Safety Warnings

General Safety Warnings

It is important you read

and understand the

instruction manual

before use and keepthe

manual in a safe place

for future reference.

Safety precautions must

be observed to reduce

the risk of personal

injury when operating

this machine.

It is recommendedyou

complete formal training

on how to use your

equipment if you are

unfamiliar with any

aspectof the machine

or its use.

Do not expose yourself or others to

danger.Do not permit others to use this

machine unless they have read this

manual and are trained in its operation.

Do not operate if the machine is

damaged or is in an excessively worn

state. To reduce fire hazards keep the

engine and exhaust free of debris,

leaves, or excessive lubricant. Do not

useanyattachments oraccessorieswith

the machine other than the ones

recommended by the supplier. Serious

injury to the operator or bystanders can

result as well as cause damage to the

machine. Always use proper handles

when moving the machine. Keep the

machine in a horizontal position on a

firm flat surface. Do not tilt. Do not use

the unit if it is damaged or poorly

adjusted. Never remove the machine’s

coverings. Serious injuryto the operator

or bystanders could result as well as

damage to the machine.Do not use this

unit for any job other than those for

which it is intended as described in this

manual. In start-up or during or after

operation of the engine, never touch hot

parts such as the muffler or the spark

plug. Do not operate the machine in the

rain or under wet conditions. Always

ensure all handles, guards and covers

are fitted when using the machine.

Always keep the machine away from

naked flame or sparks. Always stop the

engineordisconnectfrom mains before

cleaning / clearing a blockage or

checking,maintaining or working on the

machine. Before starting the pressure

washer, be sure you are wearing

adequate eye protection.

Transporting

The engine should be turned off, water

supplies disconnected and all hoses

removed when the machine is moved

betweenareas andwhentransportingor

storing the machine. Always turn off the

engine. When transporting in a vehicle:

properlysecure your machine to prevent

turnover, fuel spillage and damage.

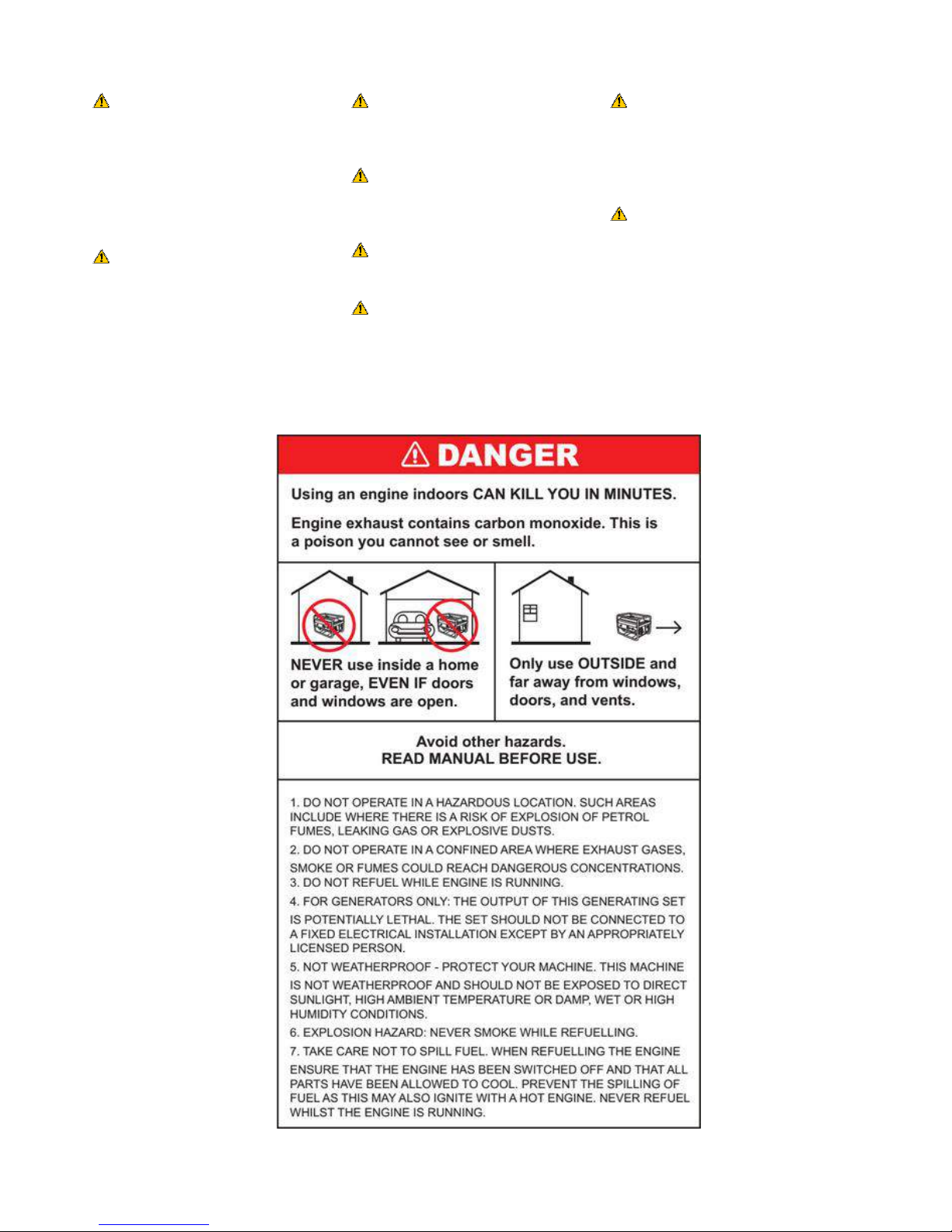

Fuelling Fuel is extremely

flammable. Keep clear

of naked flames.Do not

spill any fuel –do not

smoke near fuel or the

machine.

Always shutoff the enginebefore

refuelling.Do not fuel a hot engine –fuel

mayspillandcause a fire. Open the fuel

cap carefullyto allow any pressure

build-upinthe tank to releaseslowly

andavoid fuel spillage.Fuel your

machine onlyin well ventilated areas.If

you spillfuel,wipethe machine

immediately–if fuel gets on your

clothing,changeimmediately.To reduce

the riskof serious or fatal burn injuries,

check for fuel leakage.If fuel leakageis

found, do not start or run the engine until

leakis fixed.

During Operation

Make sure you always have good

balance and secure footing.Always be

awareof your surroundings and stay

alert for possiblehazards thatyou may

not heardue to the noiseof the

machine.Neverallowchildrento access

the machine.Avoid operatingwhile

people,especiallychildrenorpets are

nearby. To reduce the riskof injuryor

damage,do not allow anyother persons

withina radius of5 metres of your own

position.Toreduce the riskof damage

to property, alsomaintainthis distance

from other objects (vehicles,windows).

After Use

Always clean dust and dirt off the

machine –do not use any grease

solvents. Always keep the machine

clean, especially, the fuel tank, its

surroundings, and the air cleaner.After

the enginehas stopped, the engine and

exhaust components will still be hot.

Never place the machine in anyplaces

where there are flammable materials

suchas dry grass,combustiblegases or

combustible liquids etc. Let the engine

cool before storing the machine indoors.

Maintenance and Repairs

Service the machine regularly. Do not

attempt anymaintenance or repair work

not described in this instruction manual.

Have all other work performed by a

servicing dealer. We recommend that

you have servicing and repair work

carried out exclusively byan authorised

service person. Before proceeding to

adjust or repair the machine, be sure to

stop the engine and detach the spark

plug. Never attempt to make engine

adjustments while the unit is running.

Always make engine adjustments with

the unit resting on a flat, clear surface.

Replace any worn, damaged or

removed warning labels immediately. It

is recommended you complete formal

training on how to use your equipment

should you feel the need to do so.

Personal Safety

Stay alert, watch what you are doing

anduse commonsense whenoperating

a power tool. Do not use a power tool

while you are tired or under the

influence of drugs, alcohol or

medication. A moment of inattention

while operating power tools may result

in serious personal injury. Use personal

protective equipment. Always wear eye

protection. Protective equipment such

as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for

appropriate conditions will reduce

personal injuries.