and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together

with details of your nearest authorised Jefferson repair centre. On receipt of this form Jefferson

will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer’s responsibility to ensure that the equipment is appropriately and securely

packaged for collection, together with a copy of the original proof of purchase. Please note

that Jefferson cannot assume any responsibility for any damage incurred to equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions

of their road haulage association directives.

NOTE: Jefferson will be unable to collect or process any warranty requests without a copy of

the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will

be determined if the equipment is defective and in need of repair and any repairs needed are

covered by the warranty policy. In order to qualify for warranty cover all equipment presented

must have been used, serviced and maintained as instructed in the user manual. Where repair

is not covered by the warranty a quotation for repair, labour costs and return delivery will be

sent to the customer (normally within 7 working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will

invoice 1 hour labour time at £30 per hour plus return carriage costs (plus VAT). In cases

where no fault can be found with the equipment, or, if incorrect operation of the equipment

is identified as the cause of the problem, a minimum of 1 hour labour at £30 per hour plus

carriage costs will be required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to

the customer within 7 working days upon receipt of the equipment at an authorised Jefferson

Repair centre (subject to part availability). Where parts are not immediately available Jefferson

will contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call:

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all

recommendations or suggestions are made without guarantee. Since the conditions of use

are beyond their control, Jefferson Professional Tools & Equipment ® disclaim any liability for

loss or damage suffered from the use of this data or suggestions. Furthermore, no liability is

accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Professional Tools & Equipment ® reserve the right to change product specifications

and warranty statements without further notification. All images are for illustration purposes

only.

DECLARATION OF CONFORMITY

We, Jefferson Professional Tools & Equipment, as the authorised European Community

representative of the manufacturer, declare that this equipment conforms to the requirements of

the following standards:

IEC 61010 - Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use

Signed by: Stephen McIntyre (Operations Director) Date: 13.01.20

www.jeffersontools.com

JEFDMM300V

300V DIGITAL MULTIMETER

USER GUIDE

v.1.1

MAINTENANCE & STORAGE

Note: Apart from replacing the fuse and battery, never attempt to service or repair this

equipment yourself. Contact Jefferson Tools for information and advice if a fault is detected.

NOTE: Ensure the equipment is turned off and that the test leads are disconnected before

carrying out any cleaning or maintenance on this multimeter.

• Periodically wipe the case with a slightly damp cloth a small quantity mild detergent. Do not

use abrasives or solvents to clean.

• Keep the buttons / terminals clean (carefully) using a cleaning swab dipped in alcohol as

required.

• Store the multimeter in a dry environment, away from devices emitting magnetic fields, when

not in use.

BATTERY AND FUSE REPLACEMENT

Replacing the Battery:

Change the battery immediately with a like-for-like replacement (1x 9V) as required when the

low-battery indicator is displayed. Do not use the meter when the indicator is displayed.

To replace the battery remove the screw on the battery cover, remove the old battery and insert

the replacement. Replace the battery cover and screw to secure.

Replacing the Fuses:

The fuses supplied with this equipment should rarely need to be replaced and any requirement

to replace them will usually be the result of misuse of the multimeter. To replace the fuse,

remove the screws on the backcover, remove the faulty fuse and replace with a similar size and

rated fuse. Reinstall the backcover and secure with the screws. This meter is supplied with two

Ø5 x 20mm fuses: F1 Fuse: 250mA / 300V, Fast action F2: Fuse: 10A / 300V, Fast action

Please note that the warranty for this item covers manufacturing defects.

The warranty does not cover overloading, normal wear and tear and

abuse. The warranty will become invalid if the casing is opened or

tampered with in any way.

Information on Disposal for Users of Waste Electrical & Electronic Equipment

(WEEE)]

This symbol on the product(s) and / or accompanying documents means

that used electrical and electronic products should not be mixed with

general household waste.

For proper treatment, recovery and recycling, please take this product(s)

to designated collection points where it will be accepted free of charge.

Jefferson Tools, Herons Way, Chester Business Park, Chester, United Kingdom, CH4 9QR,

Popular Multimeter manuals by other brands

Keithley

Keithley DMM6500 quick start guide

Elenco Electronics

Elenco Electronics M-1750 Operator's instruction manual

gefran

gefran 556 quick start guide

Gossen MetraWatt

Gossen MetraWatt METRAHIT ISO AERO Supplement to operating instructions

AEMC

AEMC SL206 user manual

Extech Instruments

Extech Instruments 450 user guide