Jerrold SMA Series User manual

-~..:

.. IY

-

.;:,~-

mmtI@ INSTRUCTION SHEET

435-667

a GENERALINSTRUMENTcompany

-'" '"

SOLID-STATE

<I"~~~-~~",,~6-1~N'GLf;.~HANNEL VH F AM PLI FI ERS

... -"

~

"'"

,~

"--

~, . *

'Model SMA..

~U/L./isted

.. "'"

DESCRIPTION

Models SMA-" are high-gain, duaJ-output, strip amwillers

designed for head-ends of master antenna or closed-.circuit

systems, distributing vhf television channels or f.m. sound.

Outstanding features are high overload capability, excel-

lent frequency stability, and low power consumption.

In addition, each amplifier has its own built-in d.c. power

supply with line cord and plug, working directly from a

117 V a.c. outlet. The input circuitry permits the use of

plug-in attenuation pads Models PIP-" for reduction of

the input signal level over a range of 15 dB in 3-dB steps,

in accordance with system requirements. Bridged output

terminals allow interconnection of amplillers directly or

through appropriate mixing networks in order to derive

a common broadband output. Three F-659 cable con-

nectors are shipped with each unit.

The amplifiers are contained in perforated housings for

good ventilation and are designed for vertical installation

side by side on a mounting plate Jerrold Model MP-7.

\

The mounting plate in turn is designed to accept addi-

tional units such as splitters and traps, and can be mounted

on a standard relay rack or installed in an equipment

cabinet.

Models SMA-" are the solid-state advance of the well-

known Jerrold PMA-" tube type series and can be used

not only in new systems but also for expanding or mod-

ernizing existing PMA-" systems, or replacement of indi-

vidual PMA-" units.

INSTALLATION

CN-174

1. Mounting: Each SMA-" ampliller strip is mounted

with two #6 x 1/2 round-head, self-tapping screws

(shipped with the SMA-") on a mounting plate, Jer-

rold Model MP-7. Where a different arrangement is

planne~<L-the "neeessary-mounting hardware will have

to be procured separately.

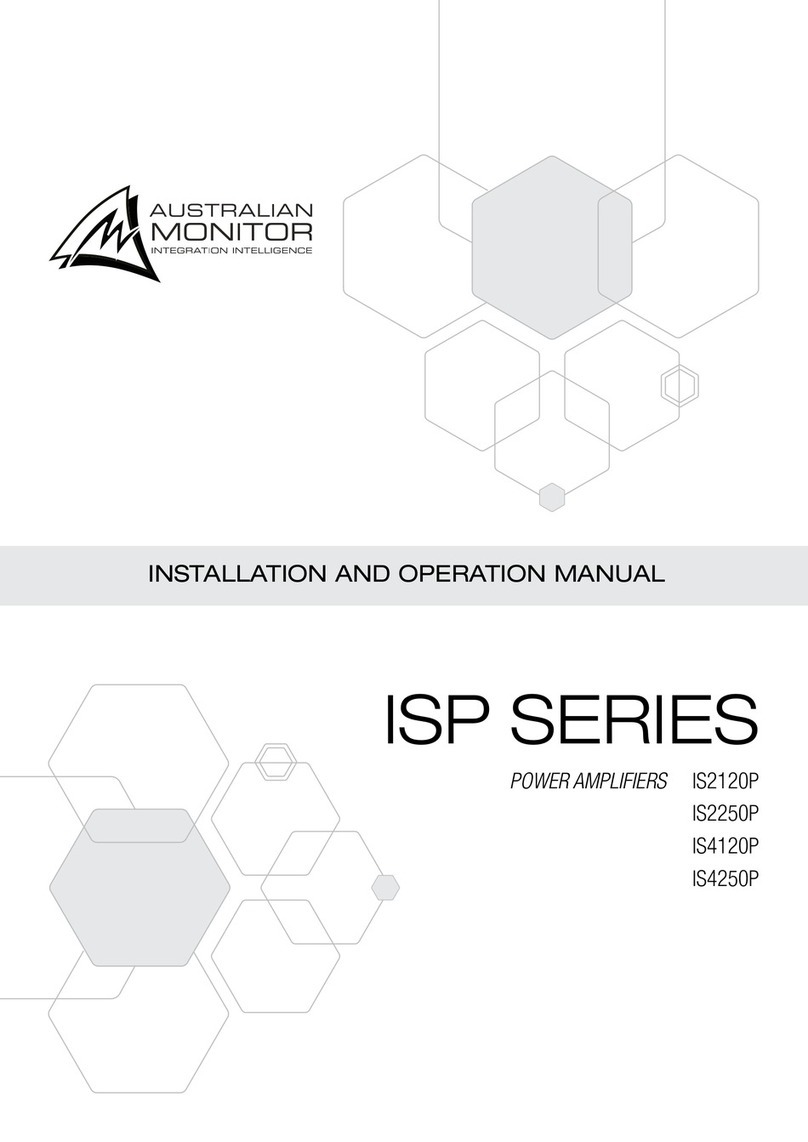

Model MP-7 will accept eight ampliller strips side-by-

side and a number of accessory units. A typical lay-out

example is given in Fig. 2. Note that the recom-

mended installation method is to mount the strips in

two groups of non-adjacent channels. The strips in

each group can be jumpered directly; the outputs of

the two groups are then combined in a hybrid

mixing network such as Jerrold Model 1596A to .....

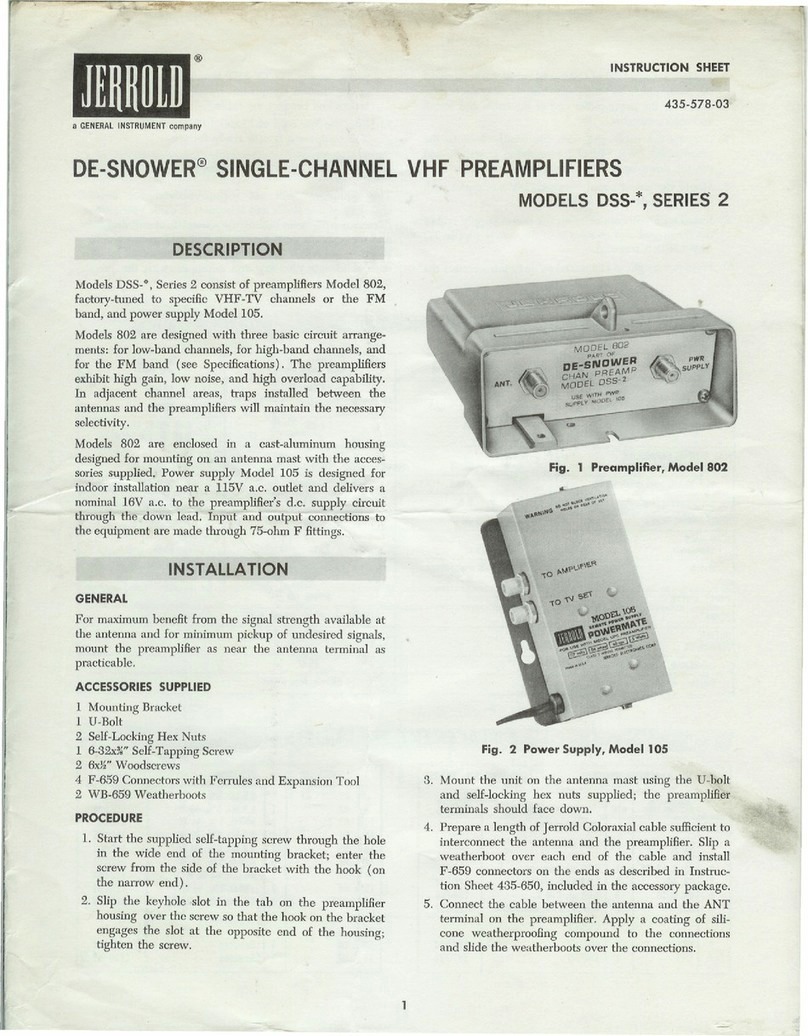

Fig. l-Typical SMA.* Strip

=ifF"~ - '=<0'

..

1

... ~

derive a common broadband output for distribution.

Where a more complex head-end equipment requires

additional units and mounting space for them, a

mounting plate Jerrold Model MP-2 designed for that

purpose can be ordered. "'-

INPUTS FROM CUT-TO-CHANNEL ANTENNAS

2411FMIIB 7

/311/0 6'"-

BROAD-BAND OUT

Fig. 2-Typical Multi.Channel Layout

2. Cabling: Mount one of the three F-659:.eoaxial con-

nectors on the input cable, the other two connectors

on the output and jumper cable respectively. Complete

details for the preparation of cable ends and installa-

tion of connectors are given in Jerrold Instruction

Sheet 435-650 enclosed in the accessory package

shipped with each SMA-".

Where only one output terminal on the SMA-" is

used, terminate the second terminal by a Jerrold

Model TR-75F.

Prepare the cables and jumpers for all other SMA-"

strips in the same manner.

3. Signa~ Tests: First connect the line cord and plug of

the S'Mir:" to its associated a.c. outlet. Then connect

a field strength meter (tunable d. voltmeter)-such as

Jerrold Model 720B or 727-to the input cable. Tune

the FSM to the visual carrier frequency of the relevant

tv channel, or to the f.m. channel if such is the case,

and check the signal level in dBmV (see Note below).

If the average input signal level,. plus the specified

amplifier gain exceed the recommended .9utput lev~ ..

replace the factory-mounted Mods!- PIP-O attenuation

plug-in pad on the SMA-" by a pad with a rating that

will reduce the output approximately to the recom-

mended level.

Disconnect the FSM from the input cable and connect

it to one of the SMA-" output terminals; terminate the

other output with a TR-75F. Then connect the input

cable to the input terminal on the SM~" and read the

FSM indication. The output level should be within

::!:1% dB of the recommended level; if it is not, replace

the PIP-" by one that will give the desired result.

Then, as an insurance test, repeat the check on the

second SMA-" output terminal. .

Repeat this procedure for every SMA-" strip instaIled~ ..

Finally, connect all output-cabreS"'and""jumpers t'otheTr

associated terminals on the SMA-" strips and on any

mixing or other networks designed to make up the

head end.

NOTE:

These signal measurements should be taken at inter-

vals throughout at least one 24-hour period so that

fluctuation of signal strength may be noted and the

average signal strength calculated. After initial instal-

lation, additional measurements should be taken at

three-month inter'lfals to determine fluctuations due to

change in seasons.

SPECIFICAnONS

HIGH.BAND LOW-BAND F.M.BAND

PASSBAND 6 MHz, any v.h.f. television channel or t.m. band

GAIN 40dBmin. I40 dBmin. 33 dBmin.

(Levelcontrol by use ot PIP.* plug.in pads)

flATNESS within::!:0.5dB within ::!:0.5dB within::!:1.5dB

OUTPUTCAPABILITY 1.0V(60dBmV)at 1.0V(60dBmV)at 44 dBmV,3 chs.

0.5 dBsyncclip 0.5 dBsyncclip tor-46 dB2A-B

NOISEFIGURE - 10 dBmax. 10 dBmax. 9 dBmax.

TERMINALS: --

IMPEDANCE 75(I 75() 75 (I

INPUT MATCH 16dBmin. ret. loss 16dBmin. ret. loss 10dB(92-108MHz)

OUTPUTMATCH 16 dBmin.ret. loss 16dBmin. ret. loss 16dB(92-108MHz)

INSERTIONlOSS 0.5 dBmax. 0.5 dBmax. 0.5 dBmax.

POWER REQUIREMENT 117 V a.c., 60 Hz, 80 mA, lOW

2

..

'" """=

..- ~

~MAINTENANCE

I""

GENERAL

The solid-state design and low power consumption make

~the SMA-" units virtually maintenance-free. Routine sys-

tem maintenance will consist mainly of periodical checks

of signal levels and on firmness of cable connections.

Should it ever happen that an amplifier becomes inopera-

tive, it is best to replace it by a spare unit so that there

~~~ only a mJn[glUmof interruption in signal distribu-

tion. The faulty- unit can then be returned to Jerrold

where it will be repaired at no charge under warranty

-conditions; otherwise it will be repaired at ~ominal

charge.

Where the user has the necessary instruments and the

skilled personnel for bench-testing and repairing an inop-

erative amplifier, the circuit descriptions, schematic dia-

grams, and replacement parts lists given here will help in

tracing the faulty component.

CAUTION:

An amplifier under test must be equipped with a PIP-O

pad. In no case should the input and output filter compo-

nents be tampered with, nor does the replacement of a

transistor in the amplifier circuitry require a retuning of

tbe frequency-dependent components.

CIRCUITDESCRIPTIONS

A. GENERAL

The SMA-" circuitry consists of:

a. A well-filtered, full-wave rectifier, d.c. power sup-

ply;

b. A tuned-to-channel input filter with plug-in attenu-

Ittioil pad facility;

c. A tuned-to-channel dual output filter;

d. A 3-stage amplifier in the case of low-band and

f.m. channel strips, or a 4-stage amplifier in the

case of high-band channel strips.

Input and output terminals are matched to a 75-ohm

impedance for connection of coaxial cables.

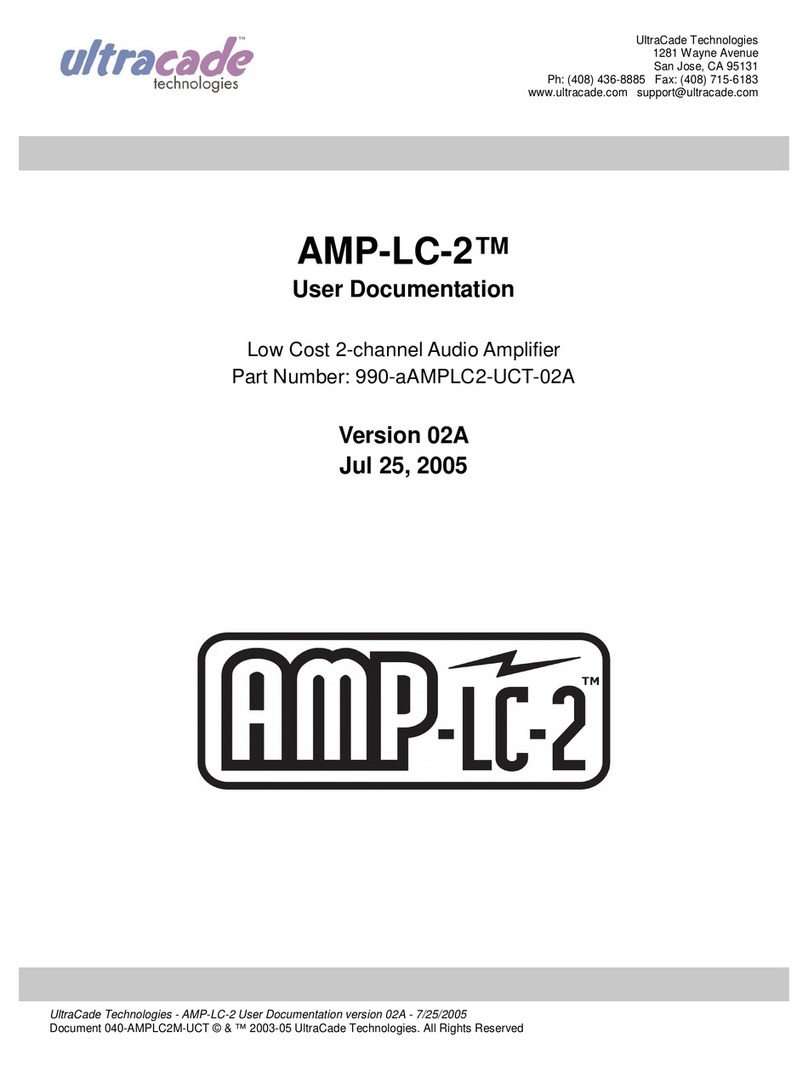

B. LOW-BAND AND FM STRIPS(see Dwg. E863-166)

1. POWER SUPPLY

The d.c. supply consists of line voltage transformer

T4, conventional full-wave rectifier made up of

CRI, CR2, C25 and C26, filter network C20 and

RI4, and smoothing capacitor CI7. This power

supply delivers a -15 V d.c. potential to the

amplifier circuitry and has a 3-wire line cord and

plug for connection to a 117 V a.c. outlet with

ground terminal.

2. INPUT CIRCUITRY

The input signal is applied at terminal JI and is

passed through a pad-plugged in at J2-to a series/

parallel LC network consisting of LI, L2, C3, CI,

---- .... ~"~'I!

~

L3, C4, C2, L4, C5, and L5. This 3-section band-

pass filter is factory-tuned to one of the low-hand

tv channels,> or to the f.m. band, as required by

the user.

3. AMPLIFIER CIRCUITRY

From .the input filter the signal is coupled by C6

to the base of the first amplifier stage Ql. This

and the follo~g stages Q2 and Q3 employ cas-

caded NPN transistQrs arranged in a common-

emitter configuration. Capacitors C9, C12, CI5,

and toroidal transformers TI, T2, and T3 are em-

ployed between stages and at the output for im-

pedance coupling. All three stages have current

feedback, with unbypassed emitter resistors R4

and RS employed in the first and second stage. The

first and third stages also have voltage feedback

from the collectors through resistors R2 and RIO

to the base coupling capacitors C6 and C12 re-

spectively. Base bias is developed across the rele-

vant resistor pairs RI, R3, R6, R7, and Rll, RI2.

Transistor operating stability is achieved by RC

networks in the emitter circuits, namely R5, CS;

R9, Cll; and RI3, CI4 respectively.

4. OUTPUT CIRCUITRY

The output from the collector of Q3 is applied to

a frequency filter consisting of series/parallel LC

network CI5, CIS, L9, CI6, LIO, and CI9. This

filter too is factory-tuned to the required tv chan-

nel or to the f.m. band. From the filter the signal

is coupled through Lll to a signal-splitting circuit

C2I, C22, C23, and C24 from where the two out-

puts are presented at terminals J3 and J4. Capac-

itor C23 is tuned to match the impedances at J3

and J4 to 75 ohms.

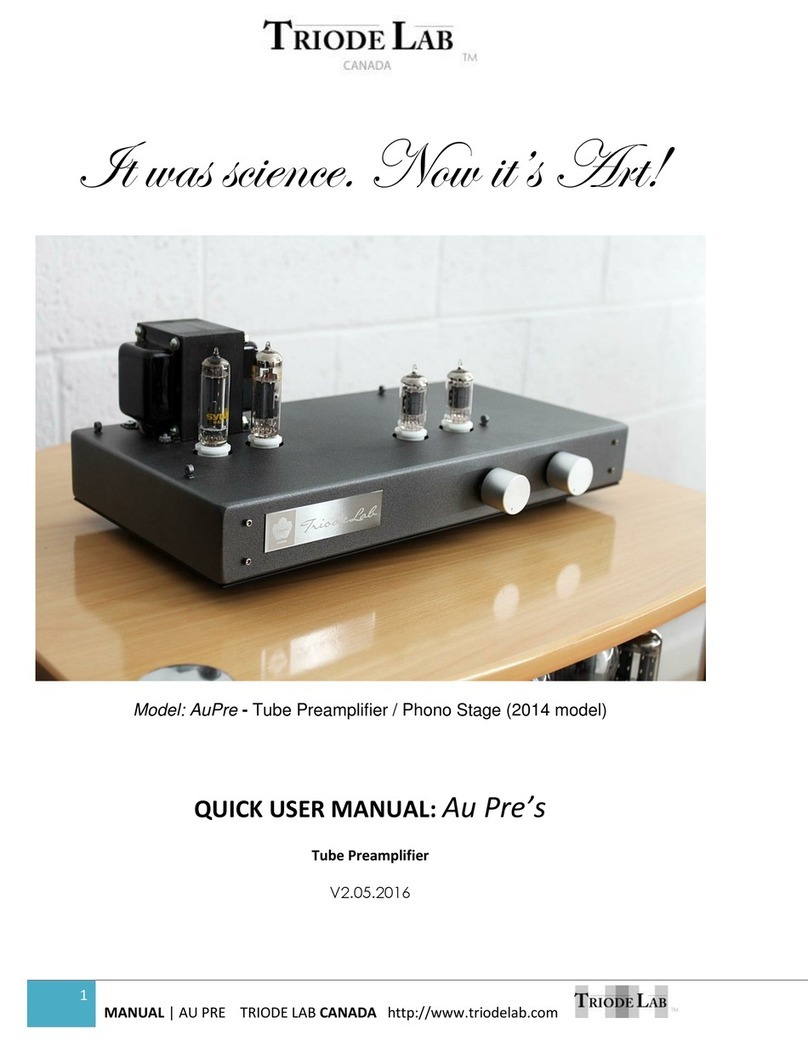

C. HIGH-BAND STRIPS (see Dwg. E863-167)

1. POWER SUPPLY

Except for component designations on the sche-

matic circuit diagram, the circuitry of the power

supply and its d.c. output is exactly the same

as that in the low-band/f.m. strips.

2. INPUT CIRCUITRY

The input signal is applied at terminal JI and first

passed through a pad -plugged in at J2 -from

where it goes through a 3-section bandpass filter.

Here too series/parallel LC components are em-

ployed, consisting of LI, L2, C4, C5, CI, L3, C6,

-C7-;-G2,:B4;eS;"€9;"'and C3. This filter is factory-

tuned to the high-band channel specified by the

user.

3. AMPLIFIER CIRCUITRY

From the input filter the signal is coupled through

CIO to the base of the first amplifier stage Ql.

This and the following three stages Q2, Q3, and

Q4 have the same basic circuit configuration as the

amplifier stages in the low-band/f.m. channel

3

.""

strips. Four NPN transistors are employed in a

cascaded common-emitter circuitry. All inter-stages

and the output stage have capacitors andJoroidal

transformers for impedance coupling: TI, .S;,JA;"""-

T2, CIS; T3, C22; and T4, are the components

involved. All stages have current feedback through

R4, R9, RI4, and RI8 respectively. Equally, all

stages have voltage feedba'Ck through RI, RB, Rll,

and R20 respectively. Base bias for each transistor

is developed across the relevant resistor pairs R2,

R3; R7, R8; RI2, RI3; and RIB, RI7. Again, tran-

sistor operating stability is achieved by RC net-

works: Cll, CI2, R5 tor QI; CI5, CI6, RIO for

Q2; CI9, C20, RI5 for Q3; and C23, C24, RI9

'IIfql£..Q4, in the respective emitter circuits.

4. OUTP.DT CIRCUITRY

From the collector of Q4 the output is inductively

coupled through LI7 to a 2"section bandpass Riter

consisting of series/parallel LC networks involving

C27, LI4, C28, C29, and LI5. This Riter too is

factory-tuned to the speciRed high-band channel.

From the RIter the signal is passed through T5 and

LIB which splits the signal energy. equally for

75-ohm impedance dual output presentation at

terminals J3 and J4.

J

.'iF"

ASSEMBLY,SMA-', HIGH-BAND REF. DWG. NO.: E863-167

REPLACEMENTPARTSLIST

REF. DWG. NO.: E863-166

~

ASSEMBLY: SMA-', LOW-BAND AND F.M.

..,--:::

"

..A\

"

4

SCHEMATIC JERROLO

ITEM liES/GNAT/ON QTY. DESCRIPTION PARTNO.

CAPACITORS

1C1,2,28 3prs. Variableplates, assembly 8215-289

2 C3 1 1.5-8.5pF,trimmer 128.572

3 C4 1 18pF,::!:5%,500V 124-079

4C5,7,9, 52-18.5pF,trimmer -128-570'

27,29

5 C6 120 pF,5%, 500V 124.119

6 C8 1 13 pF,5%, 600V 124-115

7 CI0thru25 16 0.02,uF,200V, disc 124.154

8 C30 1 400,uF,16 V, electrolytic 127-123

9C31 1 250,uF,25 V, electrolytic 127.062

CONNECTORS

10 11,3,4 3Chassisfitting Mod.F-61A

11 -3 Cableconnectors Mod.F-659

DIODES

12 CRl,2 2Rectifier,Silicon,CER68A S137.718

RESISTORS,

13 Rl 1 390O,5%, 1,4W 112.099

14 R2,7 21.5kO,5%, 1,4W 112-966

15 R3,8 22.2kO,5%,1,4W 112-932

16 R4 1 100, 5%, 1,4W 112.077

17 R5,17 29100, 5%,1,4W 112-920

18 R6,10,20 33600, 5%, 1,4W 112.098

19 R9 1150, 5%, 1,4W 112-973

20 Rll 1 2000, 5%, 1,4W 112-984

21 R12 1 2 kO,5%,1,4W 112-930

22 R13 11 kO,5%,1,4W 112.977

23 R14 1 12o, 5%, 1,4W 112-079

24 R15 1 300n, 5%, ¥2W 112-293

25 R16 1 6200, 5%,1,4W 112.998

26 R18 1 8.20, 5%,1,4W 112.075

27 R19 1 680, 5%,'12W112-212

28 R21 1620, 5%,2'Vl 112-211

29 R22 11MO,5%,1/2W 112-737

TRANSFORMER

30 T6 1 Linetransformer C141-264

TRANSISTORS

31 Ql 1 A2297 130-220

32 Q2 1 A492 130-185

33 Q3 1 A430 130-240

34 Q4 1 A210 130-200

SCHEMATIC JERROLD

ITEM DESIGNATION QTY. DESCRIPTION PARTNO.

CAPACITORS -

1Cl,2,18 31.5-8.5pF,trimmer 128.572

2C3,4, 5, 55-60 pF,trimmer 128.563

16,19

3C6thru C14 90.02 ,uF,200 V, disc 124-154

4C15 1 2-18.5pF,trimmer .. 128-570

5C17 1 400,uF,16V,electrolytic 127-123

6 C2o 1250JLF,25V,electrolytic 127-062

7C21,22 227pF,5% 124-120

8C23 15-60pF,trimmer 128-563

9 C24 1100pF,20%,1500V 124-101

10 C25,26 21000pF,200V,disc 124-020

CONNECTORS

11 JI,3,4 3Chassisfittings Mod.F-61A

12 -3Cable.fonnectors Mod.F.659

DIODES

13 CRl,2 2Rectifier,Silicon,CER68A S137.718

RESISTORS

14 Rl,6 21.5kO,5%,1,4W 112-966

15 R2 1 8200, 5%, 1,4W 112-976

16 R3,7 22.2kO,5%,1,4W 112-932

17 R4 120o, 5%,1,4W 112.083

18 R5 19100, 5%, 1,4W 1'12.920

19 R8 116o, 5%,1,4W 112.081

20 R9 13600, 5%, 1,4W 112-098

21 RIO 1 680n, 5%, 1,4W 112.105

22 R11 1 2 kn, 5%, 1,4W 112.930

23 R12 11kO,5%,1,4W 112-977

24 R13 1 300n, 5%, ¥2W 112.293

25 R14 1100n, 5%, lW 112-234

"'26 R15 ...!. 1 Mn, o, '12W112-743

TRANSFORMER

27 T4 1 Linetransformer 8141-251

TRANSISTORS

28 Q1 1A2297 130-220

29 Q2 1 A492 130-185

30 Q3 1 A43o 130.240

,

..,.:r., o.,

L

-- -

!"'"

eO

o.

.<

.eo

oi5P

e.

0<

.0

~i5P

.

:;

I' >

c

§I

.g. ;;~

".~ °HI'

= 0

~I

~I

~~Ii

;;

N..

o.~

5

~.;;

j~~

~~~;

~~ H~

~~~~ie

~U~O

0°.0'0

~~H~n

-'"

l";;>

W

0::

t'-

<.D

,

"'

<.D

(1J

W

...

'"

~

I

J

~

I

!

\

!

I

\

I

I

\

If

I

I

\

I

I

.4

-- -----

/

"!~

~

~~~ ~<~

L.- ~~ =c --~;-~#~ .~,

""""

.."."

- ~""""~~

-------

WARRANTY

Each unit of Jerrold Equipment is warranted for 90 days

against original factory imperfections in material and work-

manship.

In the event any unit of equipment should fail in service during

this period, pack the complete defective unit carefully, attach

a letter stating the reasons the unit was believed to be

defective, and return it to our Service Department, Jerrold

Electronics Corp., 15th Street and Lehigh Avenue, Phila., Pac

19132, prepaying transportation charges. It shall be repaired

or replaced at no charge.

Such service 6r repairs as may be necessary as the result of

abuse or accident are not included in the warranty. In the

event of any service breakdowns after the warranty period,

this unit may be returned for repairs at a nominal charge.

-""'"

-<"

I

~I

"'

i\

I

)

I

\

I

\ ~

\~

I

\

\

I

\

I

l

I

~

p~ ~~-

...

!j~

Ijj ,j!

mm

wm

r-"..~

E...--.-

JERROLDELECTRONICSCORPORATION

EDUCATIONAL AND COMMUNICATIONS SYSTEMSDIVISION

Philadelphia, Pac19105

... "

"""

"

?

~~~ ~-

'\

'£0

i!:

~

<:I

J

Publishedbythe JerroldElectronicsCorp.,EngineeringLaboratoryPublicationsDept.

LKEE,12/69 Printed in U.S.A. 435.667 ~@ 8016

.. J

This manual suits for next models

1

Table of contents

Other Jerrold Amplifier manuals

Popular Amplifier manuals by other brands

XFIRE AUDIO

XFIRE AUDIO E-6004D owner's manual

Kenwood

Kenwood KAC-8102D instruction manual

CIE-Group

CIE-Group TD 816 operating instructions

Absolare

Absolare Integrated Amplifier user manual

K&M Analog Designs

K&M Analog Designs Two-Rock Jet Signature owner's manual

OT Bioelettronica

OT Bioelettronica OT-BridgeAmp4 user manual