JHI-A7-06-0001

Have questions? Call us at 562-467-0260 or email larrywjhi@jethangar.com 2

TABLE OF CONTENTS

TO OUR VALUED CUSTOMERS.........................................................................4

1.0 INTRODUCTION........................................................................................5

1.1 Operation of R/C Jet Aircraft...................................................................5

1.2 The Academy of Model Aeronautics (AMA)............................................5

2.0 ABOUT THE A-7 CORSAIR II....................................................................5

3.0 GENERAL BUILDING TIPS .......................................................................6

3.1 Lightness ................................................................................................6

3.2 Adhesives ...............................................................................................6

3.3 Retracts ..................................................................................................7

3.4 Finishing .................................................................................................7

4.0 REQUIRED TOOLS AND EQUIPMENT ....................................................7

4.1 Tools ..........................................................................................................7

4.2 Adhesives...................................................................................................8

5.0 KIT CONTENTS.........................................................................................8

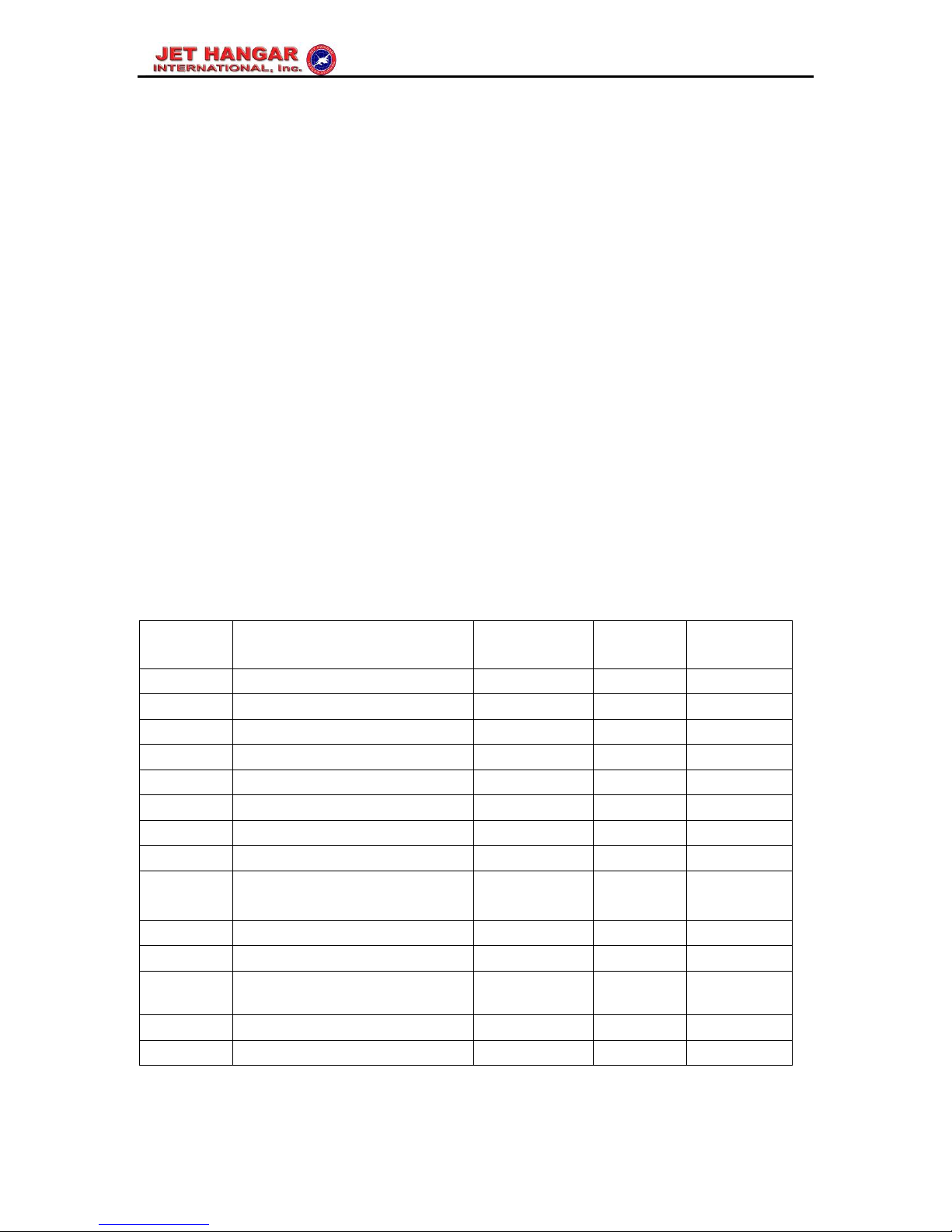

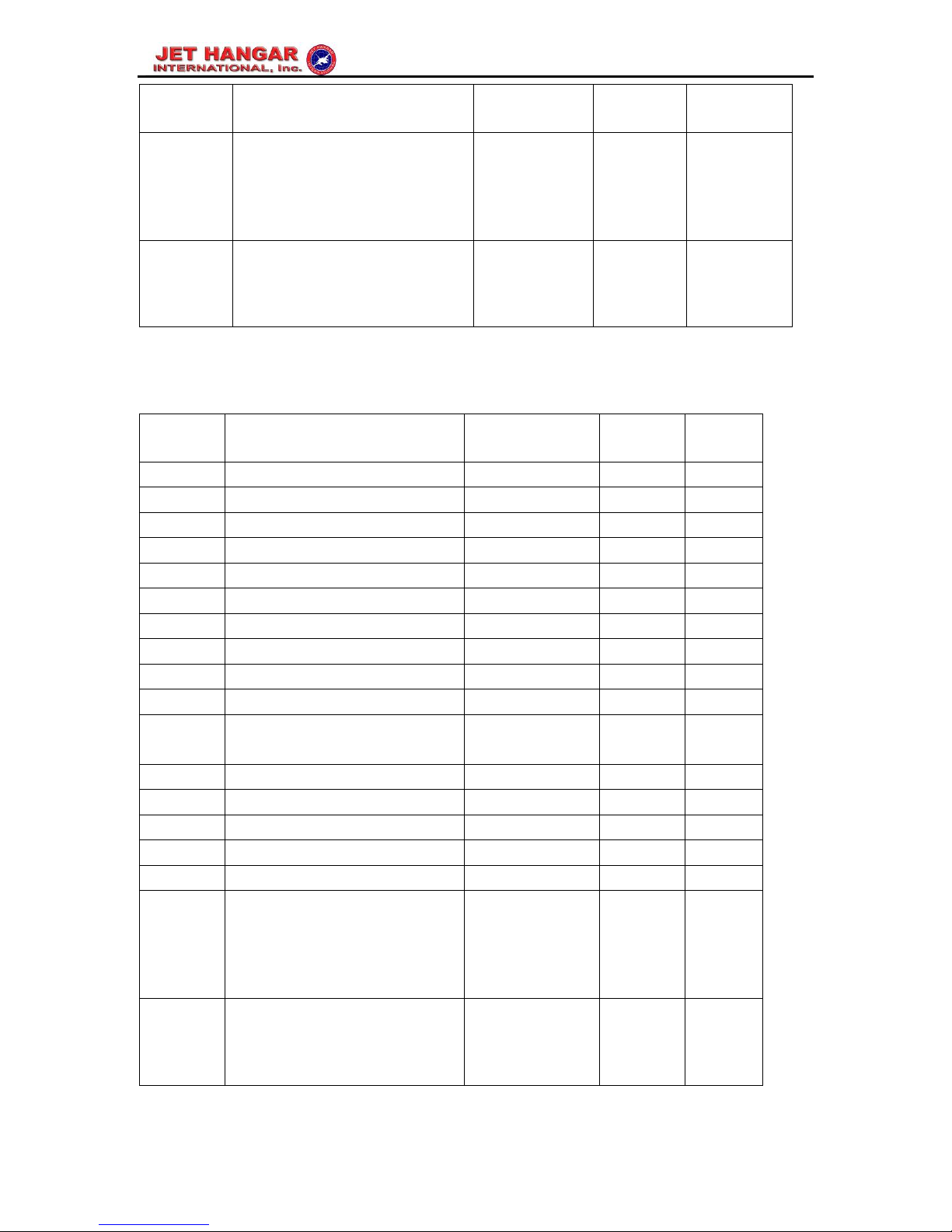

5.1 Turbine A-7 Packing List ............................................................................8

5.2 Ducted Fan A-7 Packing List......................................................................9

5.3 Additional Aircraft Accessories.................................................................10

5.3.1 Landing Gear........................................................................................10

5.3.2 Turbine Operation.................................................................................10

5.3.3 Ducted Fan Operation ..........................................................................10

6.0 AIRCRAFT ASSEMBLY PROCESS ........................................................11

6.1 Wing Assembly (Flaps/Ailerons)...........................................................11

6.2 Fuselage Assembly ..............................................................................12

6.2.1 Rudder ..............................................................................................12

6.2.1.1 Turbine ..........................................................................................13

6.2.1.2 Ducted Fan....................................................................................14

6.2.2 Elevator.............................................................................................15

6.2.2.1 Turbine ..........................................................................................16

6.2.2.2 Ducted Fan....................................................................................17

6.2.3 Retracts and Landing Gear ...............................................................18

6.2.4 Steering.............................................................................................21

6.2.5 Landing Gear Doors..........................................................................22

6.2.5.1 Main Gear Doors ...........................................................................22

6.2.5.2 Nose Gear Doors...........................................................................24

6.2.6 Propulsion Installation .......................................................................25

6.2.6.1 Turbine ..........................................................................................25

6.2.6.2 Ducted Fan....................................................................................27

6.2.7 Final Hardware Installation................................................................31

6.2.7.1 Turbine ..........................................................................................31

6.2.7.2 Ducted Fan....................................................................................32

7.0 AIRCRAFT SETUP AND CG ...................................................................33

8.0 FLYING THE A-7 CORSAIR II .................................................................34

8.1 Range Check ...........................................................................................34

8.2 Taxi Tests.................................................................................................34

8.3 First Flight ................................................................................................35

APPENDIX A: Coloring Diagrams/Decal Placement...........................................36

A.1 Decal Application Instructions...............................................................37