Jensen Marine Cal 2-46 User manual

•

•

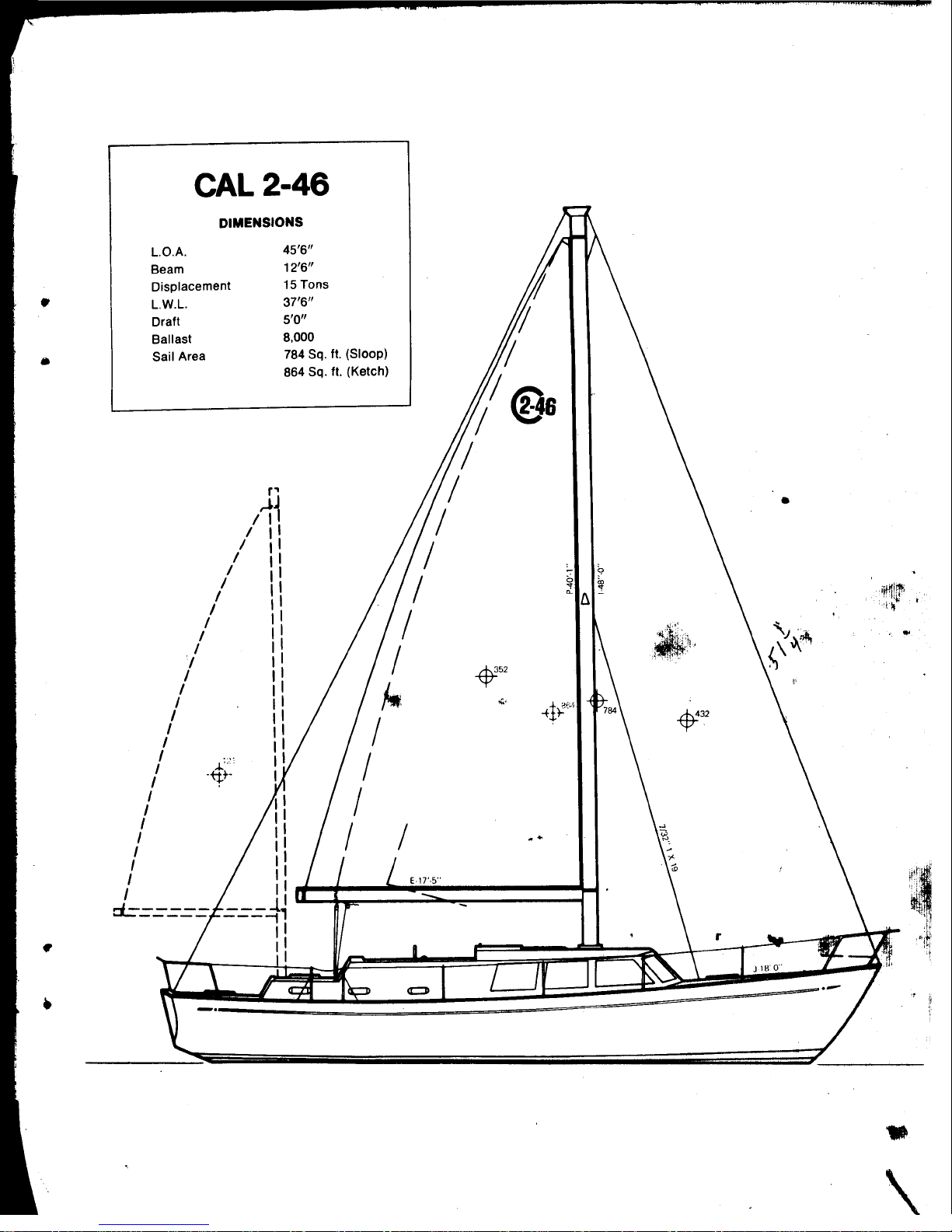

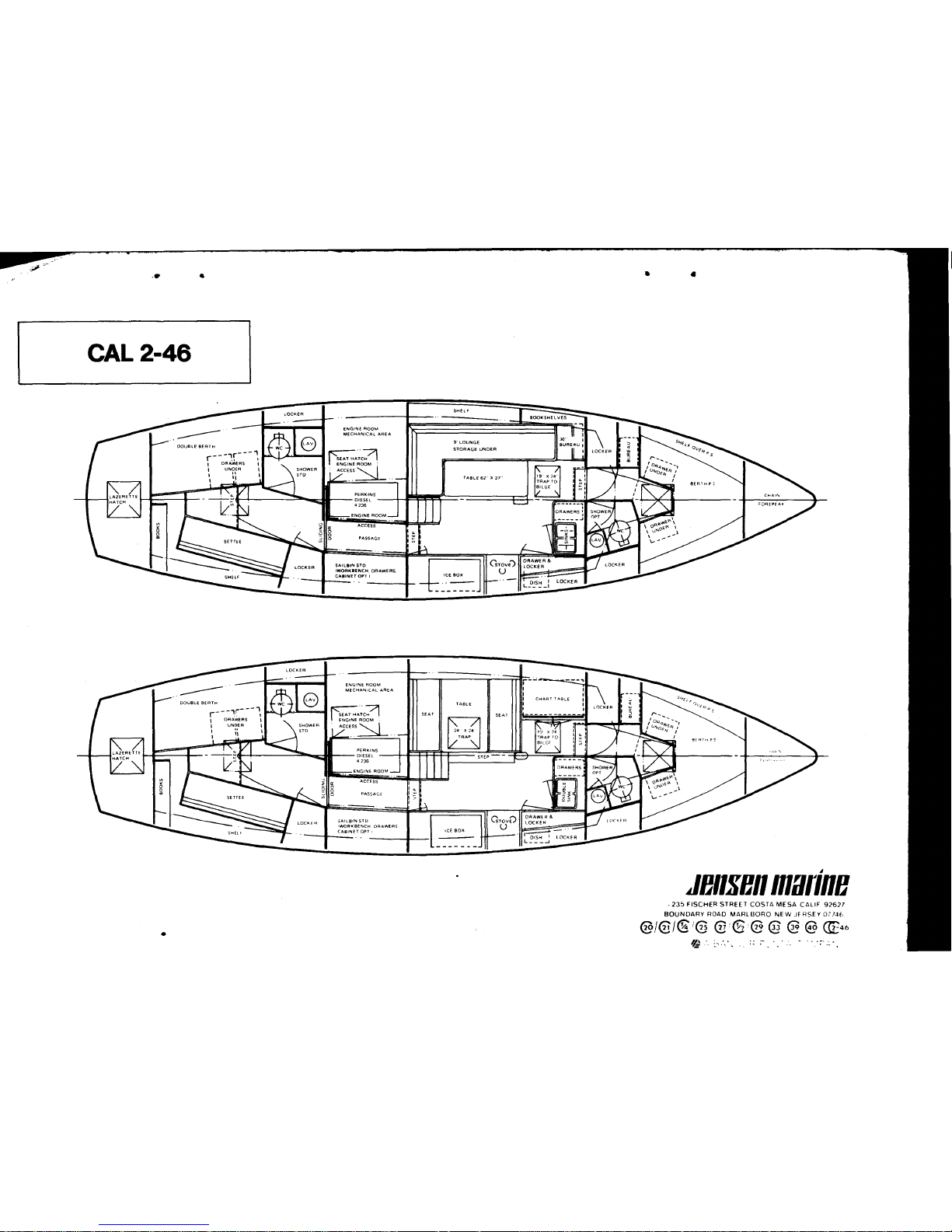

CAL 2-46

DIMENSIONS

L.O.A.

Beam

Displacement

L.W.L.

Draft

Ballast

Sail Area

/

/

/

/

/

/

I

I

'/

/

I

I

I

I

I

/

../.

'

:-"

I

·+tt-

I

I

I

I

I

I

I

I

r=====

/

/

p

,J.J

/

45'6"

12'6"

15 Tons

37'6"

5'0"

8,000

784 Sq. ft. (Sloop)

864

Sq

. ft. (Ketch)

•

".

..

•

\

..

•

CAL

2-46

•

EN

GINE

R

OOM

M

EC

HANIC

AL

AREA

~L'

I

r;;

"

"""'71

SEAT HA

TCH'

I

E

NGIN

E

AOOM

:

"'

CCESS

~

9"

LOUNGE

STOR

A

GE

UNOER

• •

I

~

.1

~~~s~'~s

I

III,

,,

0'

cd

~

I

~

& I

t-~,~')~(~.-----

t ·

:136

--

ENGINE ROOM

ACCESS

P

ASSAG

E

..

"

"NSTO

I

~

__

...

......:.

g

:...:~_~

KE

8

TE

~

;;

· 1

DRAWERS, .ICE 80 X

-------

GU

V

EJ

I~

U~

Kt~

.

e:=4.J

ENGI

NE ROOM

M

EC

IoI

AI'IIIC

AL

AREA

~

AI

L

IJ

I""

STD

rW

ORI(BEN

CM

DRA

.....

E

RS

CABIN ET

OPT.

--

....

--

t:==n:b

r-----==-=--

.

S

EAT

ST(

P

--

I

I

I

I,

Je11Se11

marine

.235

fiS

C

HER

STRHT

COSTA MESA

CALI

f

92627

BOUNDAR

Y RO

AD

MA

RL

DORO NEW

.If

RSEY

07

!

~"

@/€ /

<S

!@ 0 '

<8

'0 @

@@

crE

4b

~

•

•

•

JelIel

marile

SUBSIDIARY

OF

BANGOR PUNTA QrERATIONS. INC.

235

FISHER

STREET

/

COSTA

MESA,

CALIFORNIA

92627

~

JENSEN

MARINE

WARRANTY

Jensen

Marine

warrants

each

new

product

manufactured

by

it

to

be

free

from

defects

in

material

and workmanship under normal

use and

service

for

a

period

which

shall

expire

on

the

sooner

of

180 days

after

commissioning

by

the

original

retail

pur-

chaser,

or

one

year

after

the

date

of

shipment by

Jensen

Marine.

Jensen

Marine makes

NO

WARRANTY,

EXPRESS

OR

IMPLIED,

OF

MERCHANT-

ABILITY,

FITNESS

OR

OTHERWISE,

as

to

the

mast,

as

to

any

external

finish

applied

to

the

product

or

any

part

thereof.

Jensen

Marine makes

NO

WARRANTY,

EXPRESS

OR

IMPLIED,

OF

MERCHANT-

ABILITY,

FITNESS

OR

OTHERWISE,

as

to

engines,

toilets,

stoves,

refrigerators,

batteries,

ignition,

lighting

devices,

blowers,

propellers

(folding

or

otherwise),

and/or

other

equipment

or

trade

accessories

manufactured

by

others.

Jensen

Marine

will

deliver

to

the

original

retail

purchaser

the

warranties,

if

any,

extended

to

Jensen

Marine

by

other

manufacturers.

Jensen

Marine makes

NO

WARRANTY,

EXPRESS

OR

IMPLIED,

OF

MERCHANT-

ABILITY,

FITNESS

OR

OTHERWISE,

on

each

new

product

which

is

not

operated

or

maintained

in

accordance

with

the

Owner's Guide

fur-

nished

with

each

new

product,

or

as

to

any

product

or

part

there-

of

which has been

subjected

to

misuse,

negligent

acts

or

omissions,

or

accident.

If

within

the

foregoing

time

period

it

is

established

to

Jensen

Marine's

satisfaction

that

the

product,

or

any

part

thereof

in-

cluded

in

this

warranty,

is

defective

in

material

or

workmanship

under normal use and

service,

then

the

sole

snd

exclusive

remedy

and

Jensen

Marine's

liability

shall

be,

at

Jensen

Marine's

sole

option,

the

repairing

of

the

defective

product

or

part

thereof,

or

the

replacement

of

same

by

shipment

to

purchaser

F.o.B.

Jen-

sen

Marine's

factory

•

Defective

parts

or

products

to

be

repaired

or

replaced

pursuant

to

this

Warranty

shall

be

returned

by

the

purchaser

to

a Jensen

Marine

Dealer,

or,

if

repair

by

a

Dealer

is

determined

by

Jensen

Marine

to

be

impracticable,

returned

to

Jensen

Marine's

factory.

All

such

returns

shall

ba

freight

prepaid.

This

writing

contains

the

entire

Agreement between

Jensen

Marine

and

the

purchaser.

THERE

ARE

NO

WARRANTIES,

EXPRESS

OR

IMPLIED

OF

MERCHANTABILITY,

FITNESS

OR

OTHERWISE

WHICH

ExTEND

BEYOND

THt

FOREGOING

WARRANTY.

•

•

•

•

I.

II.

GAL/CRUISING

2-~6

INDEX

TANKAGE

.. .... ... ... . ...... . ..

Fuel

••••

Fresh Water • • ................ .. ....

SEA

COCKS

Forward Head • • • • • • • • • • • • • • • • • • • • • • • •

Engille

Room

• • • • • • • • • • • • • • • • • • • •

Aft

Head

• • • • • • • • • • • • • • • • • • • • • • • • • •

Lazerette

••

• • • • • • • • • • • • • • • • • • • • .

..

In

• P

LUMBI

l«l

IV.

ELECTRICAL

SYST»!

Battery

Condition

Indicator

••••••••••

Operation of

Circuit

Breaker

Electrical

System • ......

. .. ...

Page

1

1

1

1

1

2

2

2

2

2

3

L

V.

GALLBI

5

Mechanical

Refrigeration

and

Freezer

• • • • • • • • • • • •

••

5

VI.

HEAns

VII.

ENGINE

Vlll.

SPARS,

RIGGING

AND

HA.RIMARE

Mast

Tune

•••

• • • • • • • • • • • •

Spars

••.••.•

• • . • . • • .

Rigging

.•

• • • • • • • • • • • • • •

Hardware

. • • • • • • • • • • • • • • •

IX. SAILS

I.

FIBERGLA.SS

SURFACES

XI.

I«>OD

SURFACES

APPENDIX

·...... ...

·...........

·...........

·...........

6

7

a

8

9

9

9

10

10

10

•

•

•

OWNER'S

GUIDE

-

CAL/CRUISING

2-46

Welcome

into

the

fast-growing

owner's group of Jensen

Fiberglass

Yachts!

Your

CAL/CRUISING

2-46 has been

carefully

engineered and

built

to

require

a

minimU!Tl

of

maintenance and a

maximum

of

sailing

and powering

pleasure.

To

insure

this,

the following

is

a

description

of the

oyerational

checks and

tasks

normally

delt

with by

the

owner

to

maintain

his

CAL/CRUISING

2-46.

Each

individual

owner

should

also

be

aware

of

the

operational

and maintenance

re-

quirements of any

optional

equipment

that

has been

installed

as

that

information

may

not

be

contained

in

this

Guide •

Let's

become

acquainted

with

these

various

operations

by

preparing

a

standard

CAL/CRUISING

2-46

for

a

day's

outing and

discuss

the

maintenance

routine

which

you

should

follow.

It

is

good

practice

to

close

the

fuel

shut-off

valves

and

all

sea

cocks

when

leaving

your

boat,

especially

for

extended

periods

of

time.

The

"coming

on

board" and the opening of

these

fittings

starts

our

"Sailing

Check-off

List.

"

I.

TANKAGE

A.

FUEL

II.

The

two

135

gallon

10 gauge

steel

DIESEL

FUEL

TANKS

are

located

under the

main cabin

sole

with

their

tank

fills

on

~eck,

port

and

starboard,

and

their

vents

directly

above

on

the cabin

side.

The

Fuel

Shut-off

Valves

are

on

the

forward engine

room

bulkhead along

with

their

respective

capacity

gaui8s.

When

not

operating

the

engine,

these

valves should remain

CLOSED.

B.

FRESH

WATER

Two

85

gallon

stainless

steel

Fresh

Water Tanks

are

also

located

under the

main cabin

sole

with

their

tank

fills

and

vents

adjacent

to

the

fuel

tanks.

The

valves

for

these

tanks

are

in

a compartment

on

the forward engine

room

bulkhead along with

their

respective

capacity

gauges.

If

the

optional

50

gallon

fresh

water tanks have been mounted, they

will

be forward of

the

diesel

fuel

tanks

but

their

valves

will

also

be

here.

SEA

COCKS

'tJ.'.;,£

..

t.

All

below water

line

through

hull

fittings,

except

the

optional

speed

indicator,

are

equipped with bronze

.....

Avalves.

When

the

optional

equipment

is

added,

there

could

be

a

total

of

9,

so

it

is

vital

that

you

know

the

location

of

these

valves.

Gate

valves

OPEN

by

turning

COUNTER-CLOCKWISE

and

CLOSE

in

a

CLOCKWISE

direction.

It

is

a

good

idea

when

you open any

gate valve

to

then

close

it

a

quarter

turn.

In

this

way,

anyone can im-

mediately

tell

if

a valve

is

open

or

not.

Open

valves

are

sometimes broken

by

someone

tr,ying

to

pr.y

them

further

open,

thinking

they

are

closed.

FollOWing

is

the

location

and

function

of

the

9 gate

valves.

A.

FORWARD

HEAD,

4

valves

All

of

these

valves

are

located

in

the

locker

directly

under the lavator.y

with

the

follOWing

functions:

-1-

F

•

•

CAL/CRUISING

2-46

1.

1

1/4"

valve

for

Marine

Toilet

Discharge -

2.

3/4"

valve

for

Lavatory

and

Galley Sink

Drain]

3.

1/2:

~alve

forMar~ne

Toile~

Water Intake

4.

l/~

16va.~

Wa~p

B.

ENGINE

ROOM,

j.

val

ve5

1/

z.."

13#(.("

;tnt.. v IS

reJ

(;.~A/G

R~rOIi:

1.

1/2"

valve

to

port

of engine

for

Sea Cooling Water

~J4

vr;k'/j/e

-

l;re~F?Ic;.ERA""I'()A/

/PHP

/Y//f

?t?N'O/T/O;Y/If/<:;..

C.

AFT

HEAD,

3 valves

As

with the forward head,

all

of

these

valves

are

located

in

the

locker

under the

lava

tory

with the following functions •

1.

1

1/4"

valve

for

Marine

Toilet

Discharge

2.

3/4"

valve

for

Lavatory Drain )."'17

C-lfllEI'

r;/NI)

3.

1/2

11

valve

for

Marine

Toilet

Intake

If""!)

vvltSlf!»WN

p",P

D.

LAZERETTE,

1 valve

1.

2

1/2"

valve

on

transom

for

Engine Exhaust

Please

note

that

the

OPTIONAL

SPEED

INDICATOR

THRU-HULL

is

located

in

the main cabin

bilge

trap

and

is

the

only below water

thru-hull

without

a

~

valve.

III.

PWMBING

Closely

related

to

the sea-cocks

is

the

general plumbing system of your

CAL/CRUISING

2-46.

It

is

important

to

note

that

BOTH

the

SHOWER

and

ICE

BOX

drain

into

the

bilge.

The

optional

pA-R

Automatic

Electric

Bilge

Pump

is

mounted

in

the

engine

room

and exhausts

out

through

the

boot top

on

the

port

side.

Note

that

BOTH

the

cockpit

drains

also

discharge here and,

since

they

are

above the water

line,

are

not

equipped with gate

valves.

While

on

the

subject

of water

in

the

bilge,

you

should

also

expect

some

water

to

seep

in

thru

the

Propeller

Shaft

Packing Gland.

The

best

place

to

sound the

bilge

is

in

the

engine room, below

the

engine gear box,

where

the

pick

up

for

the

electric

bUge

pump

is

also

found.

The

Hot and Cold Pressure Water System

is

operated by a

P~

self-priming

pump

that

is

equipped

with

an automatic low-water

cut-off.

This

hot

water

system

is

operated

either

by running the

diesel

engine

or

on

the

110

volt

A.C. Shore Power.

DO

NOT

TURN

THIS

SYSTm4:

ON

UNLESS

THERE

IS

WATER

IN

THE

•

SYSTEM

AS

THE

HEATING

ELEMENT

WILL

BE

BURNED

OUT

IF

THE

TANK

IS

EMPTY.

..

I V•

ELECTRICAL

SYSTEM

I t

is

important

to

remember

that

your

BASIC

CIRCUIT

BREAKER

ELECTRICAL

SYSTEM

may

be

altered

to

conform

to

the

electrical

requirements of your

additional

optional

accessories.

In

the

event you

make

any

electrical

modifications

to

your

CAL/CRUISING

2-46 be sure

that

you follow the

WIRING

DIAGRAM

or

consult

a competent

MARINE

ELECTRICIAN.

Boat

wiring

is

con-

siderably

different

from house wiring

due

to

the marine environment and

other

conditions

not

associated

with houses.

-2-

•

•

•

GAL/CRUISING

2-46

The

Master

Power

Control Panel

features

integrated,

simplified

controls

and

circuit

breaker

protection

to

permit

safe

and

efficient

operation

of

your

boat's

electrical

equipment.

All

panel components have been

carefully

selected

for

their

proven performance

in

marine

applications.

The

baSic

panel

is

of

a metal

alloy

which

is

inherently

corrosion

resistant

and

is

doubly

protected

to

optimize

resistance

to

the

effects

of

the

marine

envir-

onment. A

one

year

warranty

will

be

validated

by Marinetics Corporation,

P.O.

Box

1015, Newport Beach,

Calif.

92663,

if

the enclosed warranty

re-

gistration

form

is

submitted

within

30

days from the date of commissioning•

~/I.

()

It

1'1(-

~1Z

1JArV1:.5

Electrical

current

is

directed

from

two

12

volt,

~

batter~ythrough

the Master

Power

Control Panel

for

engine

starting,

battery

charging, and

accessory

loads.

Since the

GAL/CRUISING

2-46

is

designed

to

do

considerable

cruising

and

"living

aboard" an

optional

208

amp

battery

may

be added

to

meet

these

additional

electrical

requirements. Panel

selection

of

"BAT

1" or

"BAT

2"

determines which of the

two

battery

sets

will

be

utilized

for

engine

starting

and subsequent charging. Before

activating

the

electrical

system,

use the

Battery

Condition

Indicator

to

ascertain

the condition of your

batteries.

A.

BATl'ERY

CONDITION

INDICATOR

This type of

"indicator"

or

"meter"

is

technically

referred

to

as

a

"Suppressed Zero Voltmeter".

Note

that

calibrations

do

not

start

at

zero

but

provide a

full

scale

reading from 8

to

10

or

16

volts,

depending

on

the

meter.

Below

8

to

10

volts

the

battery

charge

is

so

low

that

terminal

voltage readings

are

meaningless. Approximate voltage range

interpretations

are

as

follows:

Engine

Not

Running

or

at

Idle

Engine

Running

Above

Idle

)

)

)

Below

II

- - - - - - Very

low

battery

charge

11 -12 ------

Low

battery

charge

12

-13 - - - - - - Well charged

battery

------------------ - ------

)

)

)

13

to

13* -----

Low

charge

rate

131

to

l5t

- - - - -

Alternator

&Voltage Regulator

OK

15i

or above - - - - Voltage Regulator out of Adjustment

It

is

iaportant

for

you

to

understand

that

the reading

on

the

Battery

Condition

Indicator

Dial

is

indexed from the

TOGGLE

TEST

SWITCH

POSITION

REGlRDLISS

OF

THE

MASTER

SWITCH

POSITION

unless

it

is

in

the

"BOTH"

position

•

When

the Master Switch

is

in

the

"BOTH"

position

then the

Battery

Condition

Indicator

Dial

wUl

indicate

BOTH

BATTERY

CONDITIONS

NO

MATTER

WHICH

WAY

THE

TOGGLE

TEST

SWITCH

IS

INDEXED.

When

the

Master Switch

is

in

either

the

"OFF",

"BAT

1"

or

"BAT

2" pOSitions, the

_ter

will

read the

condition

of

the

battery

TCJWA.RnS

which you index the Toggle

Test

Switch.

Note

that

panel

and meter

illumination

is

also

provided

bY'

this

same

Toggle

Test

Switch.

Before

activating

the

electrical

,sY'stem,

check the

condition

of

both

battery

sets

and then

select

the

STROl«lEST

BATTERY

FOR

ENGINE

STARTING.

-3-

•

•

•

CAL/CRUISING

2-46

Index

the

Master

Switch

to

the

strong

battery

and

then

start

your

engine.

It

will

usually

require

about

15

to

)0

minutes

of

engine

running

time

to

bring

the

starting

battery

back

up

to

charge.

Check

the

anuneter

to

assure

that

charging

is

normal and when

the

selected

starting

battery

has been

restored

it

is

placed

on

reserve

by

switching

to

the

other

battery

so

sub-

sequent

charging

and

accessory

loads

will

be

confined

to

this

second

battery.

IT

IS

A

GOOD

PRACTICE

TO

BRIt«}

THE

FIRST

SELECTED

BATTERY

UP

TO

FULL

CHARGE

BEFORE

PUTTING

IT

ON

RESERVE

AND

CHANGING

TO

THE

SECOND

BATTERY.

Use

the

Master

Switch

in

"BOTH"

position

ONLY

for

emergency

starting

when

both

batteries

are

low,

or

for

"top

off"

charging

when

both

batteries

are

near

full

charge.

When

both

batteries

are

canpletely

charged,

transfer

to

either

battery,

keeping

one

battery

always

in

reserve.

This

is

especially

important

when

you

realize

that

there

is

no

way

to

start

your

engine

with

a dead

battery,

like

pushing

a

car

when

you're

in

the

same

predicament!!

NEVER

MOVE

THE

MASTER

SWITCH

TO

"OFF"

WHILE

THE

ENGINE

IS

RUNNING

OR

THE

ALTERNATOR

DIODES

MAY

BE

BURNED

OUT.

B.

OPERATION

OF

CIRCUIT

BREAKER

ELECTRICAL

SYSTEM

Accessory

loads

may

be

selected

as

desired

by

indexing

the

appropriate

panel

breakers

"ON"

so

current

may

flow

from

the

switched

battery

to

the

accessory.

A

branch

circuit

overload

will

cause

the

accessory

circuit

breaker

to

"trip",

i.e.,

the

breaker

will

autanatically

open

the

circuit

and

its

handle

will

flip

to

the

"OFF"

position.

After

correction

of

the

fault,

the

breaker

may

be manually

indexed

"ON".

The

RUNNING

LIGHTS

switch

activates

the

red

and

green

lensed

lights

forward

and

the

white,

12

point

stern

light

aft.

The

COMPASS

LIGHT

connection

for

the

cockpit

is

also

on

this

switch.

When

under

sail

at

night,

these

are

the

only

lights

that

should

be shown,

except

for

the

shining.of

a

white

light

on

the

sails

if

you

feel

there

is

a

real

need

for

greater

recognition.

The

WHITE

STERN

LIGHT

takes

a

GE-68

type

bulb

while

a

GE-90

bulb

should

be used

for

the

RED

PORT

LIGHT

and a

GE-94

bulb

for

the

GREEN

STARBOARD

LIGHT.

It

is

important

that

a

stronger

bulb

be

used

with

the

darker

lenses

or

visibility

of

the

lights

will

be

considerably

less

that

the

required

one

mile.

The

BOW

LIGHT

sn

tch

is

for

the

20

point

whi

te

light

on

the

mast and

is

to

be

used

in

cOnjunction

with

the

running

lights

WHEN

UNDER

POWER

OR

WHEN

MOTOR

SAILING.

It

also

serves

as

a

quick

way

of

illuminating

the

jib

at

night

to

check

its

trim

and

in

emergency

cases

when

recognition

is

important.

This

light

will

use

a

GE-68

bulb

if

replacement

is

necessary

•

The

cabin

lights

have

their

own

individual

switches,

but

must

be

activated

by

the

CABIN

LIGHT

switch

on

the

Master Power

Control

Panel.

If

the

cabin

lights

start

getting

dia,

this

is

fair

warning

that

the

battery

needs

a

charge

or

is

getting

old.

Be_.ber

that

you

have

an

automotive

type

battery

whose

charge

and

water

level

IllU8t

be

checked

at

least

once a month.

If

your

boat

is

to

be

unused

or

stored

for

extended

periods

of

time

it

is

advisable

to

re-

move

the

batterr

(s)

and

store

in

a

varll,

dry

location.

-4-

CAL/CRUISlIG

2-46

Periodically

check

all

wires,

connections,

and

terminals

for

loose

connections

which mAl cause

electric

sparks

or

power

loss.

This

is

es-

pecially

11Iportant

with

the

engine

wires.

When

leaving

the

boa

t,

FIRST

TURN

OFF

THE

DOIHE,

THEN

INDEX

THI

MASTER

SWITCH

TO

OFF.

v.

cw.LII

The

Water

S1St.

and

Sink

Drain

haft

been

covered

earlier.

Mention

was

a180

_de

tbJIt

the

100 pound

Ice

Box

drains

into

the

bilge.

Ope:sMiug-

'"

inatnletione-lw-the-

optioad--3--bumer-·

Preanre

.....

lcobol·

StOfe"COM""""1ftt1f

the

atove

'nit

a

tn

addj

tioul

.pe1ftta-are--important.

•

2

sallon

Presaure

Tank

is

in

the

locker

just

forward

of

the

stove.

When

lling

this

tank,

please

observe

the

following

BEFORE

removing

the

stopper:

"'-,

1.

All

bu~s

are

OFF

..,r/'

·

2.

Main

IlCO~-oft

""lve

on

top

of

pre~~'9"~;

/

1a

CLOSED.

3.

Tank

pressure

is

ZD(h

Remove

Sto~:/

,

/~

~

4.

Fill

the

tank

three-qua~~

'

l'~l

to

allow

for

air

pressure.

"

"'-

5. Replace

stopper

,..!._.'8~

d~t.

6.

IxperieDC~ShOWn

that

5

pounds"'o~tank

pressure

is

more

than

ad~,ati

and imposes

less

strain

on

the

ittings

than

the

re-

~nded

10 pounds.

Following

is

a

description

of

the

optional

mechanical

installed

bJ

the

factory.

MECIWlICAL

REFRIGERATION

j.HI)

FREEZER

(Mechanicold)

rigeration

system

,/

/

~

Chan1Cal

refrigeration

and

freezer

in

this

applica

on

is

defined

a.

a

run

ott

tbe

engine.

The

teaperature

is

re

d manually,

but

there

a

tMraoatat

to

prevent

the

refrigerator

CIIl

becoming

too

cold.

When

ei

tber

~friaerator

or

freezer

becOl18

va

the

engine

is

started

aDd

the

878tea

nitclled

on

and

run

until

tbe

fre

r

becCllles

cold.

The

run-

n1Dc

tiM

w111

va1'7,

~nd1nl

on

how

long

t

ra

ture

is

maintained

in

the

freezer.

'- ,

"',

" "

The

qetea

18

composed

of

the

1"0_

....

___

components, which

are

also

alphabetically

indexed

in

the

dia~<~~Appendix.

~

..

A.

The

cGlllpreaaor

is

a two

C7

der

auta.oti

v.'1i.!"

conditioning

type,

mounted

on

the

engine.

The c

ssor

pulle7

has

a 12 t

electric

clutch

and

is

clri

ftn

by

tvo

V be

otf

all

auxillary

pulley

on e

engine.

Belt

tension

is

recuJ,a

by

adjueting

the

co.pressor

or

adj

an

idler

pulley.

B. The condenae s plUllbeci

into

the

engine raw

water

cooling

Systell

b8fore

the

vater

tars

the

enline

(or

the

beat

exchanpr

in

the

CBse

of

a

fresh

water

c

ad

engine).

/'

-5-

•

•

..

•

ClL/CRU1SINl 2-46

VI.

c~\

The

Rec.iTer

incorporates

a

built-in

drier

and a

sight

glass

to

permit

~hecldng

the

amount

of

refrigerant.

/

D.

T~ExpaDs10n

Valves

control

the

flow

of

refrigerant

into

t E....

porators.

E.

The

E~porator

consists

of

tubing

coils

in

an

eutetic

so

·001.1-

'~old

plates.

F.

The

Therm~-ters

are

mounted

in

a

position

so

they

n

be

easily

observed

and

the

;l:;;nt

bulb

in

the

box

is

about

mid-heigh •

\

G. A Switch

to

cdrltrol

the

electric

clutch

may

inc

orate

a

red

light

to

show

when

the

switch

is

on.

/

H. A High

Pressure

'~ut-off

switch

is

provided

'disconnect

the

electric

clutch

if

the

system

pressure

becomes

too~igh,

usually

due

to

lack

of

cooling

water.

/

Conventional

refrigera~on.

tubing

and

~ttingS

are

used

with

refrigerant

hose between

the

compressor\and

the

re~l~f

the

system

to

absorb

vibration.

, /

The

operation

of

the

Syste~\d

tJx'

function

of

the

components

is

as

follows:

/

,

The

refrigerant

is

piped

~o

t

e~xpansion

valves

(D) from

the

receiver

(C)

as

a

liquid

and

the

amount

of

ow

i~

regulated

by

the

telllperature

of

its

thermal

bulb

(F)

attached

to

e

outl~t

line

of

the

evaporators.

In

the

evaporators

(I),

the

refrige,

nt

picks\up

heat

and

is

changed

to

a

gas.

The

gas

is

piped

to

the

compres~or

(A)

wher~

it

is

changed from a gas

at

low

pressure

to

a gas at

high

"pressure.

Thi~

high

pressure

gas

is

piped

to

a

condenser (B) where

the

peat

is

'taken

out

~

the

engine raw

water.

This

changes

the

gas

to~

ai

uid

which

is

piped

~

the

receiver

(C) and

the

cycle

continues.

No

ad.jus

nts

are

required,

simpq

run

the

compressor (A) long

enough

to

maintain

e

desired

temperature.

'\

I

~

/ "

The

High

Press~e

cut-off

awi

tch

(H)

is

an

exc~ent

safety

device,

as

it

prevents

damage

~QIl

excessive

pressure

due

to

lack'\¢'

cooling

water.

This

can be

the

re~t

of

a clogged

inlet

line,

the

thru

~l

water

intake

valve

accidently

lett

closed,

or

being

heeled

over

far

enou~

for

the

water

intake

thru-hull

to

be

out

of

the

water.

\

\

The

reftigerator

temperature

control

can be

adjusted

th

prevent

too

low a

temperature

in

the

box, which would

freeze

Ililk,

vegetables,

beer,

etc.

The

Freezer

/can

be

run

as

long

as

desired

wi

thout

ill

effects.

~is

provides

an

I

.~

exceUent

way

of

_king

ice

cubes.

',.

j .

.ad1tional

information

and

replacement

parts

must

be

obtained

ts:om

the

or,tg1nal

manufacturer:

Boat

SpeCialists,

Inc.,

2439

West Coast Highway,

lf6wport Beach, Ca. 92660. Phone 114/645-0901.

HEADS

Complete

operating

instructions

for

the

Marine

Toilets

are

on

metal

plates

wbich

may

be

mounted where

desired.

These

plates

along

with

additional

in-

structions

and

parts

lists,

bave

been

included.

-6-.

•

•

•

CA.L/CRUISIIIl

2-46

OON'

T

FORGET

THE

EARLIER

TANKAGE

AND

SEA

COCK

INSTRUCTIONS.

VII.

ENGINE

Operating

procedure8

are

well

covered

in

the

enclosed

manual, however

several

important

pOints

should

bere-emphasized:

A.

Turn

the

Main

Battery

Switch,

located

on

the

Master Power

Control

Panel,

to

the

position

you have

de8ignated

'

as

tile engine

battery.

When

the

engine

is

IDLING

you

may

switch

from

one

b~ttery

position

to

the

other

for

ch~rging

•

NiVER

paS8

through

the

"OFF"

position

or

the

Alternator

Diodes

will

be burned

out.

The

"BOTH"

position

is

used

to

start

the

engine

when

both

batteries

are

low.

When

the

engine

is

not

running,

use one

of

the

batteries

for

ship's

gear,

thus

saving

the

second one

for

starting

the

engine.

B.

Prior

to

starting

the

engine,

please

check

the

following:

1.

The

engine

is

fresh

water

cooled

through a

salt

water

heat

exchanger.

It

is

extremely

1JIportant

that

the

fresh

water

header

tank

be

full

to

within

an

inch

of

the

top

and

the

cap

on

tight.

.

For

technical

reasons,

the

choice

of

lubricating

oil

is

more

important

in

a

Diesel

than

in

a

gasoline

engine.

Check

the

dip

stick

on

the

engine's

port

side.

The

oil

must be

drained

every

50 hours and

re-

placed

with

5

quarts

of

a "H.D."

detergent

oil.

Also

change

the

filter

at

this

t:ille.

"RPM

DELO

Multi-5ervice

SAE-30"

is

used

at

the

factory,

but

other

approved

oils

are

listed

on Page

37

of

the

manual.

The

transmission

bas

one

quart

of

"Chevron Automatic Transmission

fluid-

which

should

be

changed

after

the

fir8t

50

operating

hours and

evel'1 500 hour8

thereafter.

C.

Place

Shift

lever,

port

side

of

Control

Unit

in

NEUTRAL

or

the

vertical

position.

D.

Pull

out

1natrument knob

to

activate

in8truments.

E. Water and

Fuel

ON?

Exhaust Valve

OPEN?

F.

Push

Starter

Button.

When

engine

starts:

1.

Adjust

Throttle,

starboard

lever

on

Control

Unit,

to

Idling

Speed

of

700

RPM.

2.

Check 011

pres8ure

-

40

pounds•

3.

Cooling system

is

operating

only

if

water

i8

coming

out

of

Exhaust

Outlet

in

transOJll. Engine

operating

temperature

is

1700,

•

4.

If

water

doe8

not

begin

to

flow

out

of

the

transom

outlet

within

3

or

4

minute8,

STOP

the

engine and check

water

intake

and exhaUlit

gate

valves.

5.

If

oU

pre8Bure

i8

low,

STOP

the

engine and check

oil

level.

-7-

•

•

•

•

CA.L/CRUISIIG

2-46

6.

The

Propeller

Shaft

Packing Gland,

located

under

the

AFT

Cabin

Sole,

should

be

damp.

Tighten

the

nuts

snug enough

to

eliminate

aq,y

excess

water

drips.

Q.

Run

engine

at

idle

when

shifting

into

forward

or

reverse.

At 2100

RPM

the

atL/CRUISING

2-46

will

power around 8.2

knots

using

about

1.7

gallons

of

fuel

per

hour.

In

smooth

water,

higher

speeds can be

obtained

with

higher

RPM's

but

fuel

consumption

will

increase

accordingly.

B.

To

Shut

Down

Engine:

1.

Pull

"KILL"

Knob

in

instrument

panel.

2.

Push

in

Instrument

Knob.

3. Close

Fuel

Valves and

Gate

Valves.

I.

There

are

only

two main

reasons

a

Diesel

engine

will

stop

running.

One,

when

the

engine

has

run

out

of

fuel

or

there

is

an

air

bubble

in

the

fuel

line

j and two,

if

the

engine

bas overhea

ted

caUSing

the

engine

to

"freeze".

If

the

water

level

is

OK,

and

there

is

sufficient

fuel

(and

fuel

shut-off

valves

are

open)

the

fuel

system

will

have

to

be

"bled".

This

can

be

done

without

the

assistance

of

a mechanic and

is

explained

in

the

Appendix.

With

the

engine

running,

your

CAL/CRUISING

2-46

is

ready

to

get

underway.

We

should

pause

for

a

moment

and

look

about

the

deck

thus

becoming

acquainted

with

the

sailing

gear.

VIII.

SPARS,

RIGGIW

AHD

HARDWARE

It

is

!.possible

to

fully

guaran~e

the

mast

of

your

CAL/CRUISING

2-u6

under our

current

warranty

program. Rigging

as

well

as

tuning

becomes

all

iaportant

when

setting

up

the

mast because

of

the

light

weight

section

we

use.

J.

knowledgeable

person

should

oversee

the

rigging

and

tuning

so

as

to

eliminate

the

possibility

of

an

eccentric

load

which might

occur

with

an

improperly

loaded

shroud.

Special

attention

should

be

given

to

the

initial

stretch

of

the

uppers and a

further

gradual

stretch

of

the

wire

over

the

first

few

hard

8ails.

A.

MAST

ruNE

The

JJa8t

should

be

set

straight

athwart-ships

in

the

boat

and have a

slight

rake

aft.

A

straight

mast can

best

be

obtained

by

turnbuckle

adjustment

while

sailing

to

windward

in

a ,

to

10

mph

breeze.

The

head

of

the

mast

should

NOT

"hook"

to

windward.

If

not

straight,

it

would

be

more

desirable

to

have

the

head

"fall-otf"

slightly

to

leeward.

This

should

give

the

mast a smooth,

even

curft

froll

head

to

deck.

Sighting

along

the

back

of

the

mast

on

each

tack,

from deck

level,

will

give

a

canparlson

and

indicate

the

necessary

ad-

jusi'.-nta.

For

noraal

cruising

conditions,

we

recOllJll8nd

a

"firm"

rig.

Thus a dock-

side

starting

point

would have

the

heads

tal'

,

backatay,

Jdd-stay

and uppers

tight,

the

inter.diates

not

so

tight

and

lovers

fairly

firm.

low

the

back-.

stay

..

y

be

_de

slightly

tighter

to

"hook"

the

top

of

the

mast

aft.

One

•

•

•

..

CAL/CRUISING

2-46

should

be

able

to

stand

facing

the

mast,

reach

out

and

pull

on any

stay

and

see

the

mast

move

in

that

direction.

Try

to

get

tension

on

both

stays

equal

with

about

1/2"

to

2"

of

play

on

the

uppers,

2"

to

3"

on

the

lowers

and

about

2-

on

the

intermediates.

The

intennediates

are

set

last

and

serve

to

balance

the

pull

of

the

uppers

and

lowers.

A

dascription

of

all

standing

and

running

rigging,

if

replacement

is

neceseary,

can

be

found

in

the

Appendix. FollOWing

are

sane maintenance

tips

which

should

be

of

value

•

B.

SPARS

The

finish

of

natural

aluminum

is

protected

against

corrosion

by a

thin,

transparent

film

of

aluminum

oxide.

Dust,

dirt,

smoke,

salt

and

traffic

fumes

will

adhere

to

this

film,

making

the

surface

dull

and

unsightly.

Coating

the

new

surfaces

with

a good

paste

wax

like

Vista

or

Simonize,

will

help

protect

the

aluminum

oxide

from

foreign

matter.

If

the

surface

has

become

tarnished,

any

high

grade

cleaner

-

wax

-

polish

(Collinite

#34

or

#38

for

example)

will

restore

the

original

sheen.

Heavier

pitting

can be

removed by

wet-sanding

with

IIfIJO

paper

prior

to

polishing

and waxing.

You

need

not

worry

about

sanding,

cleaning

or

polishing

destroying

the

aluminum

oxide

fUm

as

it

reforms

or

-beals"

immediately.

If

spars

are

black

anodized,

hose

down

portions

subject

to

salt

water

spray

after

each

sail.

~L.VMINVh

The

spreaders

are

of

apNea

and

haft

'heft

"a.de o

Blitbhed.

Beee1Hle

ef

84

1)

ahafe

and

weather,

they ah8lllEi

l!Ie

la_eEl

and

l'e-v.udshed

e,e17

"8ix

months and

the

UpS

re

taped.

C.

RIGGING

Clean

rigging

means

clean

saUs.

A

quick

trip

aloft

with

damp

rags

takes

care

of

this

problem. While

aloft,

check

the

entire

rig

for

loose

screws,

nuts,

bolta,

cotter

pins

and

chafe

which

may

have

resulted

from

hard

sailing.

Periodic

inspection

of

the

rig

from

aloft

is

your

best

insurance

against

rigging

and

spar

failure.

Keeping

halyards

tied

away

fran

the

mast

stops

the

annoying

dockside

clanldng

and

saves

the

mast

finish.

Salt

water

will

gradually

stiffen

dacron

line.

HOSing

with

fresh

water

or

soaking

in

warm

soapy

water

will

make

the

line

soft

and

flexible

again.

Keep

coiled

and stowed

in

a

dry

spot

below•

D.

HARIWARE

Many

materials

are

used,

all

of

which

clean

well

with

fresh

water

and a

chamois. Winches must be

kept

clean

and

well

oiled

(Lubriplate

is

excellent

unless

the

manufacturer

rec~nds

otherwise)

as

do

all

turnbuckles,

track

slides,

sbeaves

and

shackles.

The

cbrolll and

stainless

steel

brighten

up

with

the

chamois

while

a

good

automotive chrome

cleaner

or

mild

kitchen

abrasive

like

Comet

takes

care

of

the

tarnished

spots.

-9-

•

•

•

'"

CAL/CRUISIJI)

2-46

IX.

Keep

all

gear

lubricated

and

in

good working

condition.

Remember,

the

less

an

ite.

is

used,

a

turnbuckle,

for

example,

the

more

apt

it

is

to

fr

•••

e-up.

The

_insail,

with

battens

rellOved and

outhaul

slacked,

is

properly

furled

on

the

boom,

under a

cover.

Headsails

have been

stripped

of

sheets,

properly

folded

and

are

bagged below

ready

to

be

brought

on deck.

The

dacron and

~lon

sails

do

get

wet and

beCQ18

caked

with

salt.

When

they

do, hose them

orf

with

fresh

water

and dr,y

thoroughly

by

hoisting

them

at

the

dock

on

a

stUl,

wara

day

•

Take

care

of

your

sails

with

periodic

checks,

especially

spinnakers,

for

small

tears

and

chafe.

Hoisting

and

lowering

sails,

except

spinnakers,

while

head-to-wind

is

good

practice

and

easier

on

the

sails.

X.

FIBERGLASS

SURFACES

Periodic

application

of

Tide and

fresh,

warm

water

with

deck

brush

and

sponge

followed

b;y

a good

hosing

and chamois

will

do

the

cleaning

job.

If

the

glos.

dulls

or

fades,

wax

the

smooth

surfaces

with

Vista

or

Megu1ar's

Mirror

Glase

paste

wax.

Surfaces

that

have

started

to

oxidize

can

be

brought

back

with

Maguiar's

Fiberglass

Boat

Cleaner

or

DuPont White

N7

Polishing

CoapolUld.

Wax

the

hull

with

a power

burfer

and

paste

wax

once a

year.

The

non-skid

surfaces

can be

brought

back

to

life

with

a

lather

of

Tide

or

Mr.

Clean.

Be

sure

to

follow

up

with

lots

of'

fresh

water

to

avoid

streaks

on

the

topsides.

Avoid anT

metal

filings

on

the

fiberglass

surfaces

as

they

will

leave

rust

spots.

These

spots

can

be removed

with

oxalic

acid

or

Teak-Brite

but

first

test

a

amall

area

against

bleaching

out

the

surface

color.

XI.

WOOD

SURFACES

All

of

the

exterior

is

teak

which

is

weather

resistant

due

to

its

natural

oils.

Teak does

fade

to

a·

dull

gray,

which,

it

objectionable,

can be scrubbed

clean

with

"Teak-Brite."

Teak's

natural

color

and

texture

can

be

preserved

by

applications

of

Weldwood's "Woodlife"

or

similar

sealers.

Teak,

when

well

varn1shed,produces

the

ult1.Jll8te

in

a

yacht

wood

finish

but

requires

constant

loving

care!

All

below deck

teak

surtaces

are

finished

with

a

sealer.

Treat

all

the

I18tarials

used

below deck

as

a

home

interior.

Air

is

a wonderful

cleaner:

bring

the

vacuum

cleaner

aboard and always keep

the

boat

well

ventilated,

especiall7

the

bUge

and

lockers.

Jensen

Marine's

interest

in

both

custClD.8r

and

product

continues

long

after

you

have cOllllis.ioned 1'O'lr

CAL/CRUISING

2-46.

Within

limits

of

our

speCifications,

the

cOl1lpaDT'.

Parte

Depsrtment

is

ready

to

serve

your

nearest

dealer

quickly

and

efficiently.

All

replaceJllent

parts

or

accessories

are

delivered

through

your

dealer.

He

must have

detailed

information

trom you

to

be

certain

we

send

the

parts

requested.

-10-

•

•

•

..

CAL/CRUISING

2-46

Addi

tional

sailing

and

maintenance

tips

can

be

found

in

various

boating

publicationa.

Yachting'

a Annual Maintenance

Issue

in

April

is

an

excellent

starting

pOint.

This

brings

us

to

the

end

of

our

"Sailing

Check-List"

and

leaves

only

the

securing

of

your

CAL/CRUISING

2-46.

If

we

ran

the

list

in

reverse,

adding

only

one

item,

your

CAL/CRUISING

2-46

will

be

ready

for

the

next

sail.

This

one

important

item

is

a

GOOD

HOSING.

Nothing keeps a

boat

better

than

fresh

water

and

the

chamois.

Use

plenty

of

pressure,

espe

cially

in

the

cockpit

scuppers.

non-skid

areas

and

metal

surfaces.

Turn

to

with

sponge and chamois and you

will

be

rewarded

with

a

sharp,

sparkling

yacht

that

is

only

matched

by

its

comparable

performance

•

Good

Luck and Happy

Sailing

JENSEN

MARINE

-11-

•

•

•

STAR11NG

TIlE

ENGINE-D.

I

STARTING THE ENGINE

(D)

Preparadon for

StartInc.

Check the header tank water level when fitted.

Check the engine sump oil level.

See that there

is

fuel oil in the tank.

Check that the starter battery

is

fully charged

and that all electrical connections are properly

made and all circuits are in order.

Check that

sea

cock

is

open. when fitted.

Lubrka

....

00.

During the normal winter period, a lubricating

oil of S.A.E.

lOW

viscosity of high detergency

conforming to MIL/L/2104A

or

OEF/210~B

specification should

be

used.

For

approved

Oils.

see

appendix.

PrimIIIa

tile Fuel S,.tem.

In

the case

of

a new engine

or

an

engine which

has been standing idle for any length

of

time. it

is

the fuel system

be

..

bled." A

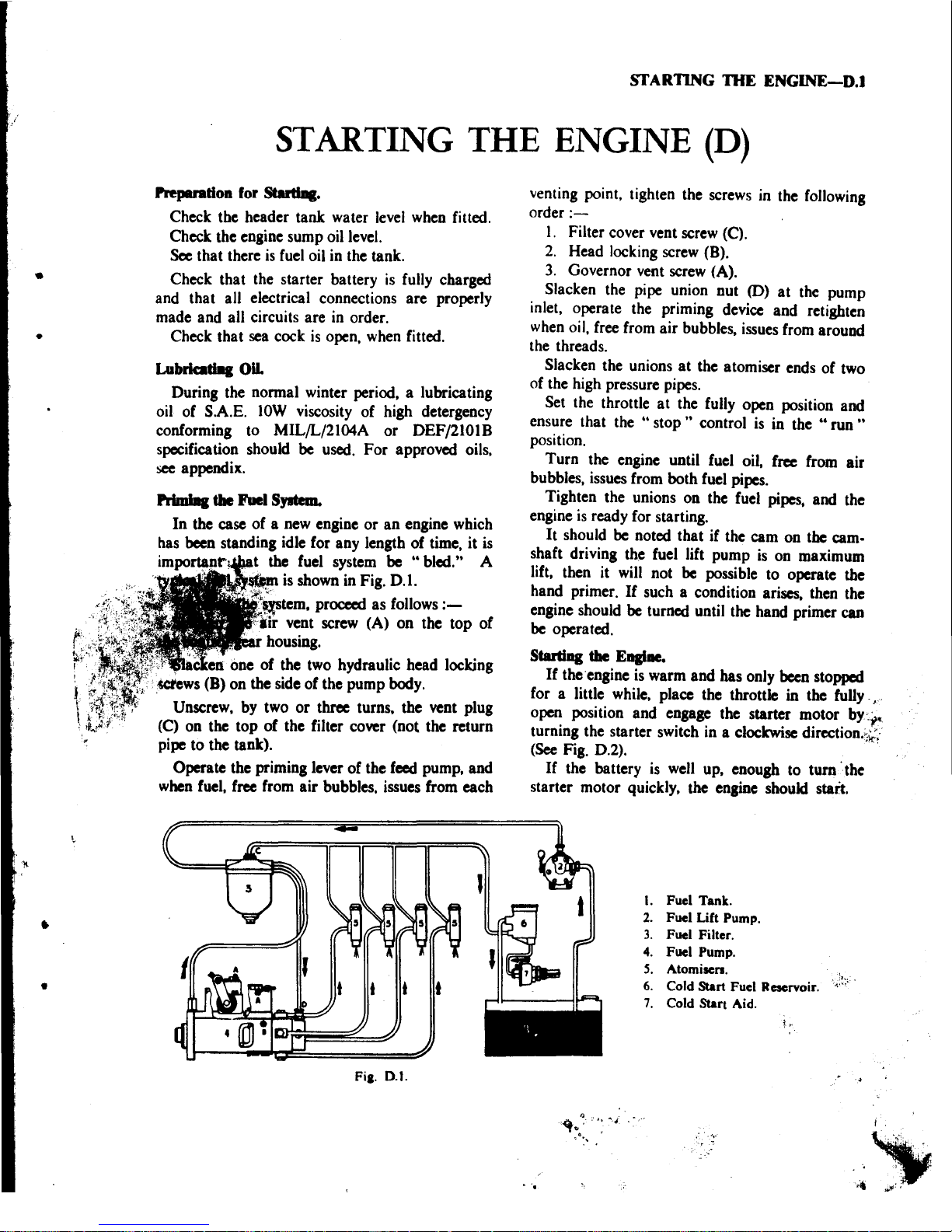

Pltl5lP./NiUI is shown in Fig. 0.1.

":'

$,lfSu:m,

proceed as follows

:-

vent screw (A)

on

the

top

of

housing.

5llCktID one

of

the two hydraulic head locking

"

_ws

(B)

on

the side

of

the pump body.

, Unscrew, by two

or

three turns, the vent plug

(C) on the

top

of

the filter cover (not the return

pipe to the tank).

Operate the priming lever

of

the feed pump, and

when fuel, free from

air

bubbles. issues from each

Fia.O

.l.

venting point. tighten the screws in the following

order

:-

I, Filter cover vent screw (C).

2.

Head locking screw (B).

3.

Governor vent screw (A).

Slacken the pipe union nut

(0)

at

the pump

inlet. operate the priming device and retighten

when oil. free from

air

bubbles. issues from around

the threads.

Slacken the unions

at

the atomiser ends

of

two

of the high pressure pipes.

Set the throttle

at

the fully open position and

ensure that the ..

stop"

control

is

in the ..

run

..

position.

Turn

the engine until fuel oil, free from air

bubbles. issues from both fuel pipes.

Tighten the unions

on

the fuel

pipes.

and the

engine

is

ready for starting.

It

should

be

noted that if the cam on the cam·

shaft driving the fuel lift pump

is

on maximum

lift. then it will not

be

possible to operate the

hand primer.

If

such a condition arises. then the

engine should

be

turned until the hand primer

can

be

operated.

Starting

the

E

......

If

the'engine is warm

and

has only

been

stopped

for a little while. place the throttle in the fully ."

open position and engage the starter motor

by

'

~

turning the starter switch in a clockwise

direction.

~.;;~'

(See Fig. 0.2). ,

If

the battery

is

well up. enough to turn the

starter motor quickly. the engine should start.

1.

Fuel Tank.

2.

Fuel Lift Pump.

3. Fuel Filter.

4.

Fuel Pump.

S.

Atomisen.

6. Cold Start Fuel Reservoir.

7.

Cold Start Aid.

~

i

,.:

.,;

,

.

I

'"

. '

''

, ..

...

...

'·4

~

..

;;

..

'. "

•

•

I)

•

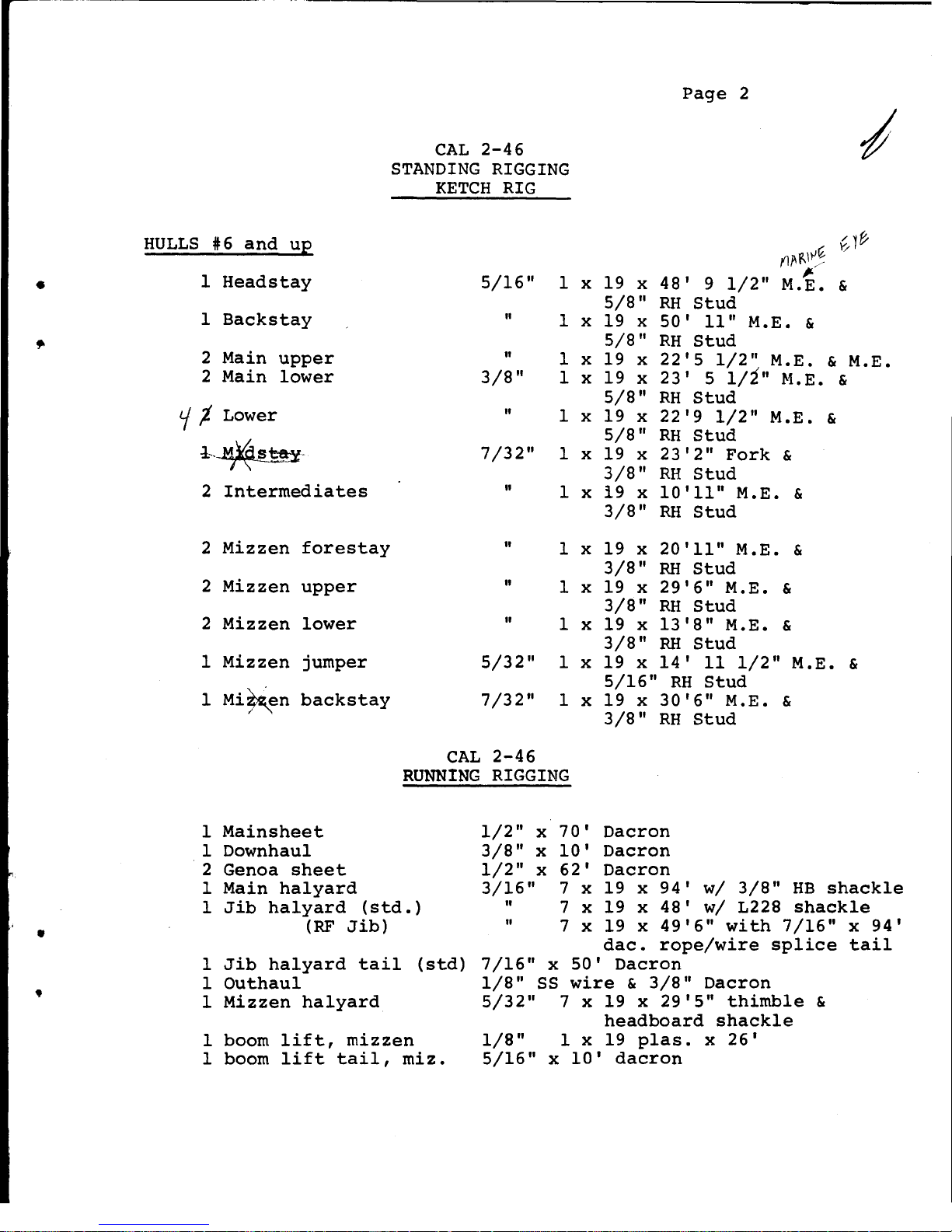

HULLS

#1 - 4

l"Headstay

1

Backsta

2

Main

upper

2 Main

lower

2 Lower

1

ay

lntermediate

HULLS

#6

and

up

1

Headstay

1

Backstay

2

Main

upper

2

Main

lower

2 Lower

1

Midstay

2

Intermediates

HULLS

#1 - 4

1

adstay

1 Bac

ay

2 Main

upp

2 Main Lower

2 Lower

1

Midstay

2

Intermediates

2

Mizzen

foresta

2

Mizzen

uppe

2

Mizzen

ers

1

Mi

z

~

.

err

jumper

l -

Mizzen

backstay

CAL

2-46

STANDING

RIGGING

SLOOP

RIG

5/16"

"

7/32"

"

5/16"

"

"

3/8"

"

7/32"

"

1.

~~

. 1

1/2"

M.E. & M.E.

~52'4"

M.E. & M.E.

1 x 19 x

22'S

1/2"

M.E. & M.E.

19 x

22'9

1/2"

M.E. & M.E.

~x-~~~lL~2:"_~M.E.

& M.E.

x 19 x

22'7

1/2"

M.E. &

Fork

x

19

x

10'6

1/2"

M.E. & M.E.

1 x 19 x

48'9

1/2"

M.E. &

5/8"

RH

Stud

1 x 19 X

53'0"

M.E. &

5/8"

RH

Stud

1 x 19 x

22'S

1/2"

M.E. & M.E.

1 x 19 x

23'S

1/2"

M.E. &

5/8"

RH

Stud

1 x 19 x

22'9

1/2"

M.E. &

5/8"

RH

Stud

1 x 19 x

23'2"

Fork

&

3/8"

RH

Stud

1 x 19 x

10'11"

M.E. &

3/8"

RH

Stud

CAL

2-46

STANDING

RIGGING

KETCH

RIG

5/16"

"

"

3/8"

"

"

"

5/32"

7/32"

1 x 19

1 x 19

1 x 19

72"

M.E. & M.E.

50'

'M.E.

& M.E.

2'5

1/2"

M.E. & M.E.

22'9

1/2"

M.E. & M.E.

22'

1

1/2"

M.E. & M.E.

21'

3

1/2"

M.E. &

Fork

x

10'6

1/2"

M.E. & M.E.

, 4

1/2"

M.E. &

M.E.

2" M.E. & M.E.

1

1/2

E.

& M.E.

1 x

19 11

1/2"

. &

5/16"

RH

Stud

1 x 19 x

30'6"

M.E. &

3/8"

RH

Stud

-

-----------

---

•

•

HULLS

#6

and

up

1

Headstay

1

Backstay

2 Main

upper

2

Main

lower

CAL

2-46

STANDING

RIGGING

KETCH

RIG

5/16"

1 x

II

1 x

II

1 x

3/8"

1 x

19 X

5/8"

19 X

5/8"

19 x

19 x

Page

2

{,,1(/

M{I,\)i~

~ /

48'

9

1/2"

M.E. &

RH

Stud

50'

11"

M.

E.

&

RH

Stud

22'5

1/2"

M.E. & M.E.

23'

5

l/ill

M.E. &

RH

Stud

tf

j. Lower " 1 x

5/8

11

19 x

5/8"

22'9

1/2"

M.E. &

RH

Stud

l

'-

~Sru

-

7/32"

2

Intermediates

"

2

Mizzen

forestay

"

2

Mizzen

upper

"

2

Mizzen

lower

"

1

Mizzen

jumper

5/32"

1

Mi~en

backstay

7/32

11

1 x 19 x

23'2"

Fork

&

3/8"

RH

Stud

1 x 19 x

10'11"

M.E. &

3/8"

RH

Stud

1 x 19 X 20'1111 M.E. &

3/8"

RH

Stud

1 x 19 x

29'6"

M.E. &

3/8"

RH

Stud

1 x 19 x

13'8"

M.E. &

3/8"

RH

Stud

1 x 19 x

14'

11

1/211 M.E. &

5/16"

RH

Stud

1 x 19 x

30'6"

M.E. &

3/8"

RH

Stud

CAL

2-46

RUNNING

RIGGING

1

Mainsheet

1 Downhau1

2 Genoa

sheet

1 Main

halyard

1

Jib

halyard

(std.)

(RF

Jib)

1

Jib

halyard

tail

(std)

1

Outhau1

1

Mizzen

halyard

1 boom

lift,

mizzen

1 boom

lift

tail,

miz.

1/2"

X

3/8"

x

1/2"

x

3/16"

II

"

70'

Dacron

10'

Dacron

62'

Dacron

7 x 19 x

94'

w/

3/8

11

HB

shackle

7 x 19 x

48'

w/

L228

shackle

7 x 19 x

49'6"

with

7/16"

x

94'

dac.

rope/wire

splice

tail

7/16

11

x

50'

Dacron

1/8"

SS

wire

&

3/8"

Dacron

5/32"

7 x 19 X

29'S"

thimble

&

headboard

shackle

1/8"

1 x 19

p1as.

x

26'

5/16"

x

10'

dacron

1

Boom

lift,

main

1

Boom

lift

tail,

1

Mizzen

staysai1

(optional)

1

Mizzen

sheet

•

,

Page

3

CAL

2-46

RUNNING

RIGGING

3/16"

1 x 19

p1as.

main

3/8"

x

15

t

Dacron

hal

3/8"

x

65'

Dac wi 2

7/16"

x

42'

Dacron

x

42'

1/2"

t

(5.

&

K)

snap

shackle

Table of contents

Other Jensen Marine Boat manuals

Popular Boat manuals by other brands

Mercury

Mercury Dynamic 250/260 manual

Dufour Yachts

Dufour Yachts 365 Grand Large owner's manual

Kangui SURF

Kangui SURF Maui Installation instructions & user guide

Oru Kayak

Oru Kayak COAST XT Assembly guide

Walker Bay

Walker Bay Genesis Console 310 Assembling instructions

Bayliner

Bayliner 197 owner's manual