-4-

2

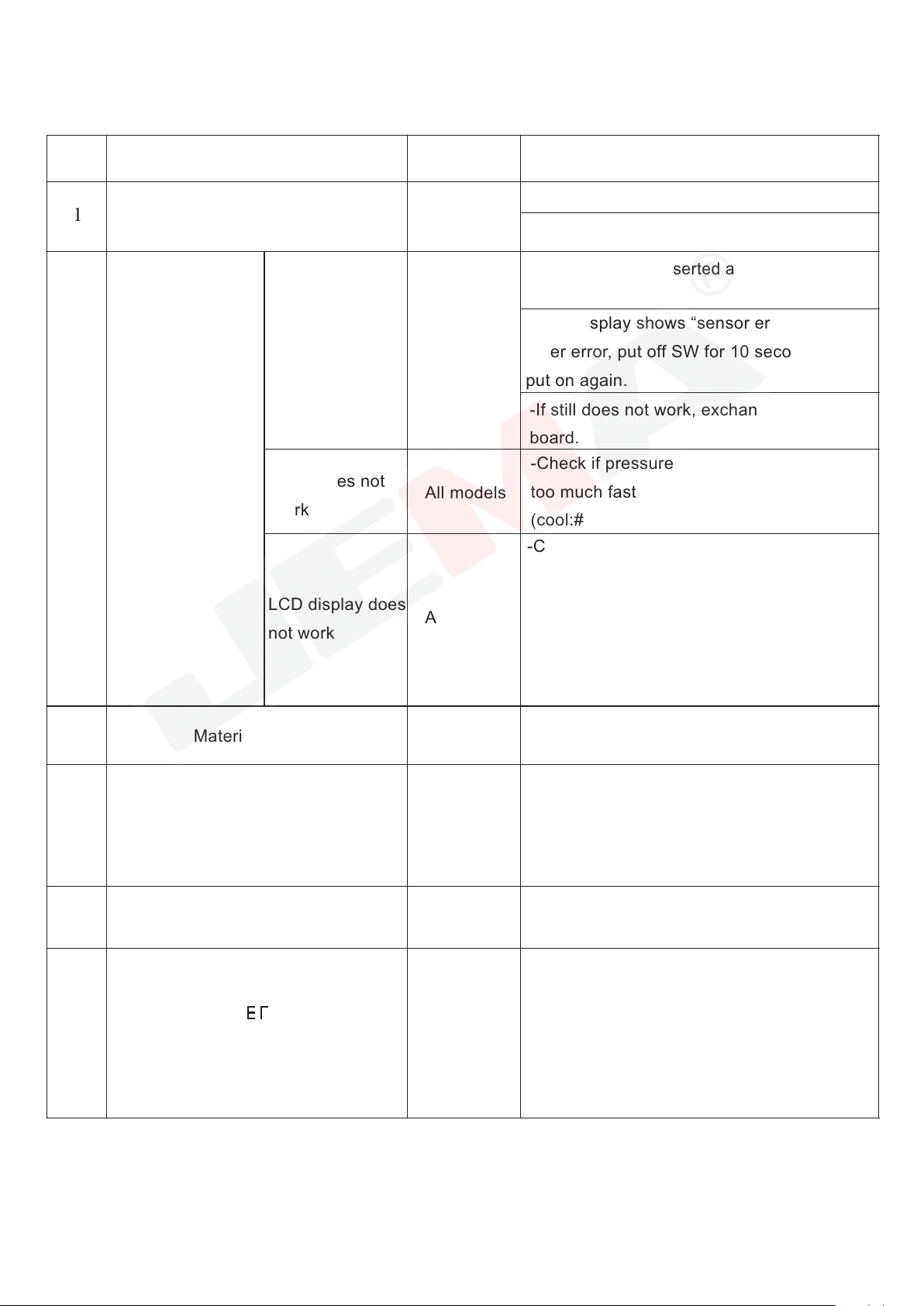

8.Trouble shooting of 110 series(only reference)

NO.Troubles Applicable

Model Causes & Measures

No power supply All models

All models

Power is on,

but no work

Feed roller does

not work

-Check if electric cord is connected well

-Check if the fuse blows out or not

-Check if there is inserted any alien substance

in roller

-If the display shows “sensor error” or any

other error, put off SW for 10 seconds and

put on again.

-If still does not work, exchange the drive

board.

Knife does not

work

All models

-Check if pressure plates of upper knife are

too much fastened or not.

(cool:#20&29,hot:#32&36)

LCD display does

not work All models

-Check if the temperature is too high with

over-time working, switch off the machine

for seconds, if still doesn’t after several

times’ trying.. Please opening the cover

and check the connection. (Especially

between operation and CPU board)

3Material is no cut Hot cutter -Check if temperature goes up to set-degree

-Check if knife blades are even.

4Material is cut one side All models

-Check if blades are damaged or wears

-After making both knives close each other

by M/CUT button and check if they are even

or not. (If they are not, adjust them by bolts)

5Cut-length is different from set-length All models

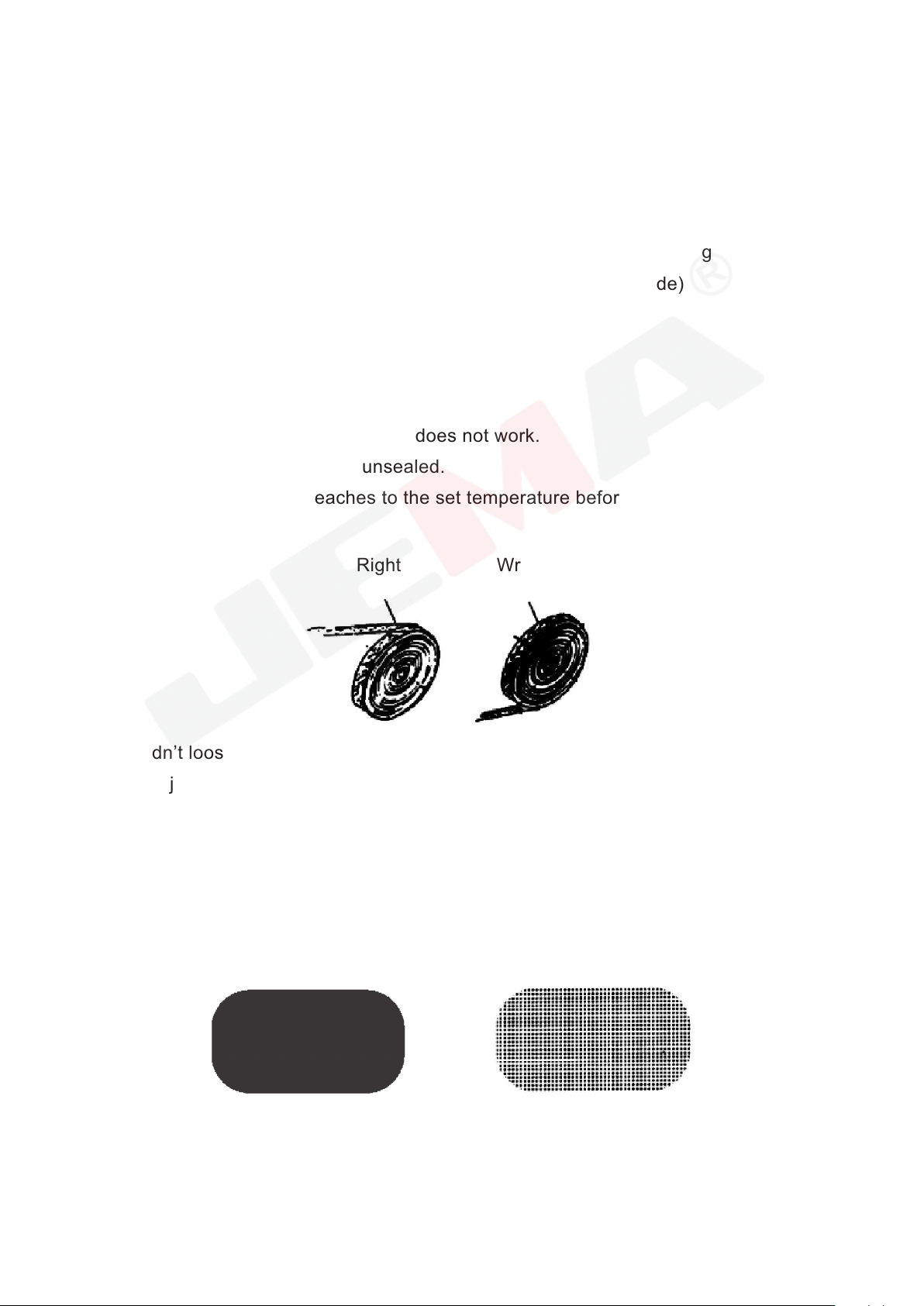

-Test after loosening material from the reel

by hand or attaching feeding device.

01

Alarm of no material All models

-Check if the materials are used up, and

please replace with new materials then needed.

-Check if there is material or if the pressing

plate drops into the slot.

-If all is confirmed normal, check if the travel

switch is stuck and doesn’t bounce back.

6